Clean wiping cloth and its producing process

A manufacturing process and technology of wiping cloth, which is applied in cleaning wiping cloth and its manufacturing process, cleaning fabric and its manufacturing field, can solve the problems of durability, pollution of the environment, and difficulty in degradation, etc., and achieve the effect of high-strength cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

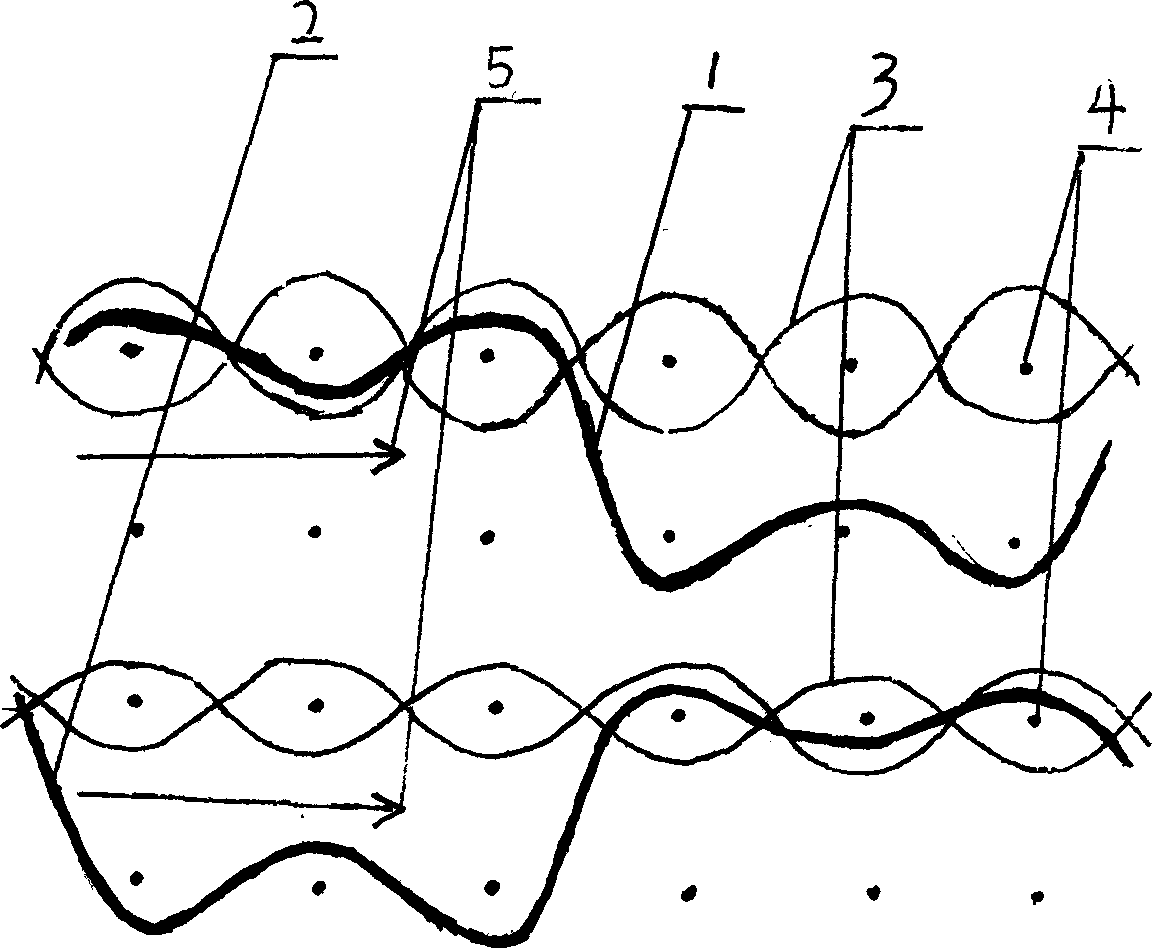

Image

Examples

Embodiment Construction

[0024] Product parameters: (16.7×4+21×2)×21×2×216×220, inside the brackets is the ply and number of the cashmere warp and the number of the ground warp, and 21×2 outside the brackets indicates the ply and yarn number of the weft yarn, 216 represents the number of warp yarns of 10 cm, and 220 represents the number of weft yarns of 10 cm.

[0025] The technological process of the cleaning wipe cloth of the present invention is as follows: compounding and twisting, warping, weaving, fiber opening, gluing and shaping.

[0026] (1) Composite twisting process

[0027] Merge the required polyester / nylon composite yarns by 2-12, and add 50-400 twists / m twist.

[0028] (2) Warping process

[0029] Focus on controlling the uniformity of the tension of the single yarn. One is to wrap five turns on the tension roller, the other is to reduce the speed to 250m / min, and the speed is 50m / min when reversing the shaft. Cover each bobbin with a plastic bag to facilitate the yarn backing. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com