High-efficiency clean resource utilization method for quadratic aluminum dust

A technology for secondary aluminum and resource utilization, which is applied in the preparation of alumina/aluminum hydroxide, alkaline earth metal aluminate/alumina/aluminum hydroxide, magnesium aluminate, etc., to achieve broad technical application prospects and achieve environmentally friendly treatment And the effect of high-value resource utilization and stable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

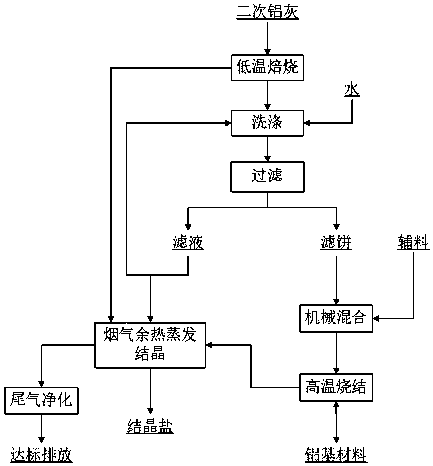

Image

Examples

Embodiment 1

[0032] The present invention proposes a method for efficient and clean resource utilization of secondary aluminum ash, comprising the following steps:

[0033] 1) Low-temperature roasting: roast the secondary aluminum ash in a microwave heating kiln at 500°C for 10 hours to remove nitrogen, carbon and fluorine in the secondary aluminum ash to obtain stabilized aluminum ash.

[0034] 2) Washing and dehydration: Cool the above stabilized aluminum ash, then perform slurry washing according to the liquid-solid ratio of 5:1, wash off impurities such as sodium salt and potassium salt, filter and dehydrate to obtain a dehydrated filter cake, and the moisture content of the filter cake is 25%.

[0035] 3) Mixing and stirring: 40wt%-55wt% dehydrated filter cake and 45wt%-60wt% limestone powder are mechanically mixed to prepare mixed raw meal.

[0036] 4) High-temperature sintering: the above-mentioned mixed raw materials were sintered in a high-temperature furnace at 1400°C for 2 hour...

Embodiment 2

[0040] The present invention proposes a method for efficient and clean resource utilization of secondary aluminum ash, comprising the following steps:

[0041] 1) Low-temperature roasting: roast the secondary aluminum ash in an electric heating kiln at 800°C for 2 hours to remove nitrogen, carbon and fluorine in the secondary aluminum ash to obtain stabilized aluminum ash.

[0042] 2) Washing and dehydration: Cool the above stabilized aluminum ash, then perform slurry washing according to the liquid-solid ratio of 3:1, wash off impurities such as sodium salt and potassium salt, filter and dehydrate to obtain a dehydrated filter cake, and the moisture content of the filter cake is 20%.

[0043] 3) Mixing and stirring: 75wt%-90wt% dehydrated filter cake and 25wt%-10wt% silica powder are mechanically mixed to prepare mixed raw meal.

[0044] 4) High-temperature sintering: Sinter the above-mentioned mixed raw materials in a high-temperature furnace at 1500°C for 3 hours to prepare ...

Embodiment 3

[0048] The present invention proposes a method for efficient and clean resource utilization of secondary aluminum ash, comprising the following steps:

[0049] 1) Low-temperature roasting: roast the secondary aluminum ash in a natural gas heating kiln at 650°C for 4 hours to remove nitrogen, carbon and fluorine in the secondary aluminum ash to obtain stabilized aluminum ash.

[0050] 2) Washing and dehydration: Cool the above-mentioned stabilized aluminum ash, then add water according to the liquid-solid ratio of 6:1 for slurry washing, wash off impurities such as sodium salt and potassium salt, filter and dehydrate to obtain a dehydrated filter cake, the moisture content of the filter cake is 30%.

[0051] 3) Mixing and stirring: 68wt%-74wt% dehydrated filter cake and 26wt%-32wt% magnesite powder are mechanically mixed to prepare mixed raw meal.

[0052] 4) High-temperature sintering: The above-mentioned mixed raw materials were sintered in a high-temperature furnace at 1650...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com