Method for forming punctate pattern on surface of metal

A metal surface, dot-shaped technology, applied in the direction of adhesive type, electrolytic coating, electrophoretic plating, etc., can solve the problems of blunt border of spot pattern, difficult to make spot pattern, difficult switching, etc., and achieve acid salt spray corrosion resistance Good, the effect of the boiling test is good, the effect of reducing the production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

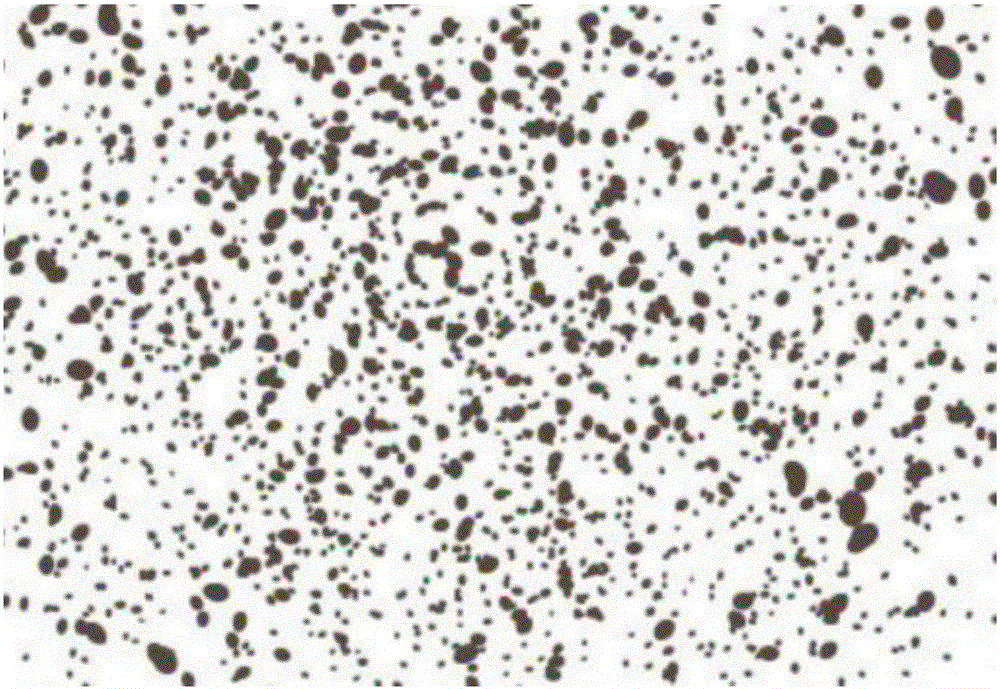

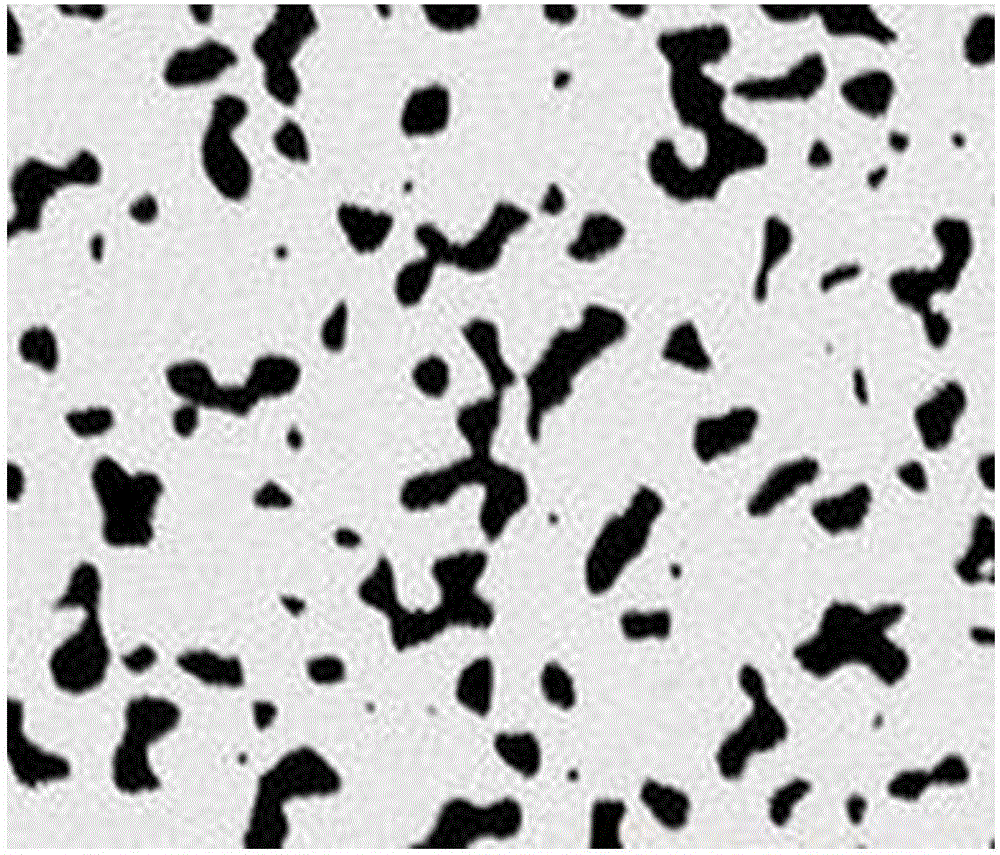

[0039] A method for forming a dot pattern on a metal surface. The masking powder is made of hot melt adhesive, the masking powder is adhered to the metal surface, and electrophoretic paint of different colors is deposited on the area covered by the masking powder and the area not covered by secondary electrophoresis. Thereby forming a predetermined dot pattern.

[0040] The masking powder is a point-like structure formed by hot melt adhesive, its fineness ranges from 50-1500 μm, and the softening point range of hot melt adhesive is 80-180°C. In one embodiment, during production, the materials forming the hot-melt adhesive are mixed and stirred according to the proportion, and after melt-blending, large-sized hot-melt adhesive blocks are formed by extruding granulation or pouring into a mold and cooling, and then Through the cryogenic pulverizer, liquid nitrogen is used as the refrigerant to pulverize at low temperature, and the pulverization fineness can be controlled between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com