High intensity and large length-diameter ratio ceramic spinneret and production method

A technology of large aspect ratio and spinneret, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc., can solve problems such as deformation of metal parts, and achieve excellent high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Select Si 3 N 4 The biscuit is drilled by the laser directional distribution drilling technology, and the dense Si is obtained after sintering. 3 N 4 spinneret. The aspect ratio of the spinneret hole is 15, the pitch of the spinneret hole is 1 mm, and the diameter of the spinneret hole is 190 μm. The surface tension of the spinneret and the PAN-DMSO spinning solution is more than 30% smaller than that of conventional stainless steel spinneret materials through surface tension measurement and comparison.

Embodiment 2

[0018] Choose Al 2 o 3 Or Sialon green body or pre-sintered high-strength material is punched in the same manner as in the embodiment, the hole distance is 0.8 mm, the hole diameter is 0.2 mm, and the rest is the same as in embodiment 1.

Embodiment 3

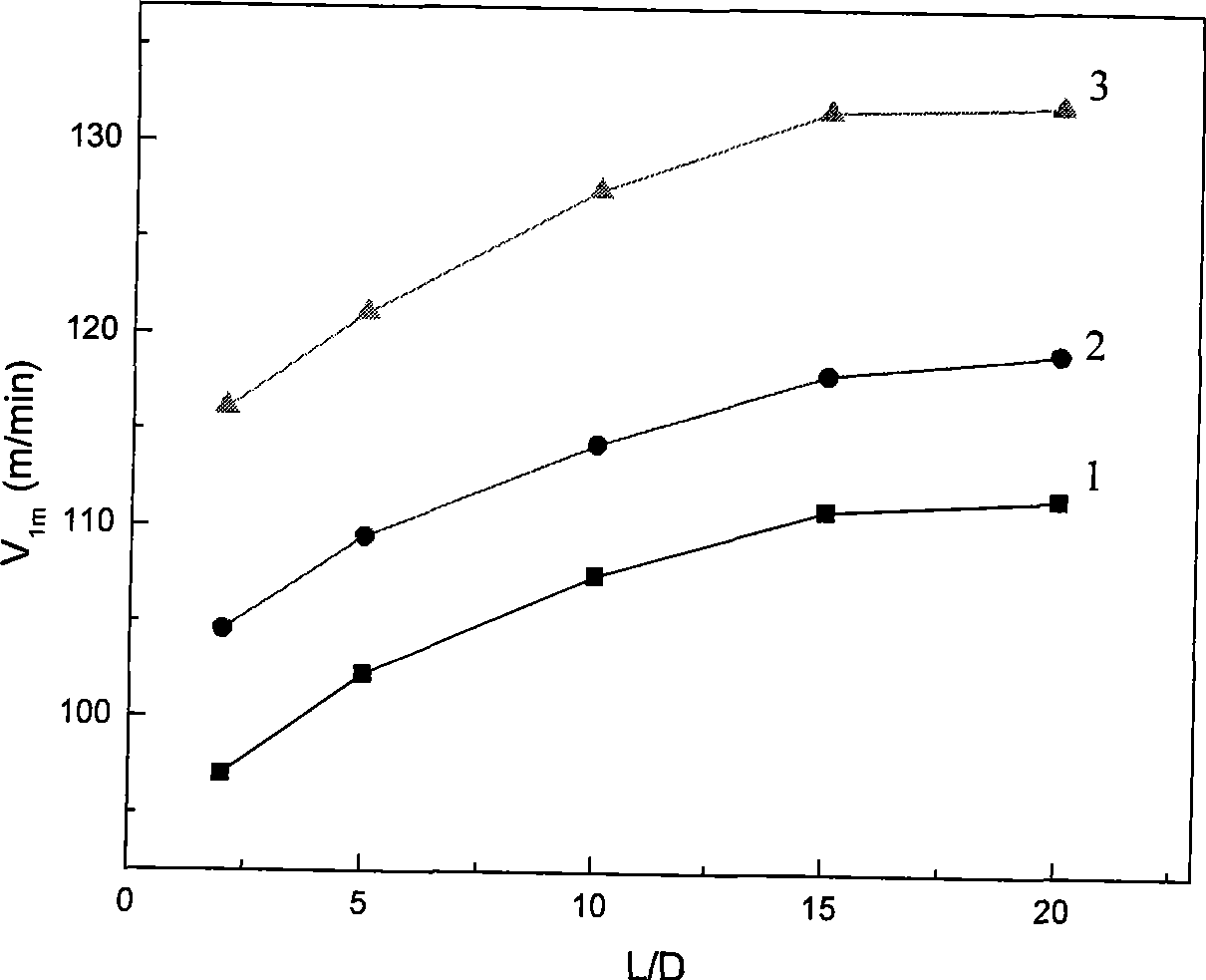

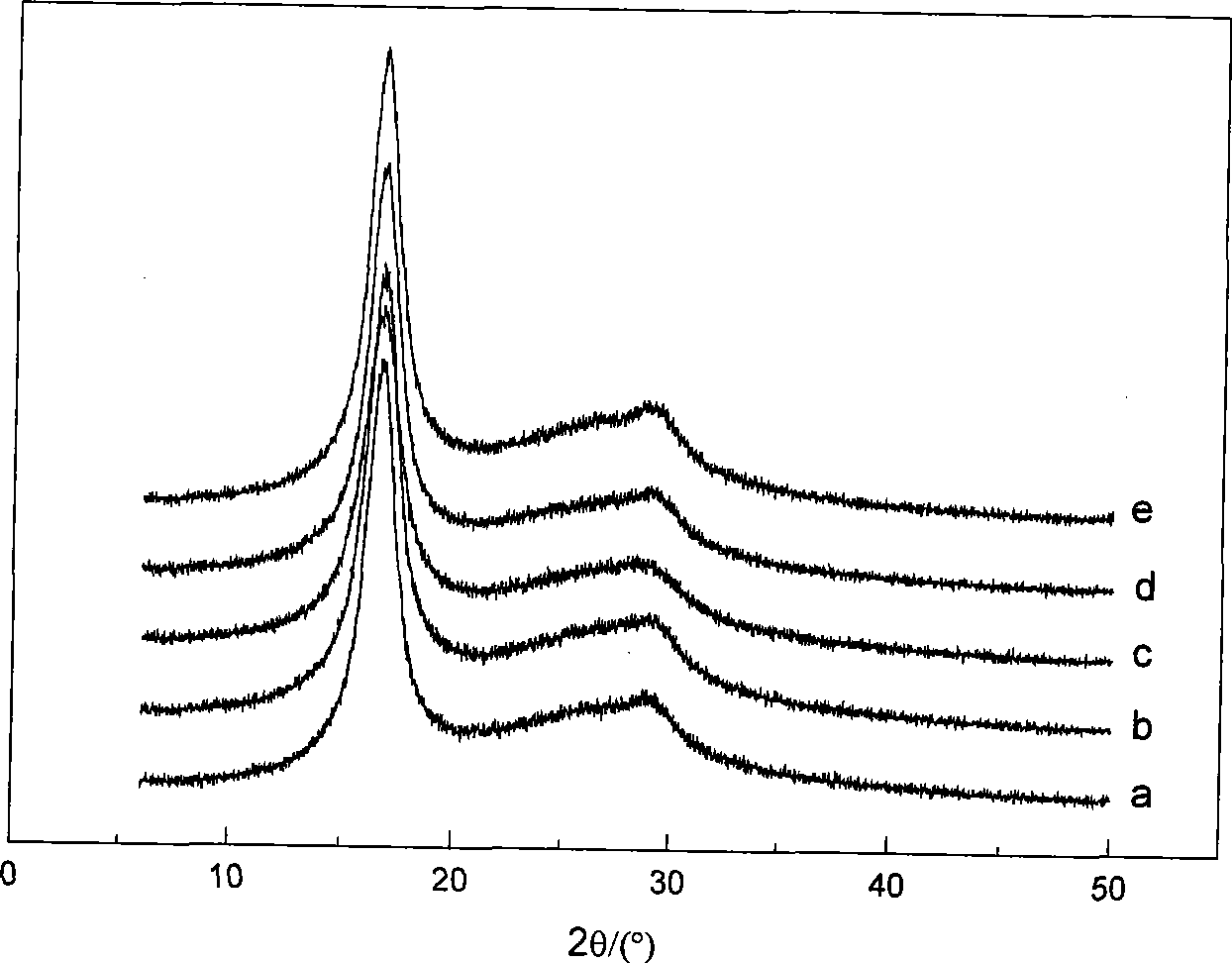

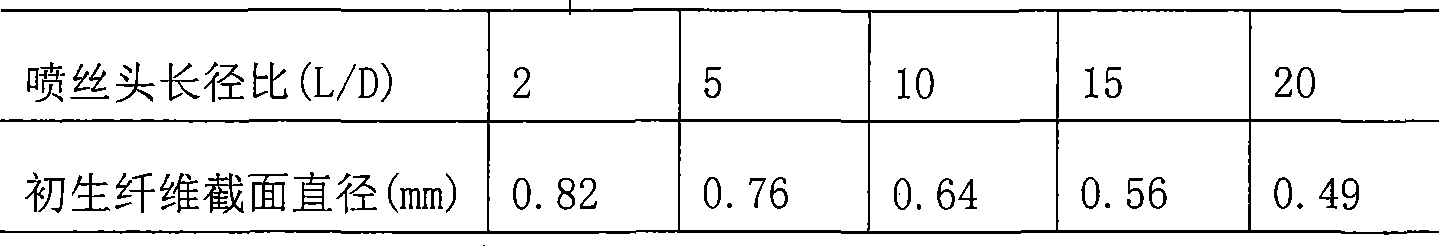

[0020] The influence of different aspect ratio ceramic spinnerets of embodiment 1 or 2 on the original structure and properties of PAN was tested.

[0021] 1 Test materials and conditions

[0022] 1.1 Experimental raw materials: PAN copolymer (acrylonitrile: itaconic acid = 98:2): Shanghai Synthetic Fiber Research Institute, viscosity average molecular weight Wv = 7.8×10 4 g·mol -1 ;

[0023] Dimethyl sulfoxide DMSO (analytical pure): Shanghai Wulian Chemical Co., Ltd.;

[0024] 1.2 Experimental conditions

[0025] The length-to-diameter ratio (L / D) is 2,5,10,15,20 respectively, and the single-hole ceramic spinneret with aperture=0.2mm; uses DMSO as solvent, and configures a spinning stock solution with a concentration of 23%; spinning temperature They are 60°C, 65°C, and 70°C respectively; the concentration of the coagulation bath is 50%, and the temperature is 40°C; the extrusion speed of the stock solution is 1.4m / min and 3.4m / min respectively; the height of the air lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com