Patents

Literature

75results about How to "Cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

Powerful cleaning agent

InactiveCN105273861AEasy to useSafe storageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSide effectAlcohol

The invention relates to a powerful cleaning agent and belongs to the field of fine chemical automotive chemicals. The cleaning agent is prepared from surface active agents, alcohol additives, oiliness additives, auxiliary agents and water. The surface active agents and the oiliness additives play roles of solubilization, dissolving and washing, the alcohol additives jointly act with the two mentioned components for forming stable microemulsion and have certain permeation, moistening and dissolving functions, the three components jointly act so that the cleaning agent can achieve a good cleaning effect, and the auxiliary agents are functional additives. The cleaning agent has no side effect on cast iron, cast aluminum, leather, fabric, rubber, plastic and the like and can effectively clean an engine or the surface of the interior without generating phenomena of corrosion, color fading, bubbling, falling and the like.

Owner:蚌埠市神丰贸易有限公司

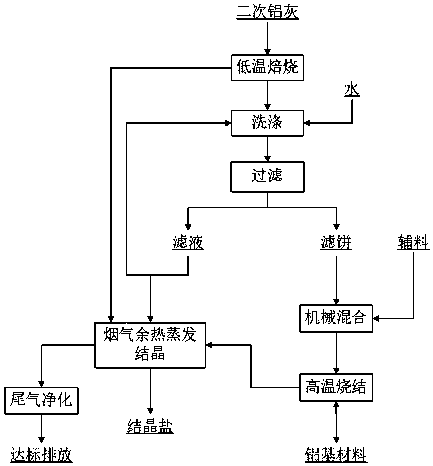

High-efficiency clean resource utilization method for quadratic aluminum dust

ActiveCN109179464AClean and efficient treatmentRealize high-value utilizationHuman health protectionCalcium aluminatesResource utilizationPotassium

The invention discloses a high-efficiency clean resource utilization method for quadratic aluminum dust. The method comprises the following steps: performing low-temperature roasting treatment on quadratic aluminum dust, removing harmful elements such as nitrogen, carbon and fluorine, pulping, washing, desalting and dehydrating the quadratic aluminum dust, removing sodium salt, potassium salt andother impurity components, washing brine and evaporating and crystallizing by utilizing flue gas waste heat. The purified quadratic aluminum dust can serve as a raw material to be directly utilized, and after the quadratic aluminum dust is mechanically mixed with auxiliary materials (calcium-based, silicon-based and magnesium-based), an aluminum based inorganic material is prepared at a high temperature, and the sintering exhaust gas realizes up-to-standard discharge by virtue of dust removal and dry defluorinated purification. According to the technology in the invention, the quadratic aluminum dust can be safely, cleanly and efficiently treated and converted into the high-value aluminum based inorganic material to the greatest degree, and environmental-friendly treatment and high-value resource utilization of the quadratic aluminum dust can be realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Clean wiping cloth and its producing process

The clean wiping cloth and its production process belong to the field of weaving technology. The clean wiping cloth is produced with composite polyester-Jinlun yarn as material and through the steps of compounding twisting, warping, weaving, opening, and gluing to set. In the opening step, the composite polyester-Jinlun yarn is soaked in sodium hydroxide solution of concentration 6-8 g / L at 98-105 or 1 hr. The high efficiency clean wiping cloth made of superfine fiber has fine fuzzy fibers in much greater quantity than that in common fabric, high dirt holding capacity, no dust, high hygroscopicity and high cleaning power.

Owner:沂水恒泰纺园有限公司

Degreasing agent used for workpieces, preparation method and workpiece surface spraying pretreatment method

ActiveCN108384645AGood degreasingImprove washing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPretreatment method

The invention relates to a degreasing agent used for workpieces, a preparation method and a workpiece surface spraying pretreatment method. The degreasing agent includes 3-5% by mass of a component A,3-5% by mass of a component B and the balance of tap water or deionized water, wherein the component A includes deionized water, an inorganic base, a complexing agent and a compounded low-foam solubilizing surfactant, and a mass ratio of the deionized water to the inorganic base to the complexing agent to the compounded low-foam solubilizing surfactant is (65-70):(15-25):(1-2):(8-14); and the component B includes deionized water, a complexing dispersant, a corrosion inhibitor, a low-foam solubilizer, an end-capped / modified isomeric alcohol ether surfactant and a modified polyether, and a massratio of the deionized water to the complexing dispersant to the corrosion inhibitor to the low-foam solubilizer to the end-capped / modified isomeric alcohol ether surfactant to the modified polyetheris (50-70):(1-2):(0-5):(5-10):(8-15):(8-25). The degreasing agent provided by the invention can be used at room temperature during spraying, has an excellent degreasing effect, and does not generatea large amount of foam; and the method for preparing the degreasing agent and the workpiece surface spraying pretreatment method which uses the degreasing agent have simple operation, and are suitablefor mass production.

Owner:佛山科富科技有限公司

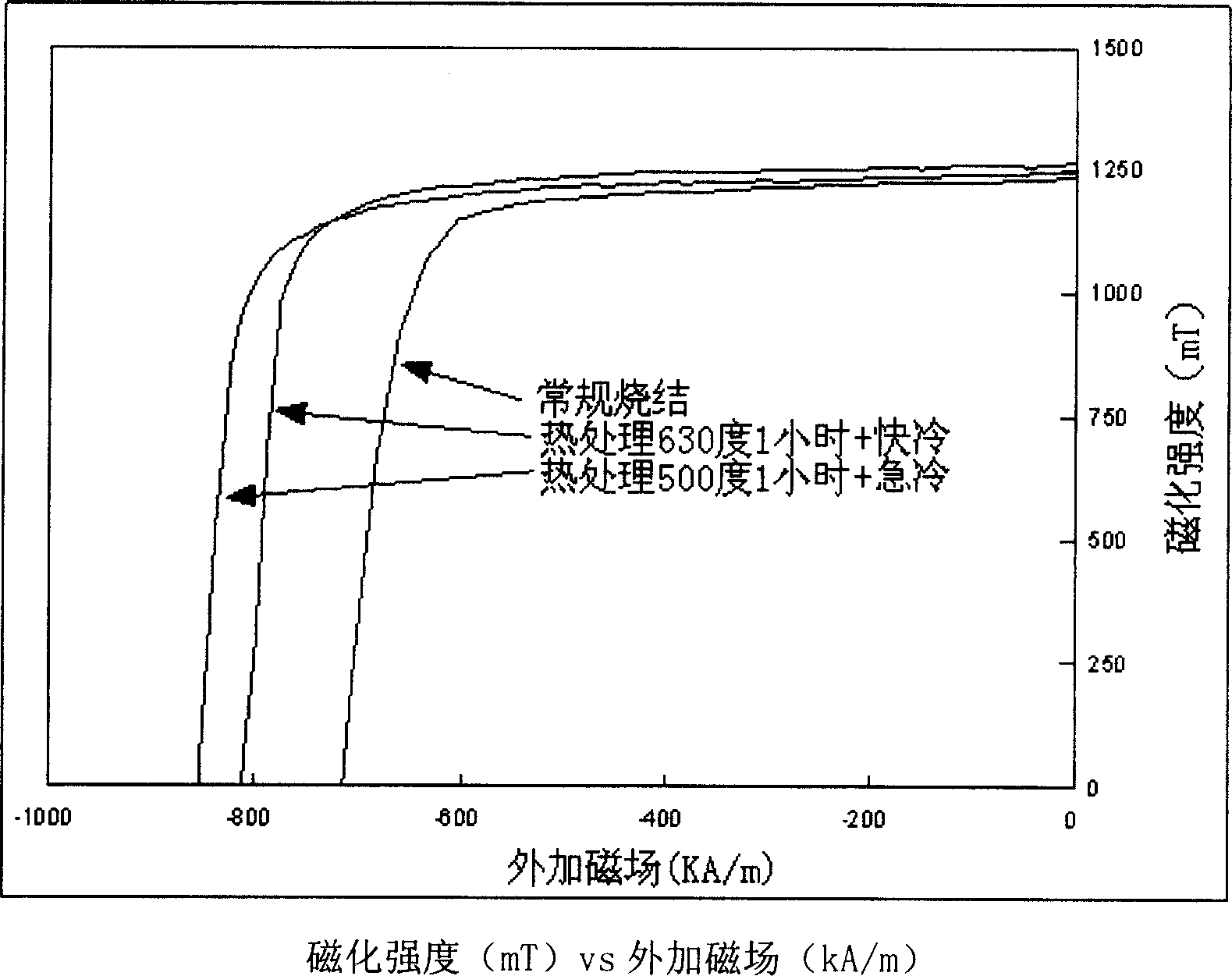

Method for regenerating high-performance permanent magnet by degenerated rare earth permanent magnet material

The invention discloses a permanent magnet regenerating method of degenerated rare earth permanent magnet material, which comprises the following steps: grinding mechanically; removing impurity; dewetting in the vacuum; proceeding hydrogen disposal or hydrogen disproportionating reaction; adding high-magnetocrystalline anisotropic element and auxiliary texture forming element or alloy; moulding through sintering or adhering to produce anisotropic regenerated permanent magnet. The technology is reasonable with little oxide reaction, which can explore new path for degenerated rare earth permanent magnet.

Owner:严高林

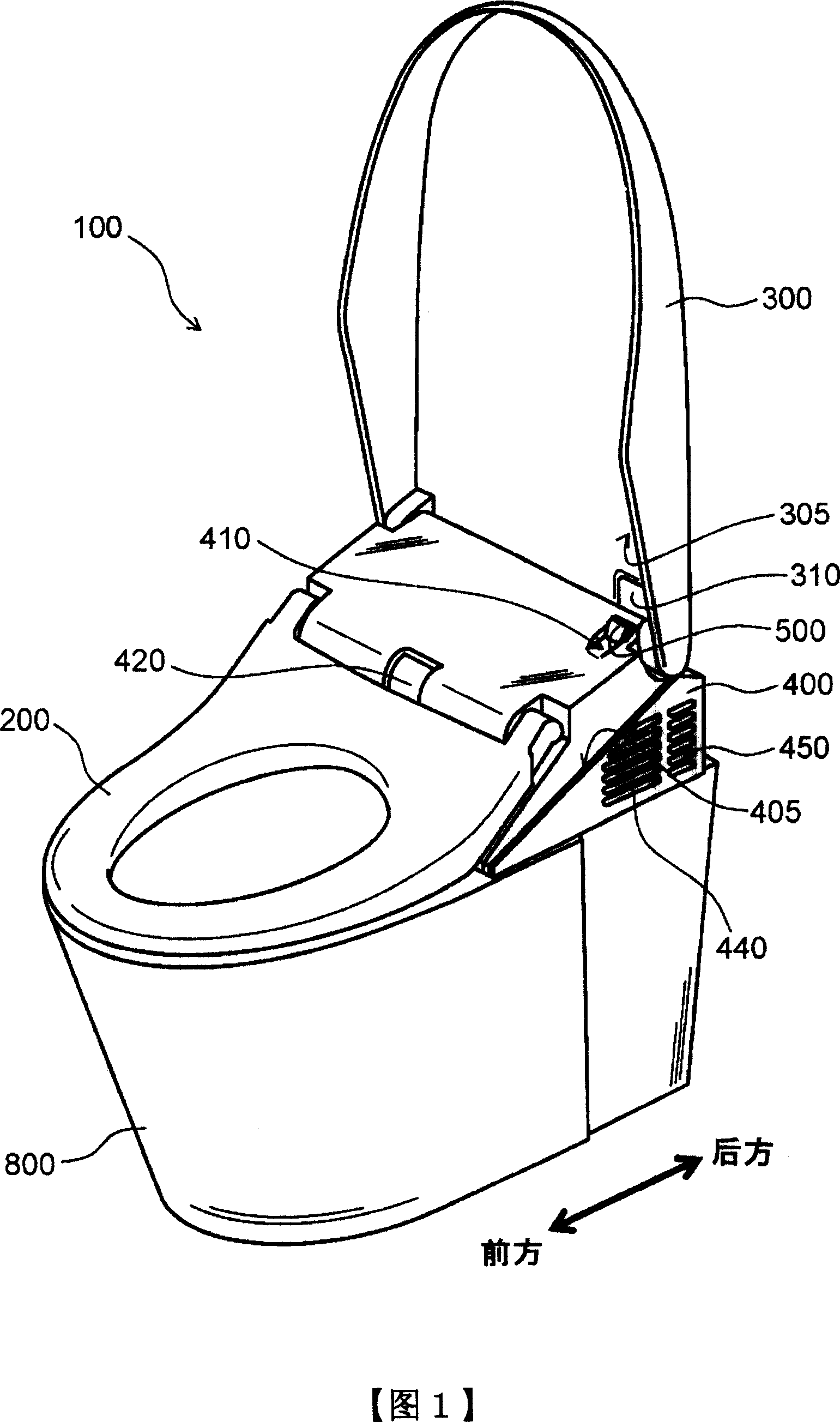

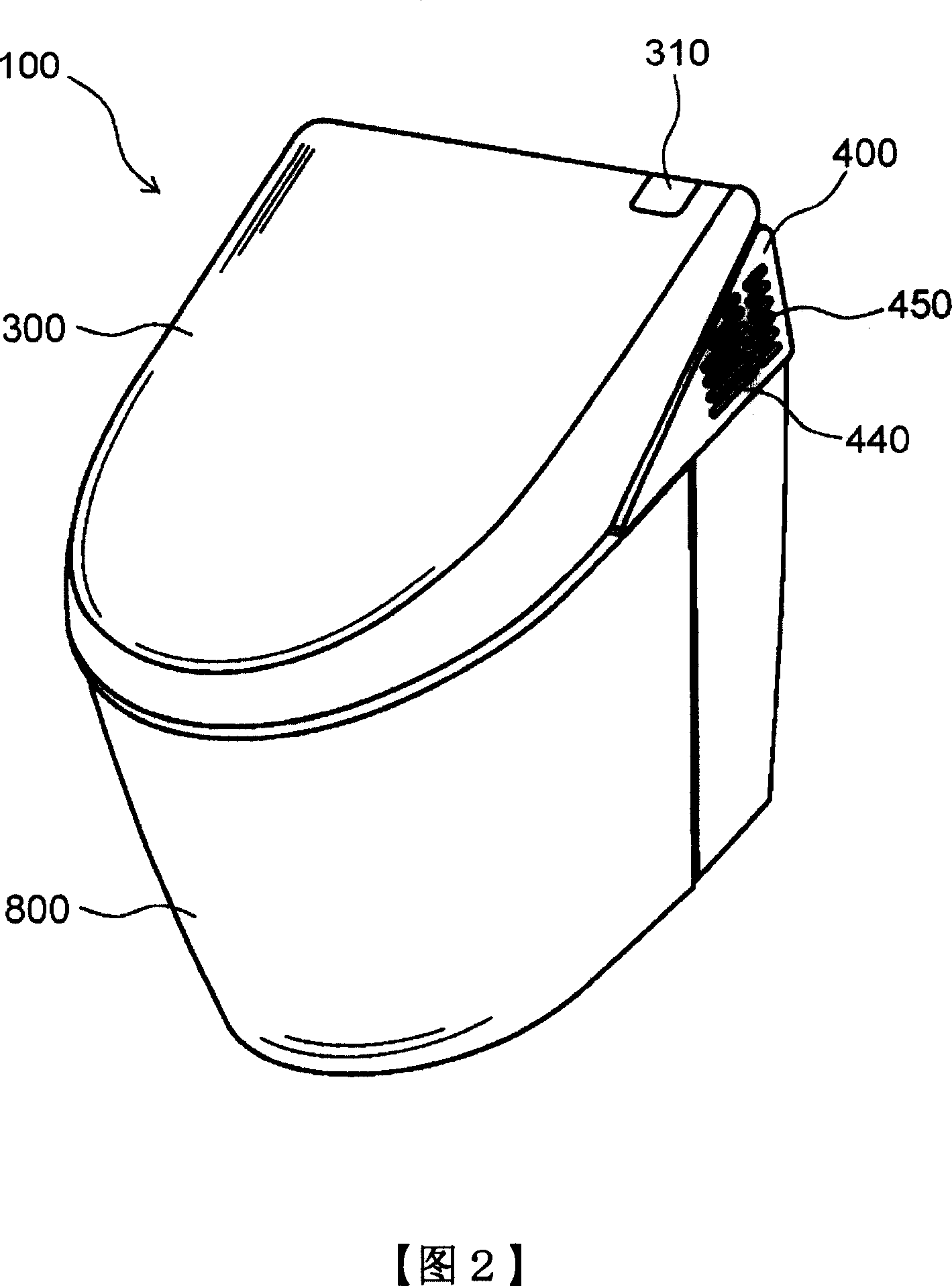

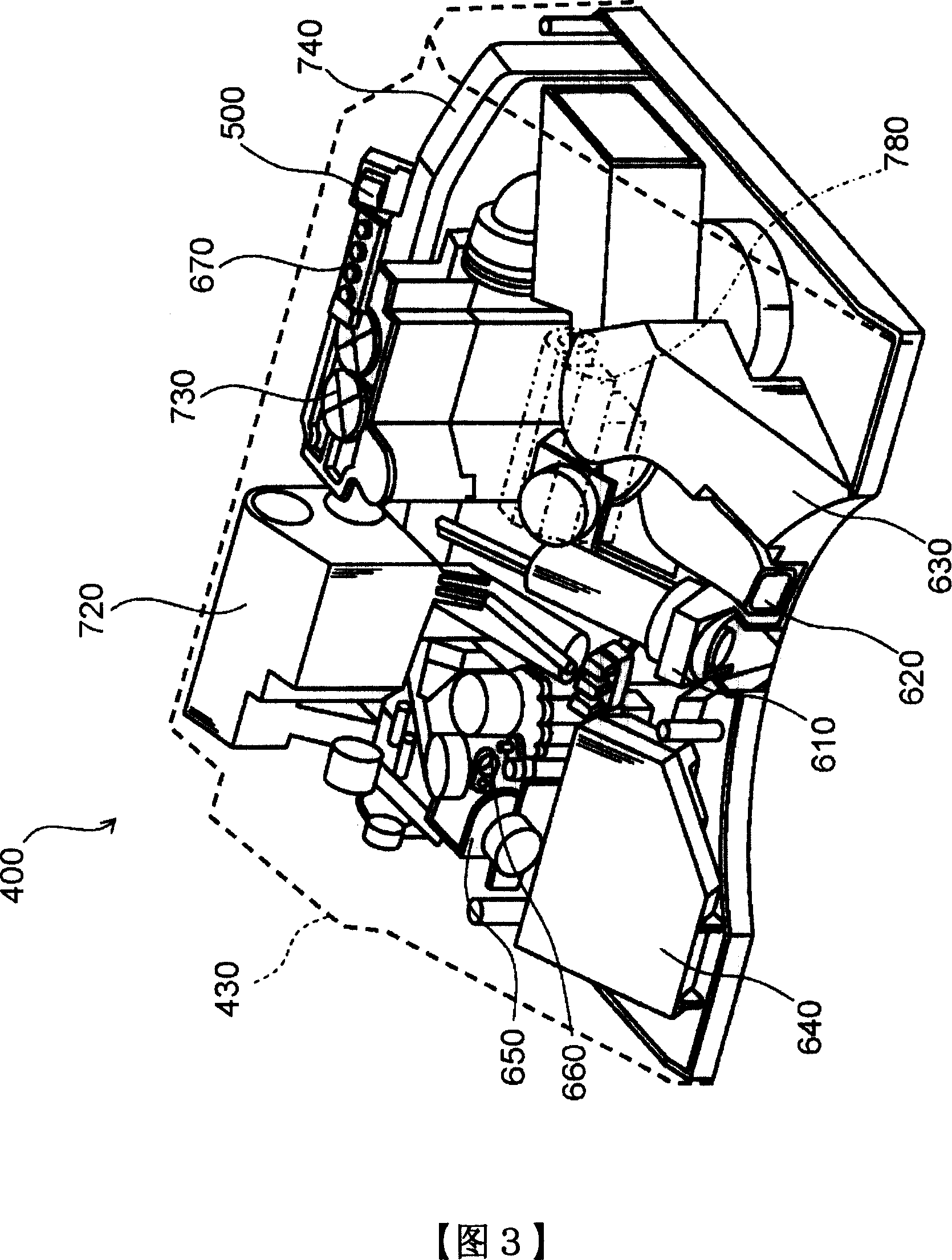

Toilet flushing device

The invention provides a pressure water pipe vertical compression-type flushing device, which is orderly in appearance and has cleaning function. The flushing device is provided with a closestool; a flushing valve body arranged inside, which can supply water to the closestool from a water supply without a water tank therein to flush the closestool; a seat, which is rotationally supported on the flushing valve body by a shaft; a cover, which is supported on the flushing valve body rotationally by a shaft. The pressure water pipe vertical compression-type flushing device is characterized in that an electric cover device for opening and closing the cover is arranged on the flushing valve body; the flushing valve and the electric cover device are arranged on the rear part of the flushing valve body and are adjacent to each other. The cover can cover the seat and approximately the entire upper surface of the flushing valve body when the cover is closed.

Owner:TOTO LTD

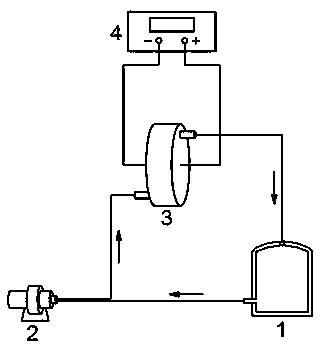

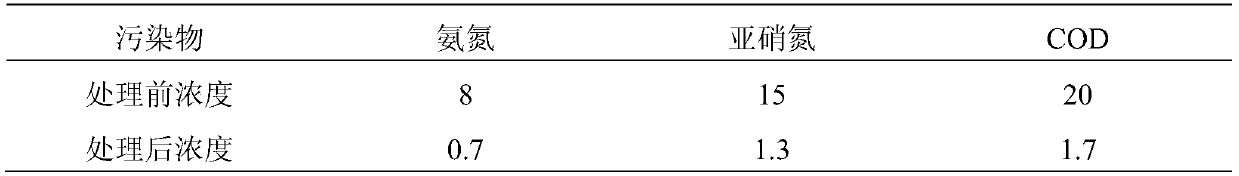

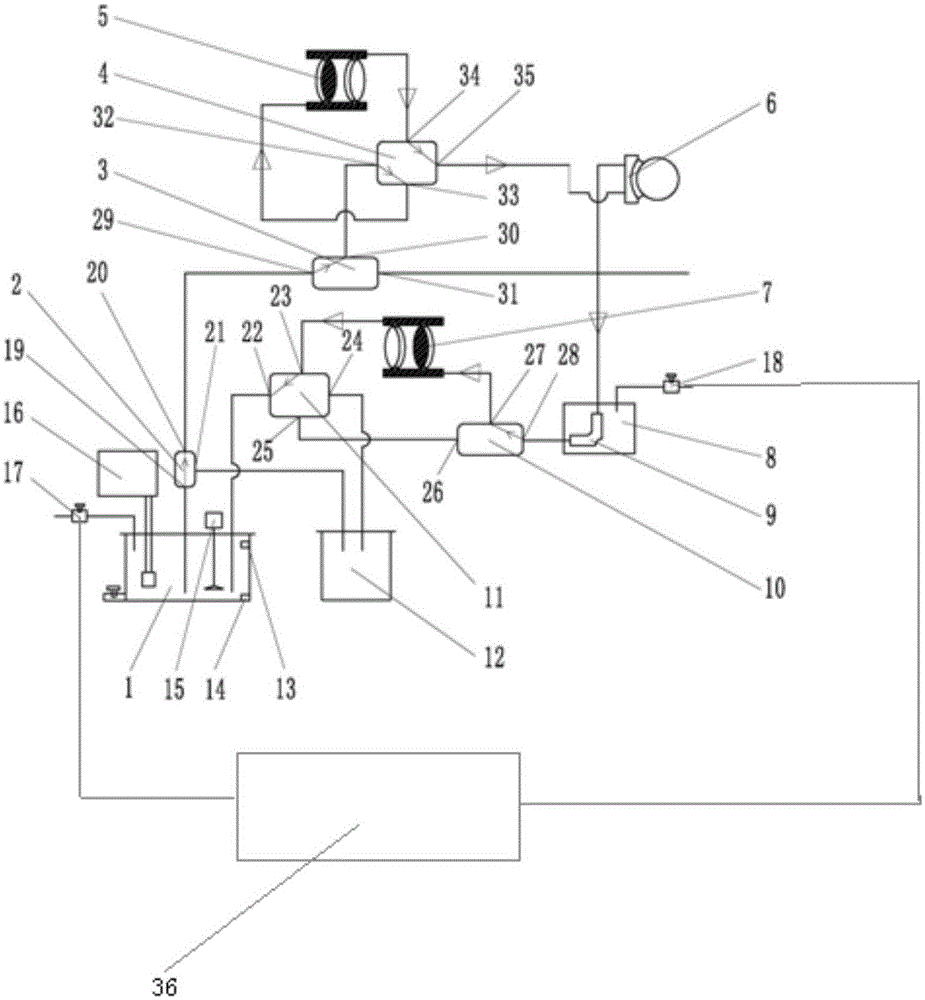

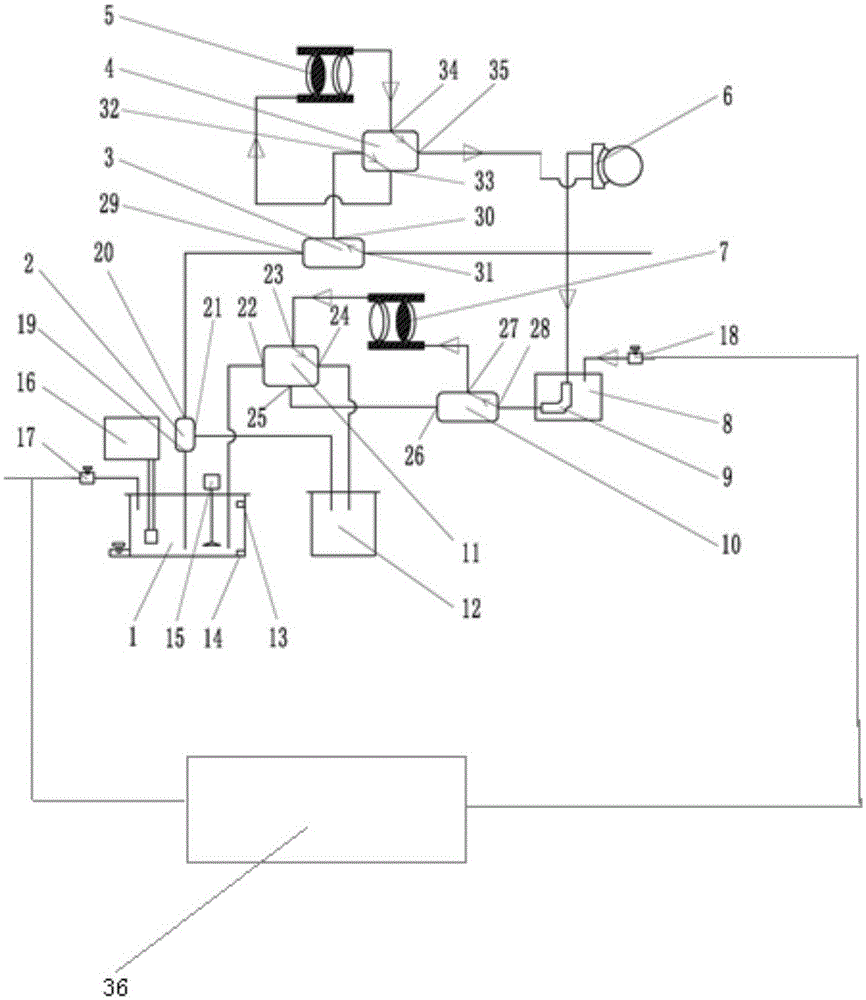

Device and method for removing ammonia nitrogen, nitrite nitrogen and COD in marine culture wastewater

InactiveCN105502584AReduce processing costsImprove securitySeawater treatmentWater contaminantsElectrochemical responsePeristaltic pump

The invention discloses a device and method for removing ammonia nitrogen, nitrite nitrogen and COD in marine culture wastewater. A water inlet is formed in the top end of an impounding reservoir of the device and communicated with a water outlet in the upper end of an electrochemical reactor, and a water outlet is formed in the lower end of the impounding reservoir and connected with a water inlet in the lower end of the electrochemical reactor. An anode, a bipolar electrode and a cathode are sequentially arranged in the electrochemical reactor through a peristaltic pump, the anode is connected with a positive electrode of a direct-current stabilized power supply, and the cathode is connected with a negative electrode of the direct-current stabilized power supply. A chemical agent does not need to be added, and thus treatment cost can be greatly reduced; free chlorine is constantly generated in situ at the anode, and thus safety performance is improved; the treatment process is clean and quick, and sludge and secondary pollution are avoided; the ammonia nitrogen, nitrite nitrogen and COD removing speed is high, and efficiency is high; only the current size needs to be controlled, and thus control is easy; the device is simple and convenient to operate and maintain.

Owner:ZHEJIANG UNIV

Metal polishing agent

The invention relates to a metal polishing agent which is characterized by comprising the following components in percentage by weight: 4%-8% of diethylene glycol butyl ether, 3%-6% of benzyl methanol, 2%-5% of disodium aminotriacetate, 1%-3% of sodium nitrite, 1%-3% of tallow fatty acid sodium, 1%-2.5% of a surfactant, 0.3%-0.8% of a corrosion inhibitor, 0.2%-0.5% of an anti-rust agent and the balance amount of water. The metal polishing agent has the characteristics of wide application range, stable polishing effect, convenience in use, high efficiency and the like.

Owner:黔东南州九黎苗妹工艺品有限公司

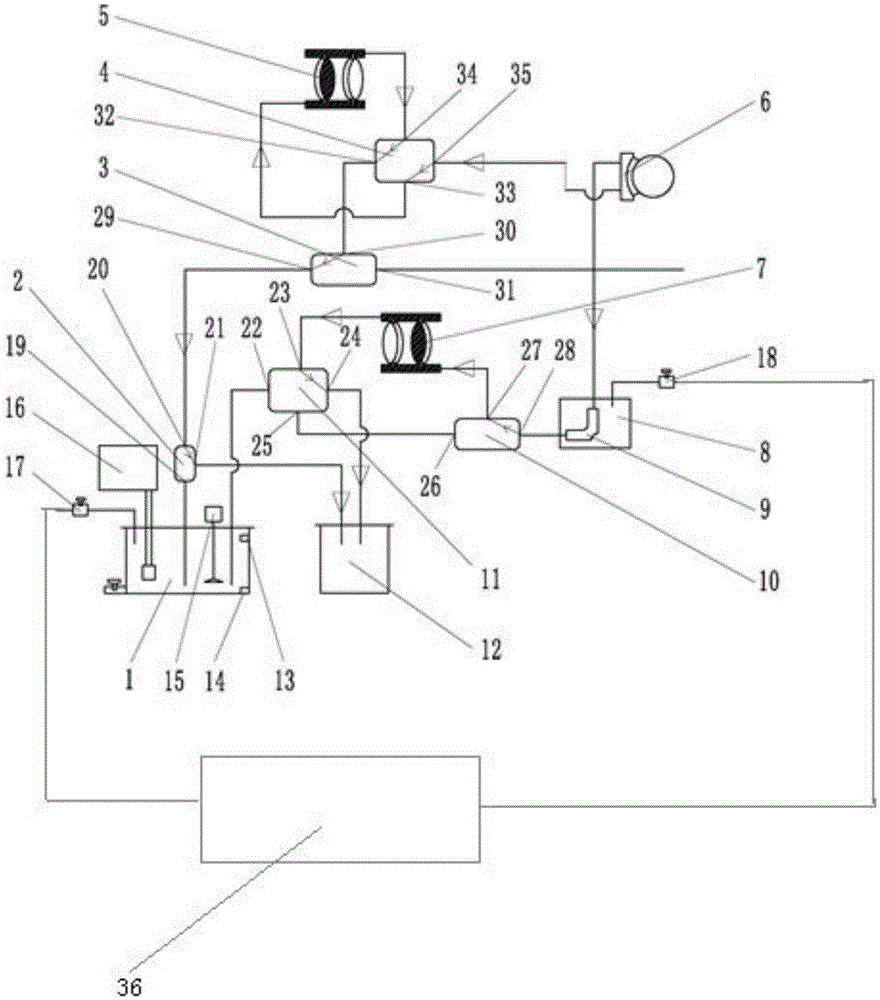

Concentrated ink supply system used in satellite type flexo printing machine

ActiveCN105128506AWith ink supplyWith ink returnRotary letterpress machinesPrinting press partsEngineeringPrinting press

The invention discloses a concentrated ink supply system used in a satellite type flexo printing machine, comprising an ink barrel, wherein the ink barrel forms a loop with an ink pump A, an ink chamber, an ink trough and an ink pump B sequentially by a pipe; an ink viscosity controller and a stirrer are further arranged in the ink barrel, an upper liquid level detector and a lower liquid level detector are respectively arranged at the upper edge and the lower edge inside the ink barrel, an electric ball valve A is connected to the outside of the ink barrel, an electric ball valve B is connected to the outside of the ink trough, and the electric ball valve A and the electric ball valve B are both connected with a PLC. The system disclosed by the invention can be used for solving the problems of the prior art that washing and replacing of the ink barrel of an ink supply system are inconvenient and manual regulation is needed when the pressure of the ink chamber is unsteady.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

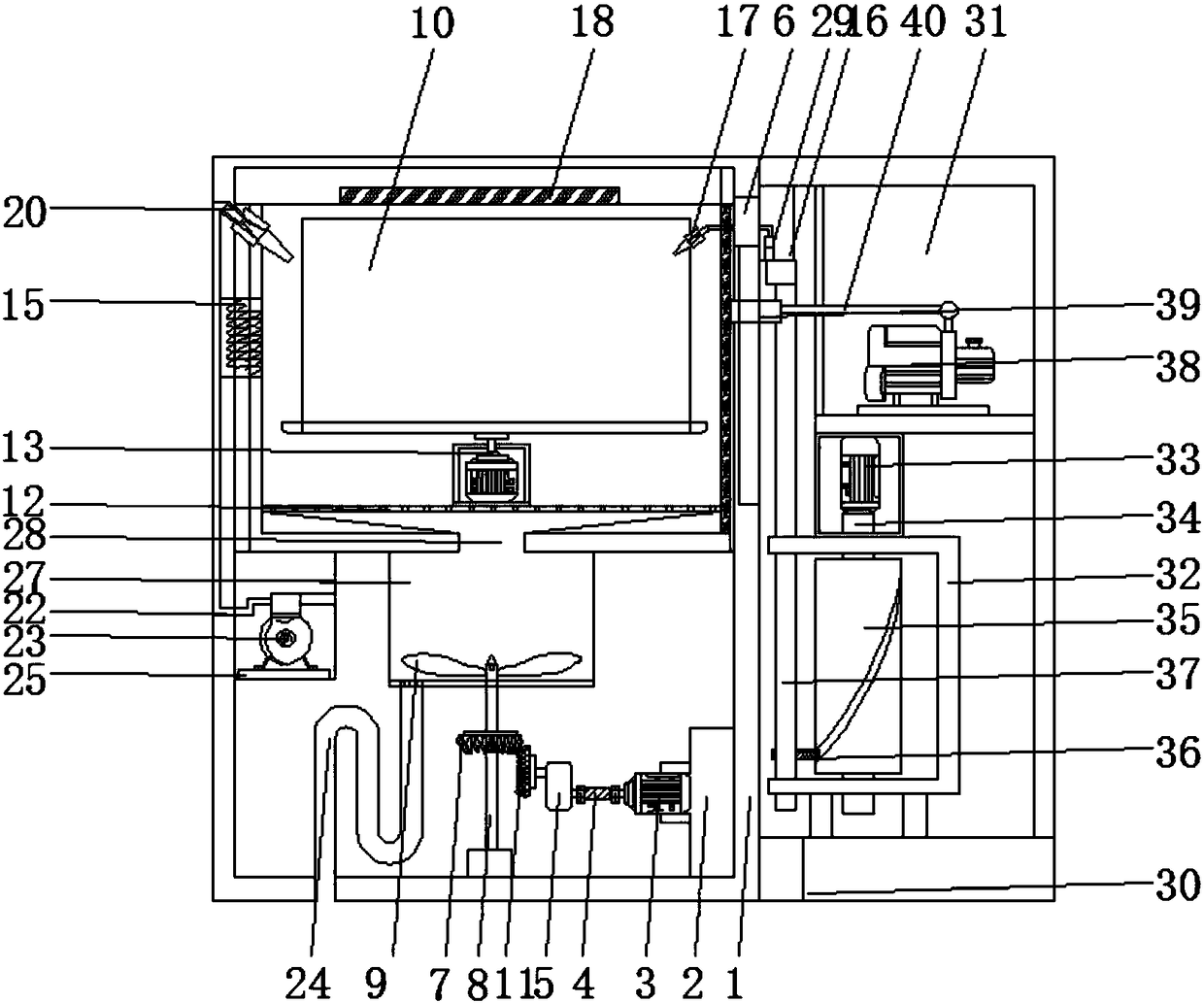

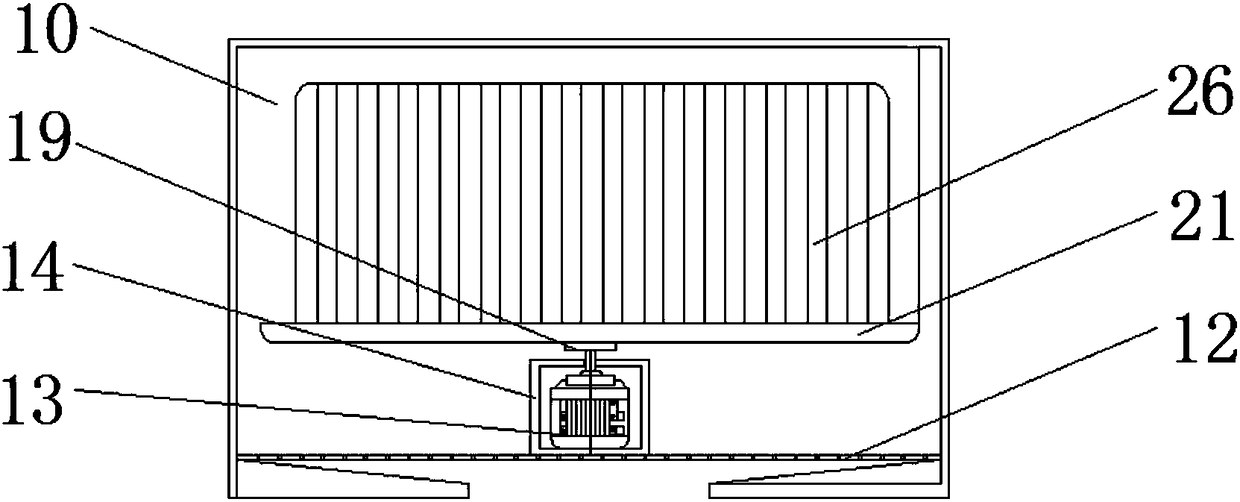

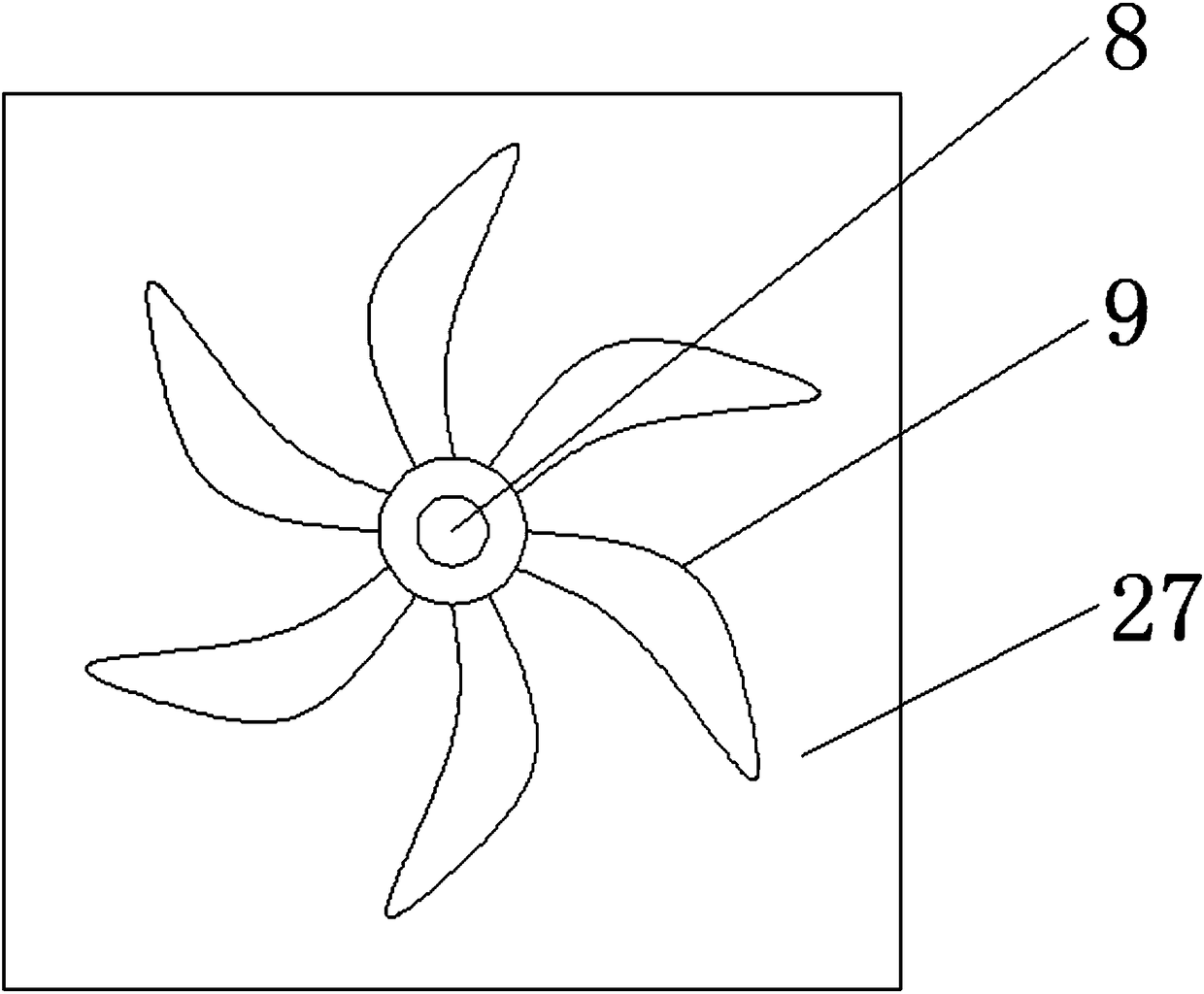

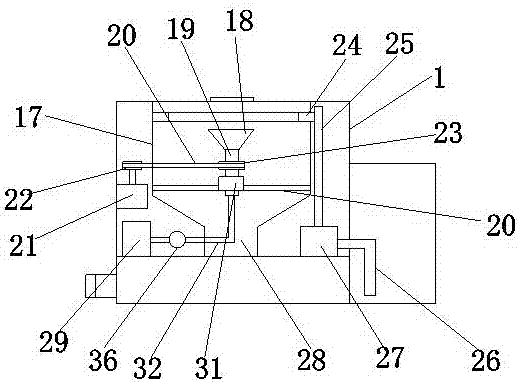

Dish-washing machine having automatically cleaning and drying and garbage disposal functions

ActiveCN108618726ACleaningFunctionalTableware washing/rinsing machine detailsCleaning equipmentCouplingReducer

The invention discloses a dish-washing machine having automatically cleaning and drying and garbage disposal functions. The dish-washing machine comprises a box body, wherein a first motor is fixedlyconnected to the bottom of the inner wall of the box body via a motor mounting platform; a speed reducer is fixedly connected to an output shaft of the first motor via a shaft coupling; a first bevelwheel is fixedly connected to an output shaft of the speed reducer; a second bevel wheel is connected to the top of the first bevel wheel in a meshed mode; a rotating shaft is fixedly connected to thesecond bevel wheel via a flat key; a crushing fan is fixedly connected to the top end of the rotating shaft via a flat key; and a dish-washing rack is fixedly connected to the top of an inner cavityof the box body. The invention relates to the technical field of kitchen supplies. With the application of the dish-washing machine having automatically cleaning and drying and garbage disposal functions, a technique integrating rapidly processing, disinfecting and drying tableware can be achieved; and kitchen waste can be processed, so that the sanitation of a user can be guaranteed and the tableware can be kept clean and sanitary; therefore, a problem that the user can feel more comfortable and ease can be solved.

Owner:浙江亨德清洗科技有限公司

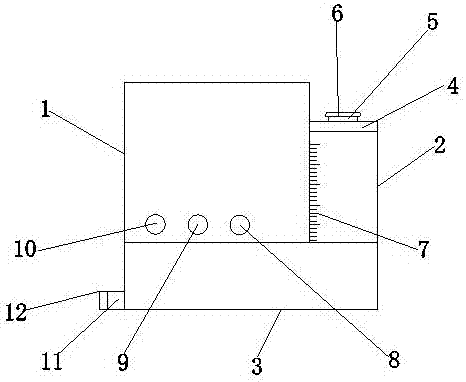

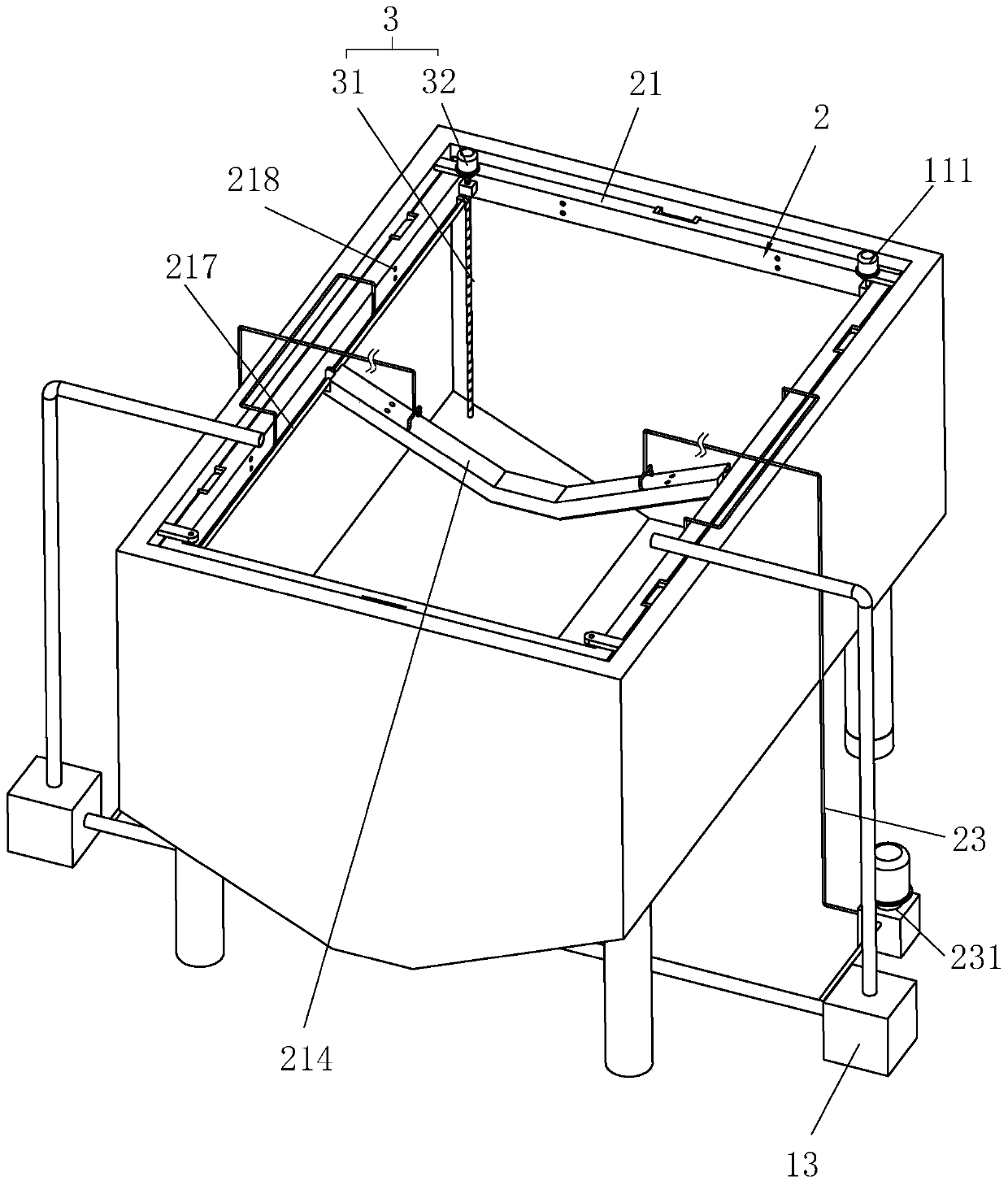

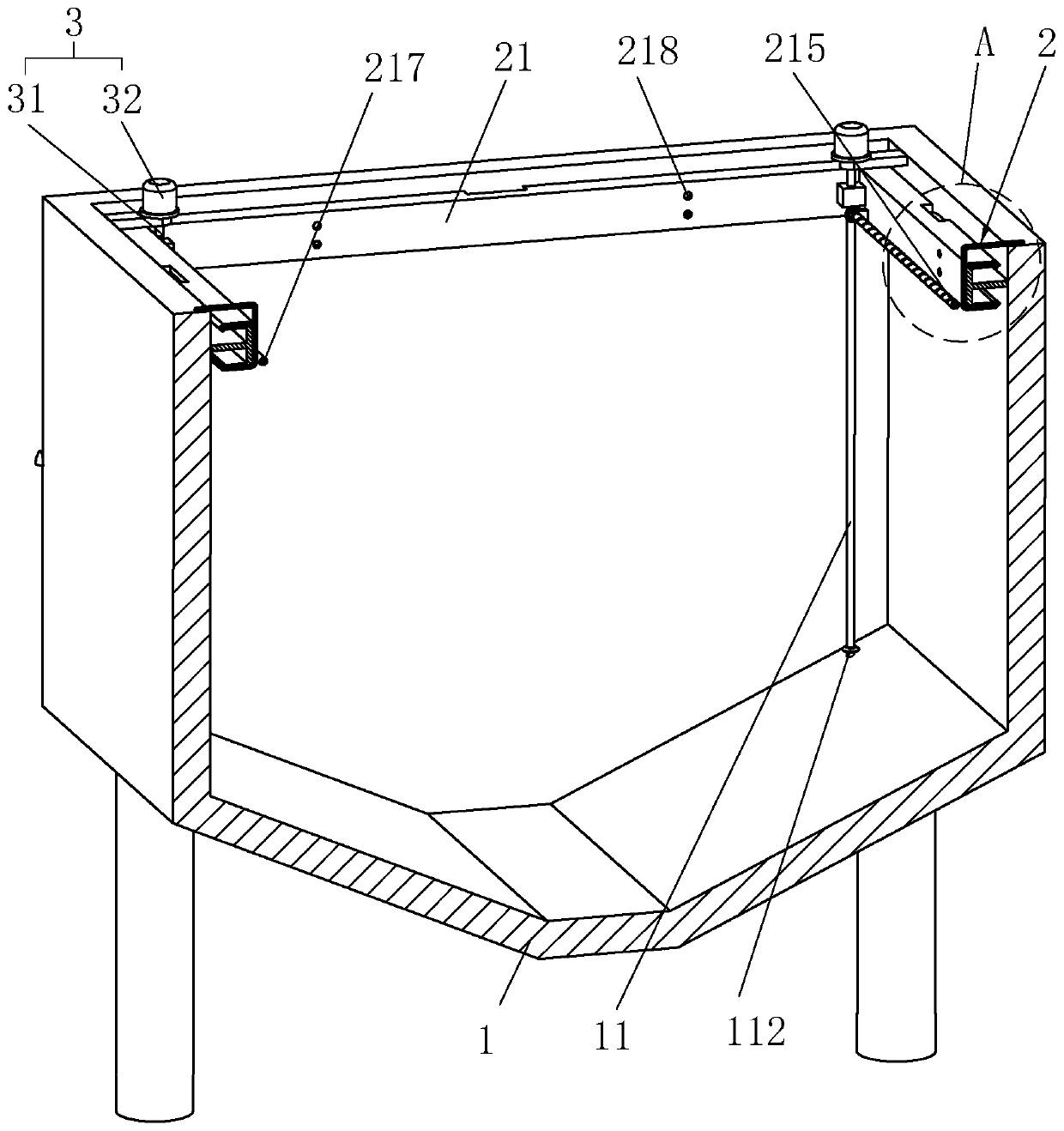

Novel color ultrasound probe disinfection device

InactiveCN107570466ACleaningFully self-cleaningCleaning using toolsCleaning using liquidsUltrasound probeLiquid tank

The invention discloses a novel color ultrasound probe disinfection device. The novel color ultrasound probe disinfection device mainly comprises an outer case, a washing liquid tank and a wastewatertank, wherein a washing box is arranged on the inner side of the outer case; the bottom of the washing box is a conical structure; a liquid discharging pipe is arranged at the bottom of the washing box; the outer case and the washing liquid tank are fixed on the upper surface of the wastewater tank. The novel color ultrasound probe disinfection device is capable of rapidly cleaning and washing ultrasound probes; meanwhile, washing components in the device can be self-cleaned; the overall device adopts a leather cup type cleaning structure; the device is capable of completely wrapping and washing the probes; an air blowing manner is also adopted, so that the self cleaning of the leather cup is achieved; the overall leather cup can be relatively completely self-cleaned.

Owner:CHENGDU FEIHANG PEIPENG TECH CO LTD

Cleaning type metal surface treatment device

The invention relates to a cleaning type metal surface treatment device, and belongs to the technical field of metal surface treatment. The device comprises a plating bath, a cleaning assembly is arranged on the inner side of the plating bath, and the cleaning assembly comprises a cleaning frame, a cleaning brush and a plurality of liquid discharge pipes. The cleaning frame is in a frame shape matched with the shape of the plating bath, the cleaning brush is fixedly connected to the middle of the side face, facing the inner wall of the plating bath, of the cleaning frame, and the cleaning brush is horizontally arranged. The top and the bottom of the side face, facing the inner wall of the plating bath, of the cleaning frame are fixedly connected with baffles, and the end faces, facing theinner wall of the plating bath, of the baffles are provided with liquid discharge grooves. The liquid discharge grooves communicate with the liquid discharge pipes, and the liquid discharge pipes communicate with a vacuum pump. The device has the plating bath cleaning effect without stopping production.

Owner:永进电镀(深圳)有限公司

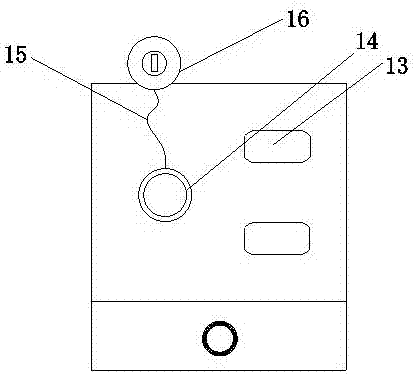

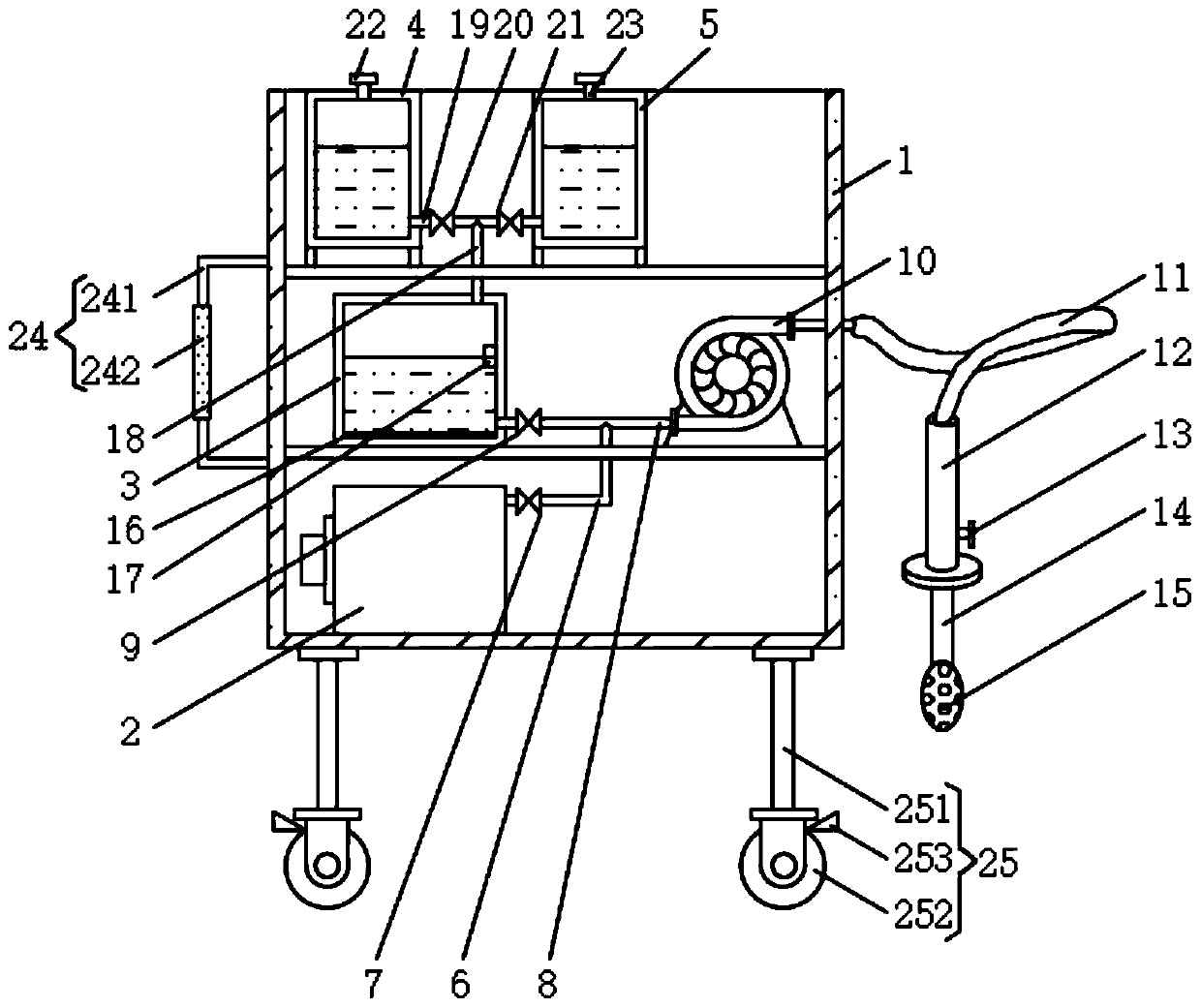

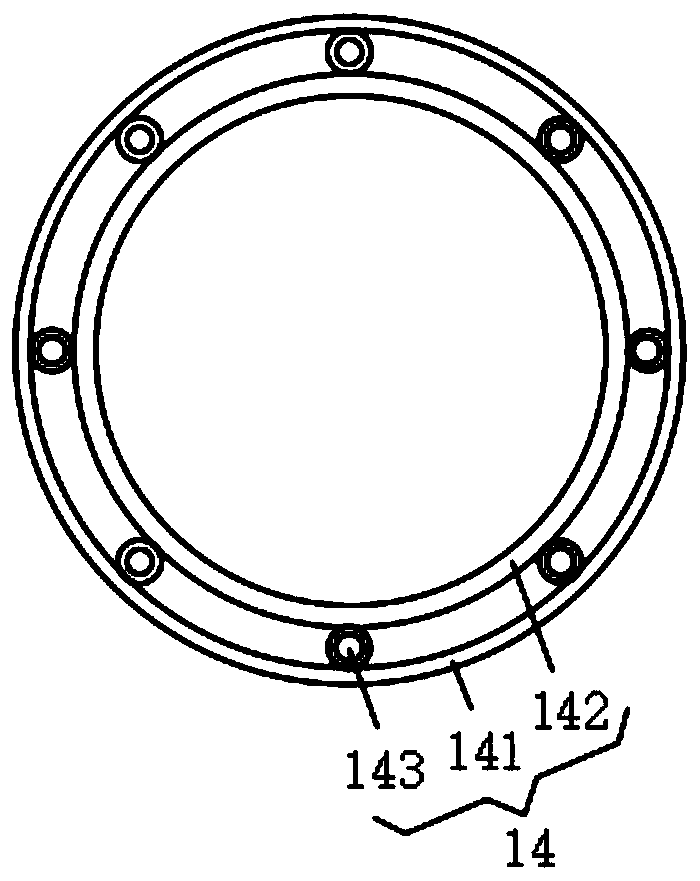

Vulva inflammation nursing device for gynaecology

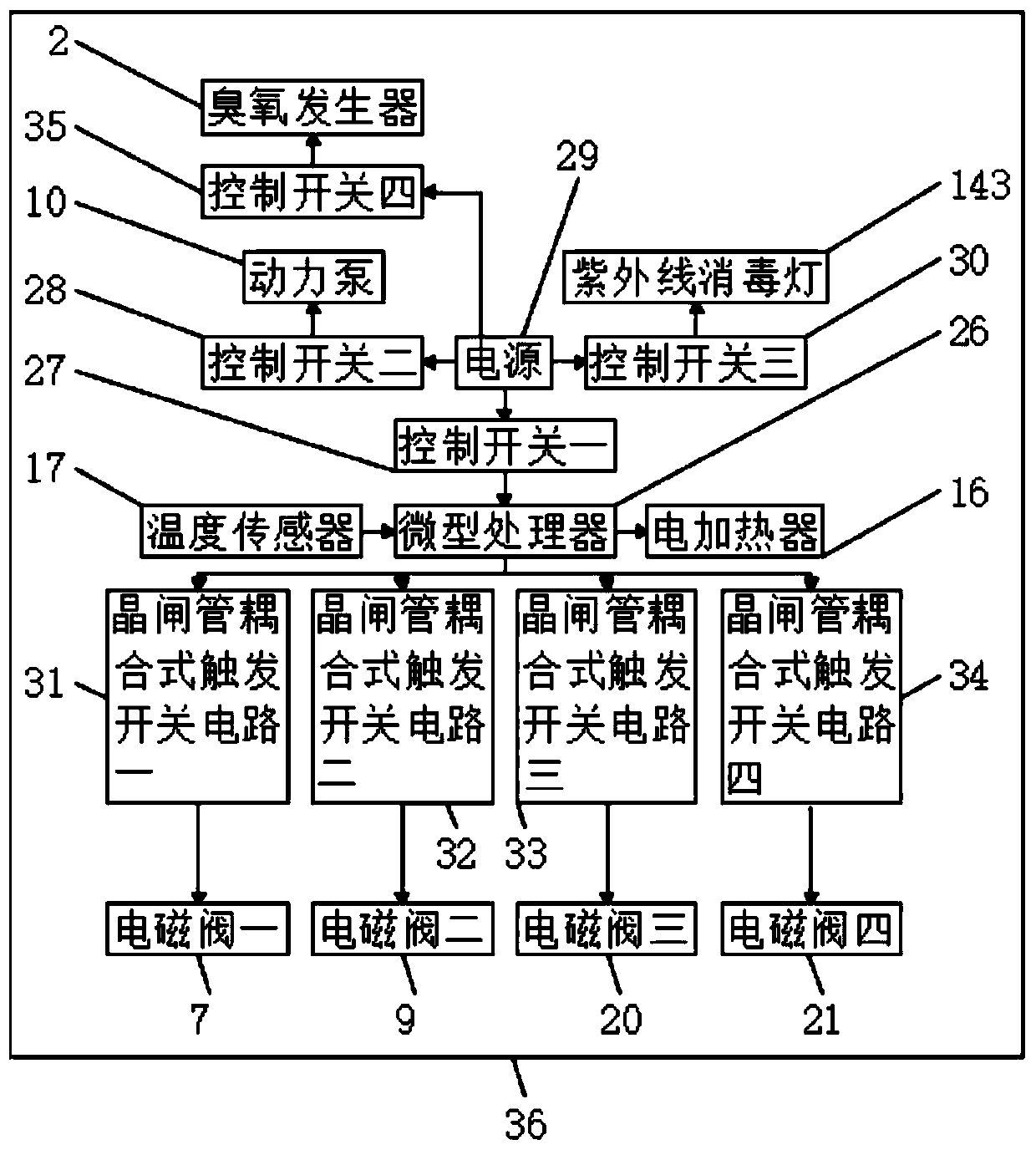

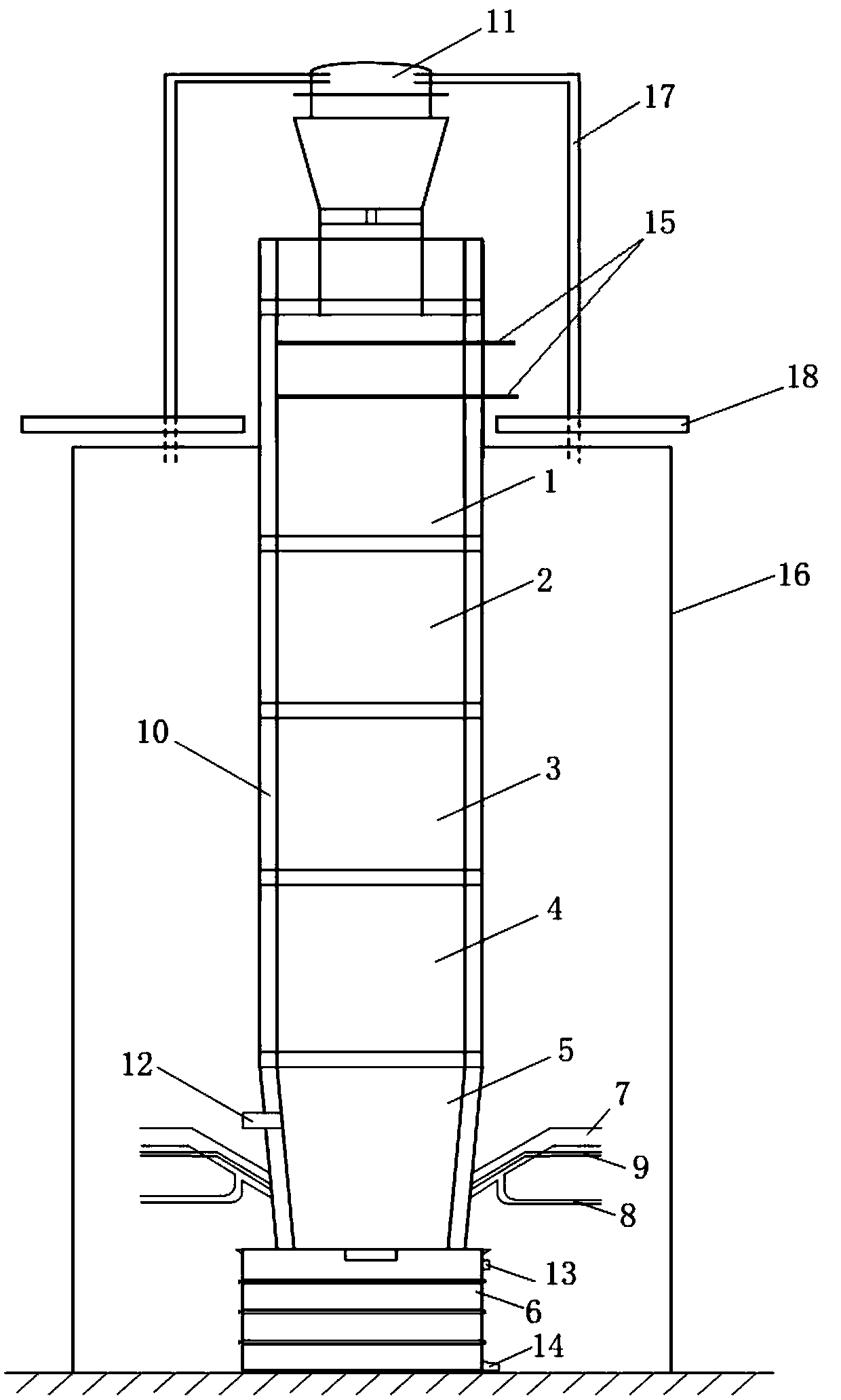

InactiveCN110302446AEasy to cleanImprove nursing effectCannulasEnemata/irrigatorsOzone generatorControl system

The invention belongs to the technical field of medical apparatuses, in particular to a vulvainflammation nursing device for gynaecology. The vulva inflammation nursing device comprises a tank body and a control system arranged on one side of the tank body, wherein an ozone generator, a heating tank, a clean water tank and a medicament tank are arranged in the tank body; the right side surface ofthe ozone generator communicates with the lower surface of a second catheter through a first catheter; and two ends of the second catheter communicate with the right side surface of the heating tank and a suction end of a power pump. According to the vulva inflammation nursing device disclosed by the invention, through mutual cooperation of the ozone generator, the heating tank, the clean water tank, the medicament tank, the power pump and a sterilizing ultraviolet lamp, when the vulva inflammation nursing device not only can perform fumigation and steaming on the vulva location of a patient,but also has the effect of cleaning and drying; under the assisting effect of the ozone generator and the sterilizing ultraviolet lamp, the sterilizing and disinfecting properties can be improved; andfunctional equipment is integrally combined, so that the total cost of the equipment can be reduce to a certain extent, and besides, the working efficiency of medical personnel can also be improved.

Owner:CHENGDU UNIV

Technology for cleanly and efficiently processing lead-bearing waste residues

PendingCN108950236AGuaranteed temperatureSecurity atmosphereProcess efficiency improvementLead smeltingSmelting process

Disclosed is a technology for cleanly and efficiently processing lead-bearing waste residues. The lead-bearing waste residues produced by lead smelting and lime are matched according to the mass ratioof 1:0.03-0.07 and are then pressed into blocky lead-bearing residue blocks, and after natural drying, by mass, 7%-15% of coke, 9%-11% of silica and 74%-84% of the lead-bearing residue blocks are matched. Materials are sequentially added into a five-section integrated type smelting furnace, ignition blowing-in is conducted for oxygen-enriched intensified smelting, materials added from a smeltingfurnace feeding section (1) pass through a preheating section (2), a sintering section (3), a half-melting section (4), a smelting section (5) and a layering section (6), and the smelting process of the materials is completed. Through the technology, material preheating, sintering, smelting and clarification laying are integrated, heavy metal, valuable metal, gangue and the like are selectively separated well, dangerous waste is processed cleanly and efficiently, and the technology has the advantages that the process is short, operation is simple and convenient, and investment is small.

Owner:个旧市沙甸永和冶炼厂

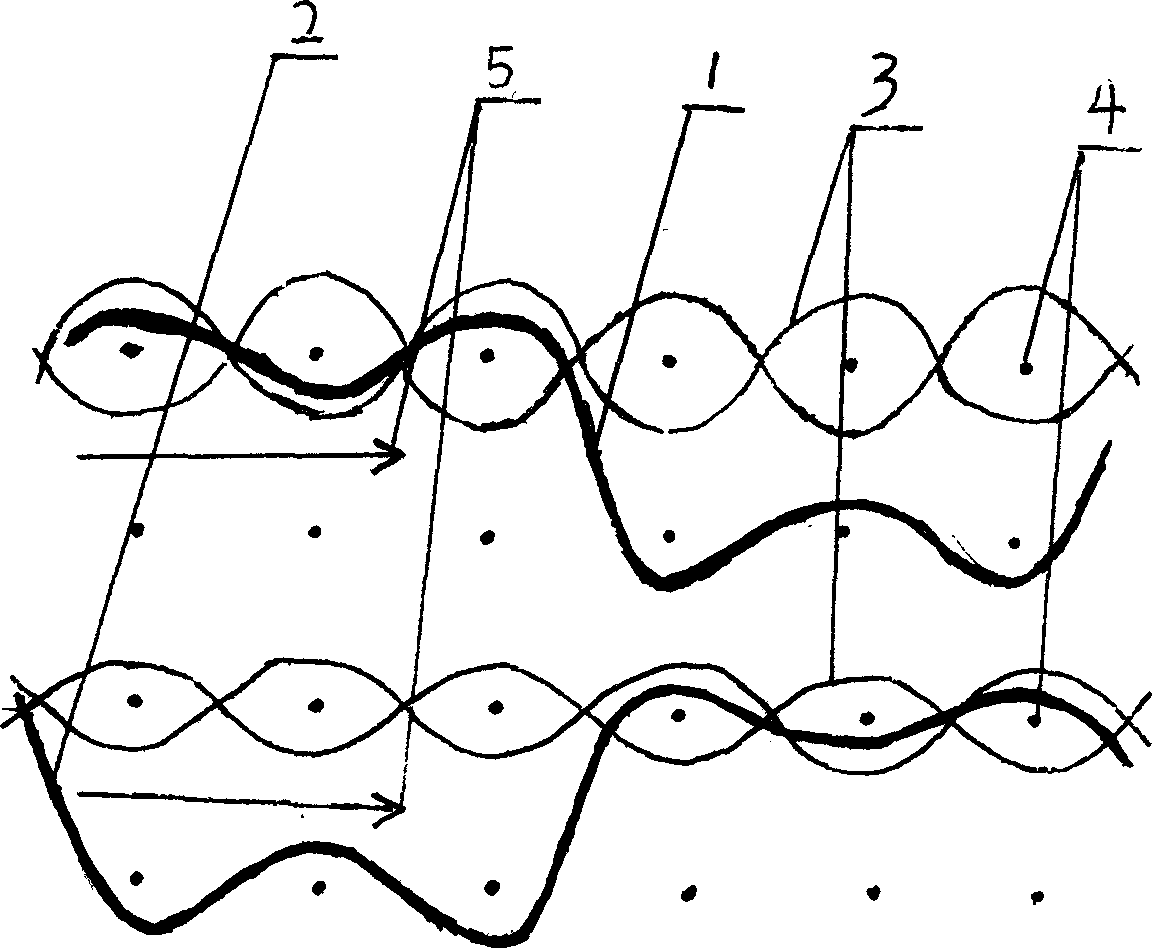

Waste crude oil pipe harmless treatment method

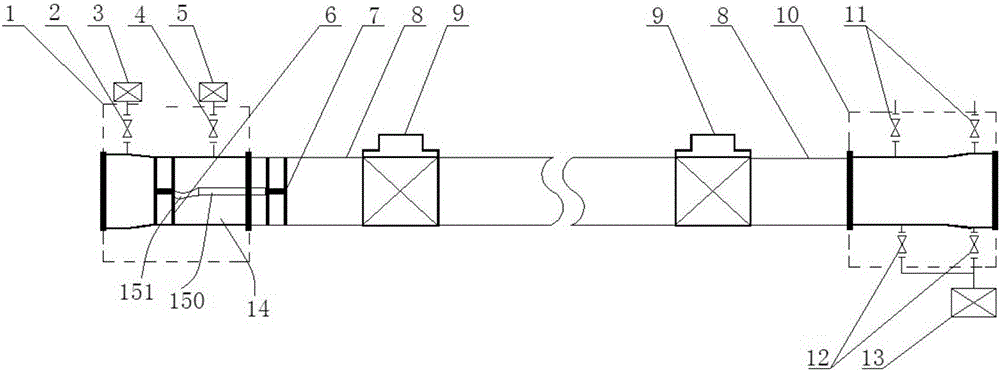

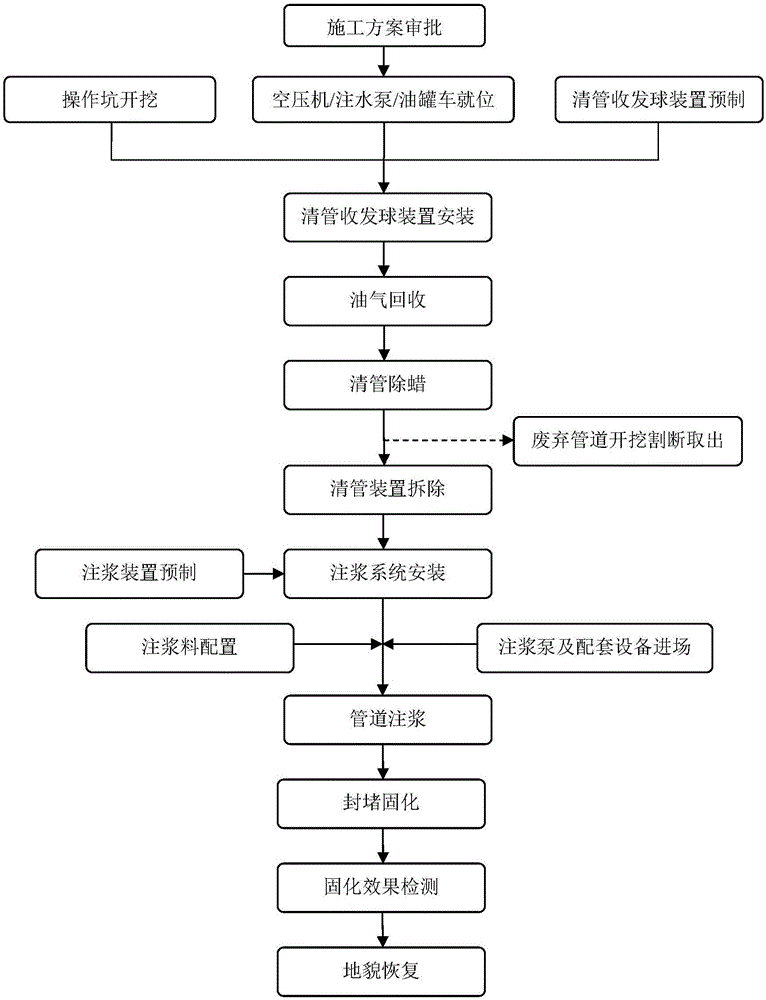

ActiveCN107433273AAvoid secondary pollutionImprove targetingSolid waste disposalHollow article cleaningLine tubingSlurry

The invention relates to a waste crude oil pipe harmless treatment method. The treatment method comprises the steps that 1, oil removing ball sets are implanted into a waste crude oil pipe, the oil removing ball sets comprise two or more pipe cleaning machines for oil removal which are distributed in the length direction of the pipe at intervals, the portion between the adjacent pipe cleaning machines for oil removal is filled with water, then air is injected into the waste crude oil pipe to push the oil removing ball sets to move forward along the pipe, and crude oil preserved in the pipe is removed; 2, wax removing ball sets are implanted into the waste crude oil pipe, the wax removing ball sets comprise two or more pipe cleaning machines for wax removal which are distributed in the length direction of the pipe at intervals, the portion between the adjacent pipe cleaning machines for wax removal is filled with cleaning agent, then air is injected into the waste crude oil pipe to push the wax removing ball sets to move forward along the pipe, and attached wax and residue crude oil in the pipe are removed; 3, solidifiable slurry is injected into the waste crude oil pipe, and the waste pipe is filled through solidification. The waste crude oil pipe harmless treatment method is low in energy consumption and high in maneuverability and safety, and meets the safe harmless treatment requirements of the waste pipe.

Owner:中石化石油工程技术服务有限公司 +1

High intensity and large length-diameter ratio ceramic spinneret and production method

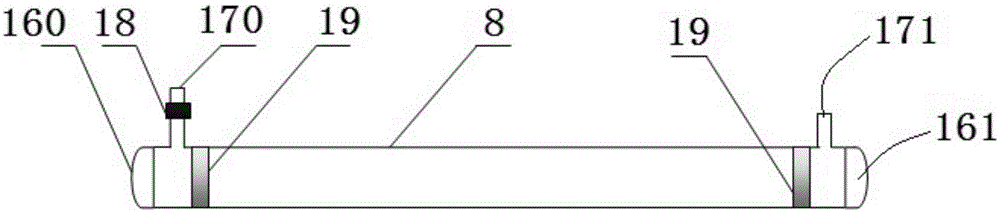

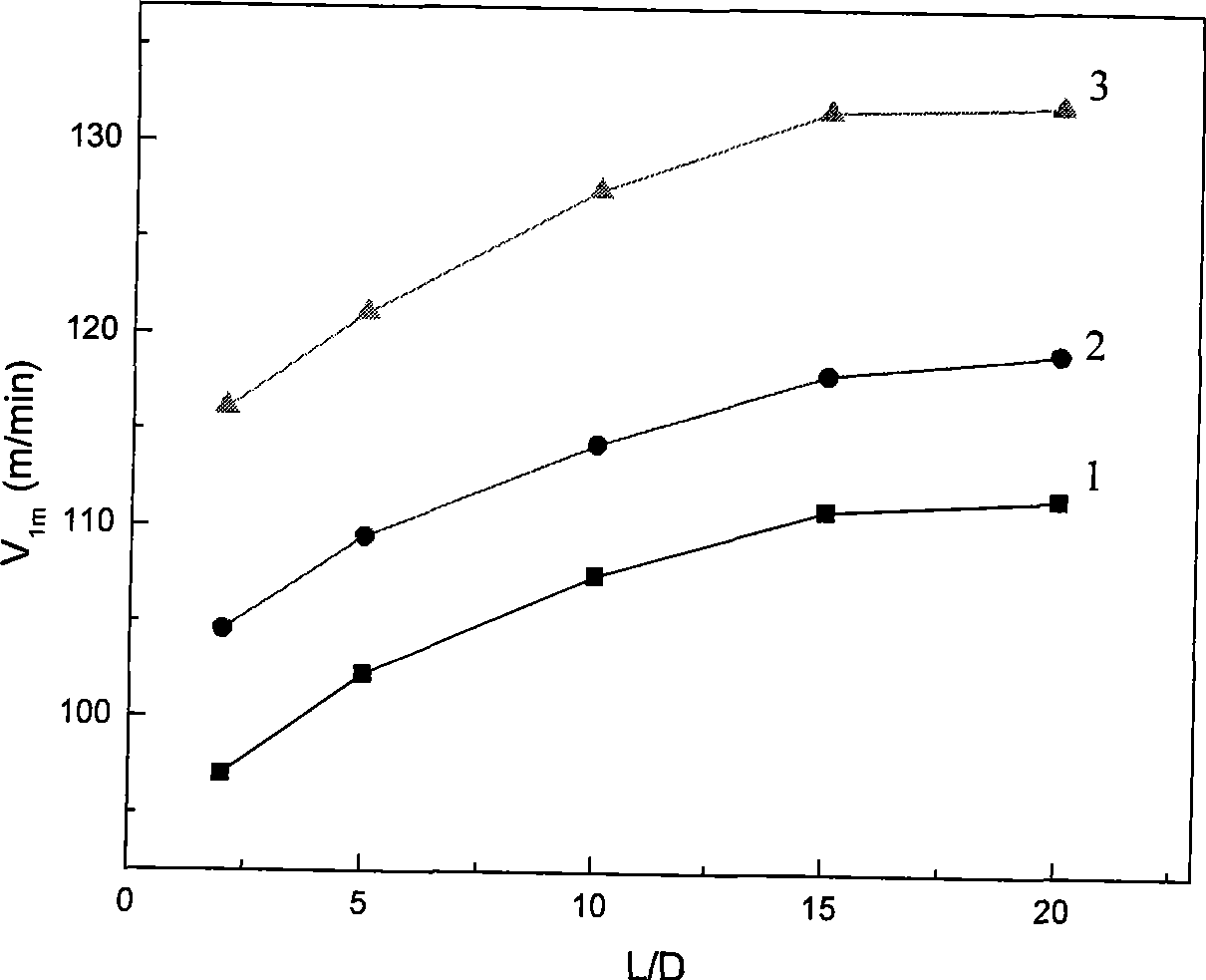

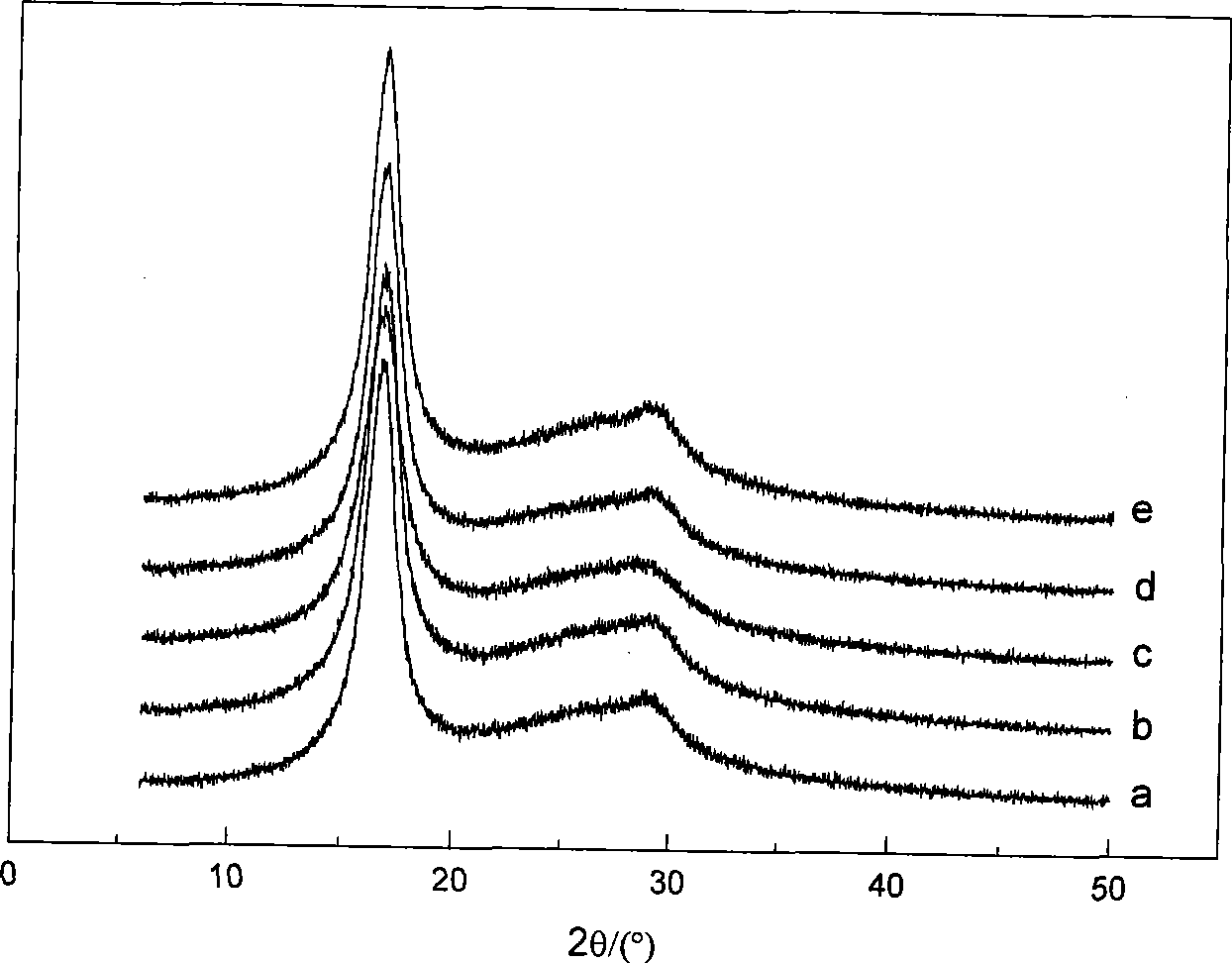

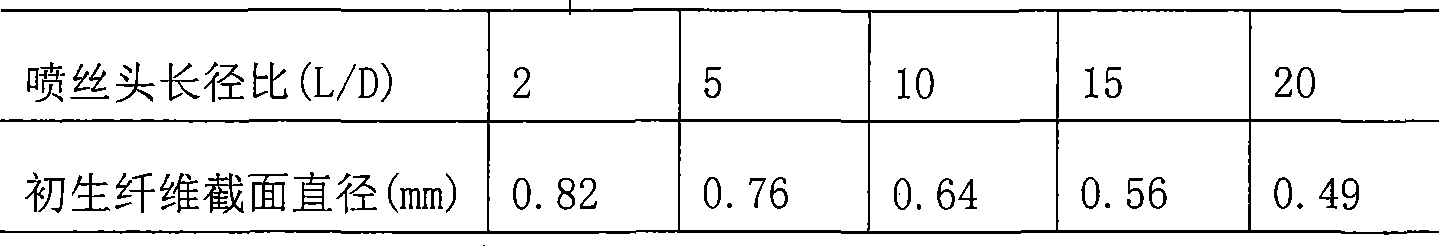

InactiveCN101457406ACorrosion resistantGood high temperature performanceSpinnerette packsFiberSpinning

The invention relates to a ceramic spinneret with high strength and large length-diameter ratio, and belongs to the textile field. The ceramic spinneret is characterized by being made from single-phase or complex phase ceramics with high strength such as Si3N4, Al2O3, Sialon and the like. Thickness of the spinneret is 3-4mm, the length-diameter ratio of a spinneret orifice thereof is more than 15, which causes the spinneret to be capable of bearing the working pressure above 30kg / cm<2>. The large length-diameter ratio can well help relieve brass bulking during spinneret jetting process, and is applicable to a dry-wet spinning process adopted in manufacturing high-strength PAN fiber, and the ceramic materials have the characteristics of good corrosion resistance, good high-temperature resistance and the like, and is suitable for being used and cleaned under a severe environment.

Owner:NINGBO DONGLIAN MECHANICAL SEAL +2

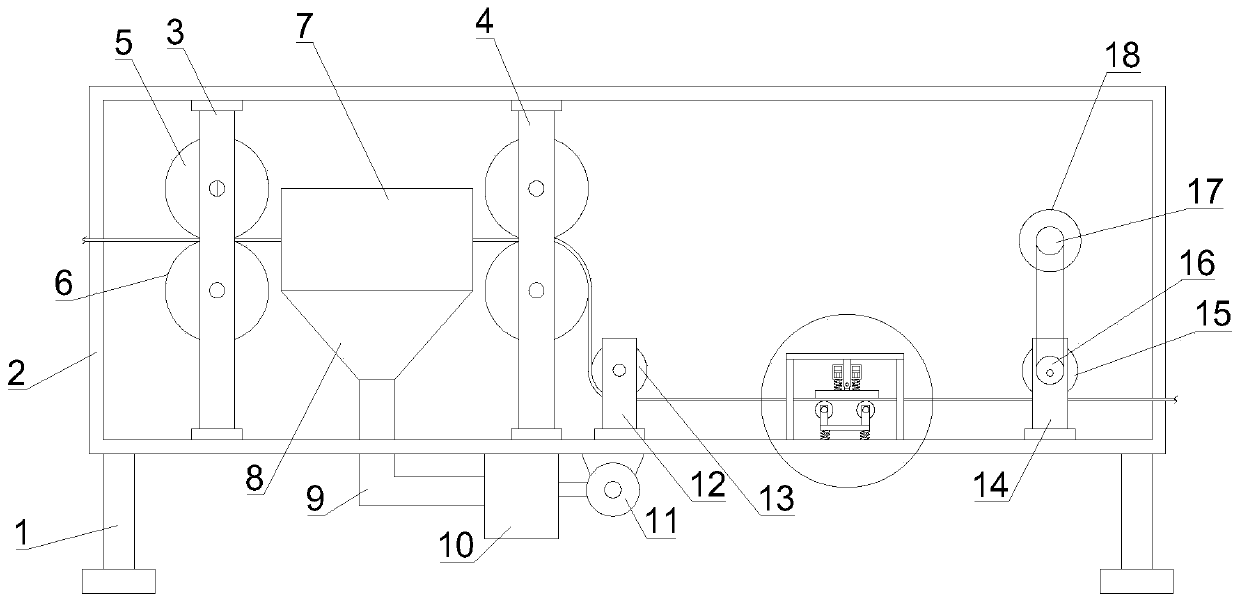

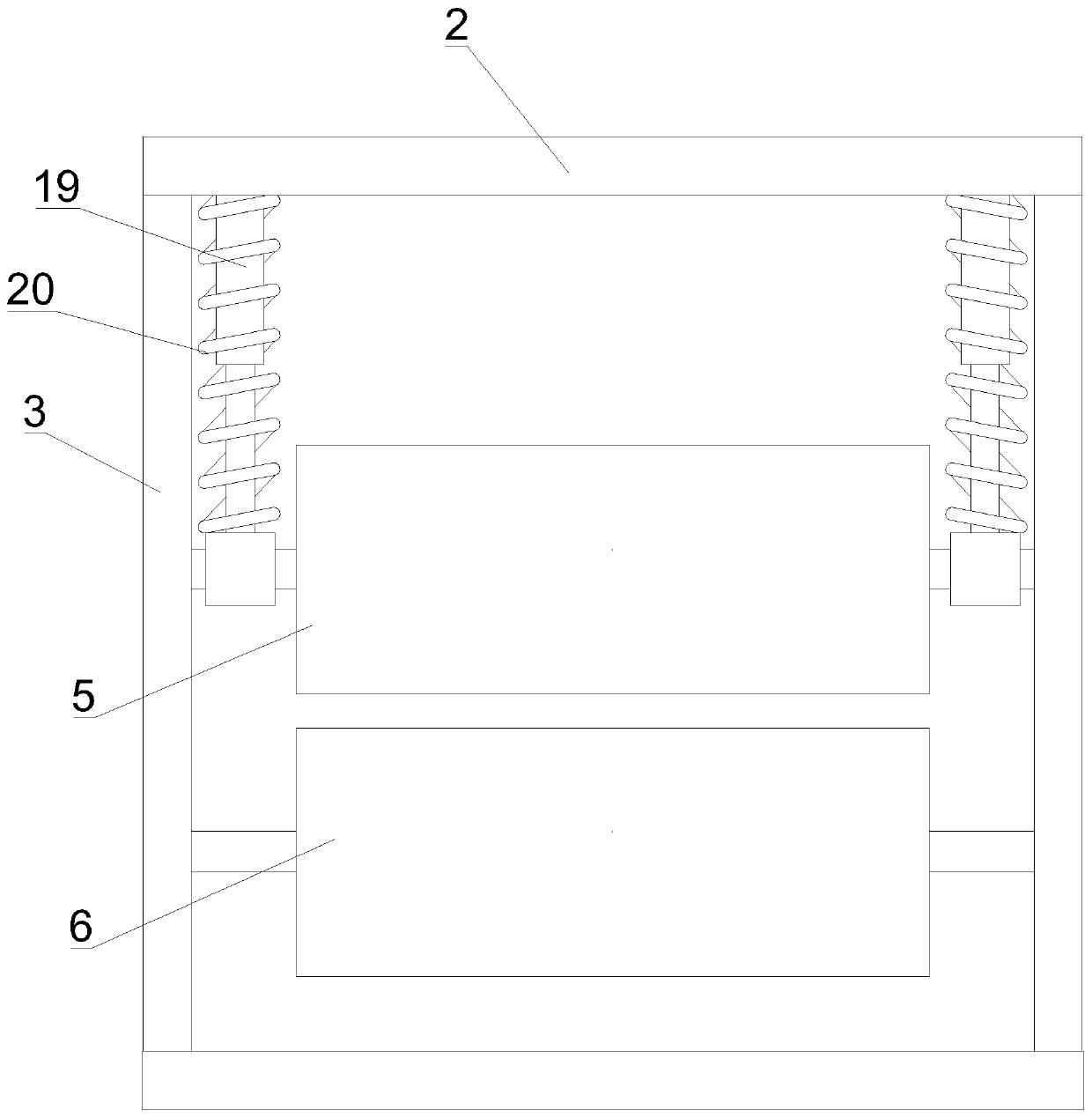

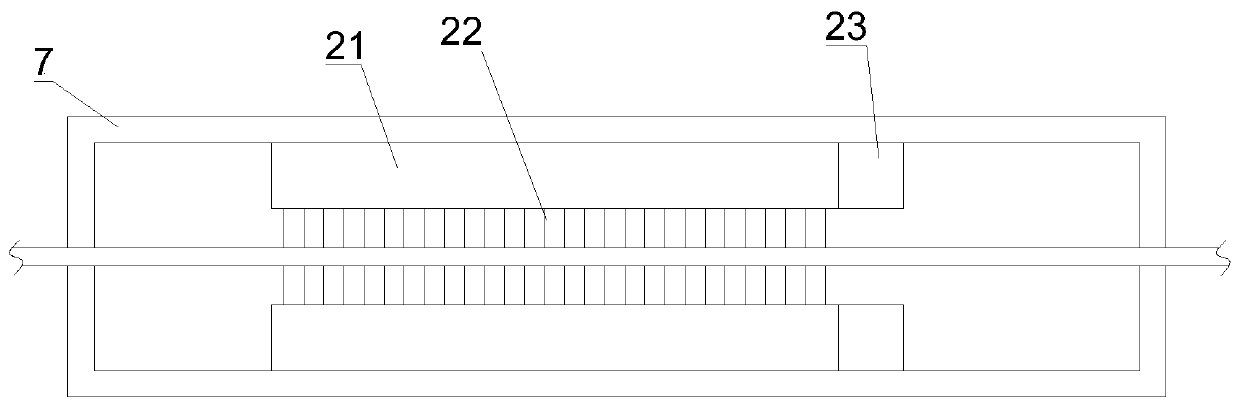

Blended yarn impurity removal and transporting mechanism

The invention discloses a blended yarn impurity removal and transporting mechanism which comprises a box body, a transporting mechanism body and an impurity removal mechanism, wherein landing legs are arranged at the bottom of the box body; the transporting mechanism body and the impurity removal mechanism are arranged in the box body; a first support plate and a second support plate are in sliding fit with a yarn feeding press roller through a first connecting shaft; a sleeve is arranged on the first connecting shaft in a sleeving manner; the sleeve is connected with the bottom end of a telescopic rod; the top end of the telescopic rod is connected with the top surface of the box body; a first spring is arranged on the telescopic rod in a sleeving manner; the first support plate and the second support plate are rotatably connected with a yarn feeding rotary roller through a second connecting shaft; the yarn feeding press roller is right above the yarn feeding rotary roller; a third support plate is rotatably connected with a yarn guiding rotary roller through a third connecting shaft; and a fourth support plate is rotatably connected with a driving rotary roller through a fourth connecting shaft. The blended yarn impurity removal and transporting mechanism can compress and transport blended yarn to enable the blended yarn to be fully unfolded during the transporting process and ensure the transporting broad width of the blended yarn, is cleaner and more comprehensive in blended yarn impurity removal and higher in efficiency.

Owner:徐州嘉搏纺织股份有限公司

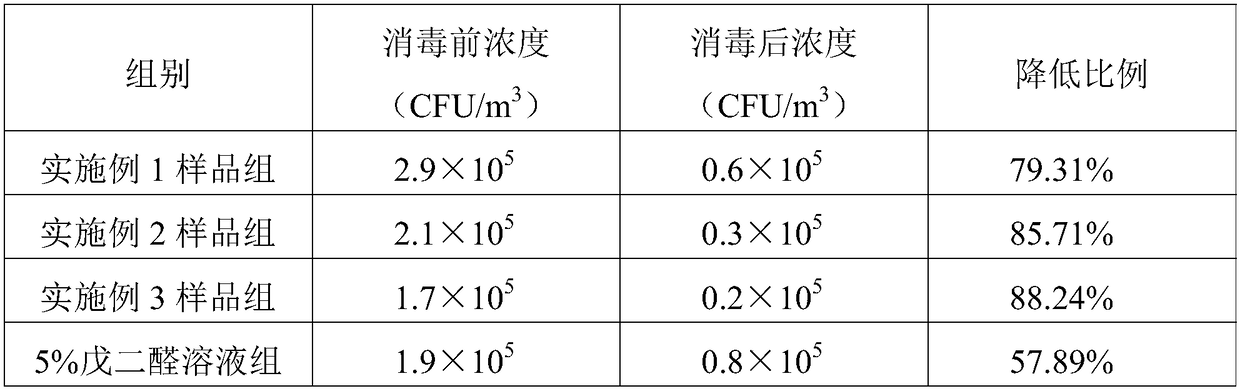

Foam type disinfectant for farms as well as preparation method and application thereof

InactiveCN108739857AStable pHImprove product quality stabilityInorganic/elemental detergent compounding agentsBiocideFoaming agentContact time

The invention relates to a foam type disinfectant for farms as well as a reparation method and application thereof. Every 100 parts by weight of disinfectant comprises the following components in parts by weight: 5 to 10 parts of active chlorine, 5 to 10 parts of aldehydes, 25 to 40 parts of foaming agent, 1 to 2.5 parts of enhancer, 0.1 to 0.5 part of buffering agent and the balance of water; during preparation, the components are weighed according to the proportion and are mixed uniformly; and the disinfectant and water are mixed according to the volume ratio of 1:(100-1000) to be applied todisinfection of the farms. Compared with the prior art, the disinfectant has the following advantages: foam is ejected through a high-pressure foam ejector, the foaming multiples reach more than 100,the disinfecting surface can be covered completely, dead angle and blank are avoided, the disinfectant is distributed uniformly, and the contact time of the disinfectant and the disinfecting surfacecan be prolonged, so that the disinfecting effect is enhanced; and meanwhile, water can be saved, and the foam type disinfectant for the farms is suitable for cleaning and disinfecting colony houses and devices in the farms.

Owner:JIANGXI AOXIN BIOTECH CO LTD +1

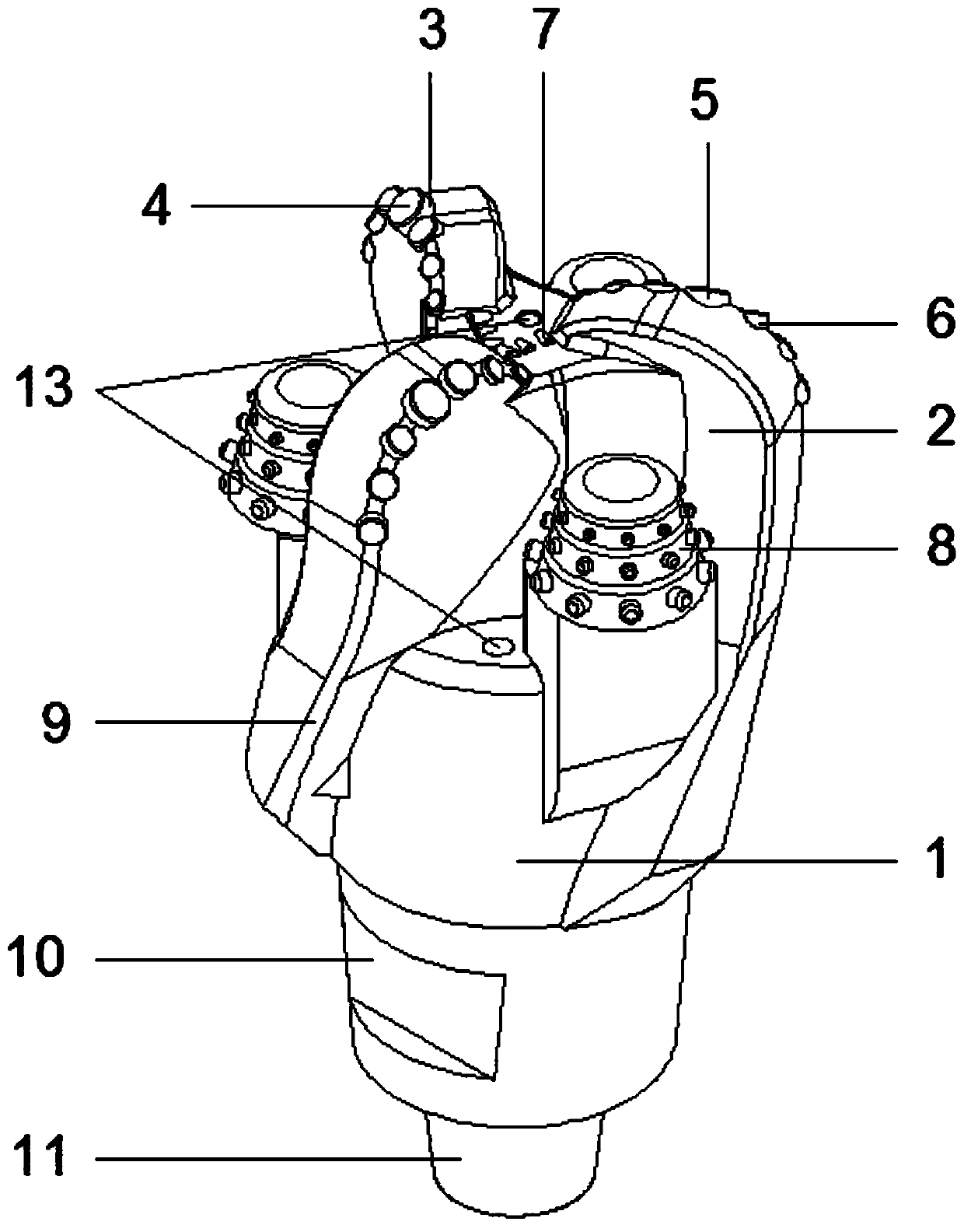

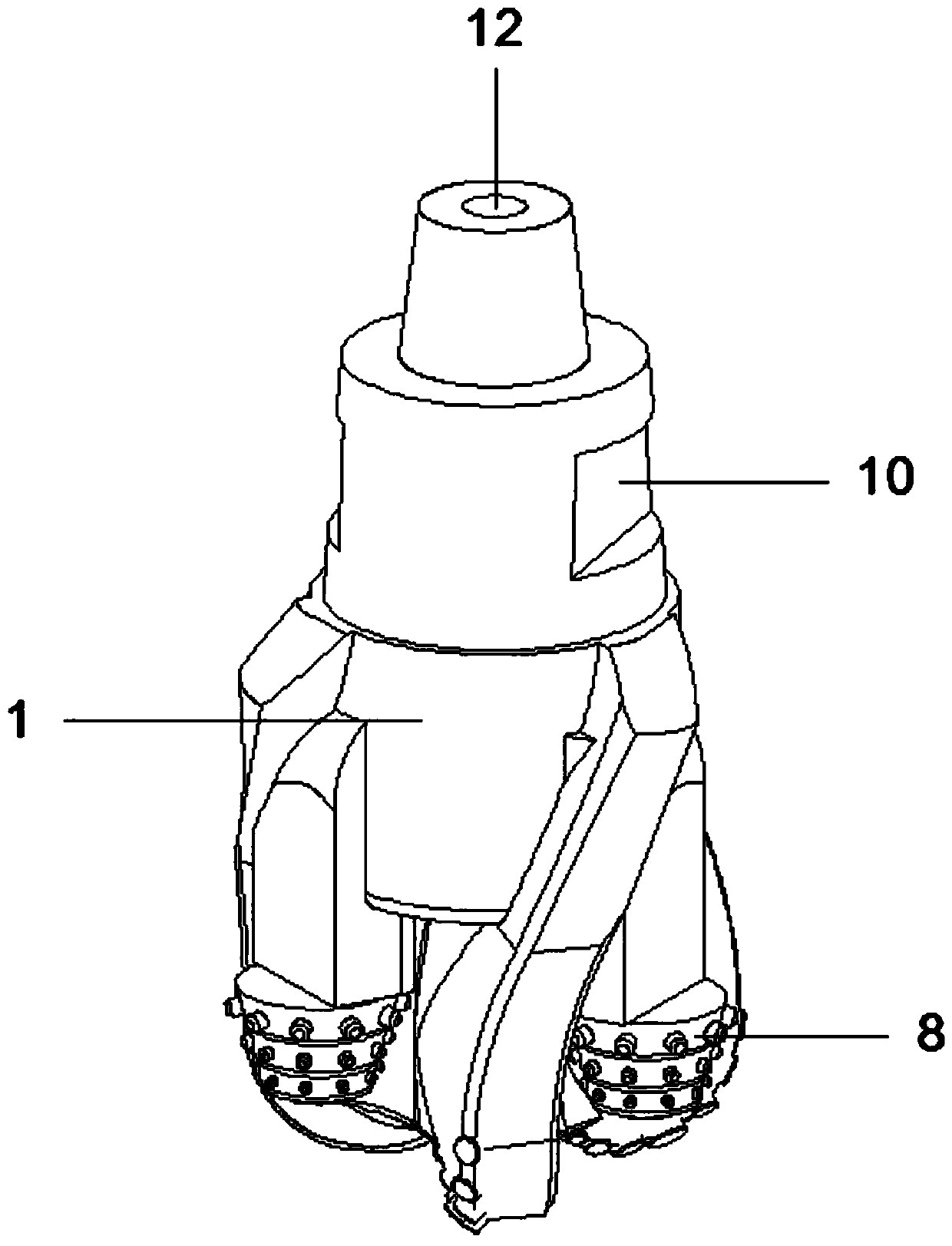

Secondary rock breaking drill bit for assisting pressurizing flow back through spiral blade

InactiveCN109898998AExtended service lifeReduce vibration amplitudeDrill bitsConstructionsWell drillingSpiral blade

The invention provides a secondary rock breaking drill bit for assisting pressurizing flow back through a spiral blade. The secondary rock breaking drill bit comprises a drill bit body, the blade anda cone; the blade is arranged at the top end of the drill bit body, and the blade and the drill bit body are of an integrated structure; and a gauge protection part is arranged on the outer wall of the blade. Through improvement for the rock breaking drill bit, primary cutting is conducted at the bottom of the drill bit to form primary rock debris, the rock debris returns to the cone under carrying flow back of a well-drilling fluid, the cone can conduct secondary breaking, the spiral blade slides in the longitudinal direction to be in surface contact with the well wall, a surface contact modeof the spiral blade is far greater than a line contact mode of a traditional straight blade, longitudinal vibration in the well-drilling process can be reduced, the rock debris generated by cutting of the drill bit flows back upwards under the action of vertical component force of the spiral face, fluid carrying the rock debris generates reactive force on the spiral blade surface, the drill bit can be pressurized, and thus the problems and deficiencies proposed in the background technology are effectively solved and overcome.

Owner:LANZHOU CITY UNIV

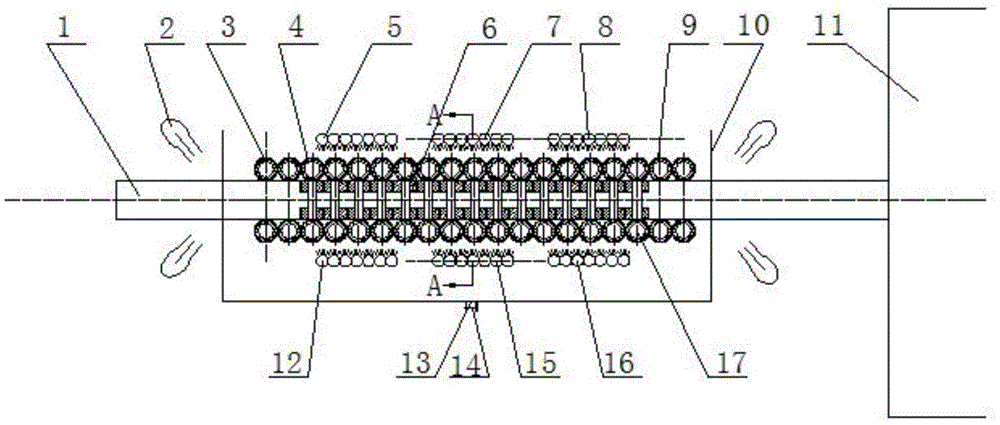

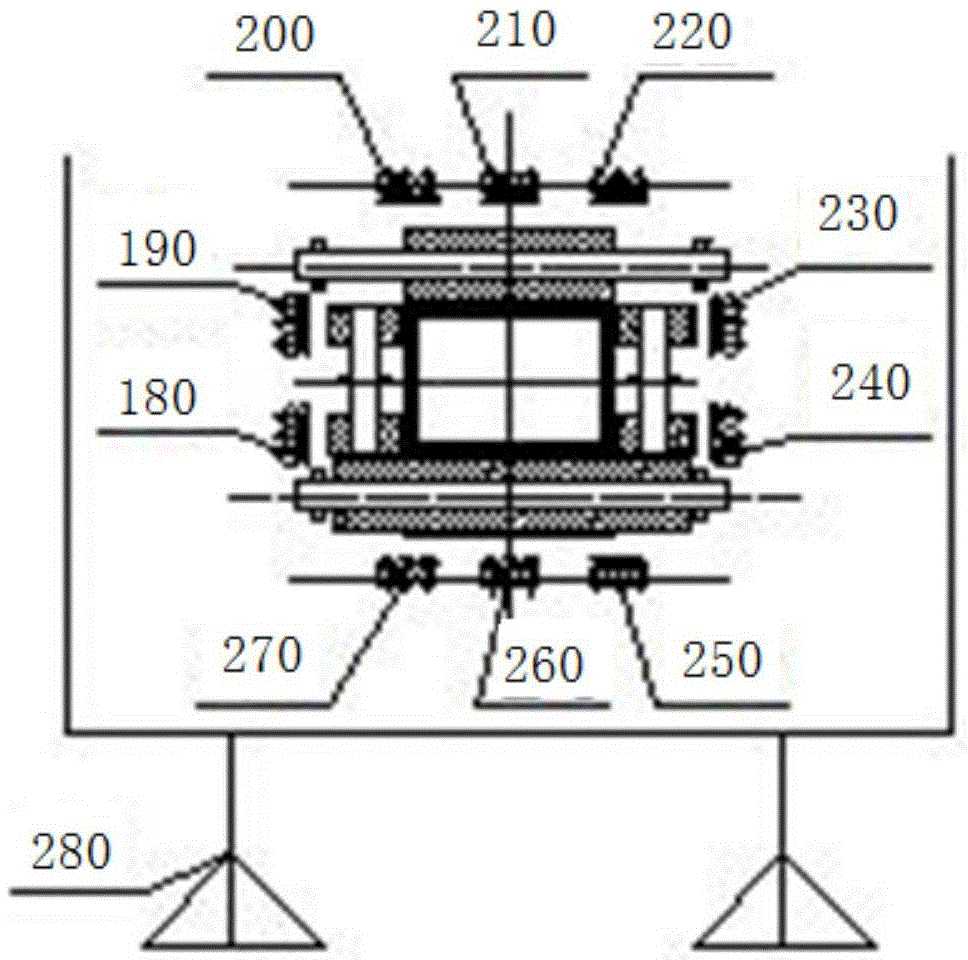

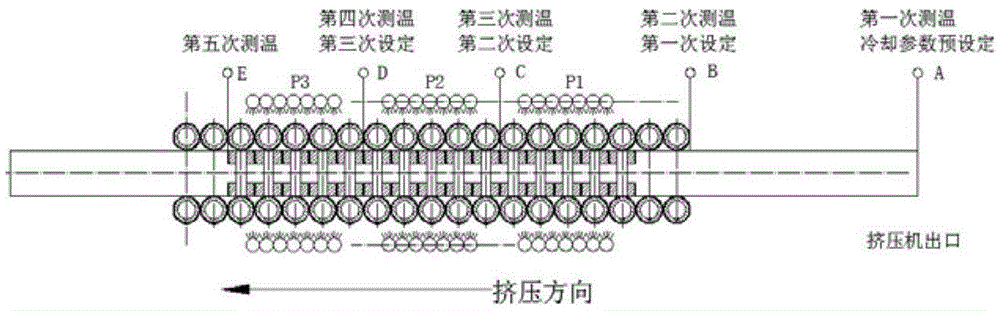

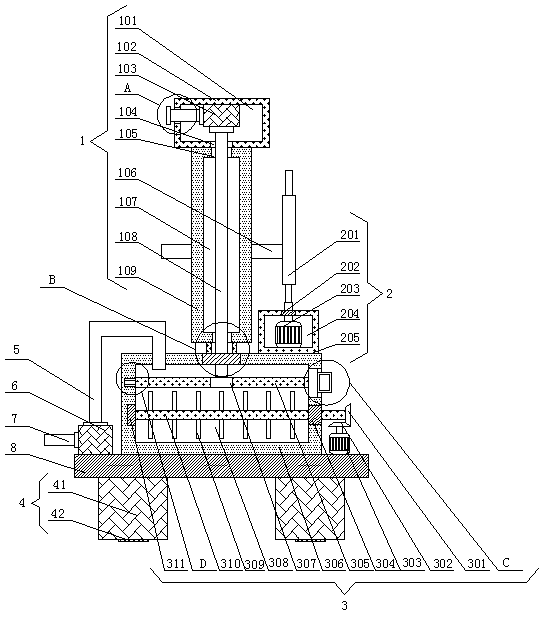

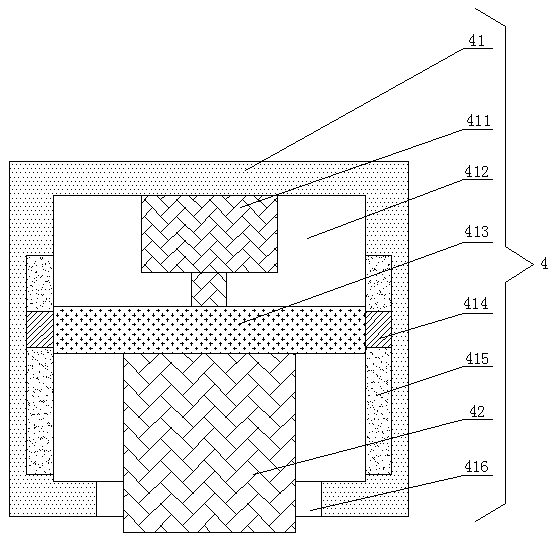

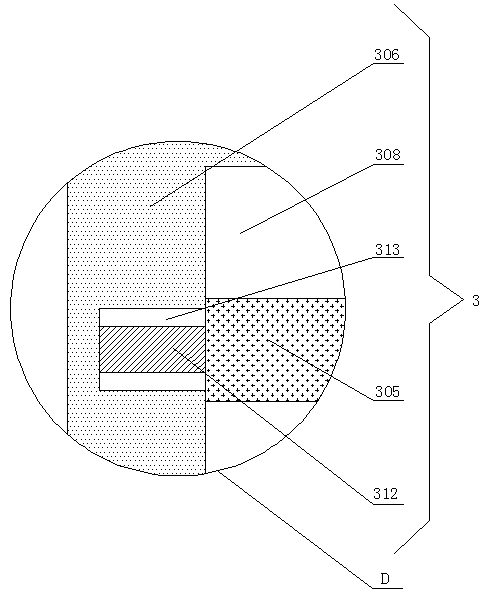

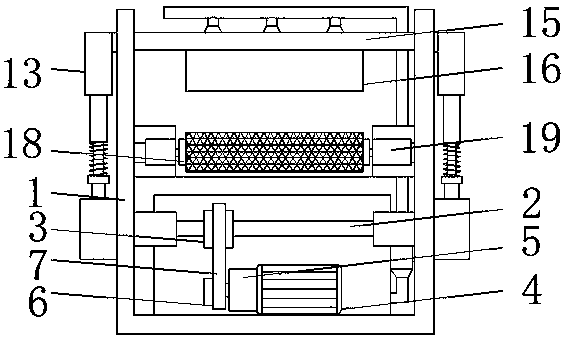

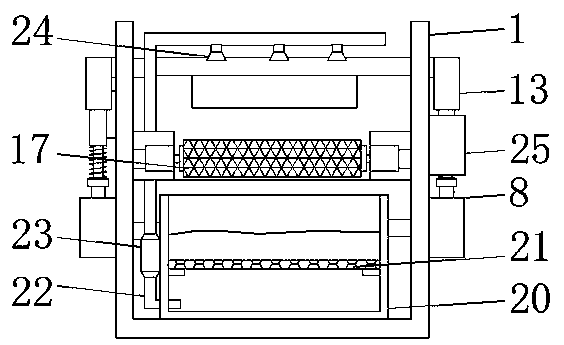

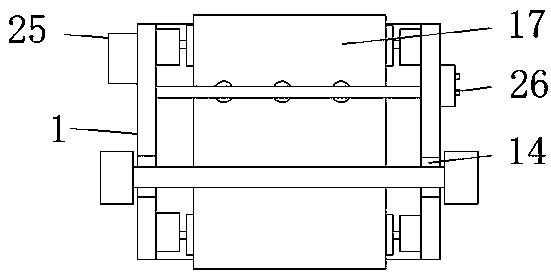

Device for avoiding online quenching deformation of aluminum profile

InactiveCN105648368ADecrease temperature cooling rate uniformity control requires accuracyProtectiveEngineeringQuenching

The invention discloses a device for avoiding online quenching deformation of an aluminum profile. The device comprises a water tank (10), wherein the water tank (10) is internally provided with a first driving felt roller (3), a second driving felt roller (9), a first driven felt roller (4) and a second driven felt roller (17); the first driving felt roller (3), the second driving felt roller (9), the first driven felt roller (4) and the second driven felt roller (17) form a channel for allowing an aluminum profile to be quenched to pass through; and the aluminum profile to be quenched is conveyed along the channel by virtue of a frictional force. According to the device, the cooling deformation of the aluminum profile is limited in a roller shaping way, so that the precision required by uniformity control of cooling speed is reduced; in addition, the aluminum profile is quenched by using the felt rollers, and a felt plays roles in protecting and cleaning the aluminum profile, so that the surface quality of the aluminum profile is improved.

Owner:NORTHEASTERN UNIV

Hot-rolling lubricating agent of magnesium and magnesium alloy plates and strips

Provided is a hot-rolling lubricating agent of magnesium and magnesium alloy plates and strips. Industrial white oil No.5 used as base oil is adopted for being matched with various composite additives, wherein the composite additives comprise an anti-abrasion agent, an oiliness agent, an oxidation-corrosion inhibitor, a sterilizing agent, an anti-foaming agent, a chelating agent, an emulsifying agent, a coupling agent and an auxiliary agent. The hot-rolling lubricating agent has the cooling, lubricating, cleaning and diffusion functions, reduces the magnesium-adhering degree of a roller, decreases the temperature of the roller, and reduces damage caused by adhesion of the surfaces of the plates and the strips.

Owner:GUANGXI UNIV

Self-rotation type blockage-proof farmland water conservancy irrigation device

InactiveCN108812210AAvoid damageEasy to irrigateWatering devicesCultivating equipmentsWater sourceFiltration

The invention discloses a self-rotation type blockage-proof farmland water conservancy irrigation device, and relates to the technical field of water conservancy irrigation. The device comprises a base, wherein the bottom face of the base is provided with a lifting mechanism, the left side of the upper surface of the base is fixedly connected with a first water pump, an input end of the first water pump is fixedly communicated with a first water inlet pipe, an output end of the first water pump is fixedly communicated with a second water inlet pipe, a blockage-proof mechanism is arranged abovethe base, an output mechanism is arranged above the blockage-proof mechanism, and the right side of the output mechanism is provided with a power mechanism. The self-rotation type blockage-proof farmland water conservancy irrigation device has the advantages that the filtration of a filter plate is utilized to perform primary filtration on a water source so as to prevent the blockage of an outputpipe caused by larger impurities in the water source, a stirring rod can be driven to rotate through the rotation of a first motor, thereby stirring the water source and preventing the blockage of the output pipe caused by the precipitation of fine sand in the water resource, so that the device has a blockage-proof function and improves the irrigation efficiency.

Owner:朱赵伟

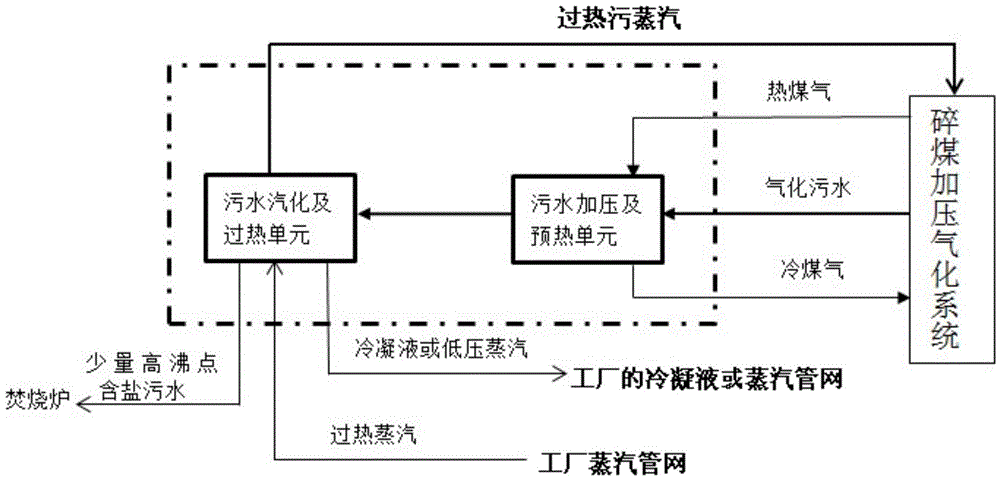

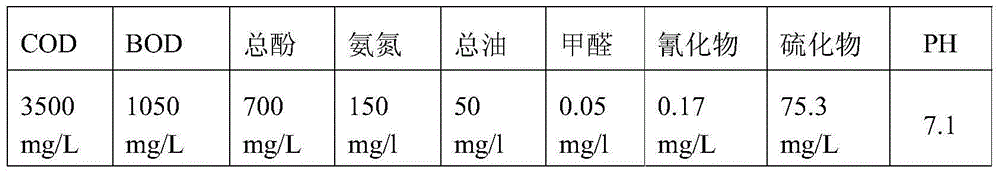

Process for treating wastewater from pressure gasification of smashed coal on fixed bed

ActiveCN104529040AEasy to handleCleaningWater/sewage treatmentGasification processes detailsWastewaterEngineering

The invention provides a process for treating wastewater from pressure gasification of smashed coal on a fixed bed. The process comprises the following steps of feeding the pretreated wastewater from the pressure gasification of smashed coal on the fixed bed into a wastewater pressurizing and preheating unit, pressurizing the wastewater to a predetermined value in the wastewater pressurizing and preheating unit, feeding the pressurized wastewater into a gas preheater, preheating the wastewater, feeding the preheated wastewater into a wastewater gasifying and overheating unit, gasifying the wastewater into saturated wastewater steam in the wastewater gasifying and overheating unit, further heating the saturated wastewater steam into overheated wastewater steam, and feeding the overheated wastewater steam which replaces the traditional gasifying agent to serve as a new gasifying agent into a gasifying furnace. Through the technical scheme of the invention, the problem of weak capacity of treating the wastewater from the gasification of coal in the prior art is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

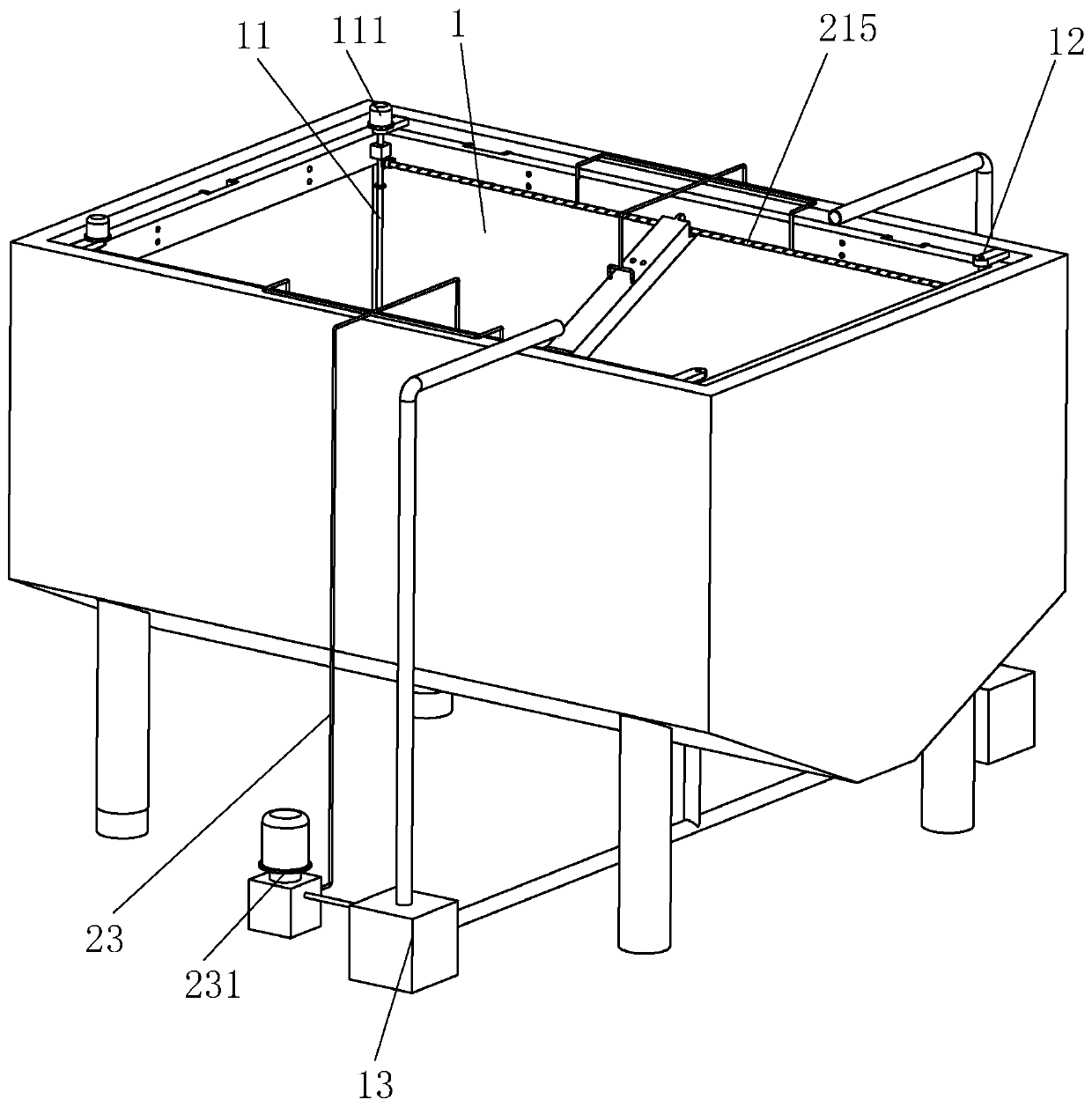

Cleaning and cutting all-in-one equipment for vegetable processing

InactiveCN109015777AImprove processing efficiencyReduce labor intensityMetal working apparatusFood treatmentVegetable processingDrive wheel

The invention discloses cleaning and cutting all-in-one equipment for vegetable processing. The cleaning and cutting all-in-one equipment for vegetable processing comprises a frame, a belt, cam-link mechanisms, a crossbeam and a cleaning pipe. A rotary shaft is mounted in the frame. A driven wheel is mounted on the rotary shaft. A driving motor is mounted on the lower portion of the rotary shaft.A driving wheel is mounted at the rotary shaft end of the driving motor. The driving wheel is in transmission connection with the driven wheel through the belt. The two ends of the rotary shaft are connected with the cam-link mechanisms mounted on the two side faces of the frame. Each cam-link mechanism comprises an outer cover, a cam, a roller driven part and a damping connecting rod, wherein thebottom of the damping connecting rod is inserted into the outer cover, the bottom end of the damping connecting rod is connected with the roller driven part arranged in the outer cover, and the roller driven part is arranged above the cam. The upper ends of the two damping connecting rods are connected with the two ends of the crossbeam through connecting blocks. The cleaning and cutting all-in-one equipment for vegetable processing has cleaning and cutting functions and is high in processing efficiency and convenient to use.

Owner:徐州佳联农业发展有限公司

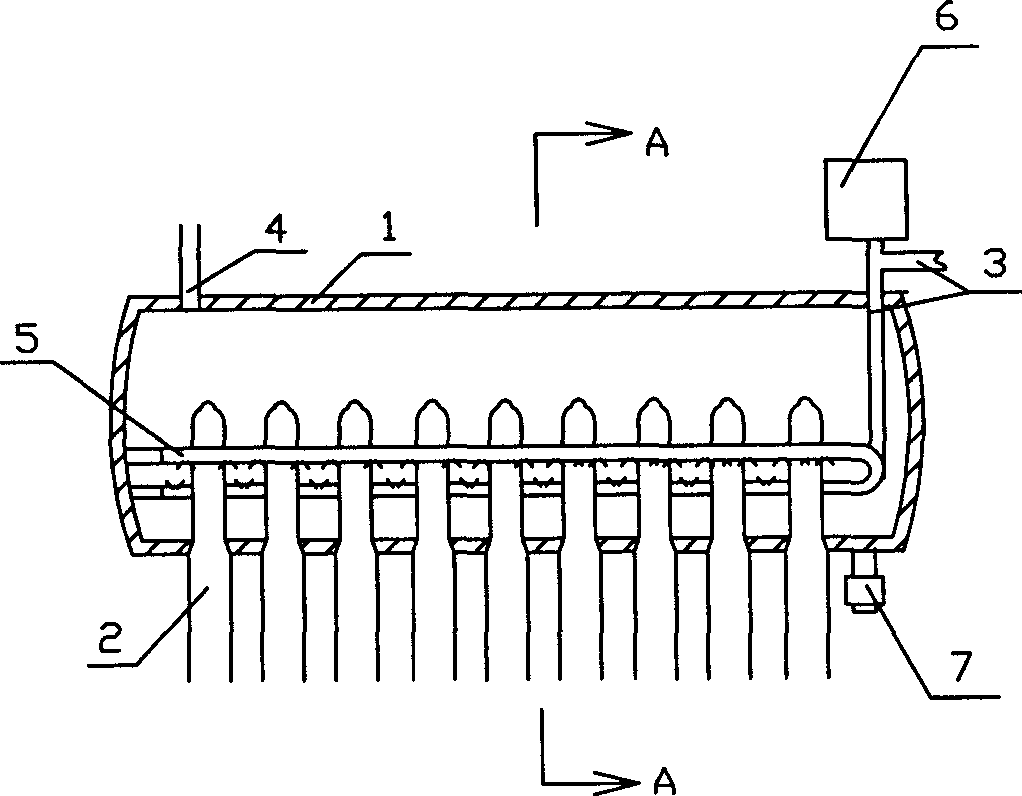

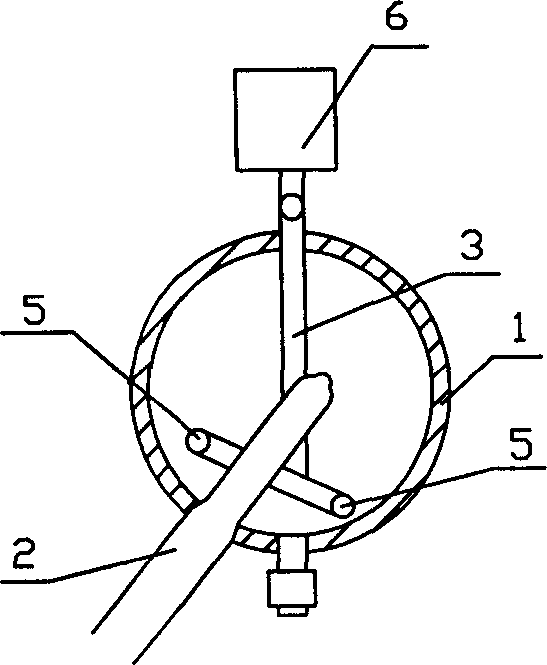

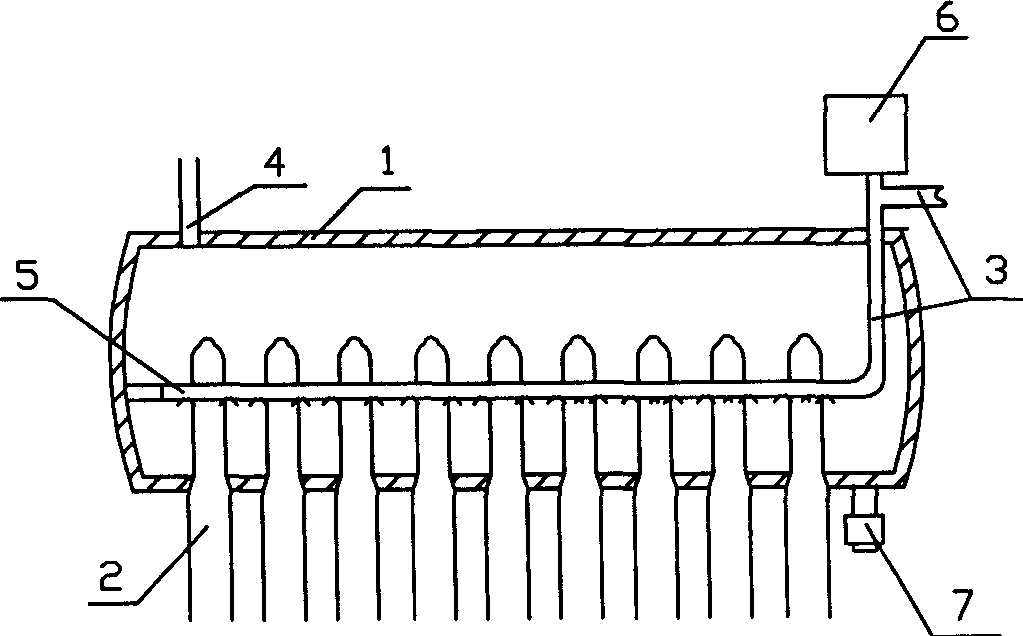

Automatic discharge-clean-drain-solar water heater

InactiveCN1743757AEmpty to achieveCleaningSolar heating energySolar heat devicesSolar waterWater spray

This invention refers to a solar energy water heater with automatic dirt cleaning and emptying function, which contains water tank, solar energy vacuum pipe inserted in water tank, water supply and discharge pipe, emptying pipe, said water tank having horizontal pipe with water spraying holes towards the solar energy vacuum pipe, horizontal pipe connected with water supply and discharge pipe which connected with emptying valve through three-way valve.

Owner:山东奥伦特太阳能科技有限公司

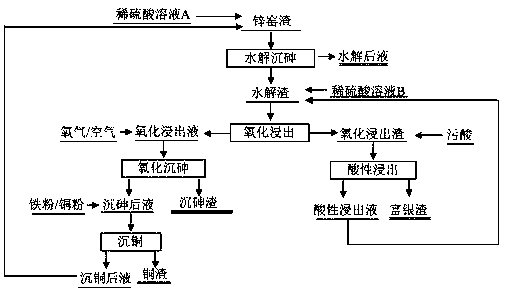

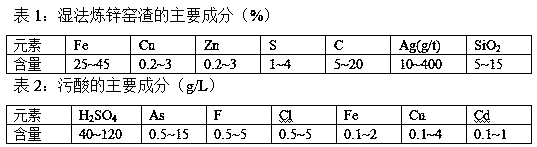

Method for comprehensive utilization of wet zinc smelting kiln residues and contaminated acid

The invention discloses a method for comprehensive utilization of wet zinc smelting kiln residues and contaminated acid and belongs to the technical field of comprehensive utilization of resources. The method utilizes wet zinc smelting kiln residues as raw materials and contaminated acid produced by a non-ferrous smelting enterprise as a leaching agent, and comprises orderly carrying out arsenic hydrolysis and precipitation, oxidative leaching and acid leaching so that iron, zinc, copper and arsenic in the zinc kiln residues enter the leaching solution and silver is enriched in the leaching residues, oxidizing the leaching solution into scorodite so that arsenic in the solution is separated and solidified, adding iron powder or copper powder into the solution after arsenic precipitation toobtain copper precipitates, adding zinc kiln residues into the solution after copper precipitation for arsenic hydrolysis and precipitation, conveying the treated water into a sewage treatment plantand carrying out treatment. The method can fully utilize the composition characteristics of the wet zinc smelting kiln residues and contaminated acid, realizes separation and recovery of valuable metals in the zinc kiln residues and realizes cleaning treatment on contaminated acid.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing electronic-grade high-purity quartz sand

PendingCN114378026AReduce intensityEffective dissociationSilicaCleaning using liquidsUltra high voltagePhysical chemistry

The invention discloses a method for preparing electronic-grade high-purity quartz sand, which comprises the following steps: washing quartz raw ore with ultrahigh-pressure water, crushing into 30 mm quartz blocks, finely selecting the quartz blocks, pretreating by adopting high-voltage electric pulse, crushing and screening to prepare-40-mesh quartz sand, carrying out magnetic separation on the quartz sand to remove magnetic minerals, and drying to obtain the electronic-grade high-purity quartz sand. Non-quartz silicate minerals are removed through flotation, residual impurity minerals on the surfaces of quartz sand and quartz particles are removed from flotation fine sand through dynamic acid pickling, the flotation fine sand is dried, calcined, rapidly cooled and acid-pickled, acid-pickled fine sand is graded to obtain quartz sand with a certain specification, and the quartz sand is subjected to vacuum degassing, cooling and packaging. It is ensured that the product meets the quality requirement of high-purity quartz sand for electronic products SJT 3328.1-2016, and the requirement of the domestic electronic industry for high-purity quartz sand is met.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Environment-friendly grinding and polishing solution

The invention provides an environment-friendly grinding and polishing solution. The polishing solution comprises the following components including, in percentage by weight, 2%-20% of organic acid, 0.5%-10% of a corrosion inhibitor, 0.5%-12% of a surfactant, 0.1%-15% of a brightening agent and the balance water. The polishing solution has no toxic influence of traditional nitric acid and has no environmental pollution caused by a phosphoric acid system. The adopted polishing solution is an organic acid environment-friendly system, is harmless to human bodies and the environment, can overcome polishing dead angles, and has the effects of a cleaning agent and a polishing agent, so that a polished product is clean and free of oil stains, and the surface has a mirror bright effect.

Owner:湖南华耀百奥医疗科技有限公司

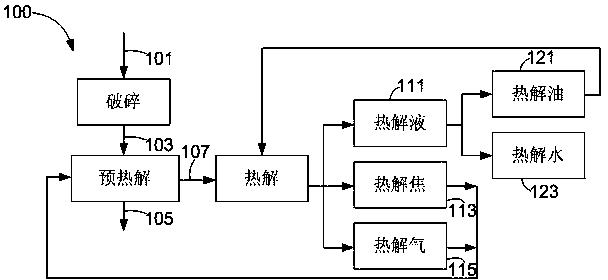

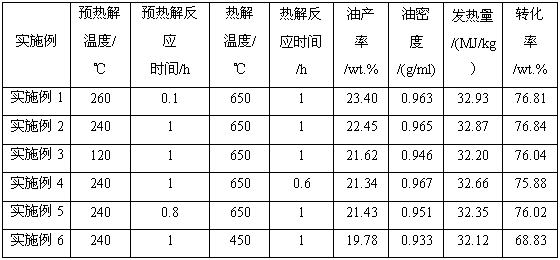

Method for preparing fuel oil through pyrolysis of waste non-setting adhesives

InactiveCN105273737AAlleviate tight supply situationReduce moisture contentLiquid hydrocarbon mixture productionSpecial form destructive distillationDistillationAdhesive

The invention provides a method for preparing fuel oil through pyrolysis of waste non-setting adhesives. The method comprises the following steps: (1) crushing the raw material waste non-setting adhesives, then placing the crushed waste non-setting adhesives in a pyrolysis reactor carrying out heating to a pre-pyrolysis temperature in a pre-pyrolysis time period and then carrying out pre-pyrolysis so as to obtain a pre-pyrolysis product; (2) carrying out heating to a pyrolysis temperature in a pyrolysis time period and then carrying out pyrolysis so as to obtain pyrolysis products, wherein the pyrolysis products comprise pyrolysis liquid and pyrolysis gas; and (3) subjecting the pyrolysis liquid to distillation so as to obtain pyrolysis oil of different fractions.

Owner:SHANGHAI FUYONG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com