Method for comprehensive utilization of wet zinc smelting kiln residues and contaminated acid

A technology for hydrometallurgical zinc smelting and kiln slag, which is applied in the field of comprehensive utilization of resources, can solve the problems of large volume of hazardous waste slag, difficulty in meeting environmental protection requirements, and high treatment costs, and achieves the effects of clean treatment, resource saving and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

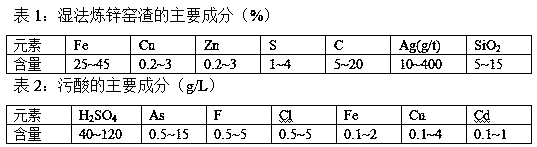

[0023] Example 1: In terms of mass percentage, the main components of the zinc hydrometallurgy kiln slag in this example are: Fe 39.54%, Cu1.16%, Zn 2.28%, As 0.65%, S 4.95%, Ag 214.3g / t; The main components of dirty acid are: H 2 SO 4 43.23g / L, F0.69g / L, Cl1.25g / L, Cu0.10g / L, As1.22g / L;

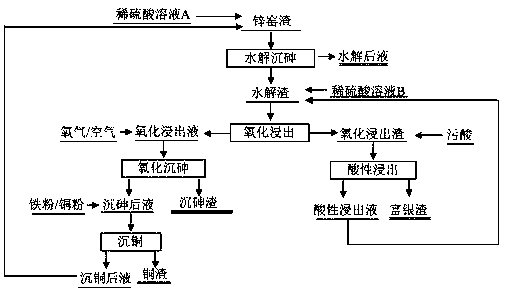

[0024] A method for comprehensive utilization of zinc hydrometallurgy kiln slag and dirty acid, the specific steps are as follows:

[0025] (1) At room temperature, add 150g of zinc hydrolysis kiln slag into 3.0L of dilute sulfuric acid solution A for hydrolysis treatment until the pH of the solution is 4.0 to obtain hydrolyzed slag and hydrolyzed liquid; among them, dilute sulfuric acid solution A The pH value is 1, and the liquid-solid ratio mL:g of the dilute sulfuric acid solution A to the zinc hydrometallurgy kiln slag is 20:1;

[0026] (2) Under the conditions of a temperature of 60°C and an oxygen partial pressure of 0.3Mpa, place the hydrolyzed slag obtained in step (1) in dilute ...

Embodiment 2

[0030] Example 2: In terms of mass percentage, the main components of the zinc hydrometallurgy kiln slag in this example are: Fe33.24%, Cu1.26%, Zn2.71%, As0.79%, S4.74%, Ag205. 0g / t; the main components of dirty acid are: H 2 SO 4 43.23g / L, F0.69g / L, Cl1.25g / L, Cu0.10g / L, As1.22g / L;

[0031] A method for comprehensive utilization of zinc hydrometallurgy kiln slag and dirty acid, the specific steps are as follows:

[0032] (1) At a temperature of 75°C, add 200g of zinc hydrolysis kiln slag into 1.3L of dilute sulfuric acid solution A for hydrolysis treatment until the pH of the solution is 5.1 to obtain hydrolyzed slag and hydrolyzed liquid; among them, dilute sulfuric acid solution The pH value of A is 0.5, and the liquid-solid ratio mL:g of dilute sulfuric acid solution A to zinc hydrometallurgy kiln slag is 6.5:1;

[0033] (2) Under the conditions of a temperature of 100°C and an oxygen partial pressure of 0.5Mpa, place the hydrolyzed slag obtained in step (1) in dilute ...

Embodiment 3

[0037] Example 3: In terms of mass percentage, the main components of the zinc hydrometallurgy kiln slag in this example are: Fe25.43%, Cu1.03%, Zn2.02%, As1.05%, S4.75%, Ag174. 3g / t; the main components of dirty acid are: H 2 SO 4 89.70g / L, F2.36g / L, Cl3.51g / L, Cu0.28g / L, As8.54g / L;

[0038] A method for comprehensive utilization of zinc hydrometallurgy kiln slag and dirty acid, the specific steps are as follows:

[0039] (1) At a temperature of 70°C, add 200g of zinc hydrolysis kiln slag into 1.0L of dilute sulfuric acid solution A for hydrolysis treatment until the pH of the solution is 6.0 to obtain hydrolyzed slag and hydrolyzed liquid; among them, dilute sulfuric acid solution The pH value of A is 1.5, and the liquid-solid ratio mL:g of dilute sulfuric acid solution A to zinc hydrometallurgy kiln slag is 5:1;

[0040] (2) Under the conditions of a temperature of 85°C and an oxygen partial pressure of 0.4Mpa, place the hydrolyzed slag obtained in step (1) in dilute sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com