Method and device for treating nitrous oxide tail gas using fuel cell

A fuel cell and nitrous oxide technology, which is applied in fuel cells, chemical instruments and methods, and nitrous oxide capture, can solve problems such as high energy consumption and complex systems, and achieve clean and efficient treatment, wide application prospects, and excellent performance Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

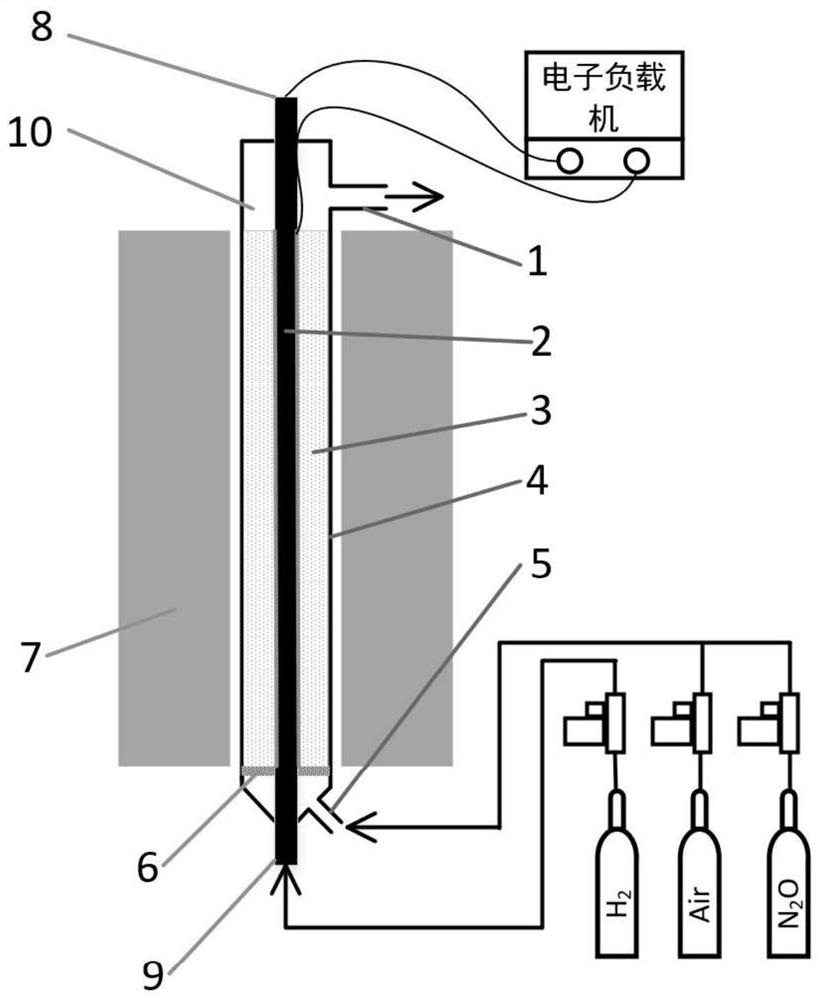

[0029] A device for treating nitrous oxide tail gas using a fuel cell of the present application includes a solid oxide fuel cell, the structure of which is as follows figure 1 As shown, it includes a casing 4, a fuel cell tube 2 and a cathode bed material 3; the casing 4 is provided with a cathode gas inlet 5 and a cathode gas outlet 1, and the cathode gas includes nitrous oxide to be treated; the casing 4 is provided with At least one fuel cell tube 2, both ends of the fuel cell tube 2 are provided with an anode gas inlet 9 and an anode gas outlet 8; a cavity 10 is formed between the inner wall of the casing 4 and the cathode outer wall of the at least one fuel cell tube 2, and the cathode bed The material 3 is filled in the cavity 10; the shell 4 is provided with an air distribution plate 6, and the cathode gas flows from the cathode gas inlet 5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com