Catalyst for preparing C5 and C6 alkane through catalyzing sugar alcohol raw material in water phase and application thereof

A water-phase catalyzed sugar alcohol and catalyzed sugar alcohol technology, which is applied in the field of catalysis, can solve the problems of increasing downstream processing energy consumption, waste acid water pollution, catalyst development and application obstacles, and poor catalyst stability, and achieves good industrial application prospects, good Hydrothermal stability, the effect of simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

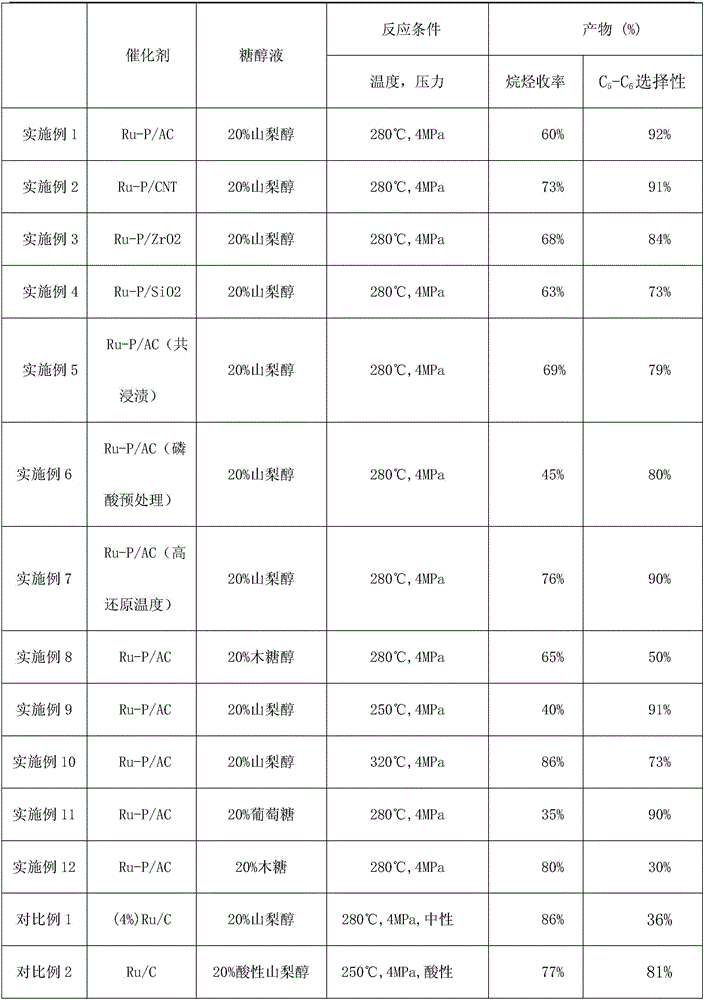

Examples

Embodiment 1

[0027] The application of the catalyst for preparing C5 and C6 alkanes from water-phase catalyzed sugar alcohol raw materials comprises the following steps:

[0028] (1) Take activated carbon carrier (AC) 10g earlier, then impregnate ruthenium trichloride (metal content 37wt%, RuCl3.H2O) 1.08g in equal volume, then put the sample in ultrasonic treatment for 2 hours and then stand overnight, then Dry in an oven at 110°C for 12 hours, and then bake in a nitrogen muffle furnace at 400°C for 4 hours.

[0029] (2) After the sample is roasted, the ammonium dihydrogen phosphate is impregnated in an equal volume, keeping the molar ratio of Ru and P at 1:1, and the loading of metal Ru at 4wt%. The loaded and impregnated samples were dried in an oven at 110°C.

[0030] (3) Place the catalyst obtained in step (2) in a trickle bed, and at 350° C., reduce the hydrogen in situ for 4 hours; drop the temperature to a reaction temperature of 280° C., and set the pressure of the reaction devic...

Embodiment 2

[0032] The application of the catalyst for preparing C5 and C6 alkanes from water-phase catalyzed sugar alcohol raw materials comprises the following steps:

[0033] (1) Weigh 10g of carbon nanotube carrier (CNT), then impregnate 1.08g of ruthenium trichloride (37wt% metal content, RuCl3.H2O) in an equal volume, then place the sample in ultrasonic treatment for 2 hours and then let it stand overnight , and then dried in an oven at 110°C for 12 hours, and then fired in a nitrogen muffle furnace at 400°C for 4 hours.

[0034] (2) After the sample is roasted, the ammonium dihydrogen phosphate is impregnated in an equal volume. The molar ratio of Ru and P is kept at 1, and the metal Ru loading is at 4 wt%. The loaded and impregnated sample is dried in an oven at 110 °C.

[0035] (3) Place the catalyst obtained in step (2) in a trickle bed, and at 320° C., reduce the hydrogen in situ for 4 hours; lower the temperature to a reaction temperature of 280° C., and set the pressure of th...

Embodiment 3

[0037] The application of the catalyst for preparing C5 and C6 alkanes from water-phase catalyzed sugar alcohol raw materials comprises the following steps:

[0038](1) First weigh zirconia carrier (ZrO2) 10g, then impregnate 1.08g of ruthenium trichloride (37wt% metal content, RuCl3.H2O) in equal volume, then place the sample in ultrasonic treatment for 2 hours and then let stand overnight, It was then dried in an oven at 110°C for 12 hours, and then fired in a nitrogen muffle furnace at 400°C for 4 hours.

[0039] (2) After the sample is roasted, the ammonium dihydrogen phosphate is impregnated in an equal volume, keeping the molar ratio of Ru and P at 1, and the metal Ru loading at 4wt%. The loaded and impregnated samples were dried in an oven at 110°C.

[0040] (3) Place the catalyst obtained in step (2) in a trickle bed, and at 320° C., reduce the hydrogen in situ for 4 hours; lower the temperature to a reaction temperature of 280° C., and set the pressure of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com