Secondary rock breaking drill bit for assisting pressurizing flow back through spiral blade

A blade and helix technology, applied in the field of rock-breaking drill bits, can solve the problems of drill bit stability, improve drilling costs, etc., achieve the effects of small vibration amplitude, improved service life, and guaranteed cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

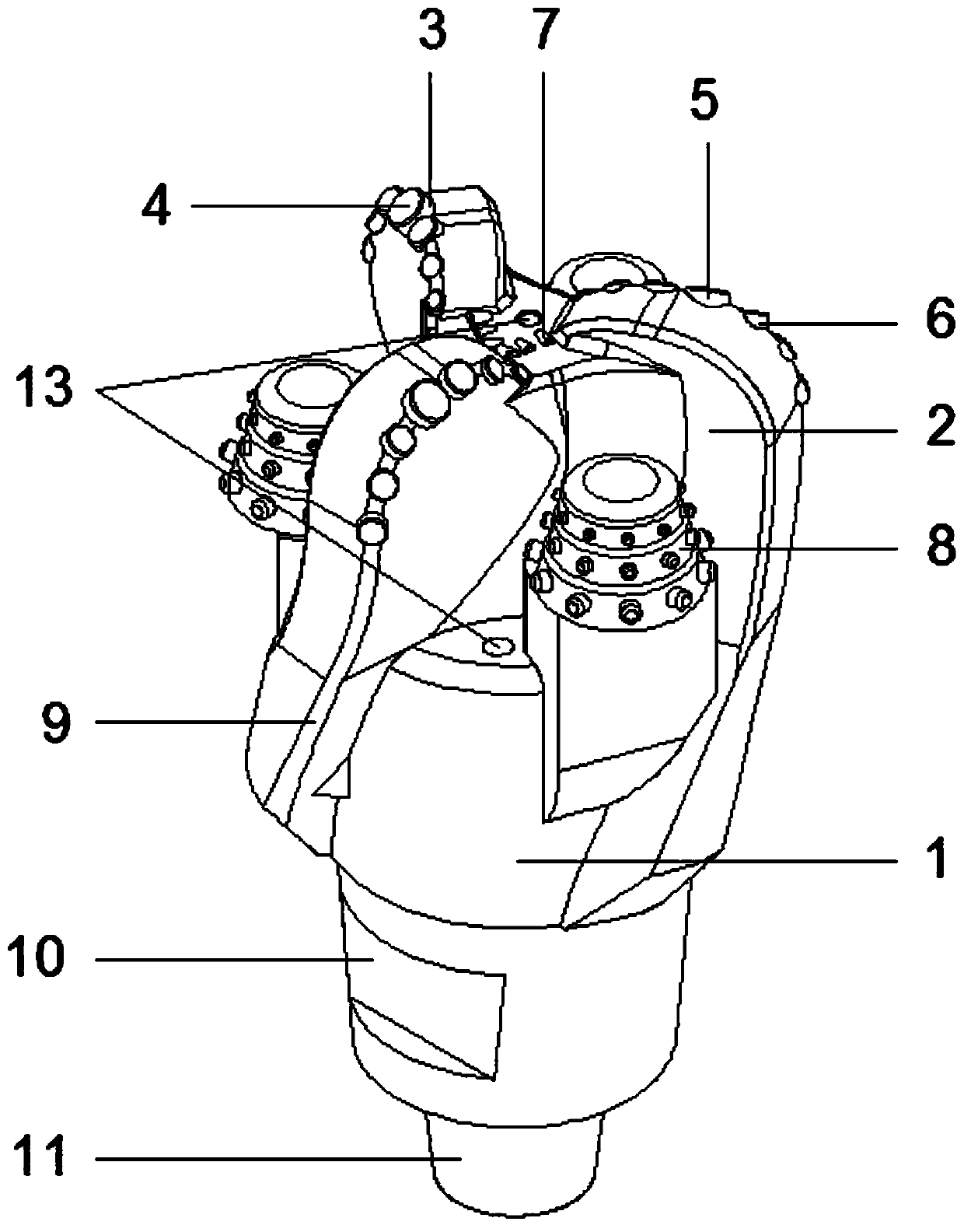

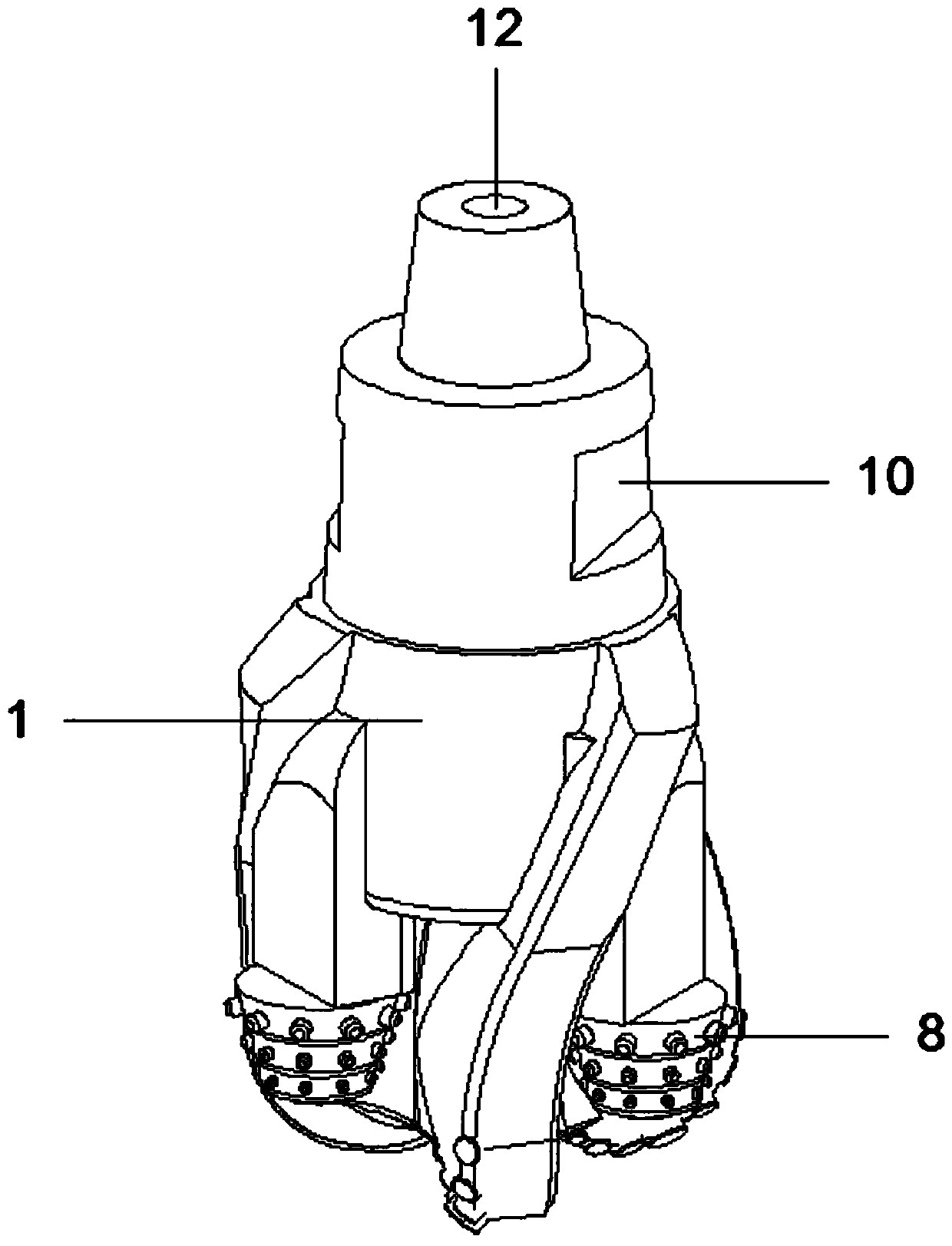

[0037] A secondary rock-breaking drill bit with helical blade assisted pressurization and flowback, comprising: drill bit body 1, blade 2, tooth column 3, composite piece 4, top tooth 5, bevel tooth 6, single tooth 7, and cone 8 , gauge part 9, shackle groove 10, screw thread 11, runner 12, water eye 13; blade 2 is arranged on the top of drill body 1, and blade 2 and drill body 1 are integrated structure; diameter gauge part 9 is arranged on the outer wall of the blade 2; the top tooth 5 is inlaid and welded on the top of the blade 2; the bevel teeth 6 are inlaid and welded on the top of the blade 2, and the bevel teeth 6 are located on both sides of the top tooth 5; 5 and bevel teeth 6 are sintered by tooth column 3 and composite sheet 4; single tooth 7 is inlaid and welded and installed in the middle of the top of drill bit body 1; cone 8 is installed on the upper part of drill bit body 1; shackle groove 10 is set in On the outer wall of the lower part of the drill body 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com