Patents

Literature

148results about "Calcium aluminates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

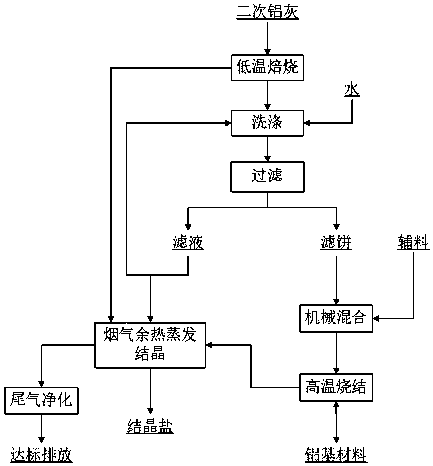

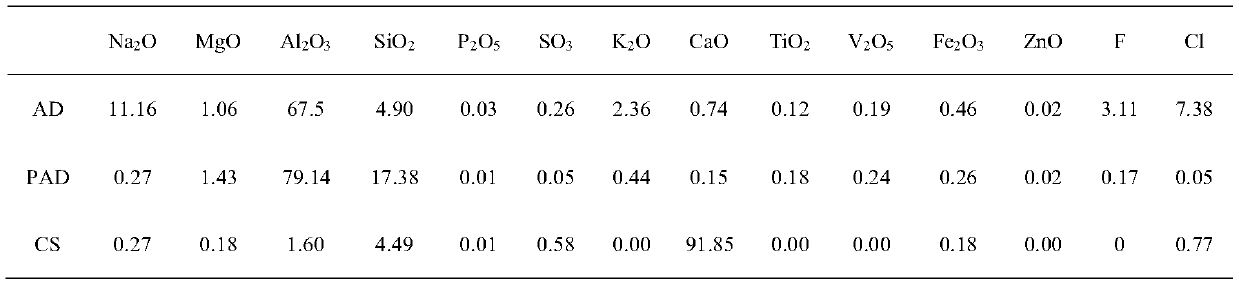

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

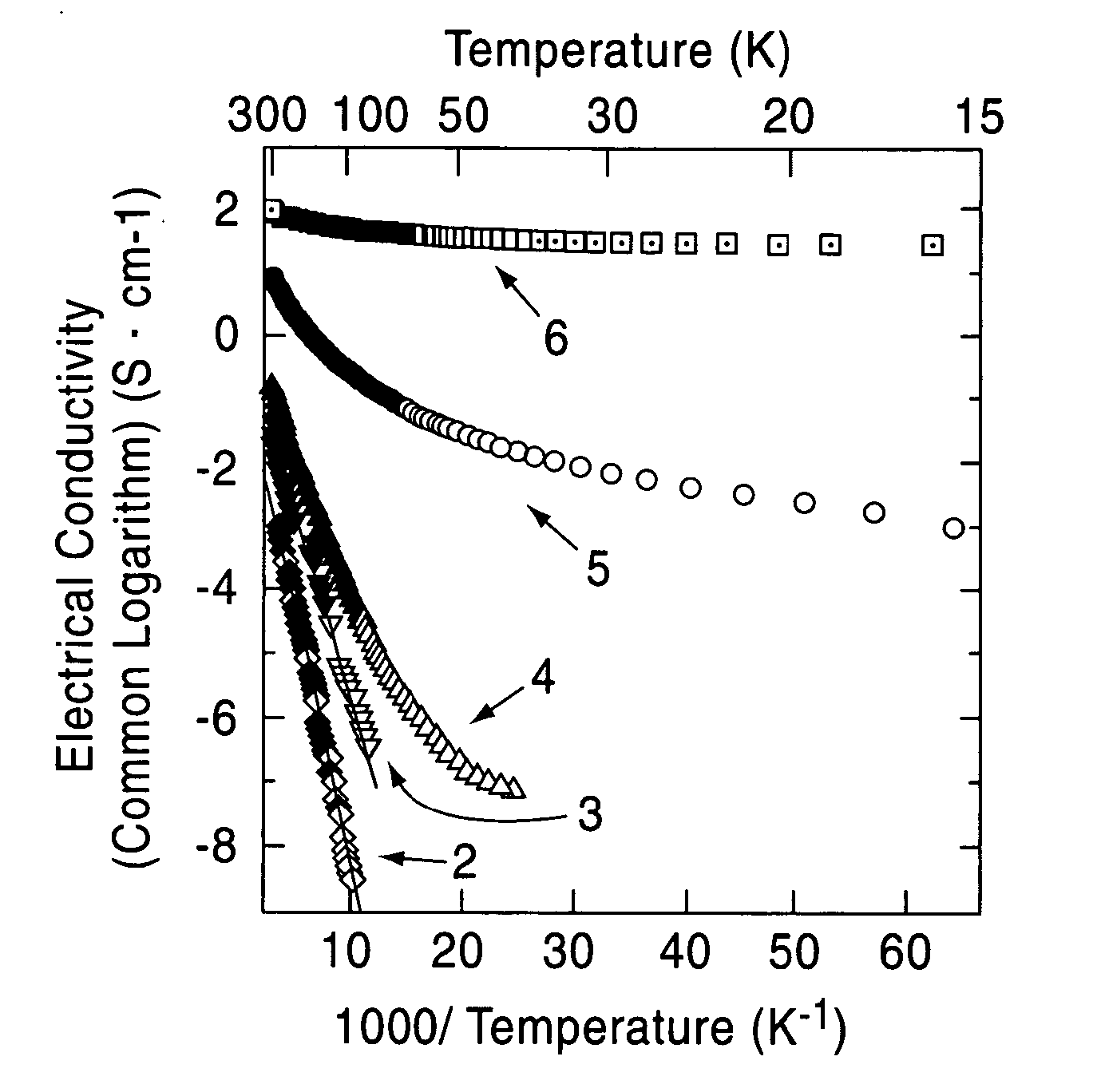

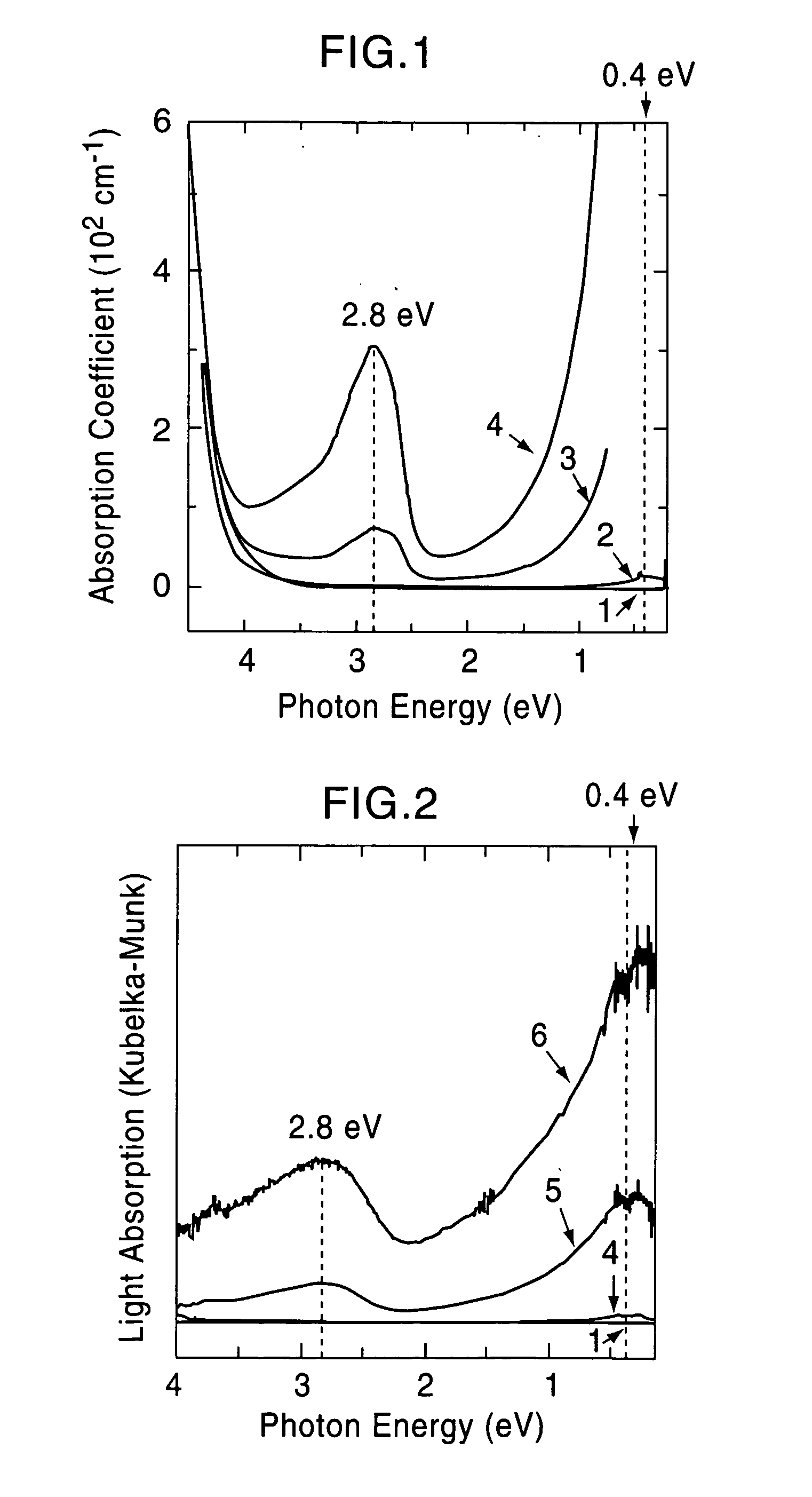

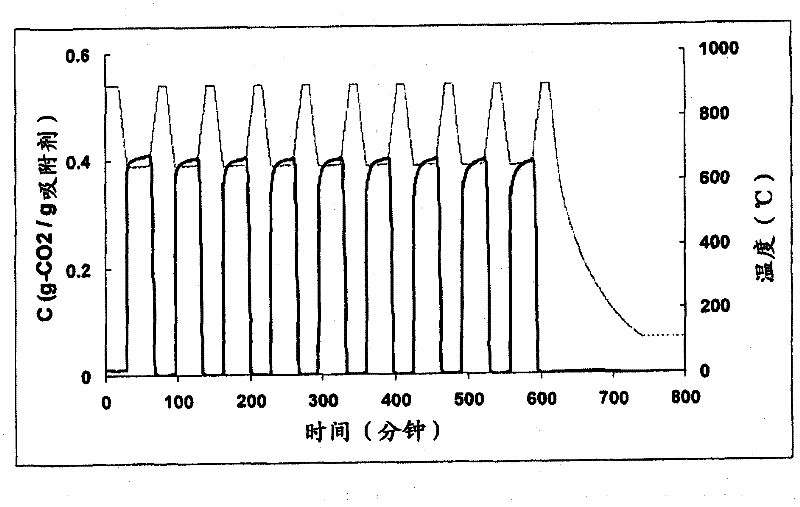

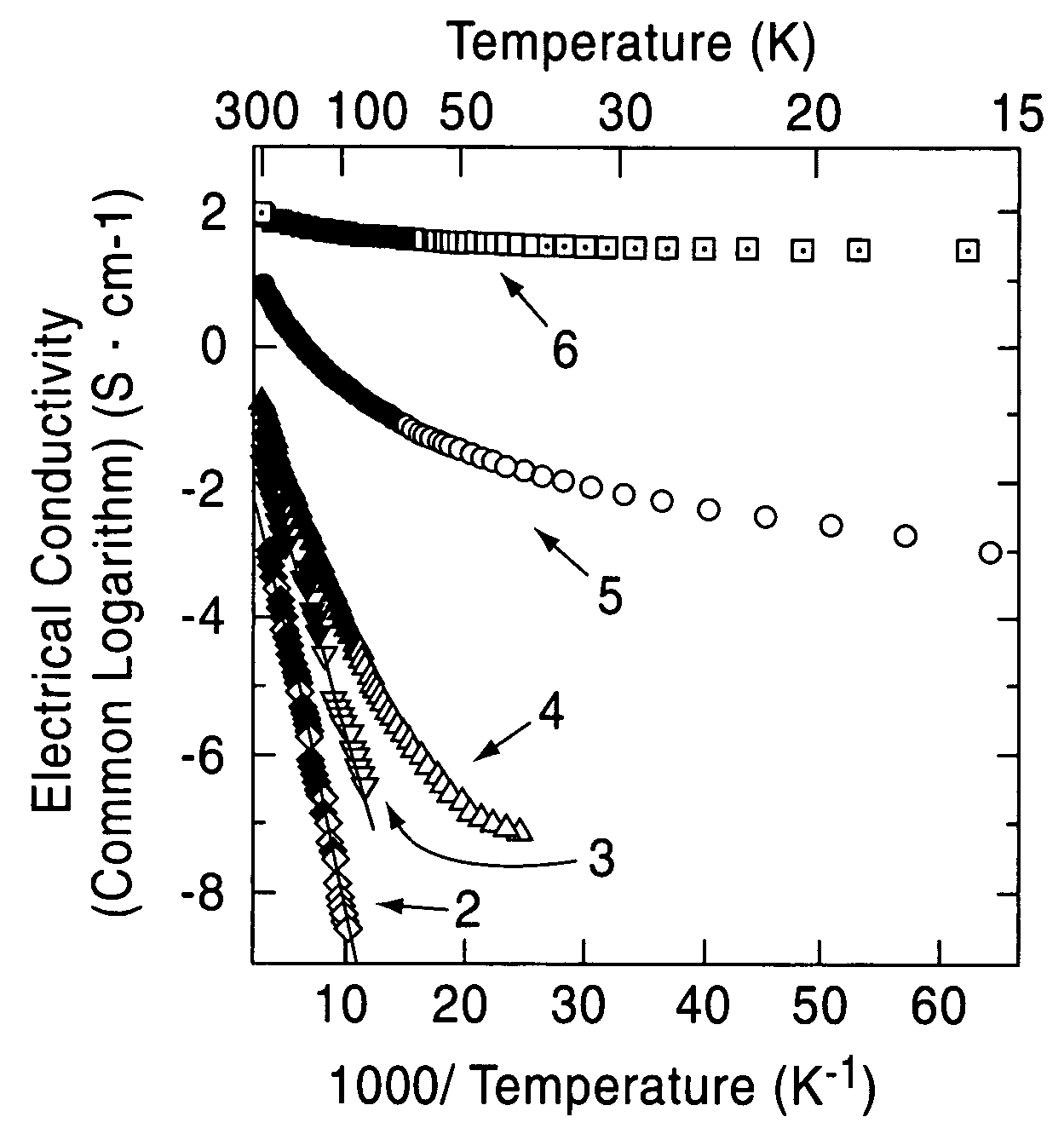

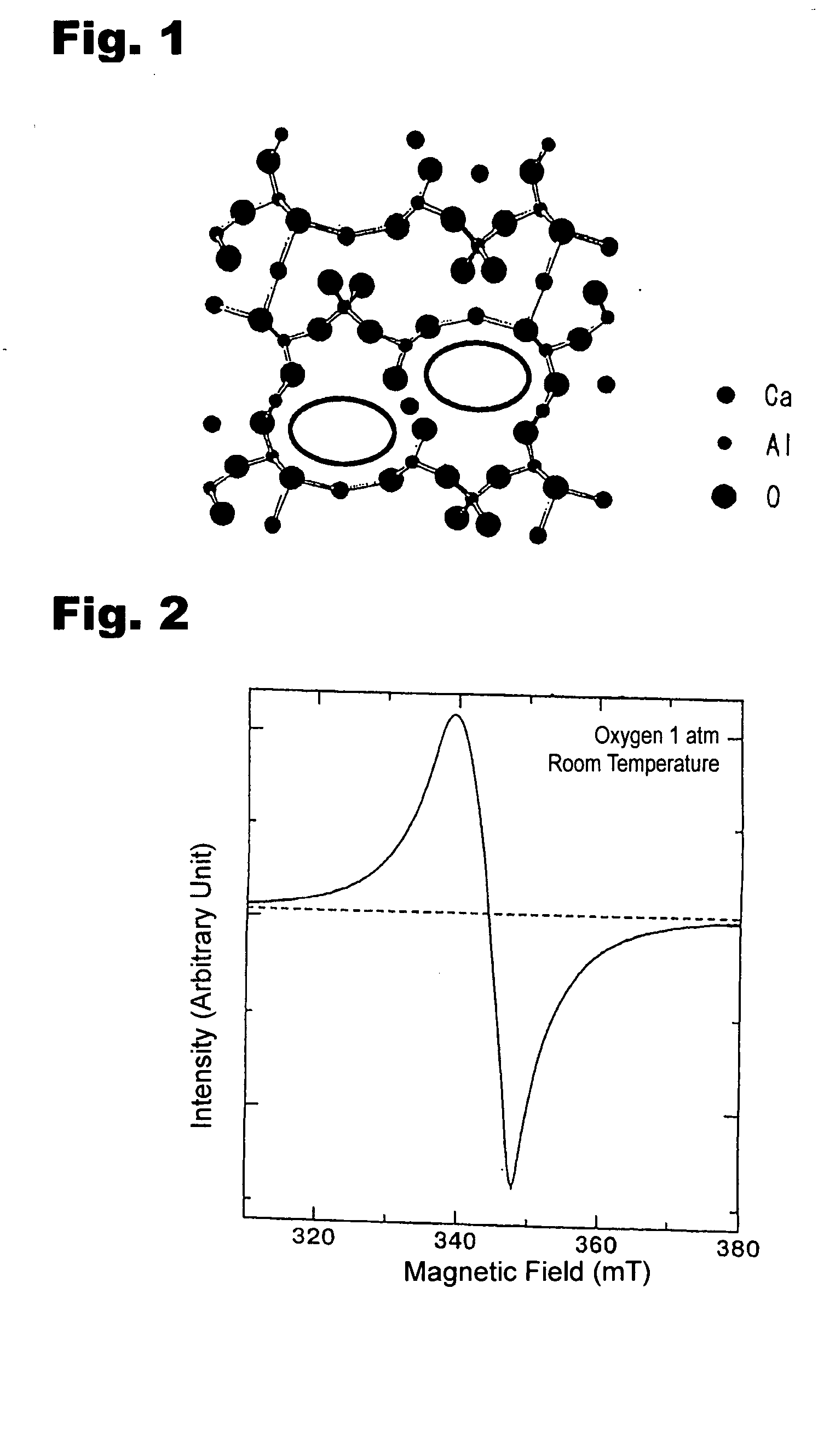

Electroconductive 12ca0.7al203 and compound of same type, and method for preparation thereof

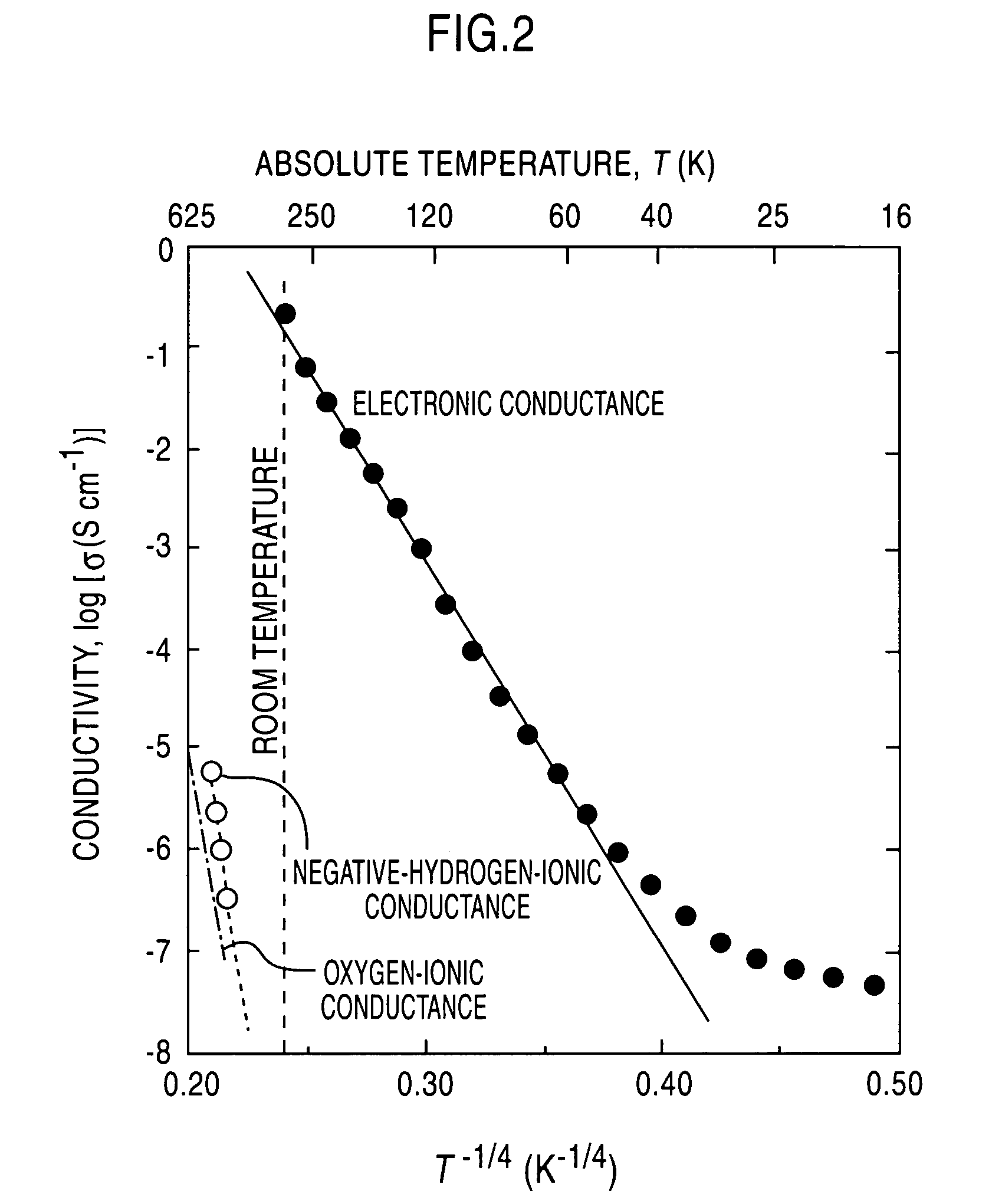

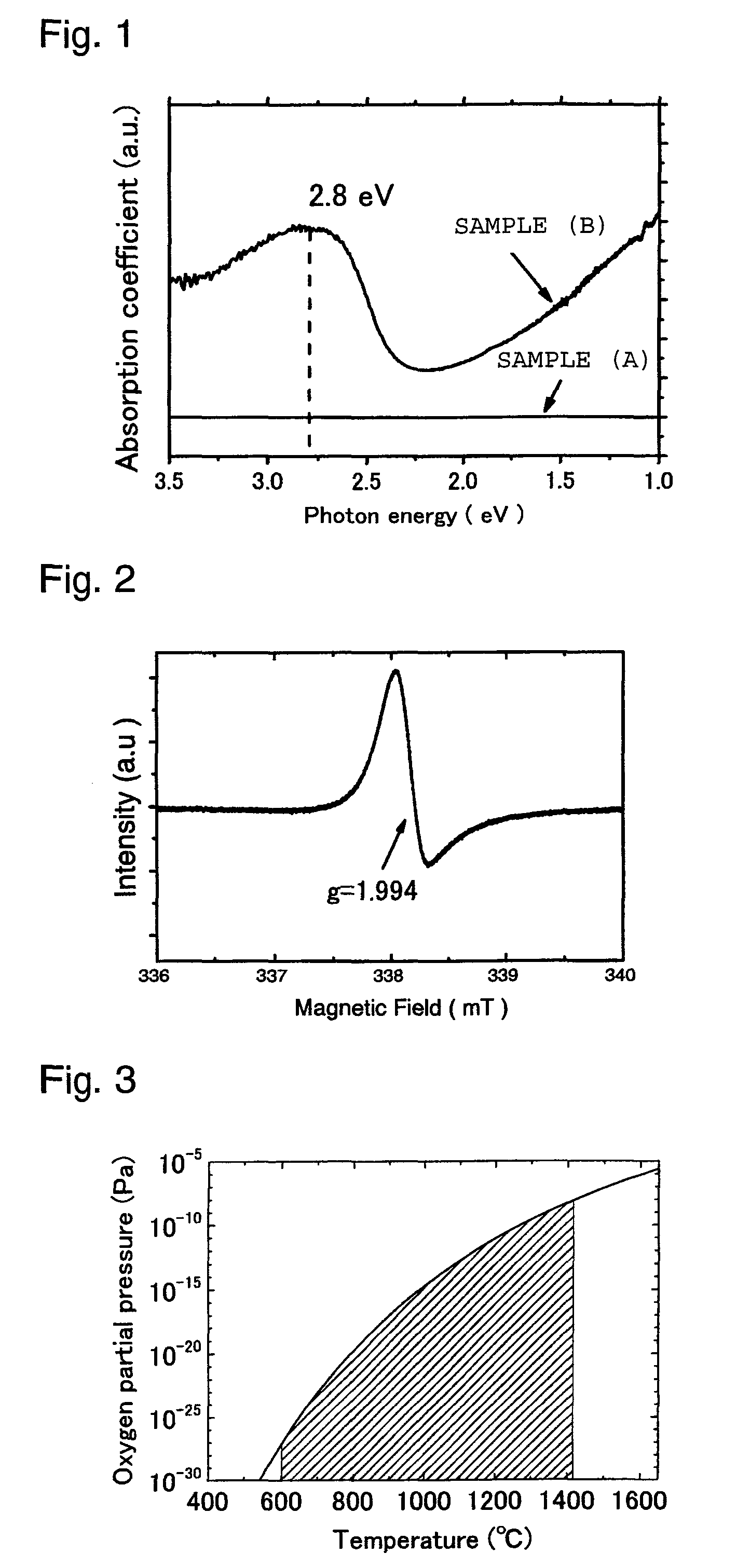

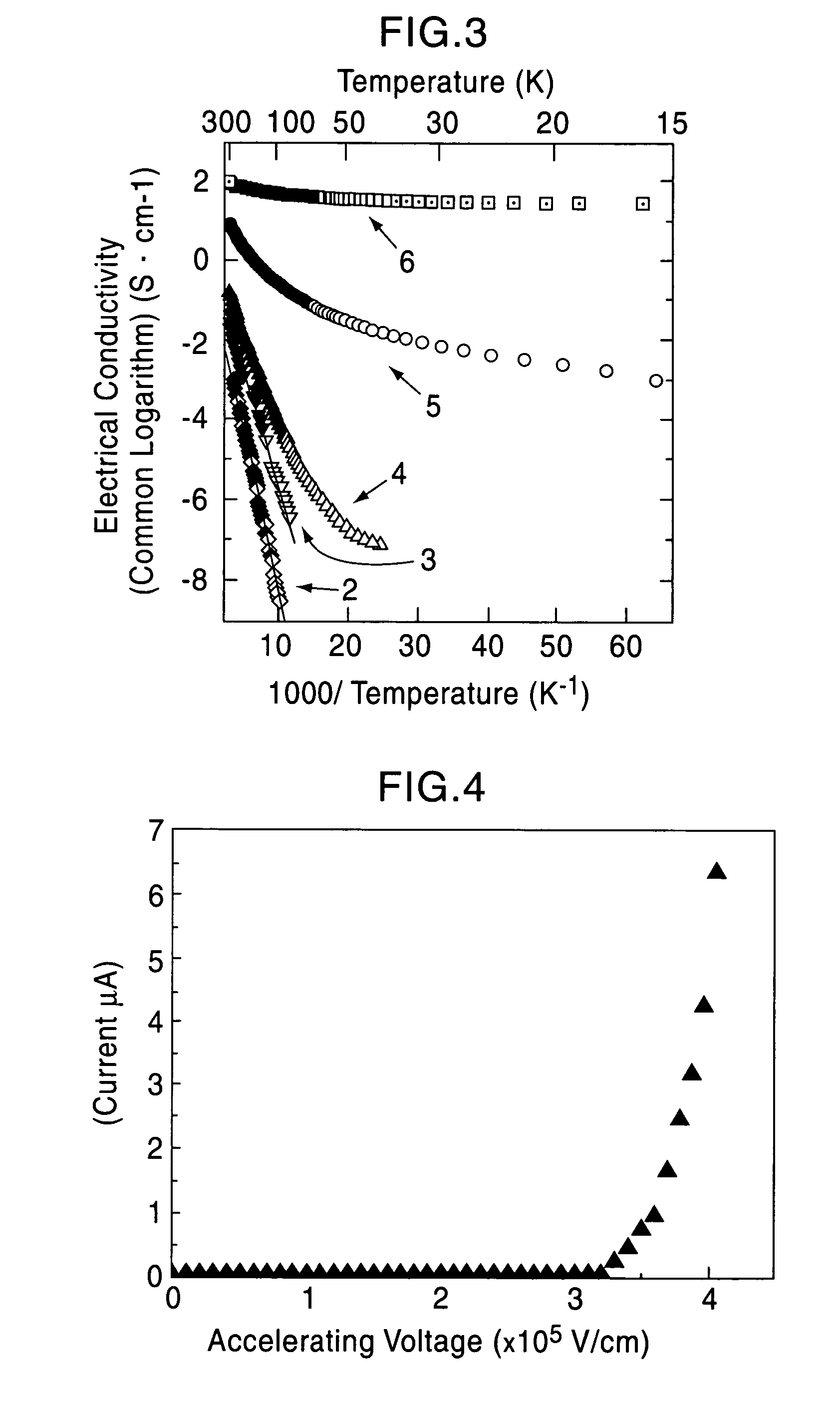

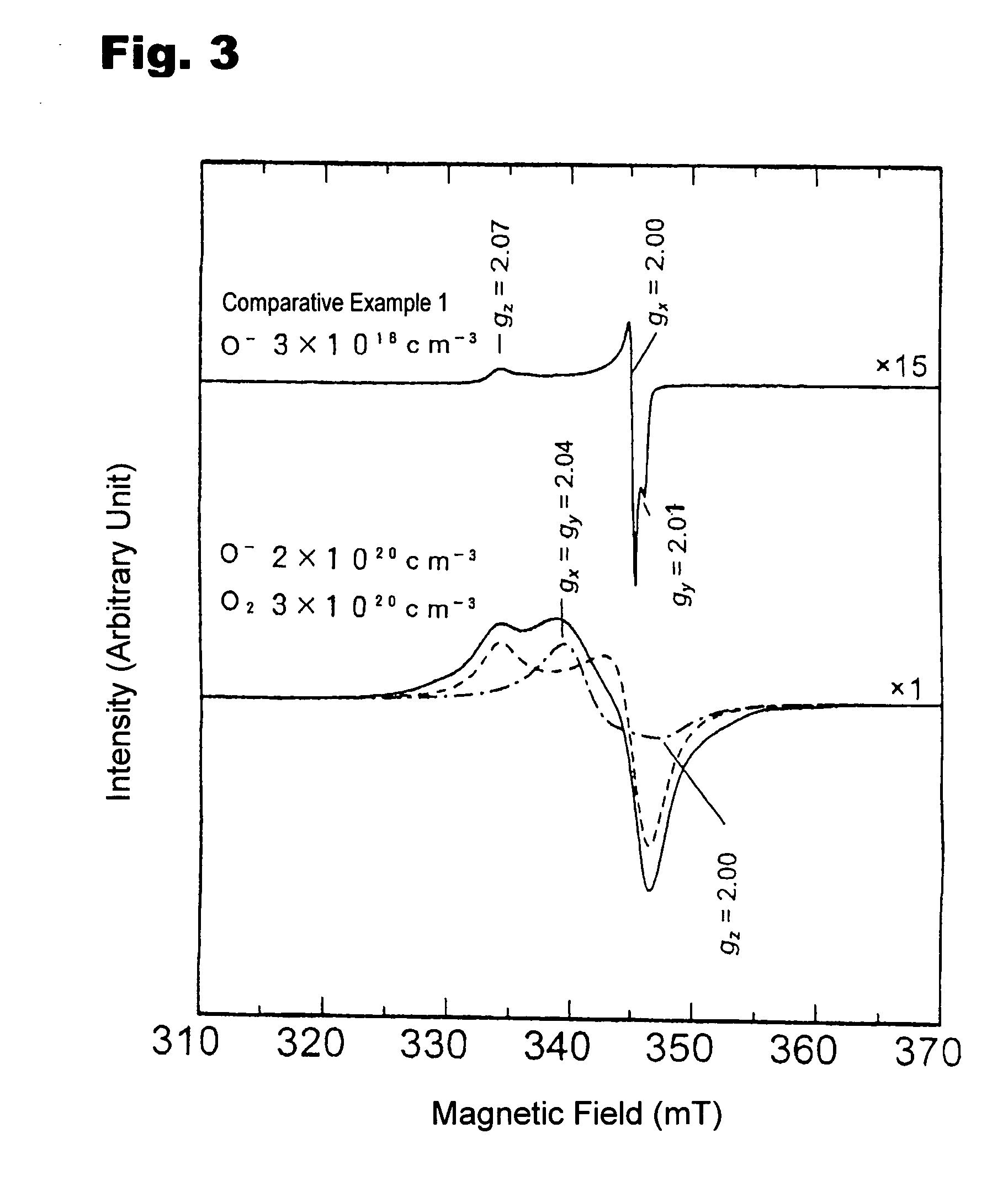

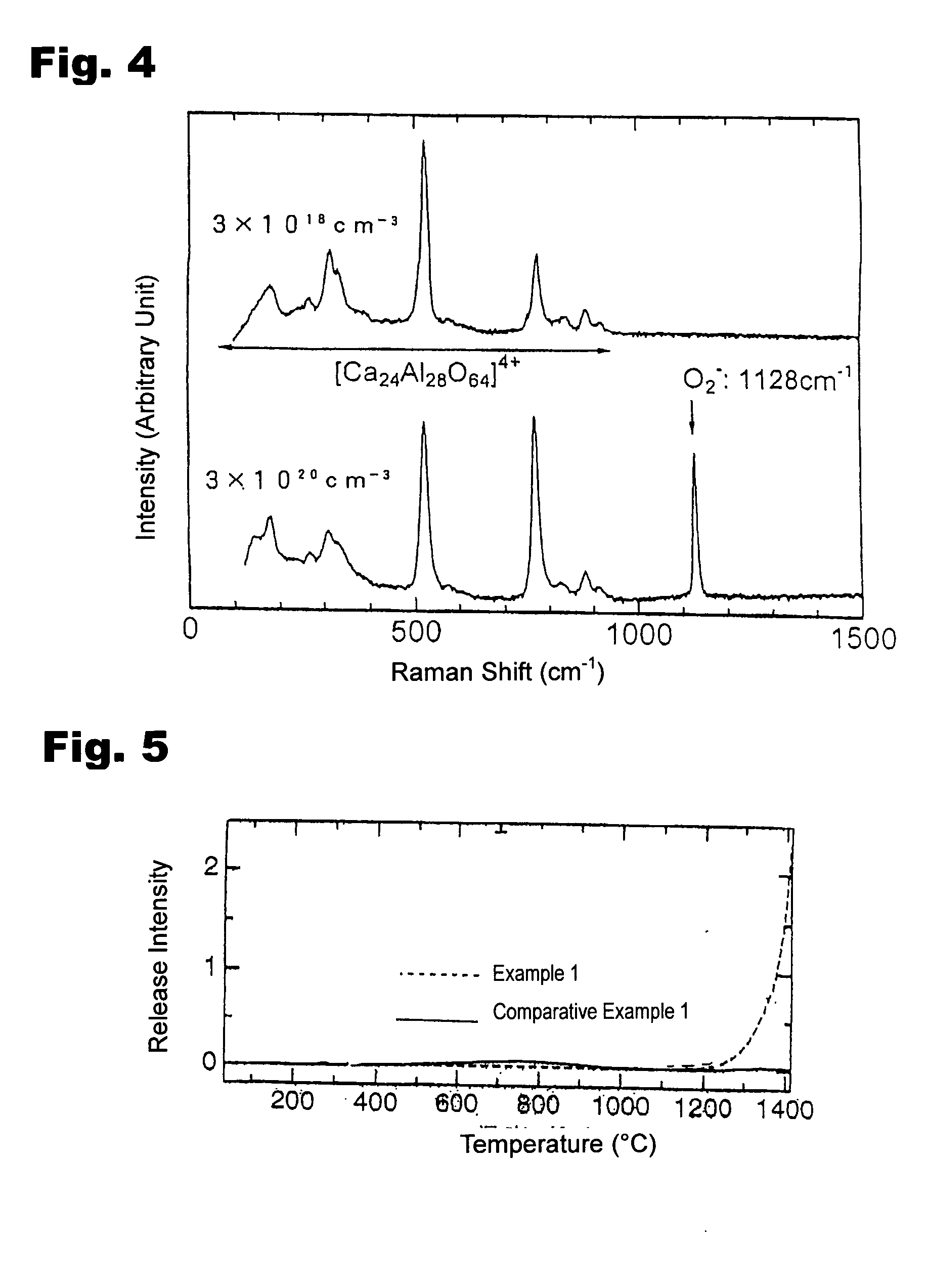

ActiveUS20060151311A1Calcium aluminatesOxygen/ozone/oxide/hydroxideHigh concentrationAlkaline earth metal

In a solid solution system of Al2O3 and CAO or SrO, it has been difficult to obtain a material having a high electrical conductivity (>10−4 S·cm−) at room temperature. A compound is provided in which electrons at a high concentration are introduced into a 12CaO.7Al2O3 compound, a 12SrO.7Al2O3 compound, or a mixed crystal compound containing 12CaO.7Al2O3 and 12SrO.7Al2O3. The compound formed by substituting all the free oxygen ions with electrons is regarded as an electride compound in which [Ca24Al28O64]4+(4e−) or [Sr24Al28O64]4+(4e−) serves as a cation and electrons serve as anions. When a single crystal or a hydrostatic pressure press molded material of a fine powder thereof is held at approximately 700° C. in an alkaline metal vapor or an alkaline earth metal vapor, melt of a hydrostatic pressure press molded material of a powder is held at approximately 1,600° C. in a carbon crucible, followed by slow cooling for solidification, or a thin film of the compound held at approximately 600° C. is implanted with rare gas ions, a great number of the free oxygen ions can be substituted with electrons.

Owner:JAPAN SCI & TECH CORP

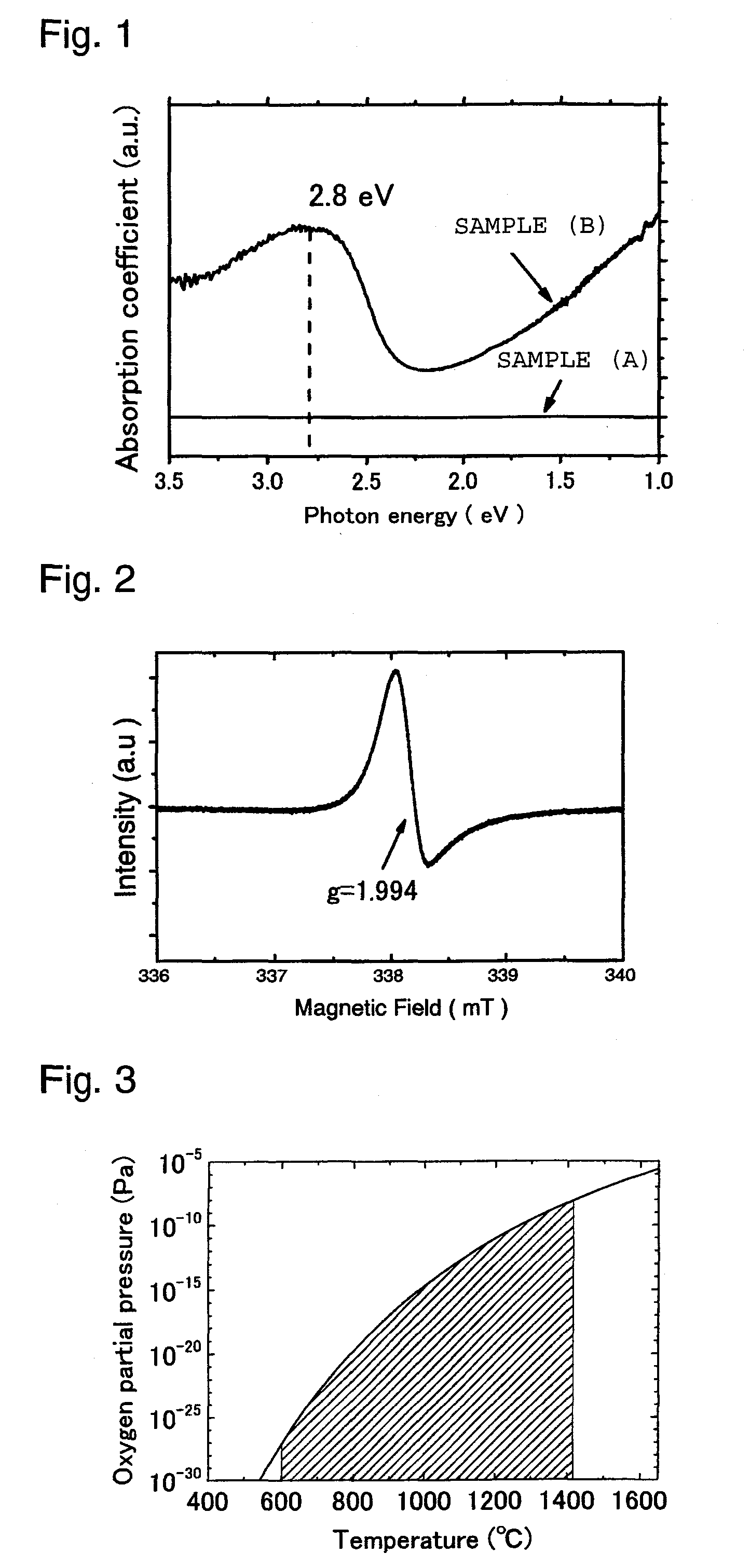

Method for preparing electroconductive mayenite type compound

ActiveUS20060276326A1Improve productivityLow melting pointCalcium aluminatesHigh concentrationAtmospheric air

To provide a method for preparing a mayenite type compound having electroconductivity imparted. A method for preparing an electroconductive mayenite type compound, which comprises melting a raw material containing Al and at least one element selected from the group consisting of Ca and Sr, holding the melt in a low oxygen partial pressure atmosphere having an oxygen partial pressure of not higher than 10 Pa, followed by cooling or annealing in a low oxygen partial pressure atmosphere or in atmospheric air for solidification, thereby to replace oxygen present in cages by electrons in a high concentration.

Owner:JAPAN SCI & TECH CORP +1

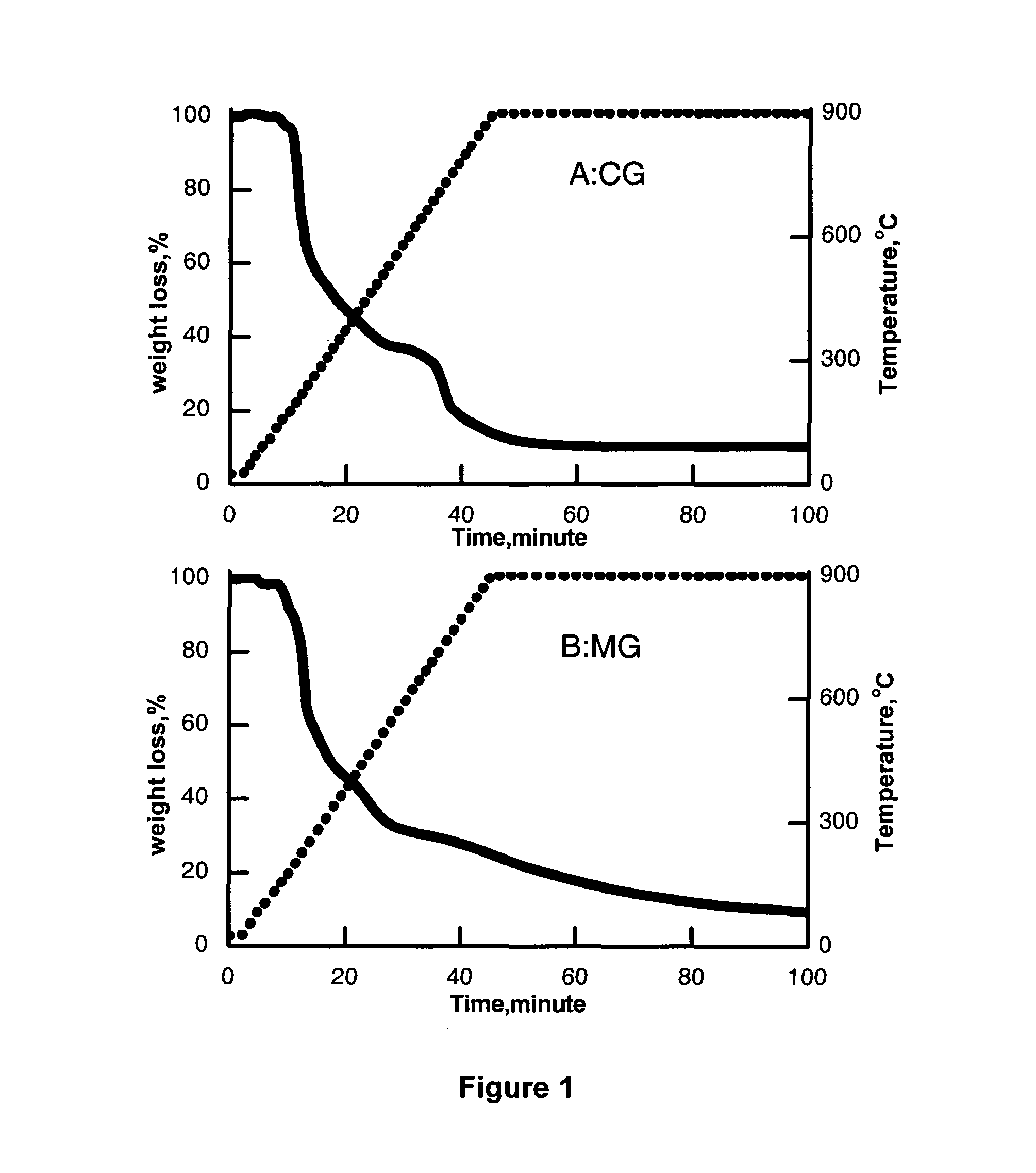

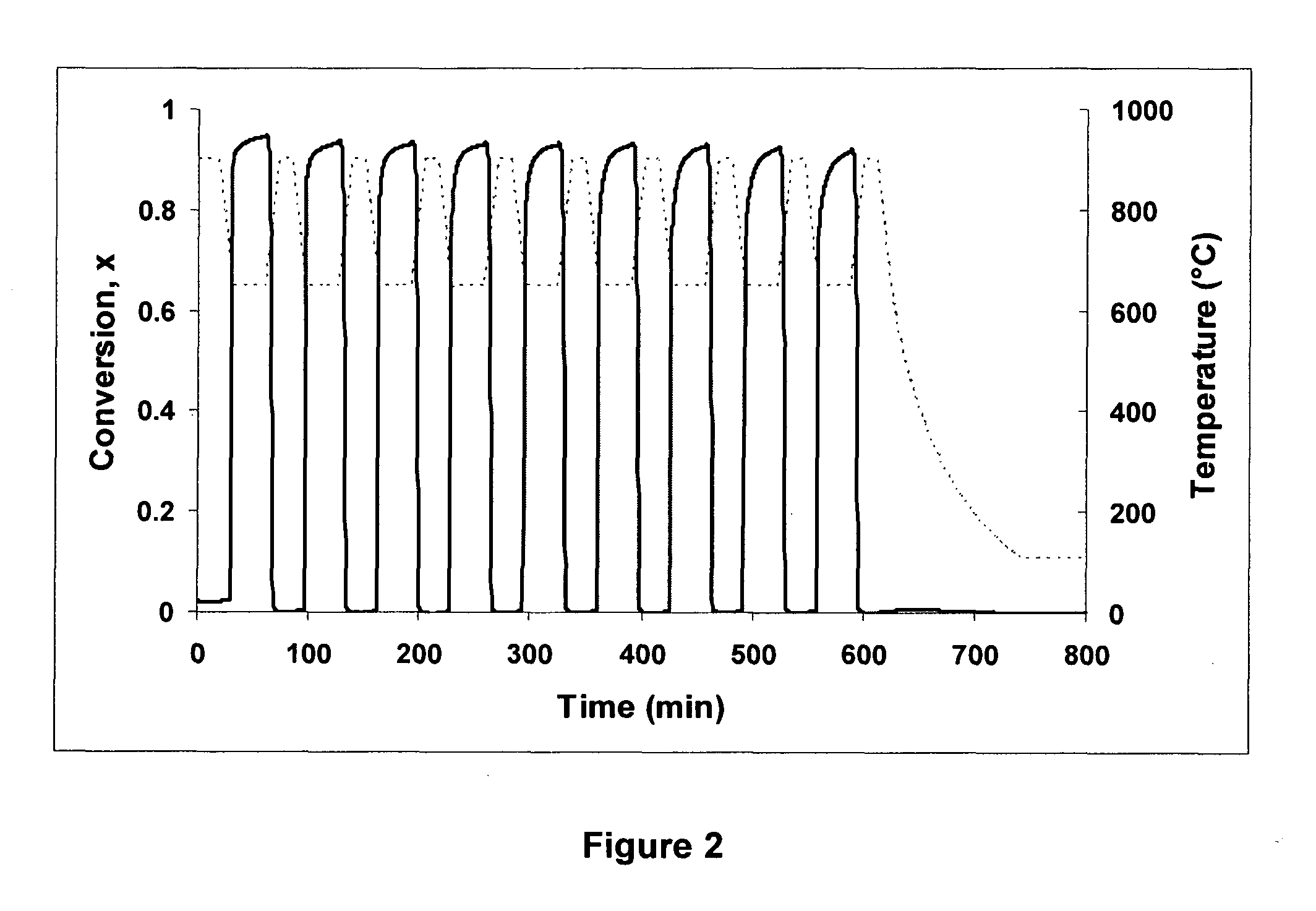

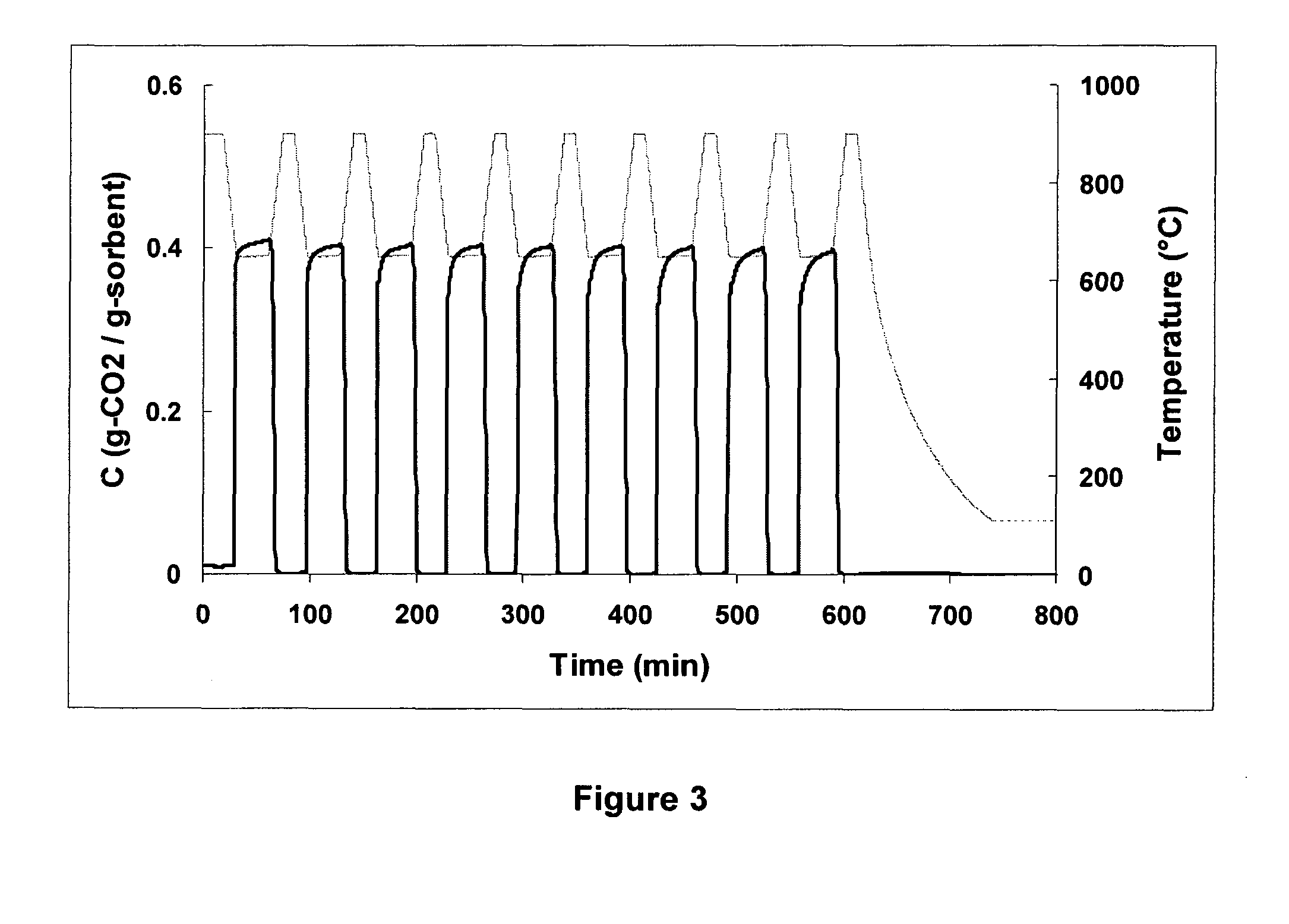

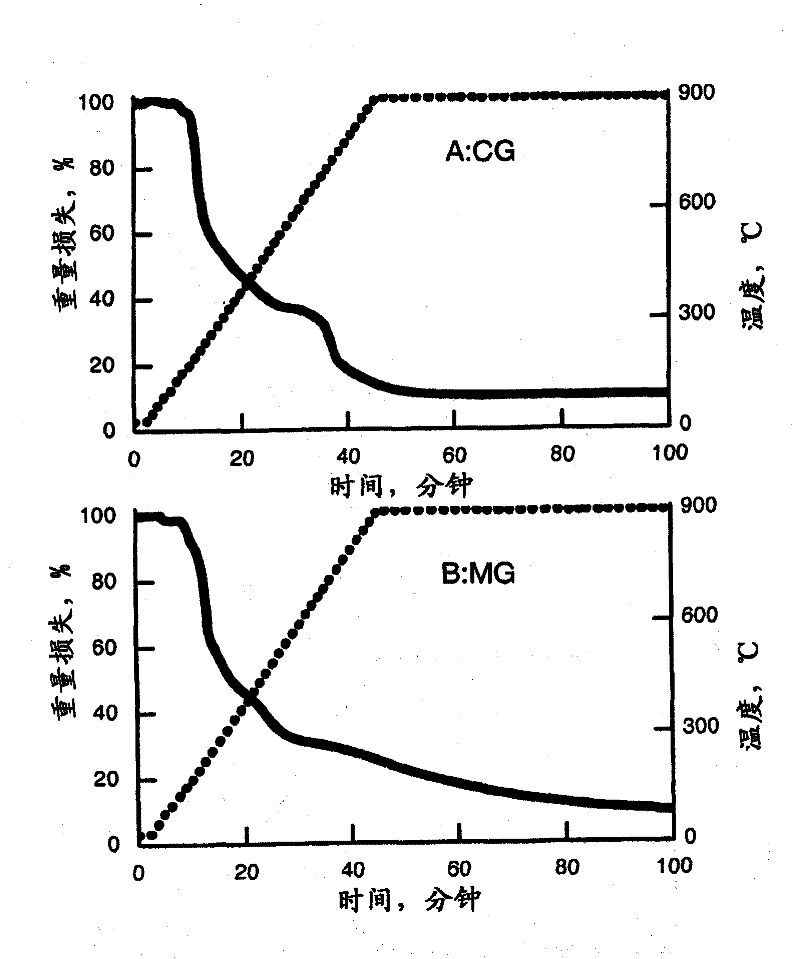

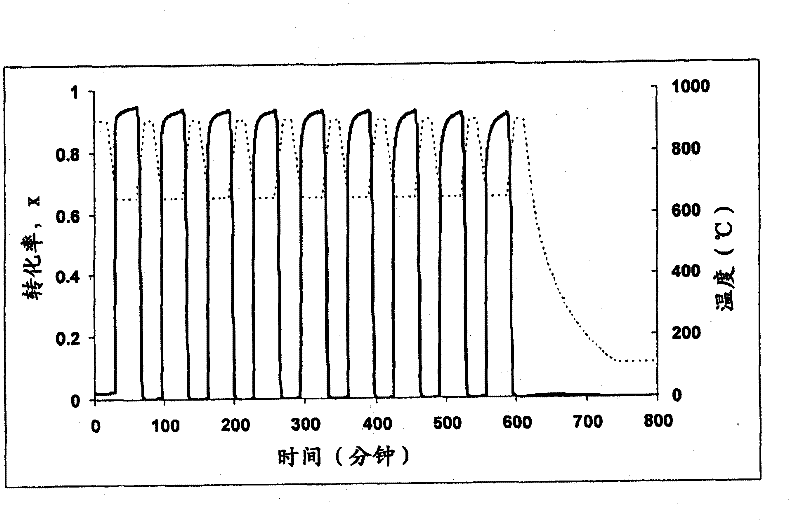

Method for producing sorbents for co2 capture under high temperatures

A method of producing a CO2 adsorbent and CO2 adsorbents. The method including the steps of: (a) producing a mixture of at least one calcium salt and at least one metal support cation in at least one solvent; (b) drying the mixture to produce a solid containing a calcium metal salt; and (c) calcining the dried solid to produce a sorbent of calcium oxide dispersed in a porous metal support.

Owner:THE UNIV OF QUEENSLAND

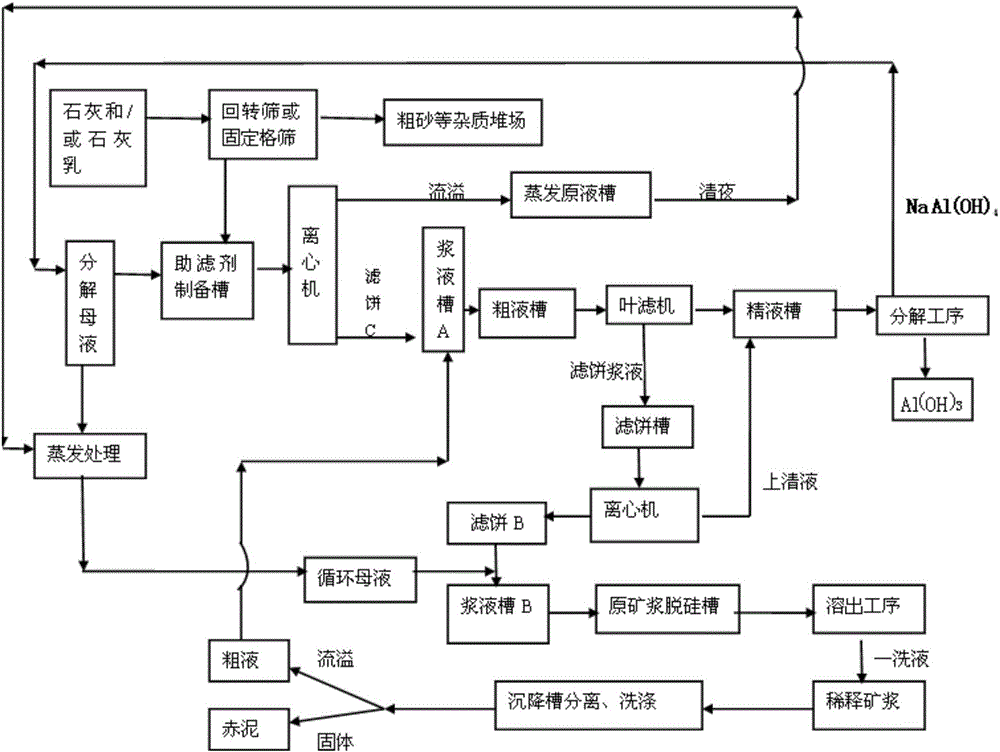

Method for preparing sodium aluminate solution purifying filter aid and utilizing filter cake in alumina production

ActiveCN105905930AImprove cycle efficiencyReduce lossesCalcium aluminatesAlkali metal oxidesDecompositionSodium aluminate

The invention discloses a method for preparing a sodium aluminate solution purifying filter aid and utilizing a filter cake in alumina production. The method comprises the following steps: 1, preparing the filter aid: adding lime milk and / or lime and a decomposition mother liquor to a filter aid preparation tank, and carrying out a reaction to obtain a calcium aluminate slurry which is the filter aid, wherein the decomposition mother liquor is a solution residual after aluminum hydroxide extraction through a decomposition process of a purified liquid in a purified liquid tank; and 2, utilizing the filter cake: filtering the filter cake through a leaf filter, centrifuging and filtering the filter cake slurry, and desiliconizing a filter cake B in order to realize repeated utilization of the filter cake. The method for preparing the sodium aluminate purifying filter aid, removing grits and other impurities and reutilizing the filter cake in the alumina refinery sodium aluminate solution purifying filter aid production has the advantages of effective improvement of the productivity of the leaf filer, prolongation of the service life of a filter cloth, increase of the alumina recovery rate, effective utilization of calcium oxide and sodium oxide in the filter cake, and high economy values.

Owner:GUANGXI HUAYIN ALUMINUM

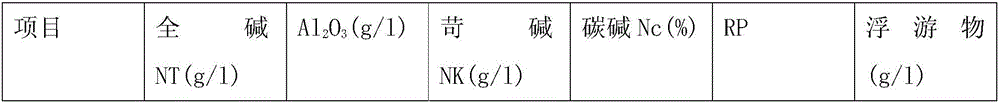

Technology method used for producing poly aluminium chloride and calcium aluminate

ActiveCN110194474AEffective eradicationAvoid harmCalcium aluminatesAluminium chloridesAluminateAluminium chloride

The invention discloses a technology method used for producing poly aluminium chloride and calcium aluminate. The technology method comprises following steps: 1, ash stir frying is carried out, and metal aluminum is recycled so as to obtain secondary aluminum ash; 2, the secondary aluminum ash is subjected to deamination processing so as to obtain a deaminated aluminum ash slurry; 3, the deaminated aluminum ash slurry is subjected to defluorination processing so as to obtain a defluorinated aluminum ash slurry; 4, the defluorinated aluminum ash slurry is filtered so as to obtain a filtrate anda filtration residue, wherein the filtrate is a poly aluminium chloride solution; and 5, the filtration residue is washed until the pH value is 7, is uniformly mixed with a calcium based auxiliary material, drying and high temperature reaction are carried out, after reaction, cooling, crushing, and grinding processing are carried out so as to obtain calcium aluminate. According to the technologymethod used for producing poly aluminium chloride and calcium aluminate, secondary aluminum ash is subjected to complete harmless processing, so that high efficiency resource utilization of secondaryaluminum ash is realized, and the produced products possess better economical benefit.

Owner:XINJIANG JOINWORLD CO LTD

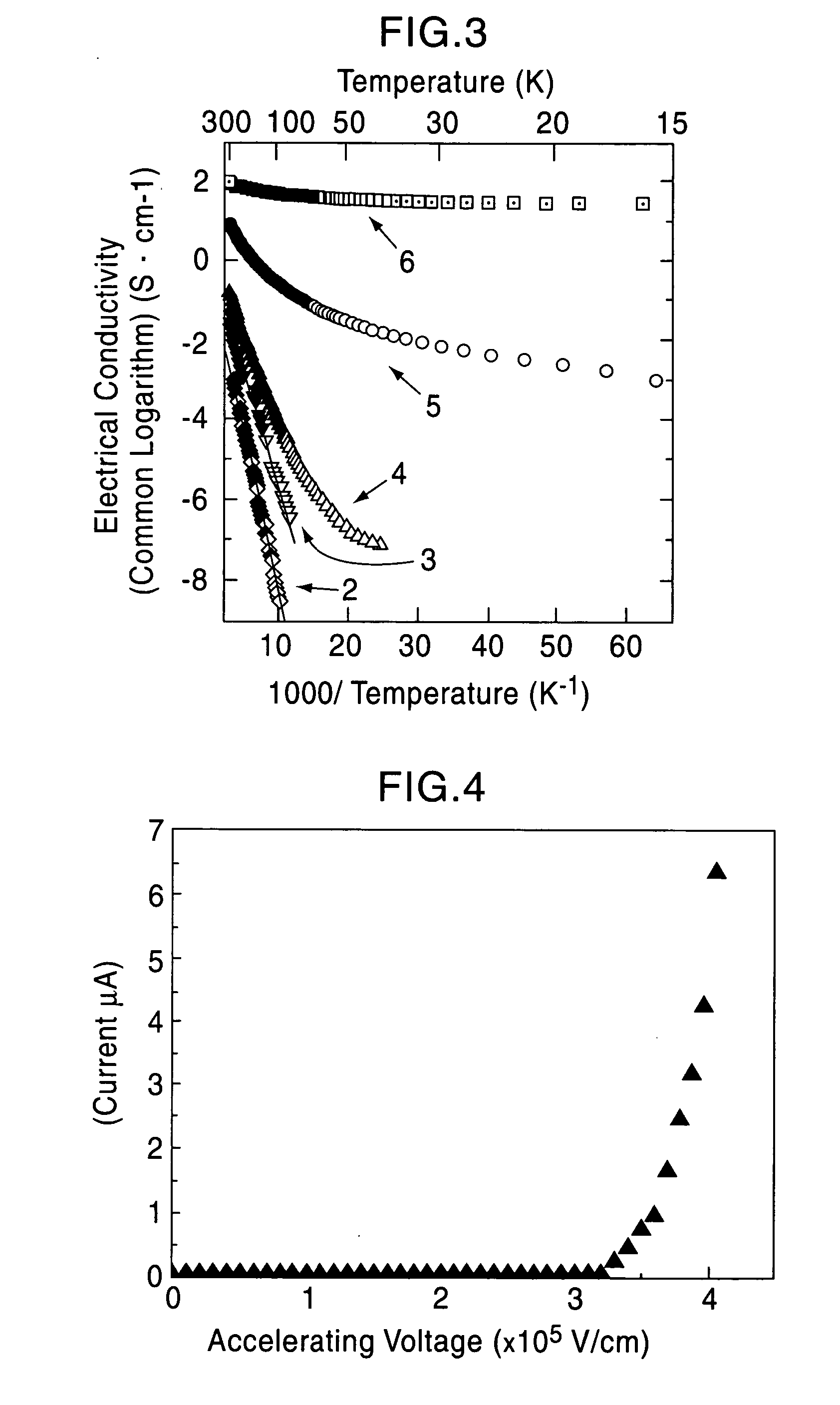

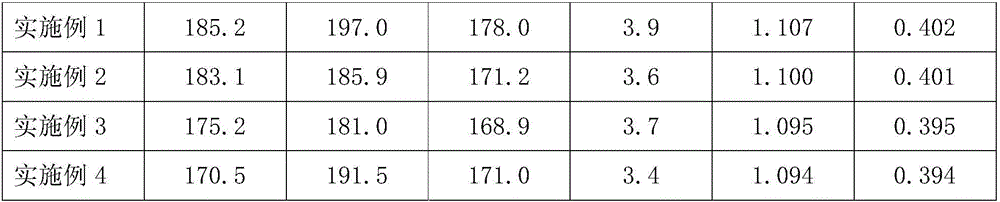

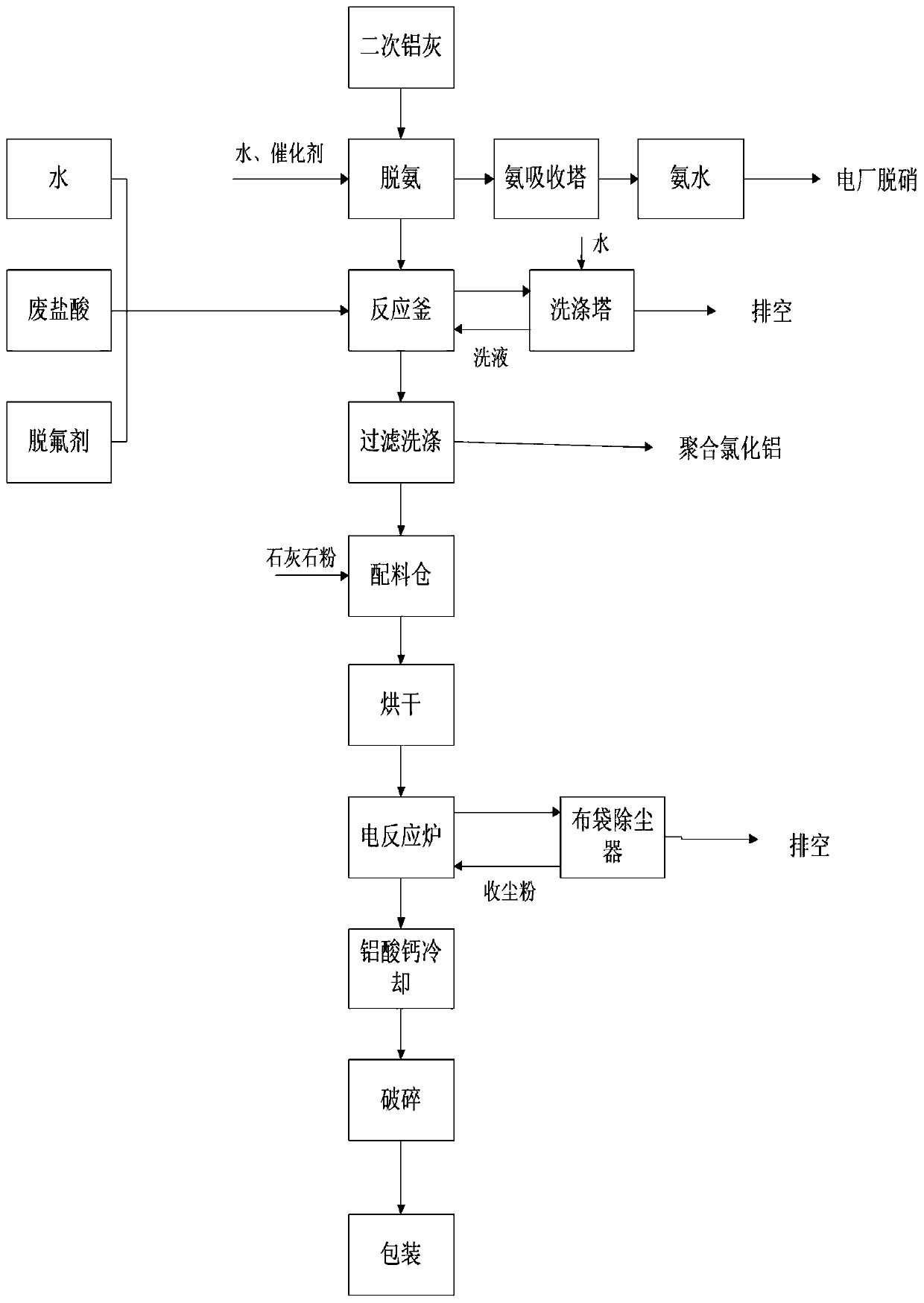

METALLIC ELECTROCONDUCTIVE 12CaO 7Al2O3 COMPOUND AND PROCESS FOR PRODUCING THE SAME

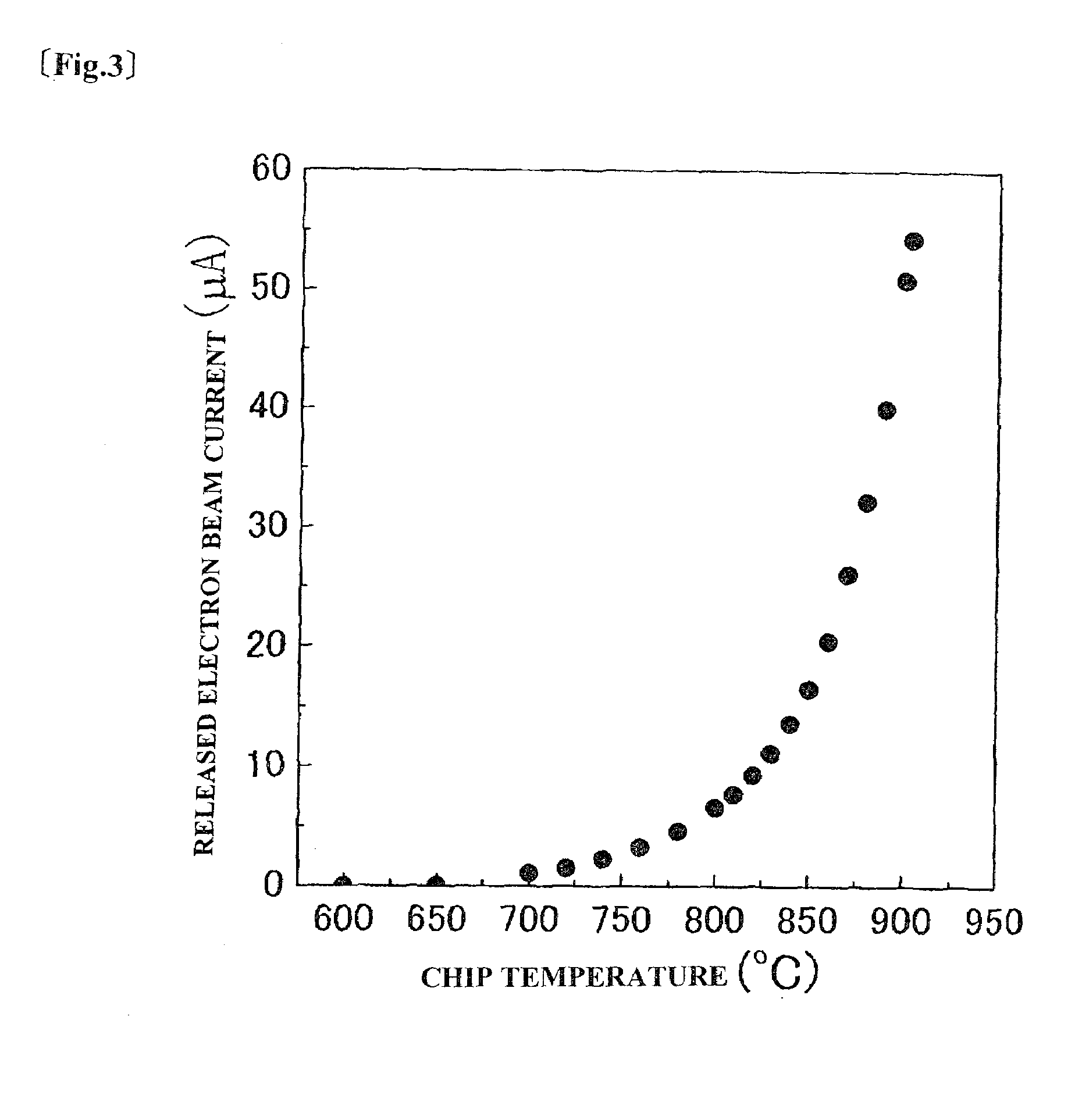

ActiveUS20090224214A1Increase the number ofIncrease electron concentrationCalcium aluminatesPolycrystalline material growth12CaO.7Al2O3Titanium metal

In an electride C12A7 provided by replacing free oxygen in 12CaO.7Al2O3 with electrons, a material having metallic electroconductivity and an electric conductivity of more than 5×102 S / cm at room temperature could not have been produced without difficulties.An electride 12CaO.7Al2O3, which has metallic electroconductivity and has an electric conductivity of more than 5×102 S / cm at room temperature, can be produced by heat-treating titanium metal vapor and 12CaO.7Al2O3 single crystal, sinter, or thin film at a temperature above 600° C. and below 1,450° C. for less than 240 hours. Further, thermoelectric field electron release can also be realized using an electron release chip fabricated from the electride.

Owner:JAPAN SCI & TECH CORP

Method for preparing electroconductive mayenite type compound

ActiveUS20080095688A1Improve conductivityLow costCalcium aluminatesStrontium aluminatesCrystalline materialsAtmosphere

Provided is a method for preparing an electroconductive mayenite type compound with good properties readily and stably at low cost without need for expensive facilities, a reaction at high temperature and for a long period of time, or complicated control of reaction. A method for preparing an electroconductive mayenite type compound comprises a step of subjecting a precursor to heat treatment, wherein the precursor contains Ca and / or Sr, and Al, a molar ratio of (a total of CaO and SrO:Al2O3) is from (12.6:6.4) to (11.7:7.3) as calculated as oxides, a total content of CaO, SrO and Al2O3 in the precursor is at least 50 mol %, and the precursor is a vitreous or crystalline material; and the method comprises a step of mixing the precursor with a reducing agent and performing the heat treatment of holding the mixture at 600-1,415° C. in an inert gas or vacuum atmosphere with an oxygen partial pressure of at most 10 Pa.

Owner:ASAHI GLASS CO LTD +1

Hydrogen-containing electrically conductive organic compound

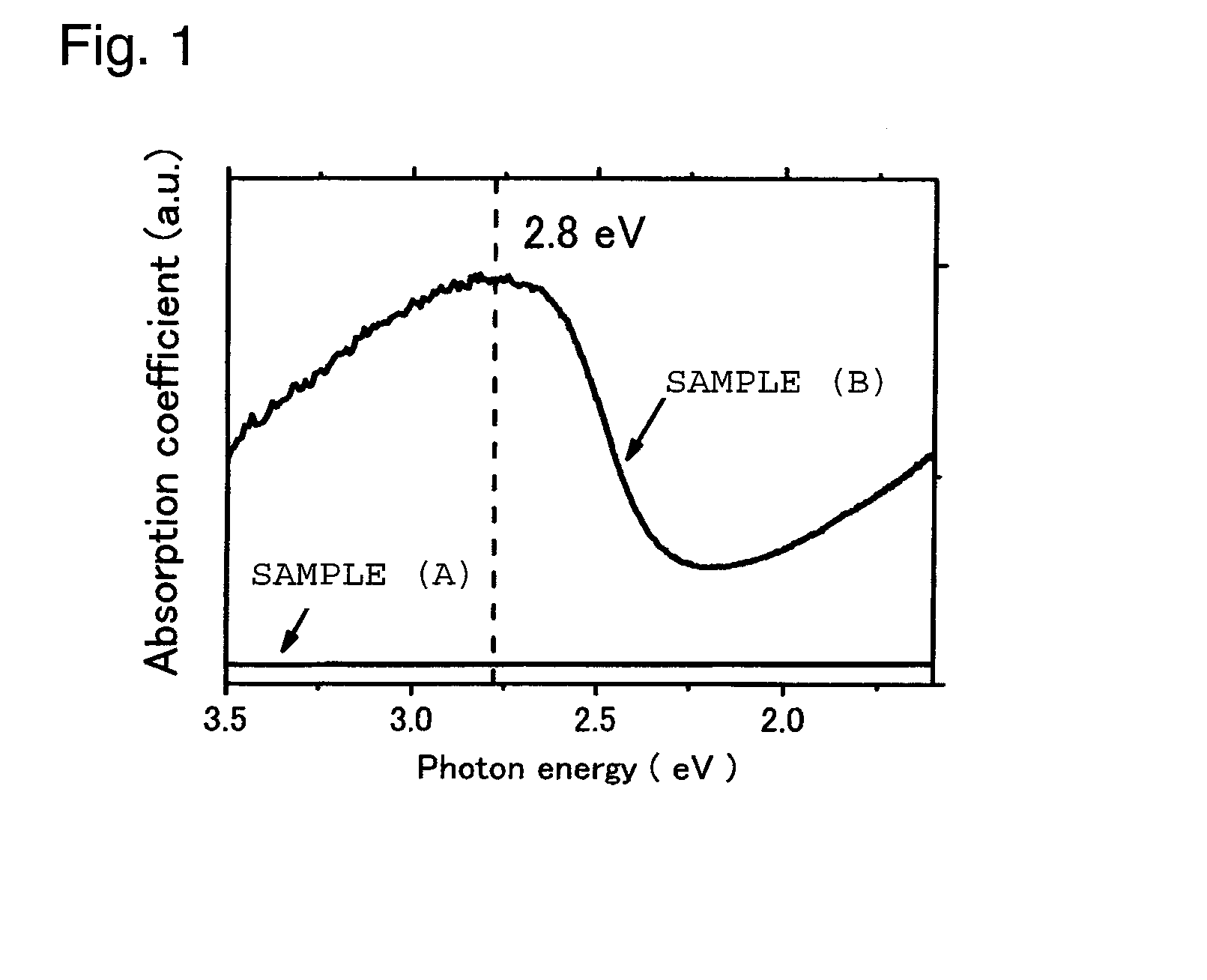

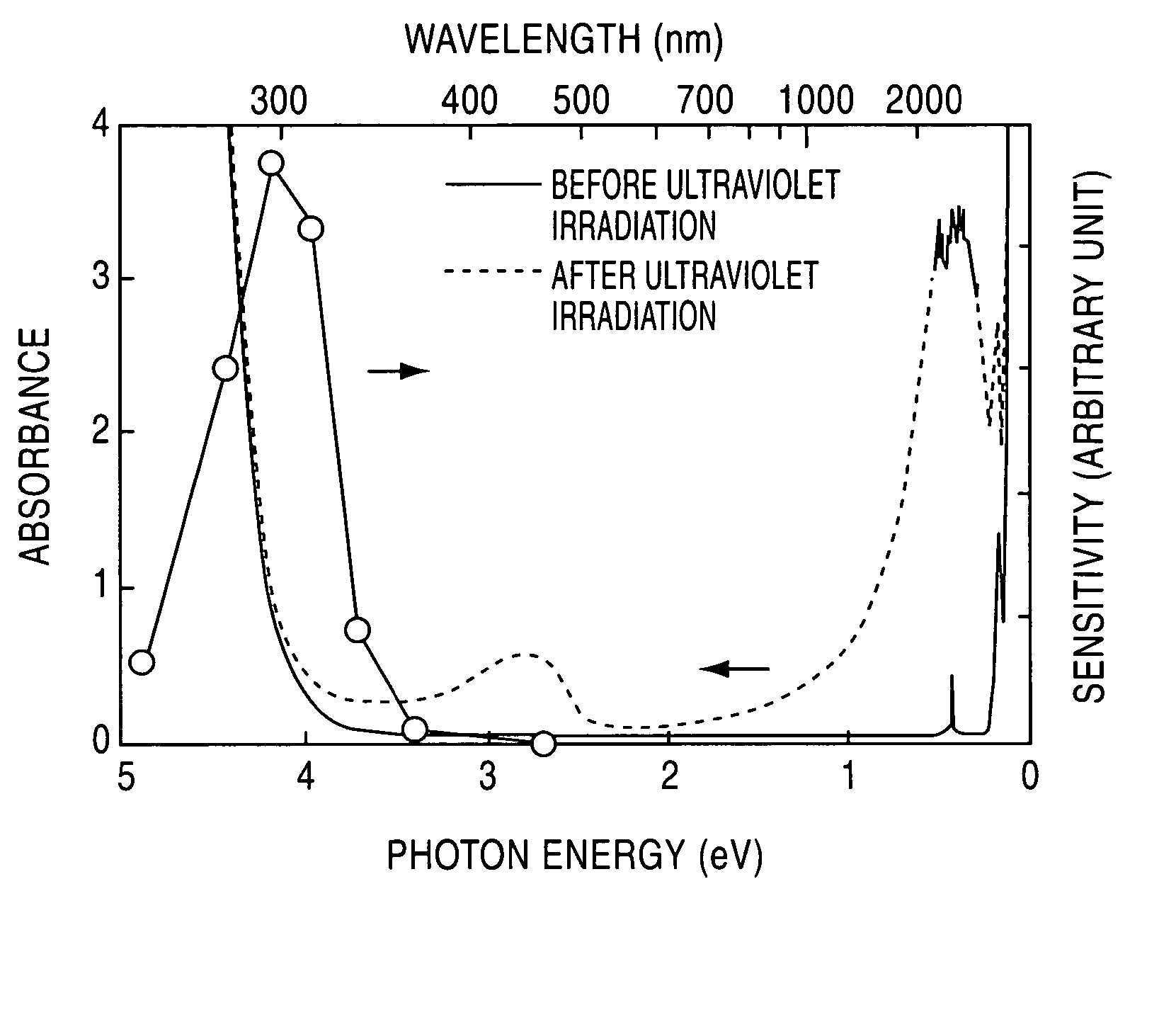

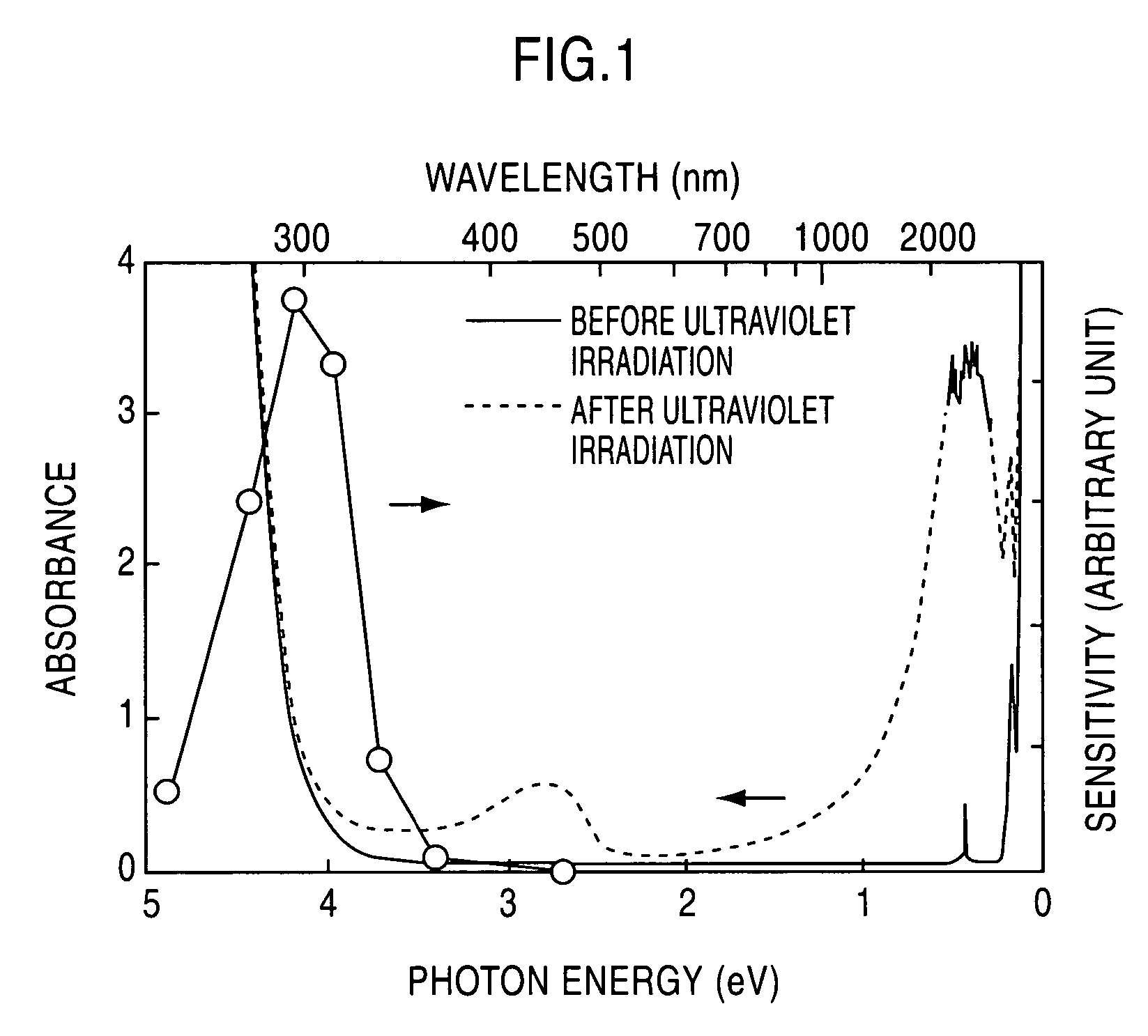

ActiveUS20050279279A1Reduced stabilityQuick breakdownCalcium aluminatesPolycrystalline material growthSimple Organic CompoundsHydrogen

Disclosed is a 12CaO.7Al2O3 compound, a 12SrO.7Al2O3 compound, or a mixed crystal compound of 12CaO.7Al2O3 and 12SrO.7Al2O3, which contains a negative hydrogen ion (H−, H2−, H2− at a concentration of 1×1018 cm−3 or more. A negative hydrogen ion comprising a primary component of a hydride ion is incorporated into C12A7 (12CaO.7Al2O3), so that a function of being converted from an insulative material to an electrically conductive material in a sustained manner by means of irradiation with light can be exhibited even in the normal atmosphere at a room temperature. The present invention also provides a solid electrolyte capable of conducting a negative hydrogen ion, and means for releasing a hydride ion from the inside of a solid into a gaseous phase using an electric field.

Owner:JAPAN SCI & TECH CORP

Method for preparing electroconductive mayenite type compound

ActiveUS7722846B2Improve conductivityLow costAluminium silicatesOxide conductorsPhysical chemistryCrystalline materials

Provided is a method for preparing an electroconductive mayenite type compound with good properties readily and stably at low cost.A production method of an electroconductive mayenite type compound comprising a step of subjecting a precursor to heat treatment, is a method for preparing an electroconductive mayenite type compound, comprising a step of subjecting a precursor to heat treatment; wherein the precursor is a vitreous or crystalline material, which contains Ca and Al, in which a molar ratio of (CaO:Al2O3) is from (12.6:6.4) to (11.7:7.3) as calculated as oxides, and in which a total amount of CaO and Al2O3 is at least 50 mol %, and wherein the heat treatment is heat treatment comprising holding the precursor at a heat treatment temperature T of from 600 to 1415° C. and in an inert gas or vacuum atmosphere with an oxygen partial pressure PO2 in a range ofPO2≦105×exp [{−7.9×l04 / (T+273)}+14.4] in the unit of Pa.

Owner:ASAHI GLASS CO LTD +1

Process for producing an oxide

Provided is a process for producing an oxide which includes an electrically conductive mayenite type compound and has an electron density of at least 1 * 1018 / cm3, starting from a combination of a calcium compound and aluminium compound, or a compound which includes calcium and aluminium with a molar ratio of calcium oxide and aluminium oxide as equivlent oxides in the range 9:10 to 14:5, wherein the process for producing an oxide includes a step of heating and holding the starting material at 900-1300 DEG C to produce a calcined powder which includes at least one oxide selected from a group comprising calcium aluminate, calcium oxide and aluminium oxide, and a step of heating and holding the aforementioned calcined powder at least 1200 DEG C and less than 1415 DEG C, in a reducing atmosphere in an atmosphere of an inert gas with a partial pressure of oxygen of no more than 1000 Pa or in a vacuum atmosphere.

Owner:ASAHI GLASS CO LTD

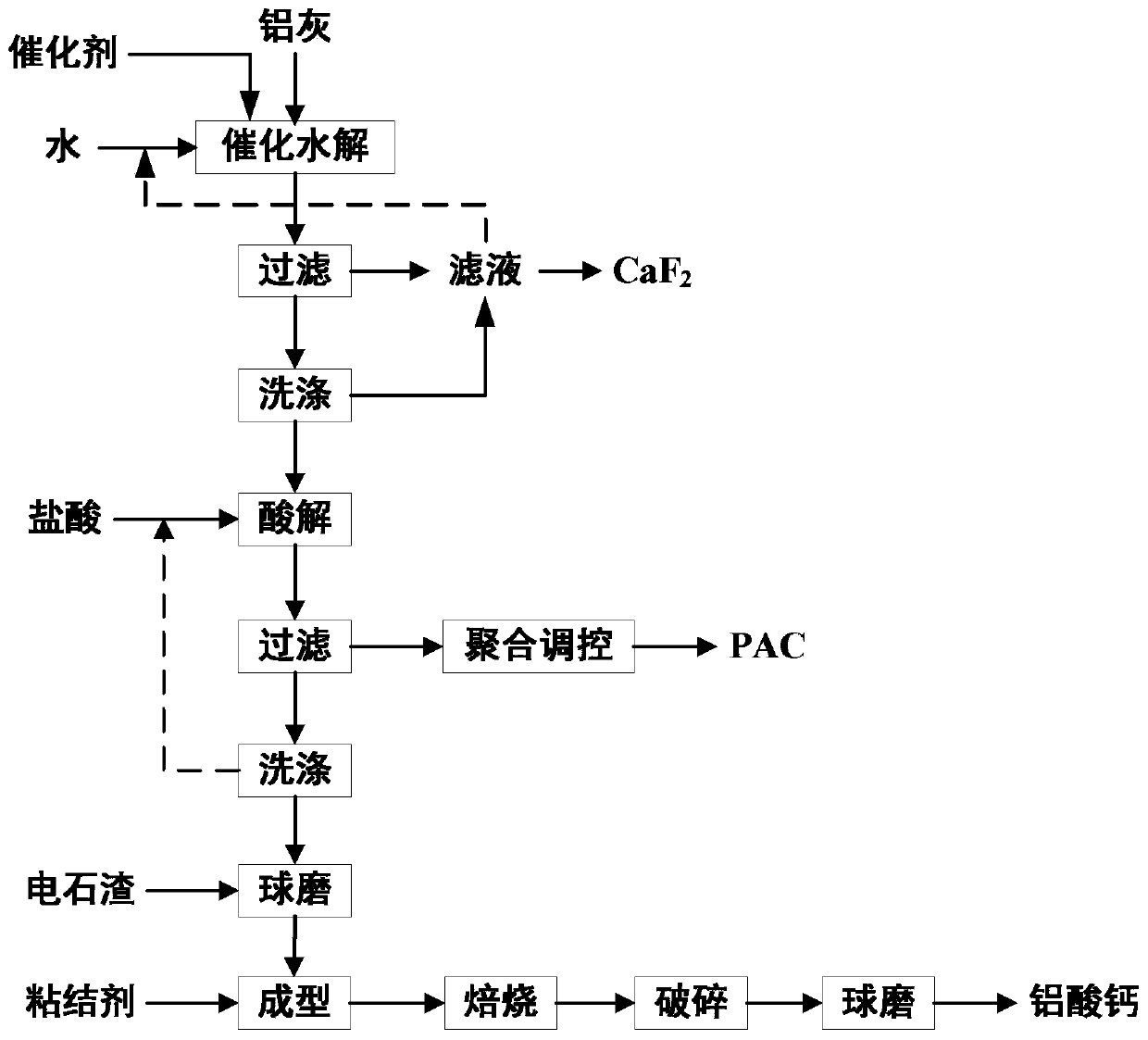

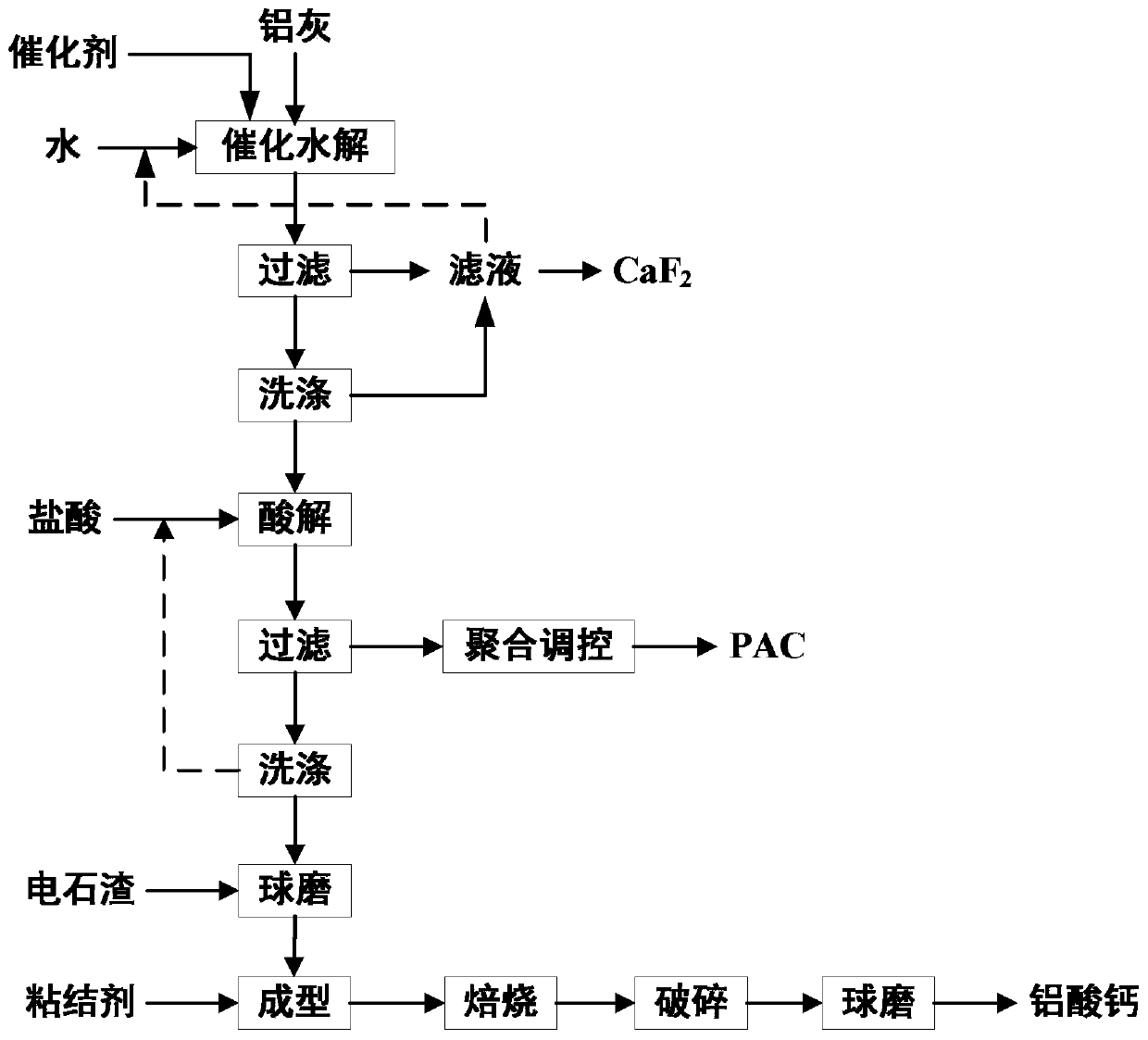

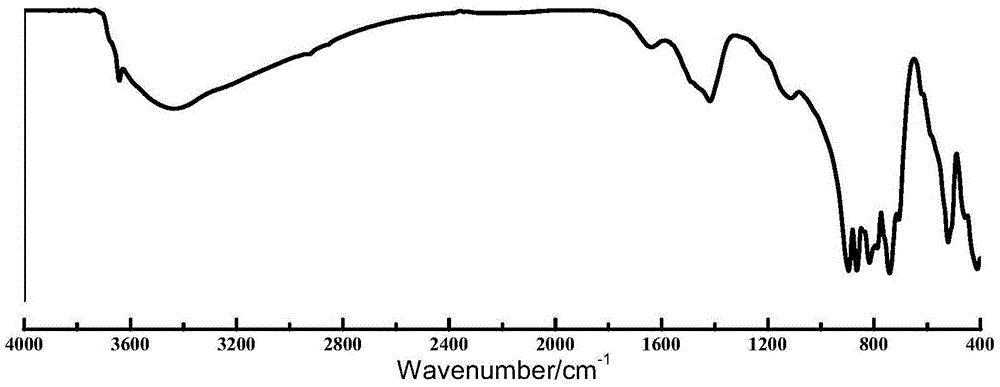

Method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge

ActiveCN110028092AFix security issuesSolve resource problemsCalcium aluminatesResource utilizationSlag

The invention discloses a method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge. The method comprises the following steps: performing catalytic hydrolysis, acidolysis and washing on aluminum ash so as to prepare high-purity aluminum ash powder; performing ball-mill mixing on the high-purity aluminum ash powder and acetylene sludge, performing compression molding onthe mixed powder, and sintering in a sintering furnace to prepare an active calcium aluminate bulk material; crushing and performing ball milling, thereby obtaining the high-activity calcium aluminaterefining agent. The calcium aluminate refining agent prepared by the method disclosed by the invention is excellent in property, and standard requirements of calcium aluminate YB / T4265-2011 for a steel-making slag remover are met. The method disclosed by the invention solves the pollution problems of the aluminum ash and acetylene sludge hazardous / solid wastes to the environment, realizes resource utilization, and has excellent environmental, economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

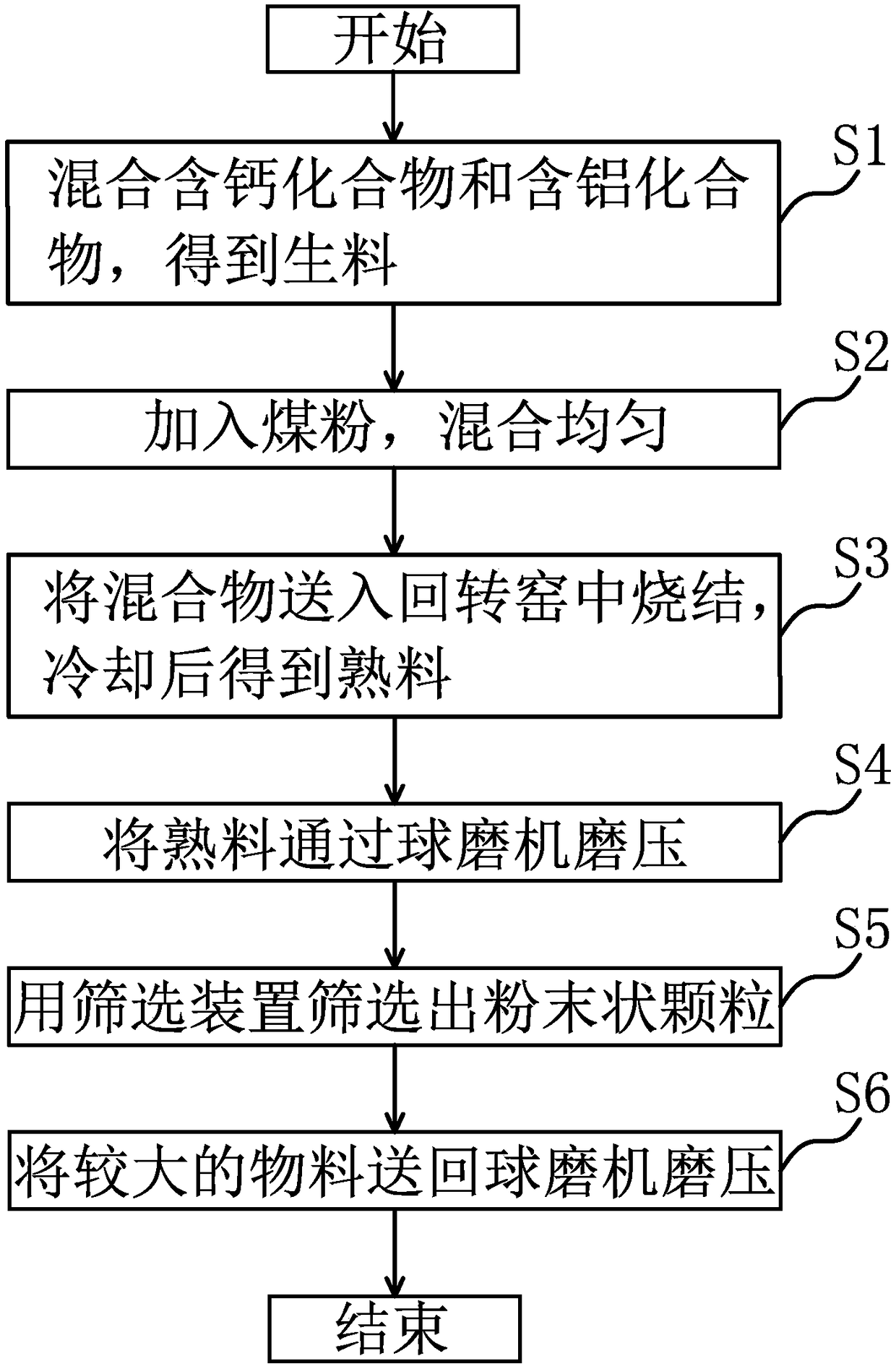

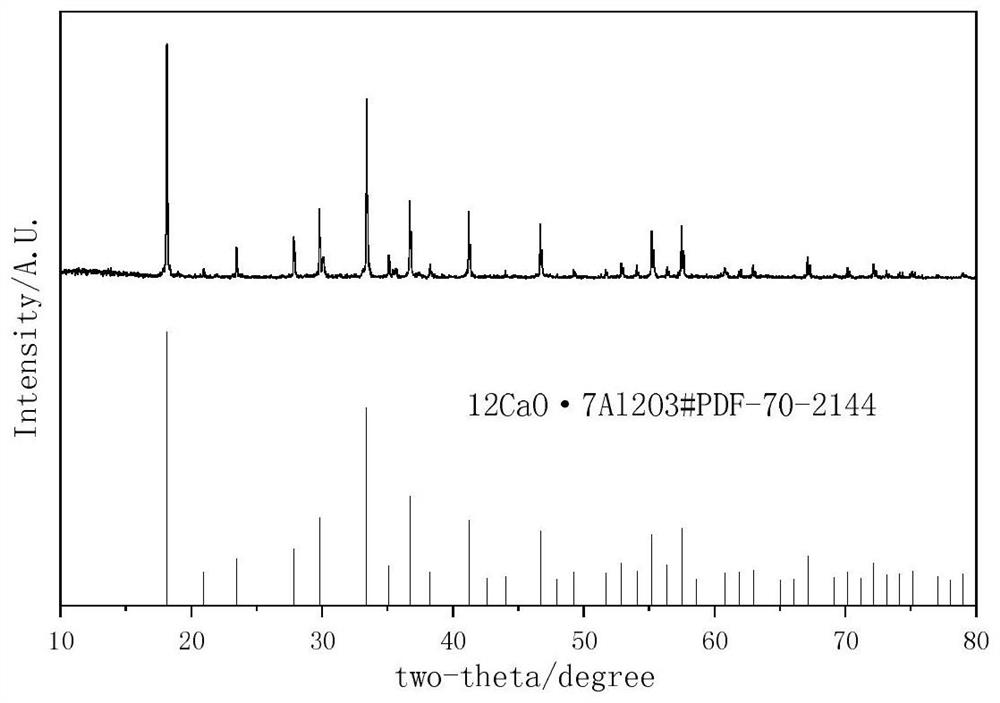

Method for preparing high-purity calcium aluminate by using rotary kiln

The invention discloses a method for preparing high-purity calcium aluminate by using a rotary kiln. The method comprises the following steps: uniformly mixing a calcium-containing compound and an aluminum-containing compound according to a molar ratio of elemental Ca to elemental Al of (1: 1.5) to (1: 4) to obtain a raw material; adding pulverized coal into the raw material, and uniformly mixing;sending a mixture into the rotary kiln, sintering at 1350-1500 DEG C for 0.5-1 hour, and cooling to obtain a clinker; milling and pressing the clinker for 0.5-1.5 hours by using a ball mill; and screening by using a screening device to obtain powdery granules, namely the high-purity calcium aluminate. By the method, the steps are simple, operation is easy, the production steps are simplified, theproduction time is shortened, the production efficiency is improved, and industrial production can be achieved.

Owner:浙江海翔净水科技股份有限公司 +1

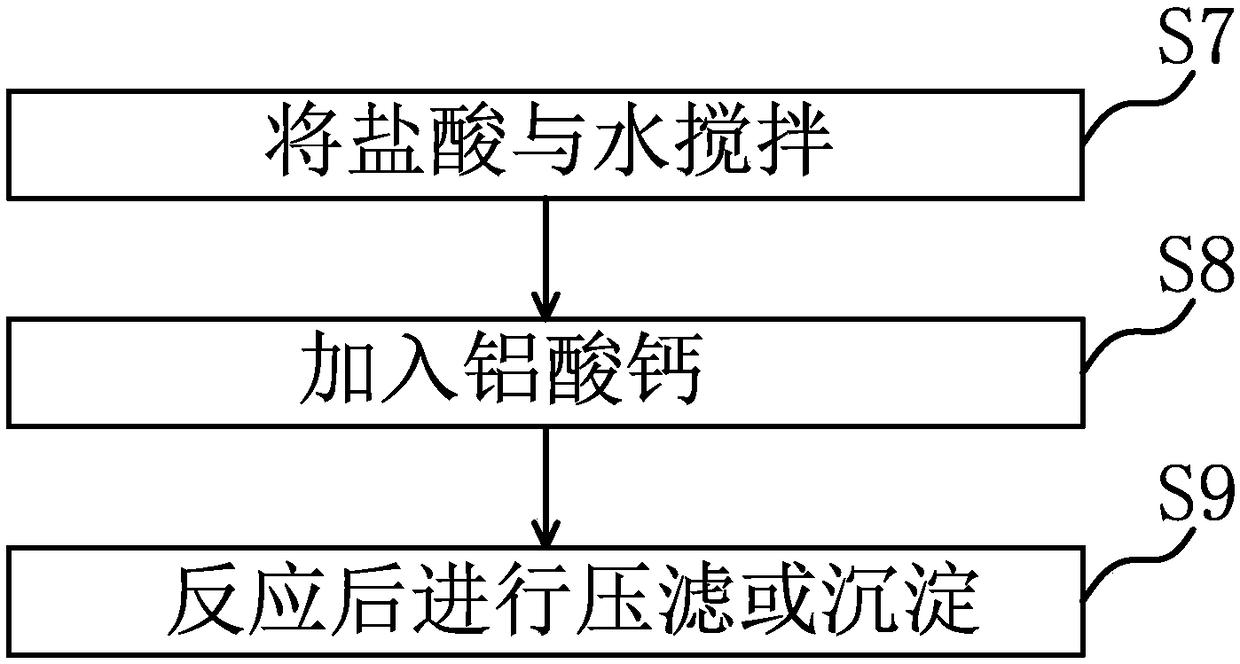

Recycling method for mold release waste liquor of aluminum profile factory

InactiveCN105585179ALow costSimple processCalcium aluminatesWater contaminantsLiquid wasteSodium aluminate

The invention relates to an alkaline waste liquor recycling method capable of being used for recycling mold release waste liquor in the aluminum profile production process and belongs to the technical field of environmental protection. The method comprises the steps that after the mold release waste liquor is filtered in a pressed mode, refined lime slurry is used for reacting with sodium aluminate in the mold release waste liquor, then aluminum in the mold release waste liquor is removed by means of solid-liquid separation, obtained alkali liquor is added into solid caustic soda to improve concentration, then the alkali liquor can return to be used in the mold release process, and generated calcium aluminate precipitate can serve as high-quality coagulant to be used for treating acid waste water. The method has the advantages of being low in cost and achieving total recovery and zero emission, working procedures and adopted equipment are simple, and the method is an ideal recycling method for the mold release waste liquor of the aluminum profile factory.

Owner:SOUTH CHINA UNIV OF TECH

A method of preparing an adsorbent for CO2 capture at high temperature

A method of producing a CO2 adsorbent and CO2 adsorbents. The method includes the steps of: (a) producing a mixture of at least one calcium salt and at least one metal support cation in at least one solvent; (b) drying the mixture to produce a solid containing a calcium metal salt; and (c) calcining the dried solid to produce a sorbent of calcium oxide dispersed in a porous metal support.

Owner:THE UNIV OF QUEENSLAND

Electroconductive 12CaO—7Al2O3 and compound of same type, and method for preparation thereof

In a solid solution system of Al2O3 and CAO or SrO, it has been difficult to obtain a material having a high electrical conductivity (>10−4 S·cm−) at room temperature.A compound is provided in which electrons at a high concentration are introduced into a 12CaO.7Al2O3 compound, a 12SrO.7Al2O3 compound, or a mixed crystal compound containing 12CaO.7Al2O3 and 12SrO.7Al2O3. The compound formed by substituting all the free oxygen ions with electrons is regarded as an electride compound in which [Ca24Al28O64]4+(4e−) or [Sr24Al28O64]4+(4e−) serves as a cation and electrons serve as anions. When a single crystal or a hydrostatic pressure press molded material of a fine powder thereof is held at approximately 700° C. in an alkaline metal vapor or an alkaline earth metal vapor, melt of a hydrostatic pressure press molded material of a powder is held at approximately 1,600° C. in a carbon crucible, followed by slow cooling for solidification, or a thin film of the compound held at approximately 600° C. is implanted with rare gas ions, a great number of the free oxygen ions can be substituted with electrons.

Owner:JAPAN SCI & TECH CORP

Method for preparing electroconductive mayenite type compound

ActiveUS20080089826A1Improve conductivityHigh yieldCalcium aluminatesPolycrystalline material growthCrystalline materialsPartial pressure

Provided is a method for preparing an electroconductive mayenite type compound with good properties readily and stably at low cost. A production method of an electroconductive mayenite type compound comprising a step of subjecting a precursor to heat treatment, is a method for preparing an electroconductive mayenite type compound, comprising a step of subjecting a precursor to heat treatment; wherein the precursor is a vitreous or crystalline material, which contains Ca and Al, in which a molar ratio of (CaO:Al2O3) is from (12.6:6.4) to (11.7:7.3) as calculated as oxides, and in which a total amount of CaO and Al2O3 is at least 50 mol %, and wherein the heat treatment is heat treatment comprising holding the precursor at a heat treatment temperature T of from 600 to 1415° C. and in an inert gas or vacuum atmosphere with an oxygen partial pressure PO2 in a range of PO2≦105×exp[{−7.9×l04 / (T+273)}+14.4] in the unit of Pa.

Owner:ASAHI GLASS CO LTD +1

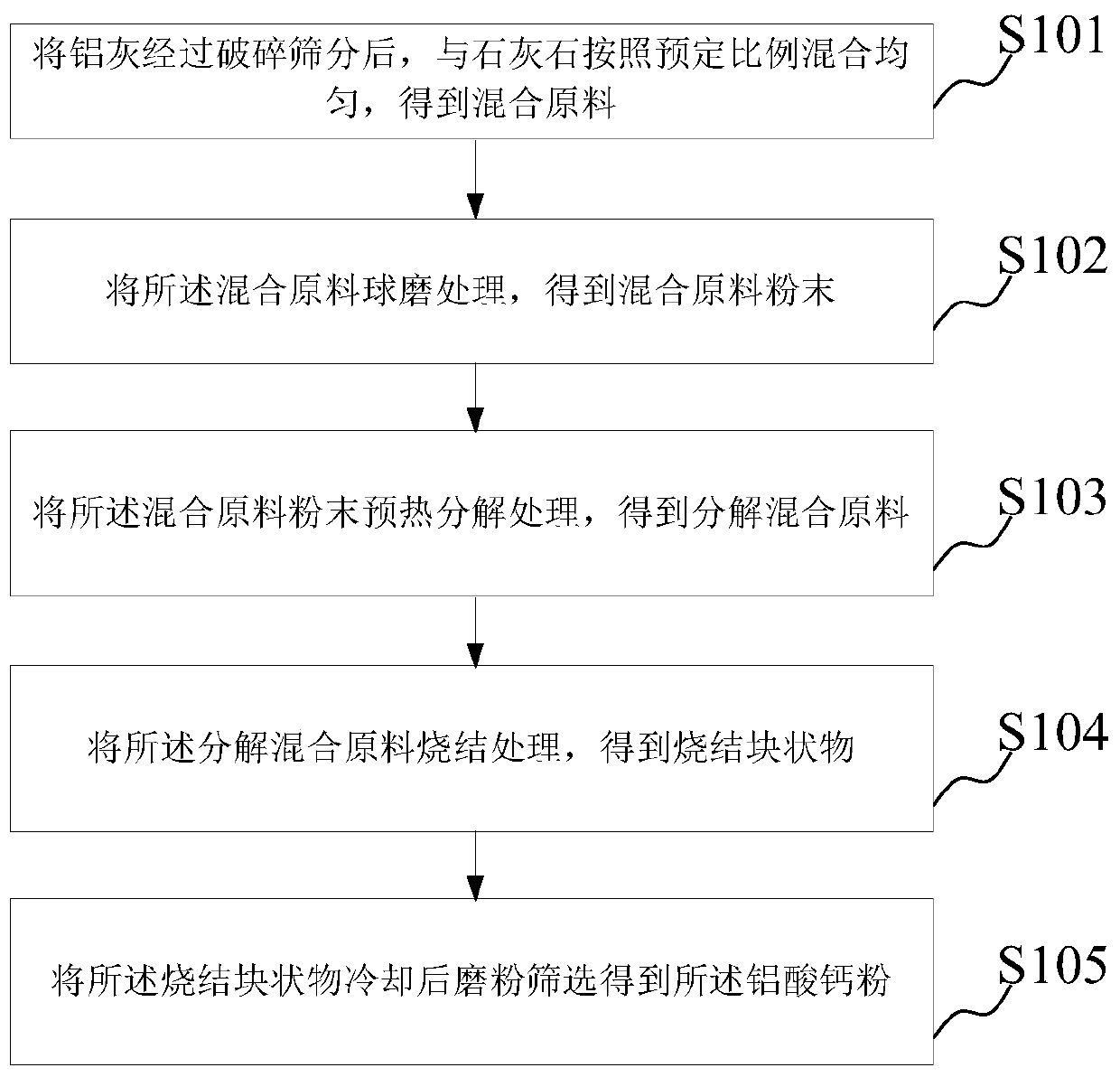

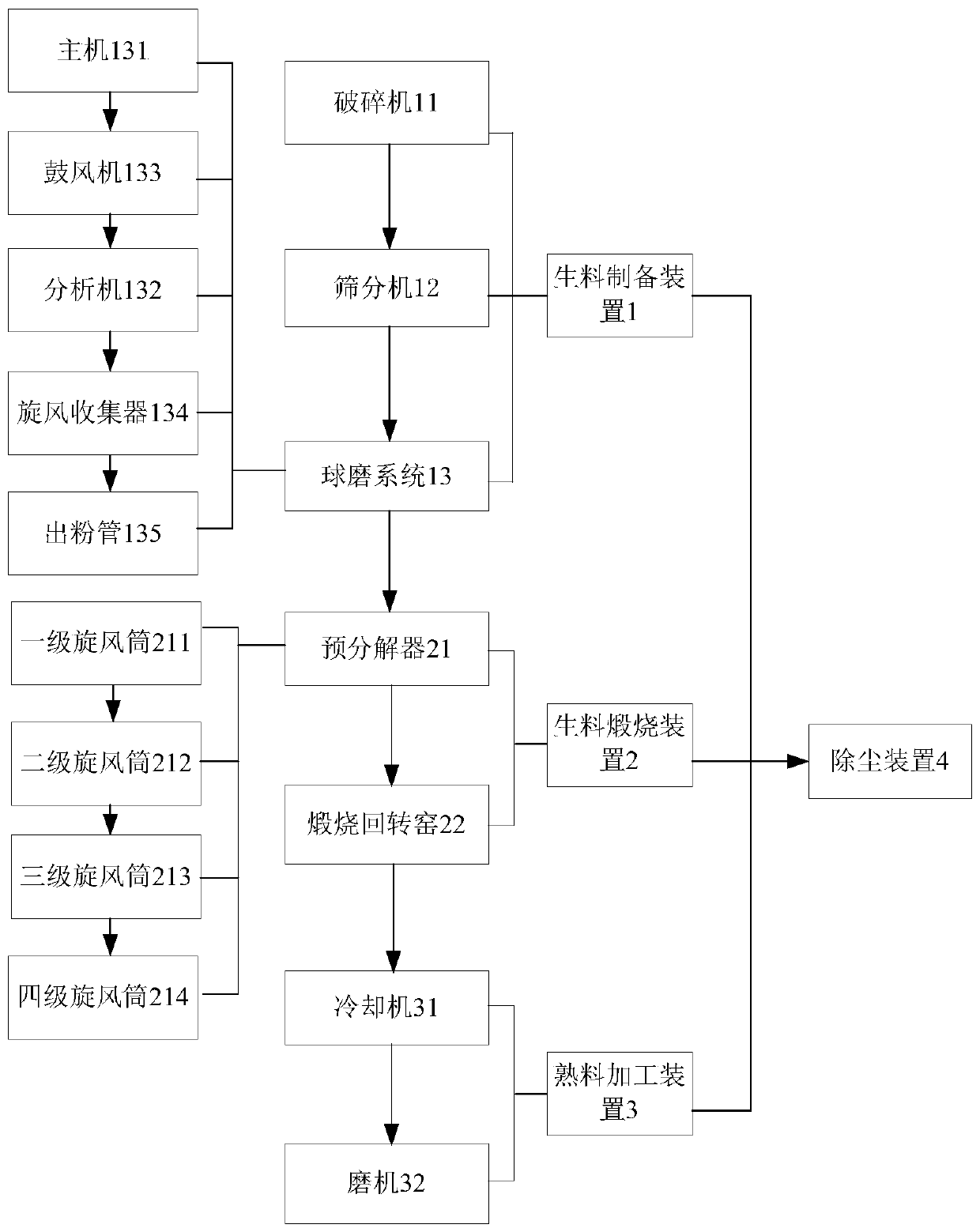

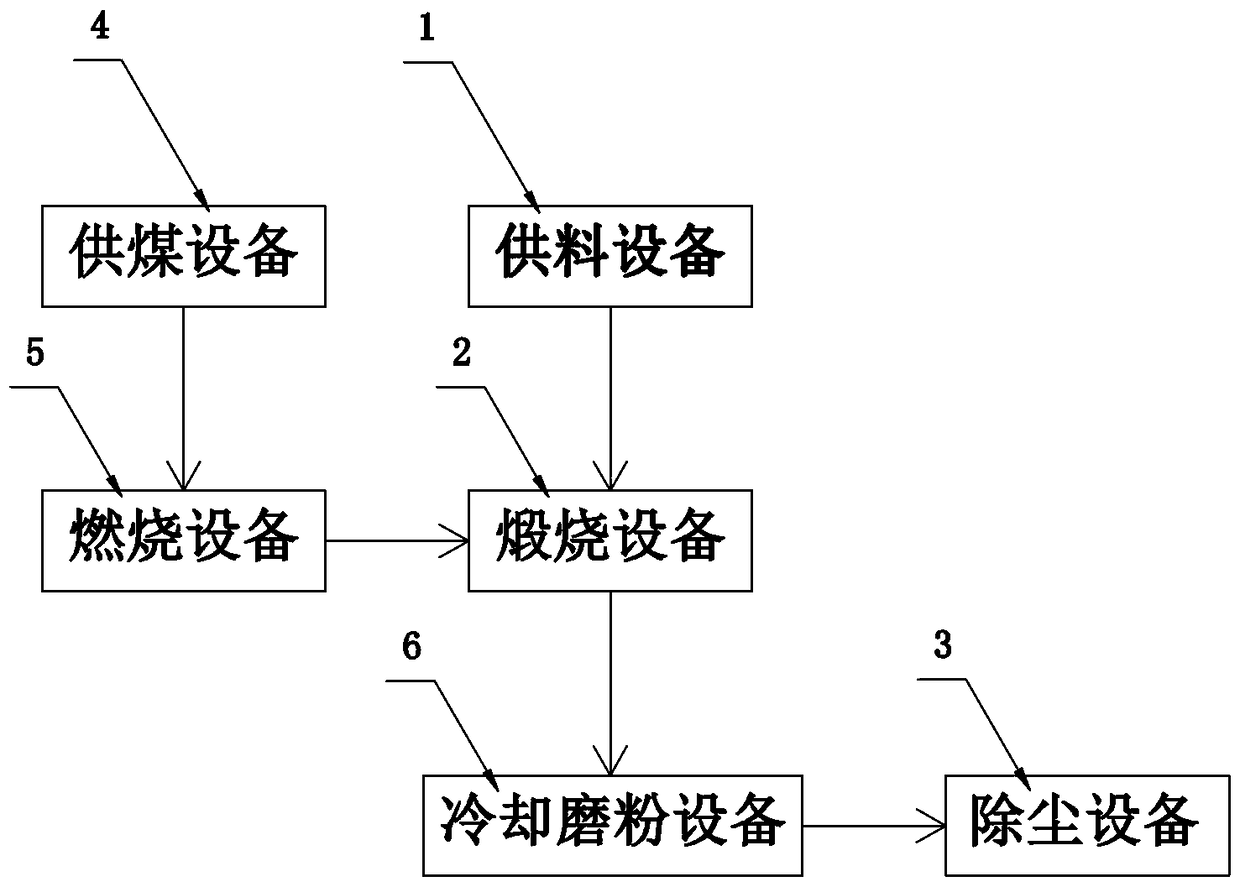

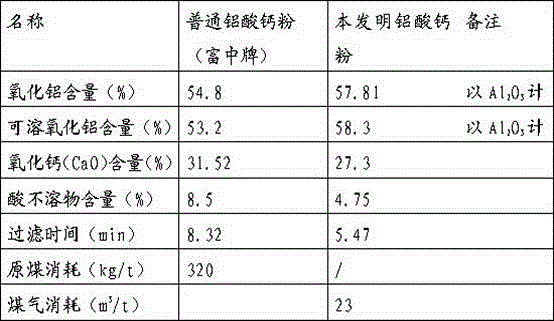

Technology and production system for producing aluminum acid calcium powder by using aluminum ash

InactiveCN110451542ASignificant economySignificant environmental benefitsCalcium aluminatesHazardous substanceDecomposition

The embodiment of the invention provides a technology and production system for producing aluminum acid calcium powder by using aluminum ash. The technology comprises the steps that after being brokenand screened, the aluminum ash is evenly mixed with limestone in a predetermined proportion, and a mixed raw material is obtained; the mixed raw material is subjected to ball milling to obtain mixedraw material powder; the mixed raw material powder is subjected to preheating decomposition to obtain a decomposed mixed raw material; the decomposed mixed raw material is sintered to obtain sinteredblocks; the sintered blocks are cooled, ground and screened in sequence to obtain the aluminum acid calcium powder. The production system for producing the aluminum acid calcium powder by using the aluminum ash comprises a raw material preparation device, a raw material calcination device and a clinker processing device. Fluorides, nitrides and other harmful substances in the aluminum ash are bound with calcium ions by using the processing technology and the production system to be prepared into harmless substances, the aluminum ash can be processed into the harmless substances to protect theenvironment, moreover, the aluminum acid calcium powder produced by using the method is a main raw material for preparing an efficient water treatment agent, and the economic and environmental benefits are significant.

Owner:宁夏正丰环保建材有限公司

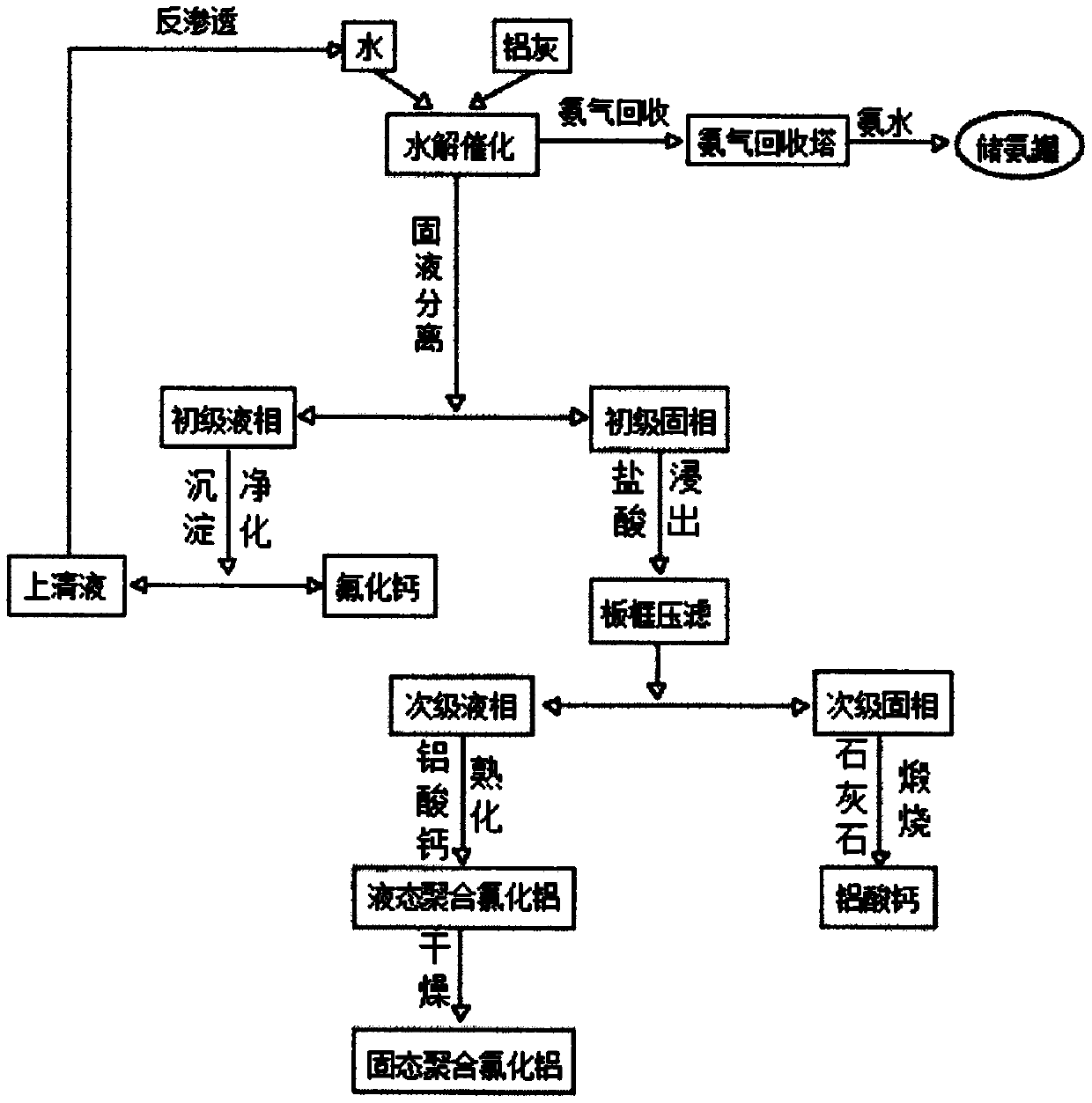

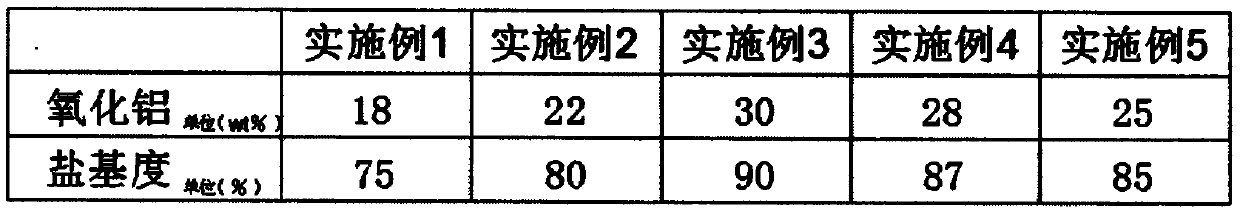

Process method for preparing high-purity calcium aluminate and polyaluminum chloride

InactiveCN110467209ALow costImprove product qualityCalcium aluminatesAluminium chloridesFiltrationHydrolysis

The invention discloses a process method for preparing high-purity calcium aluminate and polyaluminum chloride. The method comprises the following steps: allowing secondary aluminum ash to undergo a hydrolysis catalytic reaction, carrying out solid-liquid separation through a bag type vacuum filter press so as to obtain a primary liquid phase and a primary solid phase, allowing the primary liquidphase to be precipitated through saturated lime water so as to generate calcium fluoride, wherein pure water can be used for the hydrolysis catalytic reaction of the aluminum ash, then allowing the primary solid phase to undergo acidolysis through industrial waste hydrochloric acid, carrying out filtering through a filter press so as to obtain a secondary liquid phase and a secondary solid phase,allowing the secondary liquid phase to undergo a polymerization reaction so as to generate the polyaluminum chloride, carrying out pressure filtration and spray drying with a spray tower so as to prepare solid powdery polyaluminum chloride, completely grinding the secondary solid phase and limestone through a ball mill, sending ground secondary solid phase and ground limestone into a rotary kiln,and carrying out high-temperature calcination so as to obtain the calcium aluminate. The method provided by the invention has the characteristics of low cost, easily-available raw materials, simple production process, high product purity, no secondary pollutants, significant social benefits and economic benefits, etc.

Owner:北京鑫磊华易达技术有限公司

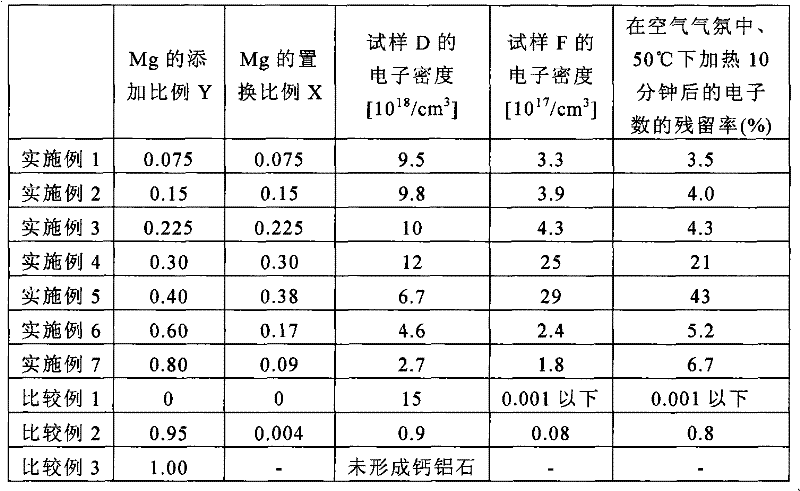

Mayenite-type compound and process for production of same

InactiveCN102131735AChemically stableImprove productivityCalcium aluminatesGas-filled discharge tubesCrystal structureOxygen

The present invention relates to a mayenite-type compound containing Ca, Al and oxygen, wherein part of the Ca atoms are replaced by at least one kind of atoms (M) selected from the group consisting of Be, Mg and Sr. The M / (Ca+M) atomic ratio is 0.01 to 0.50, and at least part of the free oxide ions contained in the mayenite-type crystal structure are replaced with anions of an element having an electron affinity smaller than that of oxygen.

Owner:ASAHI GLASS CO LTD

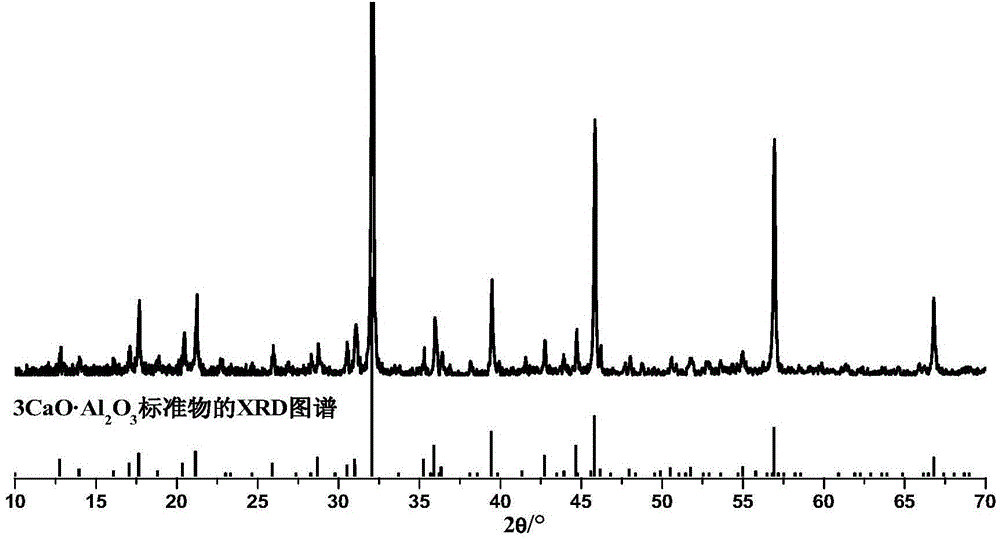

Method for preparing tricalcium aluminate by aid of spark plasma sintering techniques

ActiveCN105600813AImprove homogeneityImprove compactnessCalcium aluminatesChemical industryAxial pressureMicrometer

The invention relates to a method for preparing tricalcium aluminate by the aid of spark plasma sintering techniques. The method includes analyzing raw materials which are pure calcium carbonate CaCO3 and pure gamma-phase aluminum oxide gamma-Al2O3; carrying out ball-milling on the pure calcium carbonate and the pure gamma-phase aluminum oxide and then controlling the heating rates and the cooling rate of a spark plasma sintering furnace under the conditions of vacuum degrees of (30-50) Pa, pulse ratios (ON / OFF) of (6 / 1-48 / 8) and axial pressures of (1-3) kN; fetching samples out of the spark plasma sintering furnace when the temperatures of the samples are reduced and reach (60-90) DEG C and grinding the samples to obtain particles with the sizes smaller than 20 micrometers so as to obtain the tricalcium aluminate. The method is simple and convenient, and the synthesis efficiency is improved by (10-20) times as compared with the traditional method. The method has the advantages of speediness, high efficiency and energy conservation.

Owner:WUHAN UNIV

Method for producing conductive mayenite compound powder

ActiveUS20150239747A1Large specific surface areaAluminium silicatesGlass/slag layered productsReduction treatmentHeat treated

If a conductive mayenite compound having a large specific surface area is obtained, the usefulness thereof in respective applications is remarkably increased. A conductive mayenite compound powder having a conduction electron density of 1015 cm−3 or more and a specific surface area of 5 m2g−1 or more is produced by: (1) a step for forming a precursor powder by subjecting a mixture of a starting material powder and water to a hydrothermal treatment; (2) a step for forming a mayenite compound powder by heating and dehydrating the precursor powder; (3) a step for forming an activated mayenite compound powder by heating the compound powder in an inert gas atmosphere or in a vacuum; and (4) a step for injecting electrons into the mayenite compound through a reduction treatment by mixing the activated mayenite compound powder with a reducing agent.

Owner:TOKYO INST OF TECH +1

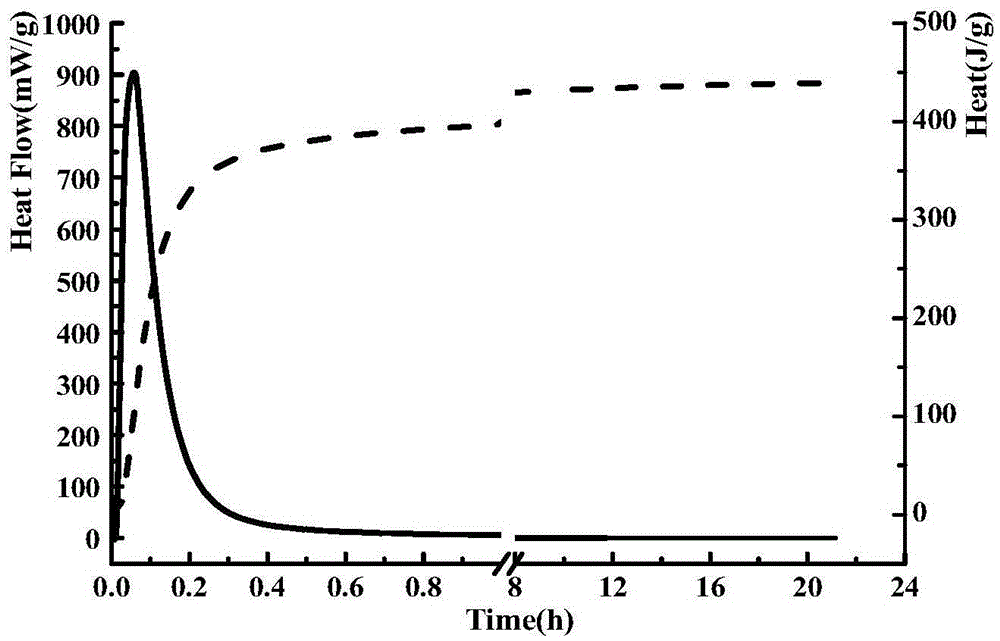

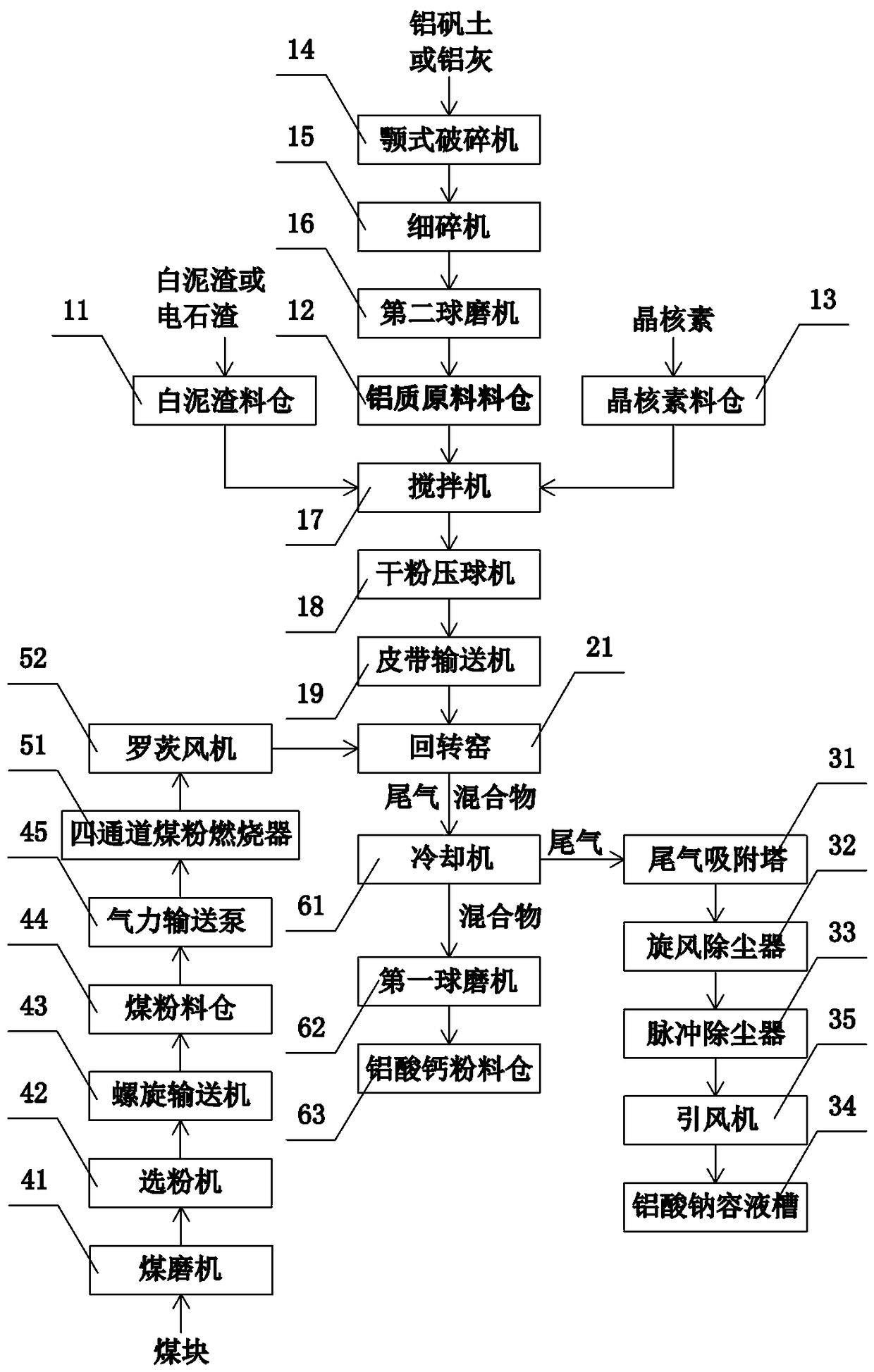

Production line and technology for preparing calcium aluminate powder through white mud

PendingCN108585009AEasy to recycleFill the gap in the marketCalcium aluminatesLand resourcesEcological environment

The invention discloses a production line and technology for preparing calcium aluminate powder through white mud. The technology includes the steps that 0.4-0.5 part by weight of white mud slag / carbide slag, 0.9-1.1 parts by weight of an aluminous raw material and 0.04-0.05 part by weight of crystal nuclein are sequentially conveyed in a stirring machine and mixed and stirred to be even; the mixture is conveyed into a rotary kiln and calcined for 20 min to 40 min till the temperature of the mixture is 900 DEG C to 1,100 DEG C; after calcining is ended, the temperature of the mixture is cooledto 300 DEG C to 400 DEG C through a cooling machine; after cooling is ended, the mixture is powdered through a first ball mill, and calcium aluminate powder is prepared. By means of the production line and technology, white mud can be eliminated, the local graceful natural-ecology human settlement environment is powerfully protected, the recycling speed of renewable resources is increased, the effects of turning waste into wealth and turning harm into good are achieved, pollution is governed, the environment is improved, occupied land resources are released, the beautiful environment can be created for persons, and the harmony and unity ecological environment between man and nature is promoted.

Owner:福建鼎盛元环保科技有限公司

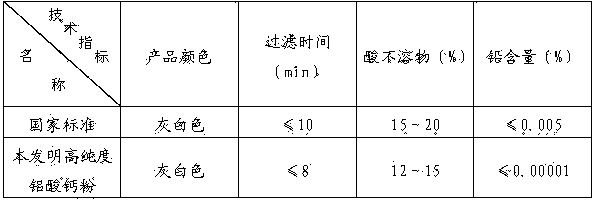

High-purity calcium aluminate powder for production of purifying agents

InactiveCN104261446AApplicable treatmentGood quality indexCalcium aluminatesAluminateMixed materials

The invention relates to a high-purity calcium aluminate powder for the production of purifying agents. The high-purity calcium aluminate powder comprises the following components in percentage by weight: 60-72% of aluminum hydroxide, 25-40% of light calcium carbonate, and the balance of water. The high-purity calcium aluminate powder produced by using the formula above is prepared through the following concrete steps: (1) preparing aluminum hydroxide and light calcium carbonate in corresponding proportion, grinding, uniformly mixing, and putting the obtained mixture into a stirring cylinder; (2) injecting water into the stirring cylinder, and stirring while injecting water until the mixed material is pasty; (3) returning the uniformly mixed pasty material to a rotary kiln, and calcining the pasty material for 30-50 minutes by using natural gas at a calcining temperature of 1200 DEG C, so that massive high-purity calcium aluminate is obtained; (4) grinding the massive high-purity calcium aluminate, and enabling the obtained product to pass through a 120-mesh sieve, so that powdered high-purity calcium aluminate is obtained; and (5) packaging and storing the powdered high-purity calcium aluminate. The heavy metal content of the high-purity calcium aluminate powder disclosed by the invention is far lower than the national standard, therefore, the high-purity calcium aluminate powder is extremely applicable to the treatment of drinking water.

Owner:贵州遵辉环保科技有限公司

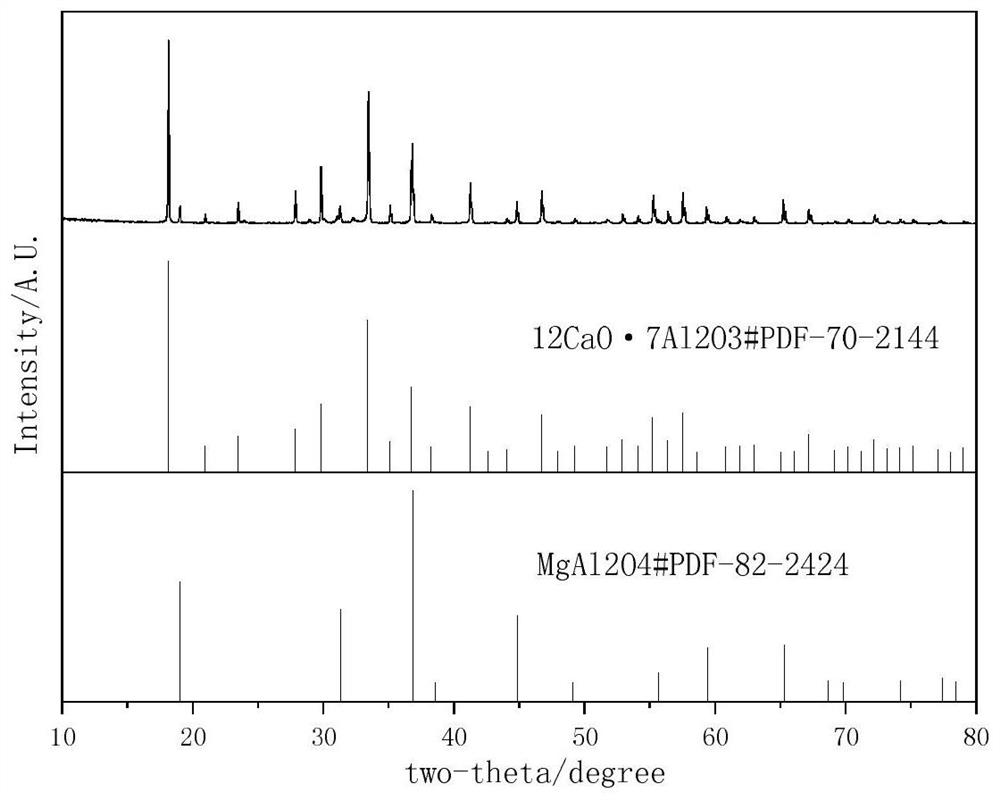

Method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash

ActiveCN112607758AImprove decomposition rateIncrease spawn rateCalcium aluminatesAluminium silicatesCalcium aluminatesFly ash

The invention discloses a method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash, which comprises the following steps: carrying out wet ball milling on high-magnesium aluminum ash, fly ash and quick lime, and sequentially carrying out washing, solid-liquid separation and roasting treatment on the ball-milled material to obtain a calcium aluminate product. According to the method, a calcium aluminate series product capable of being used for iron and steel smelting desulfurization is obtained by taking the aluminum ash generated in the aluminum smelting processing process as a raw material, so that the comprehensive utilization of hazardous wastes is realized, a relatively high economic value can be obtained, and the method is simple to operate and environment-friendly, and meets the industrial production requirements.

Owner:CENT SOUTH UNIV

12CaO 7a12O3 compound and method for preparation thereof

Owner:JAPAN SCI & TECH CORP

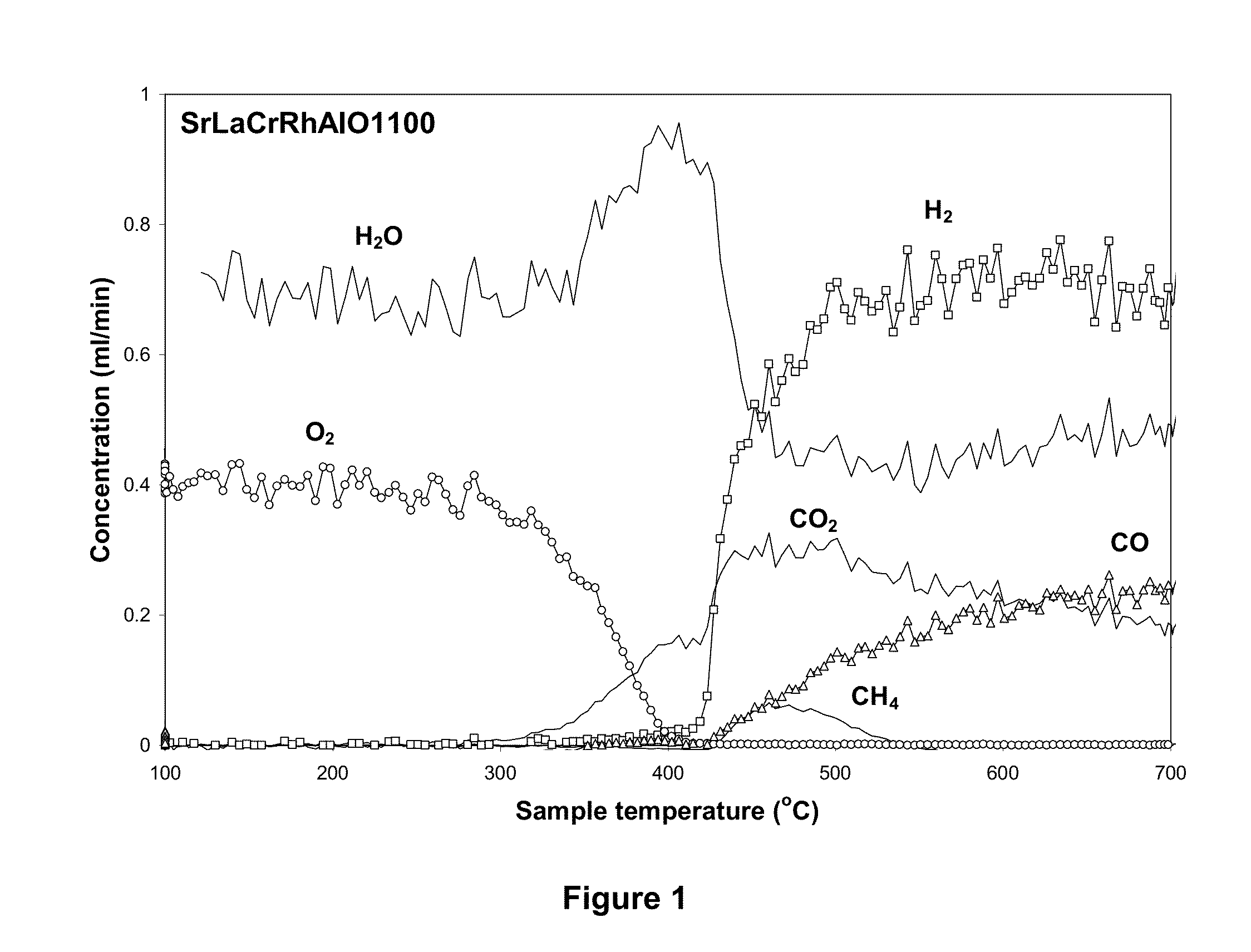

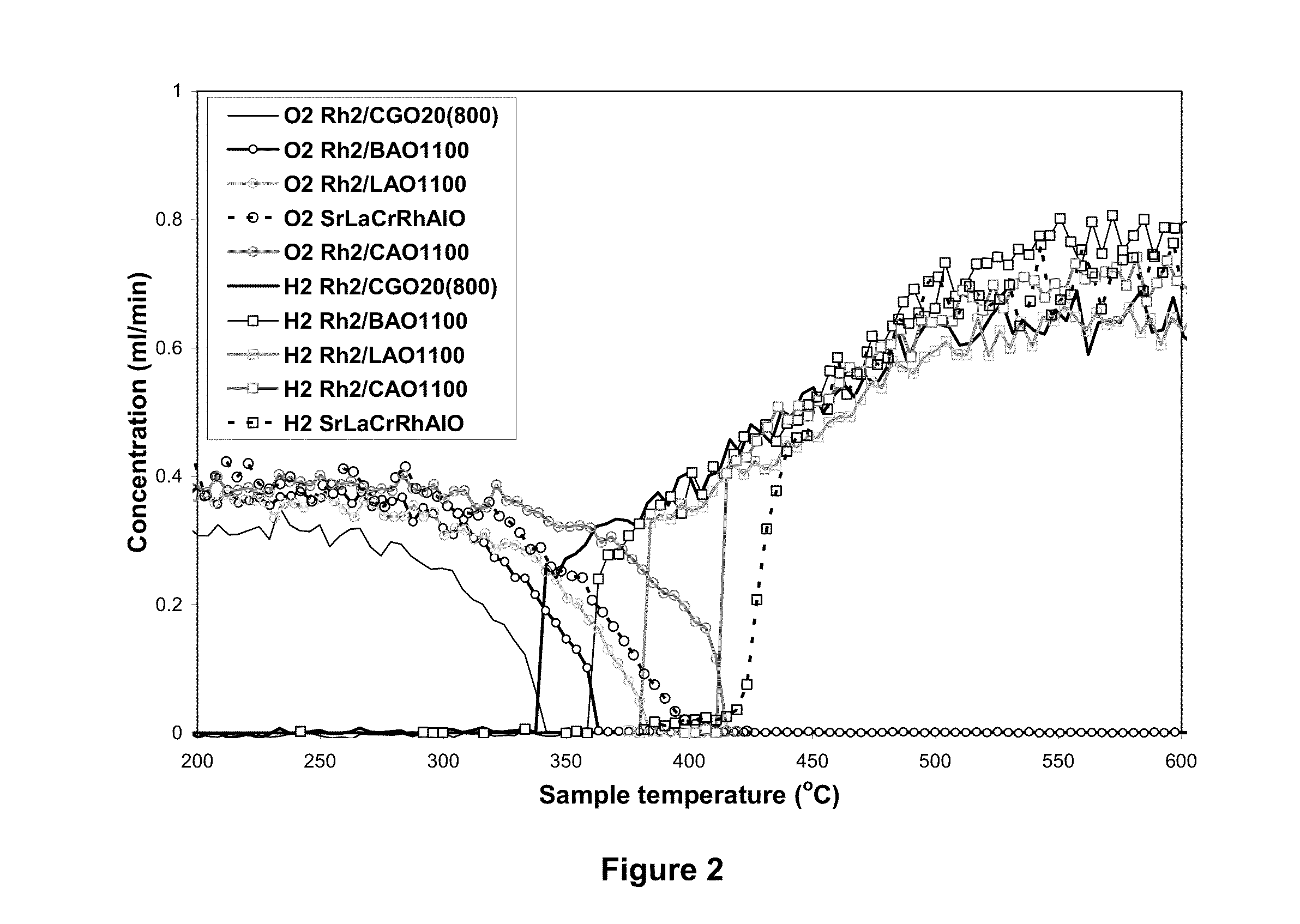

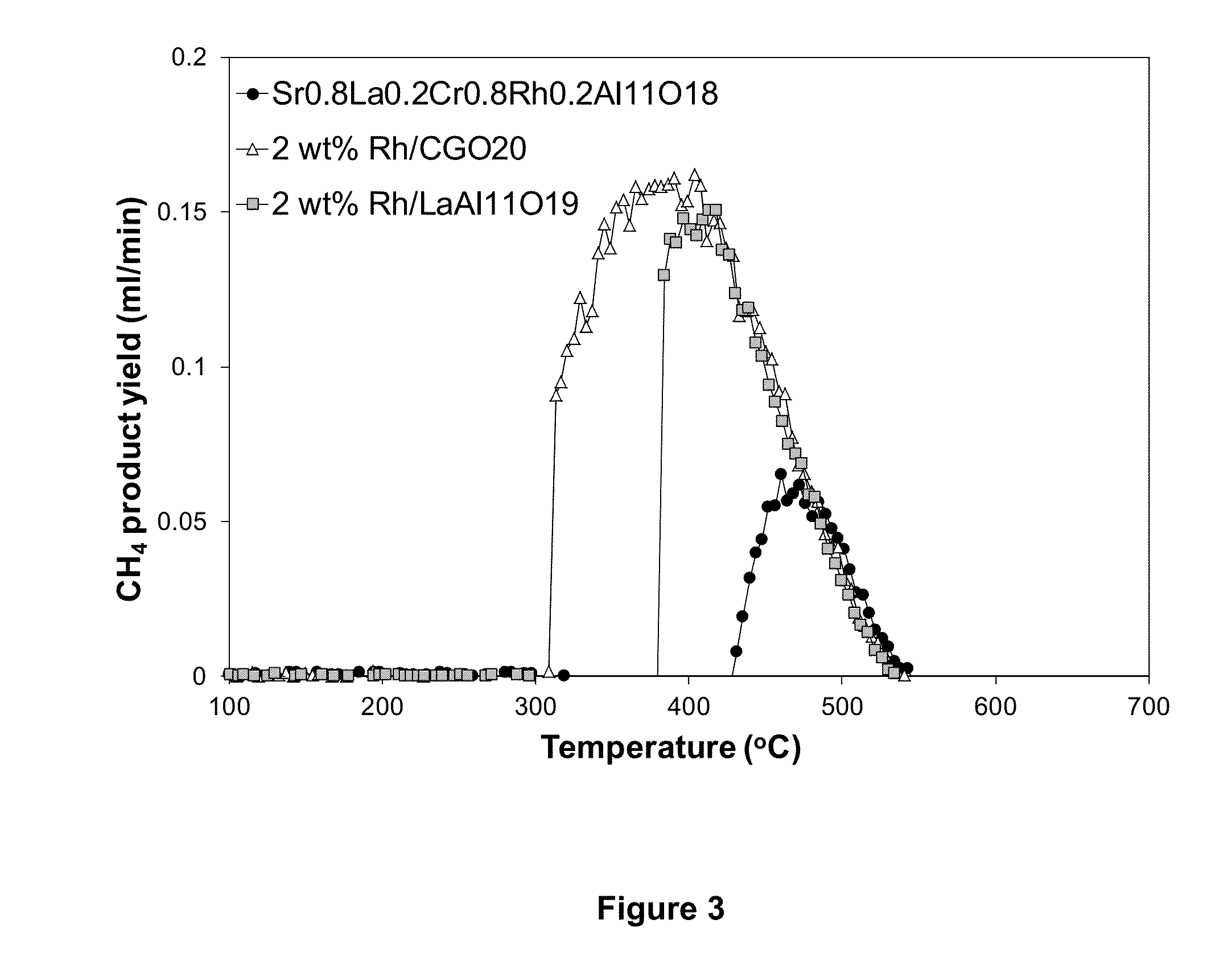

Novel formulation of hexa-aluminates for reforming fuels

InactiveUS20130085062A1Suppresses/resists poisoningOpen pore structureCalcium aluminatesBarium aluminatesCeriumCobalt

The invention is directed to a catalyst and a method for making a reforming catalyst for the production of hydrogen from organic compounds that overcomes the problems of catalyst poisoning and deactivation by coking and high temperature sintering, yet provides excellent durability and a long working life in process use. An embodiment is the formation of a unique four-metal ion hexa-aluminate of the formula M1aM2bM3cM4dAl11O19-α. M1 and M2 are selected from the group consisting of beryllium, magnesium, calcium, strontium, barium, lanthanum, cerium, praseodymium, neodymium, promethium, samarium, and gadolinium. M3 and M4 are selected from the group consisting of chromium, manganese, iron, cobalt, nickel, copper, molybdenum, ruthenium, rhodium, palladium, tungsten, rhenium, osmium, iridium, platinum, wherein 0.010≦a+b+c+d≦2.0. Also, 1≦α≦1. Further, M1≠M2 and M3≠M4.

Owner:UCHICAGO ARGONNE LLC

Calcium aluminate powder with high dissolution rate

InactiveCN105948088ASolve insufficient integrationResolution timeCalcium aluminatesAluminateWarm water

The invention relates to calcium aluminate powder with high dissolution rate. The calcium aluminate powder comprises components in percentage by weight as follows: 55%-60% of bauxite, 5%-10% of boron oxide and 30%-40% of limestone, and the sum of the components is 100%. The process for preparing the calcium aluminate powder from the components comprises the following steps: the components are weighed, ground into powder and mixed uniformly; the uniformly mixed material is stirred and mixed with warm water at 30-35 DEG C in the weight ratio of the mixed material to the warm water being 1:1.5, a product is placed into a furnace for calcination with gas as fuel at the temperature of 1,050-1,100 DEG C, and granular calcium aluminate is obtained after retention for 30 min; granular calcium aluminate is ground by a mill, and the calcium aluminate powder with high dissolution rate is obtained. The conventional raw material formula is changed, the calcination temperature in a production process is reduced, boron oxide is added as a mineralizer, and meanwhile, gas replaces pulverized coal to be taken as the fuel, so that the problems that the bauxite and the limestone of the raw materials are not mixed sufficiently, reaction time is longer, more energy is consumed and the like in the traditional production process of the calcium aluminate powder are solved effectively.

Owner:贵州遵辉环保科技有限公司

Process for preparing small size layered double hydroxide particles

InactiveCN107531503AWithout compromising purityCalcium aluminatesMaterial nanotechnologyPtru catalystSorbent

A process for preparing particles of a layered double hydroxide of the general formula [Mp z+ M'q y+ (OH)2]a+(Xn-)a / n.bH2O (I) wherein Mz+ and M'y+ are metal cations or mixtures of metal cations, z =1 or 2; y = 3 or 4; p + q = 1; b = 0 to 10, Xn- is an anion, n is 1 to 5 and a is determined by p, q, y and z such that a = zp+yq-2 comprises (a) mixing, in aqueous solution, Mz+ cations, M'y+ cationsand Xn- anions, with a base; and (b) allowing the layered double hydroxide of formula (I) to precipitate from the solution mixed in step (a). Preferably, M is Li, Mg, Zn, Fe, Ni, Co, Cu, Ca, or a mixture of two or more. Preferably, y is 3 and M' is Al, Ga, In, Fe or a mixture of two or more thereof. Also provided are particles obtainable by the process, especially wherein M is Ca, M' is Al and Xn- is NO3-. Particles of a layered double hydroxide wherein the particles have a particle size of not greater than 2000 nm, preferably not greater than 300 nm and especially not greater than 100 nm, are also provided. The layered double hydroxides according to the invention are useful in certain applications, for example, as adsorbents, coatings and catalyst supports.

Owner:SCG CHEM CO LTD

Method for preparing electroconductive mayenite type compound

ActiveUS7465433B2Suppress the reaction to withdraw oxygenImprove productivityCalcium aluminatesConductive materialHigh concentrationAtmospheric air

To provide a method for preparing a mayenite type compound having electroconductivity imparted.A method for preparing an electroconductive mayenite type compound, which comprises melting a raw material containing Al and at least one element selected from the group consisting of Ca and Sr, holding the melt in a low oxygen partial pressure atmosphere having an oxygen partial pressure of not higher than 10 Pa, followed by cooling or annealing in a low oxygen partial pressure atmosphere or in atmospheric air for solidification, thereby to replace oxygen present in cages by electrons in a high concentration.

Owner:JAPAN SCI & TECH CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com