Concentrated ink supply system used in satellite type flexo printing machine

A flexographic printing machine and ink supply technology, applied in printing machines, rotary printing machines, rotary printing machines, etc., can solve the problems of inconvenient cleaning and replacement of ink tanks, manual adjustment, and unstable pressure in the ink chamber, and achieve automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

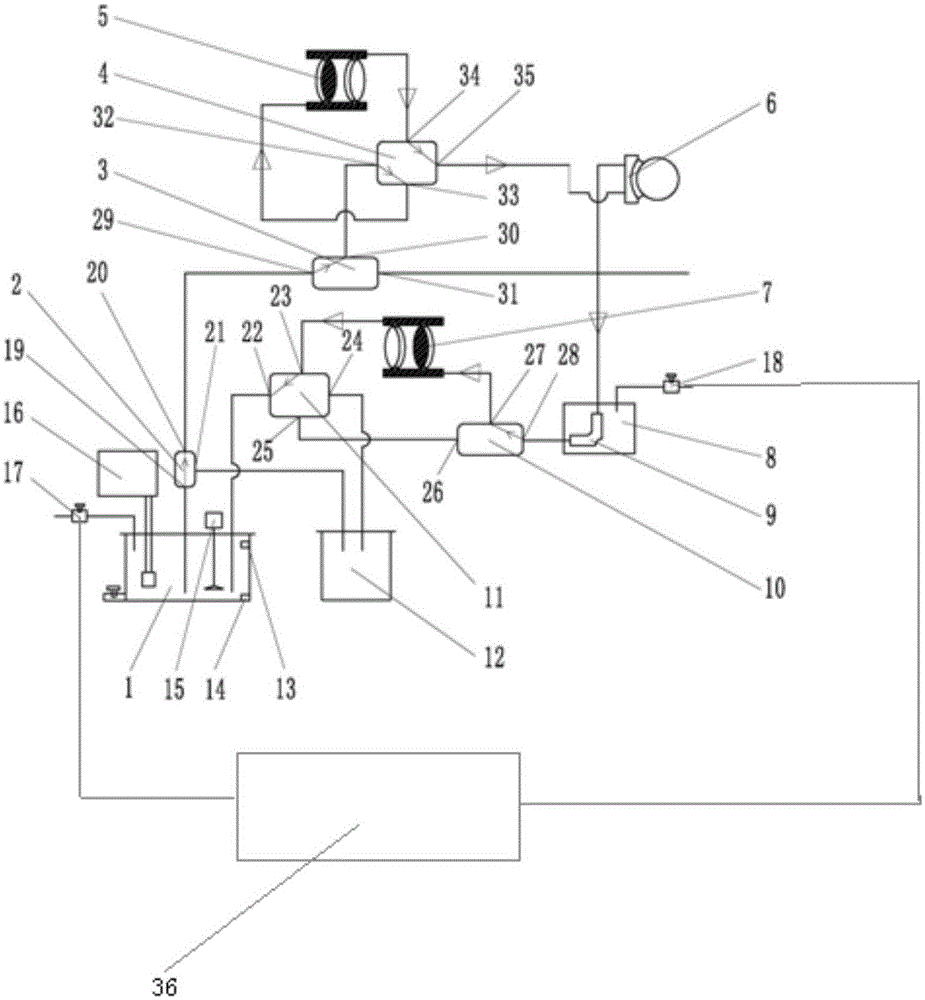

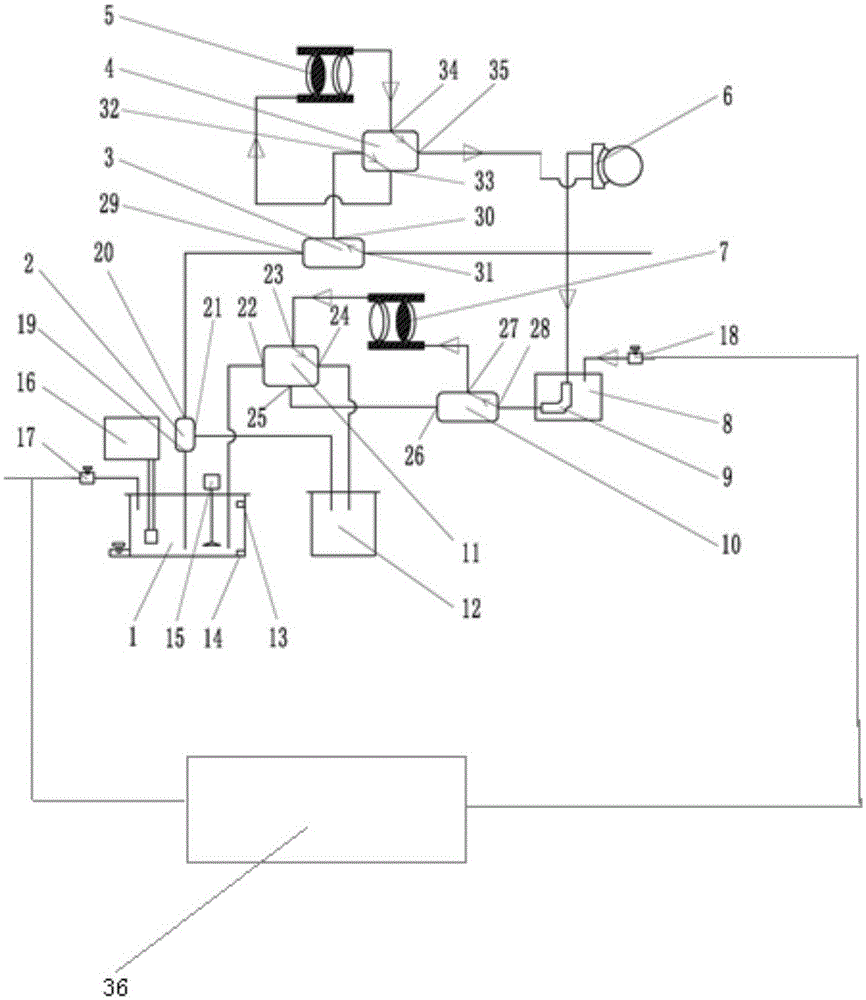

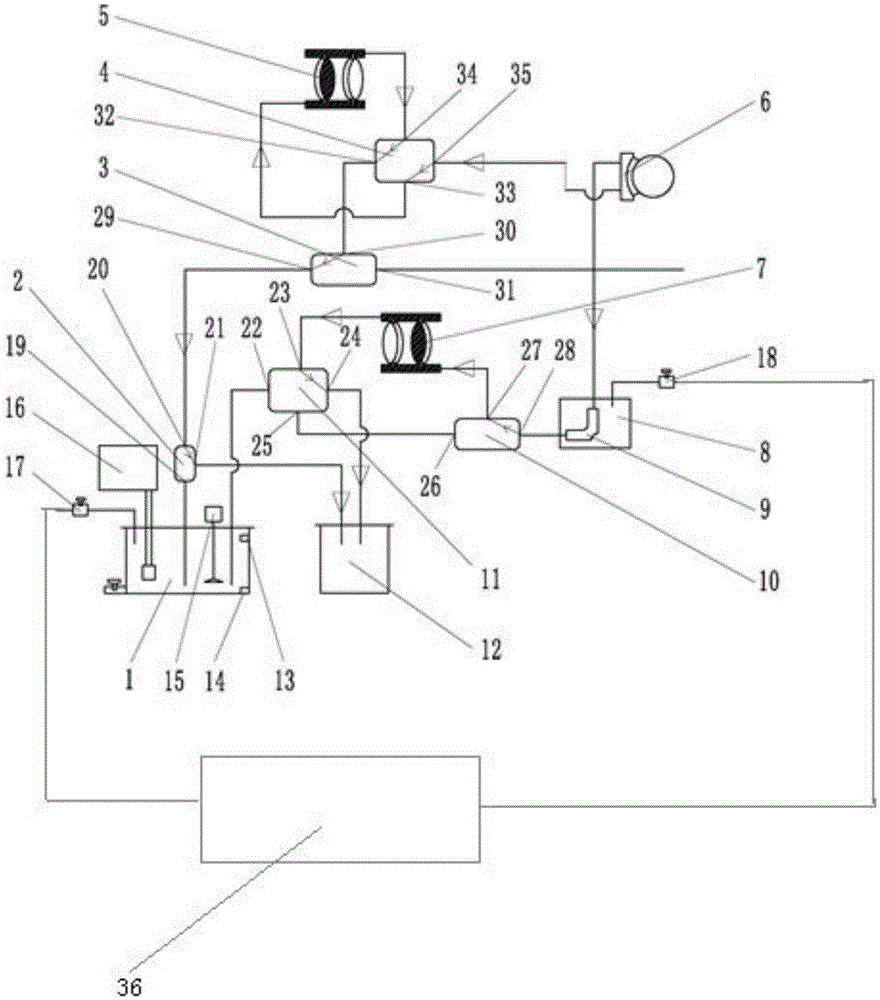

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] A centralized ink supply system for a satellite flexographic printing machine of the present invention, such as figure 1 As shown, the ink barrel 1 is included, and the ink barrel 1 forms a circuit with the ink pump A5, the ink chamber 6, the ink tank 8, and the ink pump B7 through pipelines. The pipeline inside the ink tank 8 is a connecting pipe 9 with several through holes. , between the ink barrel 1 and the ink pump A5, a Y-type pneumatic three-way ball valve 2 and an L-type pneumatic three-way ball valve A3 are arranged in sequence, an L-type pneumatic four-way ball valve A4 is arranged between the ink pump A5 and the ink chamber 6, and the ink tank 8 and ink pump B7 are provided with L-shaped pneumatic three-way ball valve B10, between ink pump B7 and ink barrel 1 are provided with L-shaped pneumatic four-way ball valve B11, Y-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com