Method for regenerating high-performance permanent magnet by degenerated rare earth permanent magnet material

A technology for regenerating permanent magnets and rare-earth permanent magnets, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of high requirements for magnetic properties and composition uniformity, increased difficulty in recycling, and low performance indicators of magnetic powder. , to avoid further degradation, easy control of magnetic properties, and good recovery of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: get degenerate Nd 16 Fe 76 B 8 It is 1000 grams of rare earth permanent magnets, mechanically crushed to a material diameter of 3 mm, and 930 grams of degraded rare earth permanent magnet materials are selected by electromagnetism, and placed in 10 -5 -bar vacuum dehumidification for 1.5 hours; at vacuum: 10 -6 bar, temperature: at 70°C, input pure hydrogen (H 2 ), hydrogen pressure: 10bar, carry out hydrogen explosion (HD) for 2 hours, and the degenerated rare earth permanent magnet material becomes hydrogen explosion (HD) micropowder; under the atmosphere of nitrogen protection, carry out jet milling to its hydrogen explosion (HD) micropowder, its The particle size is ground to 3-6 microns; according to the calculated atomic weight ratio, Cu and Co micropowders with a particle size of 3-6 microns are uniformly mixed, wherein the Cu content remains unchanged at 0.25 at%, and the Co content varies from 3.5 at% to 10 at%. See Table 1 below:

[0056] ...

Embodiment 2

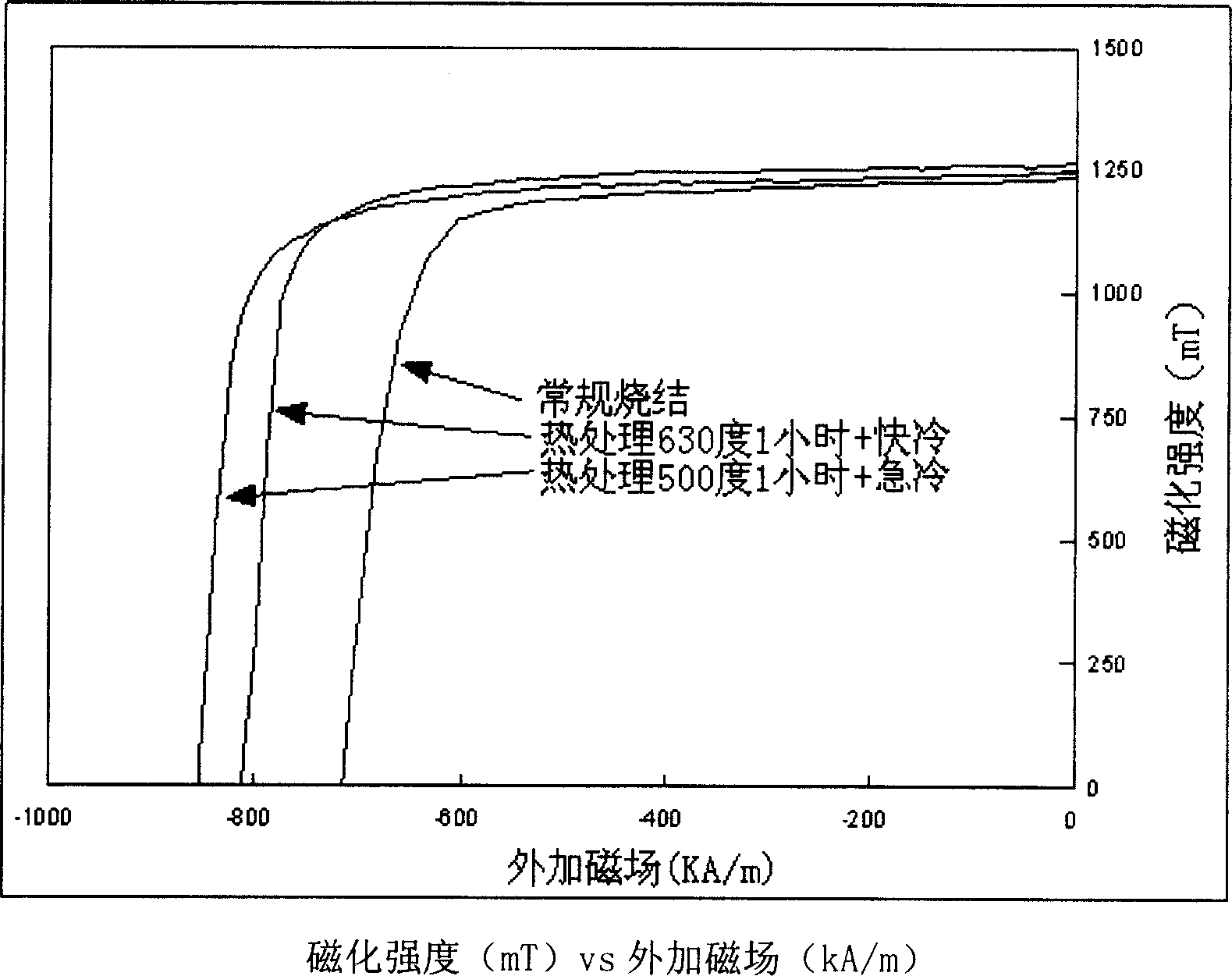

[0062] Embodiment 2: take degenerate Nd 16 Fe 76 B 8 1000 grams of rare earth permanent magnets are mechanically crushed to a particle size of 5 mm, and 940 grams of degraded rare earth permanent magnet materials are selected by electromagnets, and placed in 10 -5 -bar vacuum dehumidification for 2 hours; using the hydrogen explosion (HD) method and adding element Cu to mix the powder, under the radial magnetic field, the mixed powder is pressed and molded according to the required magnetic field direction distribution, and the conventional sintering and heat treatment are respectively used Two other heat treatment methods: A, heat treatment at 500°C for 1 hour under vacuum after rapid cooling (liquid nitrogen cooling under vacuum) and B, heat treatment at 630°C under vacuum for 1 hour after rapid cooling (air cooling under vacuum), and made Two sets of anisotropic regenerative permanent magnets. Its magnetic properties can be restored to 100% of the original performance pa...

Embodiment 3

[0070] Embodiment 3: take degenerate Nd 16 Fe 76 B 8 1000 grams of rare earth permanent magnets, crushing and dehumidification steps are the same as in Example 1, adopting disproportionation reaction (HDDR) to recycle the degraded rare earth permanent magnets, and the degraded rare earth permanent magnets after dehumidification are placed in a vacuum for 10 -6 bar, at a temperature of 700-880°C, input pure hydrogen (H 2 ), the hydrogen pressure is 15bar, and the disproportionation reaction of the degraded rare earth permanent magnet material occurs: HydrogenationDisproportionation Desorption Recombination (HDDR), the time is 2 hours, the degraded rare earth permanent magnet material becomes anisotropic magnetic powder, and the fineness of the magnetic powder is about 500 microns . Further add high magnetocrystalline anisotropy field element Dy, the addition amount of Dy is 2at%, or add alloy Dy 3 Co, the addition amount is 5wt%, mix well. Add epoxy resin according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com