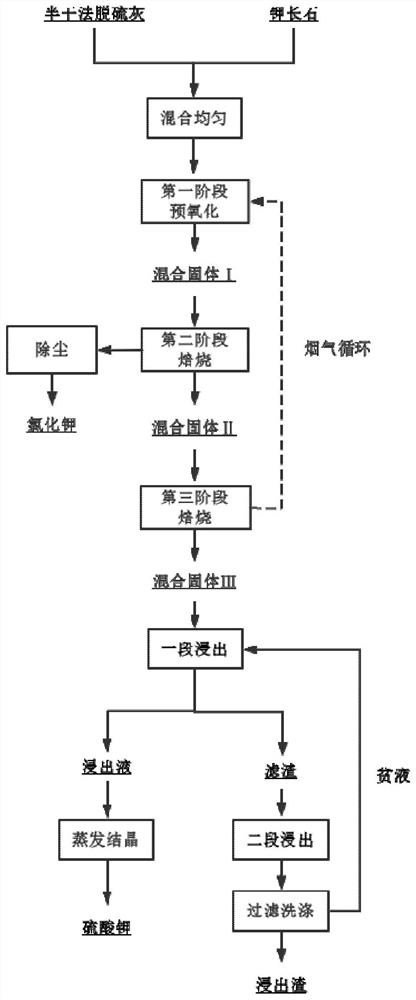

Method for preparing sylvite by pre-oxidizing-roasting semi-dry desulfurization ash and potassium feldspar

A semi-dry desulfurization and potassium feldspar technology, which is applied in chemical instruments and methods, alkali metal sulfite/sulfite, potash fertilizer, etc., can solve high oxidation cost, difficult subsequent treatment of waste liquid, and is not suitable for industrial production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Adding K to semi-dry desulfurization ash in a steel plant 2 Potassium feldspar with an O content of 8.6% is mixed according to the mass ratio of potassium feldspar: desulfurization ash is 1:5, and the first stage pre-oxidation is carried out at 400 °C, the oxidation time is 1.5h, and the oxygen content is 21% ( The remaining gas is nitrogen), and the pre-oxidation rate is 96.5%. Then, the pre-oxidized product is roasted in the second stage at 800° C. for 3 hours, and the recovery rate of potassium chloride obtained after the flue gas and dust is collected is 96.2%. The remaining solids are roasted at 1050°C in the third stage, the roasting time is 2h, the third-stage roasting flue gas is circulated to pre-oxidation, the third-stage roasted product is subjected to two-stage countercurrent leaching, and the first-stage countercurrent leaching uses the leachate obtained from the second-stage countercurrent. The roasted product is leached, the leaching solution obtained fr...

Embodiment 2

[0034] Adding K to semi-dry desulfurization ash in a steel plant 2 Potassium feldspar with an O content of 10.6% is mixed according to the mass ratio of potassium feldspar: desulfurization ash of 1:3, and pre-oxidized at 450°C, the oxidation time is 0.9h, and the oxygen content is 18% (the rest of the gas is Nitrogen), the pre-oxidation rate is 97.2%. Then, the pre-oxidized product is roasted in the second stage at 900° C. for 1.5 hours, and the recovery rate of potassium chloride obtained after the flue gas and dust is collected is 97.5%. The remaining solids are roasted at 1100°C in the third stage, the roasting time is 1h, the third stage roasting flue gas is circulated to pre-oxidation, the third stage roasted product is subjected to two-stage countercurrent leaching, and the first stage countercurrent leaching uses the leaching solution obtained from the second stage countercurrent. The roasted product is leached, the leaching solution obtained from the first-stage count...

Embodiment 3

[0036] Adding K to semi-dry desulfurization ash in a steel plant 2 Potassium feldspar with an O content of 13.4% is mixed according to the mass ratio of potassium feldspar: desulfurization ash is 5:4, and is pre-oxidized at 500°C, the oxidation time is 20min, and the oxygen content is 15% (the rest of the gas is nitrogen ), the pre-oxidation rate is 98.5%. Then, the pre-oxidized product is roasted in the second stage at 1000° C. for 0.5 h, and the recovery rate of potassium chloride obtained after the flue gas and dust is collected is 98.7%. The remaining solids are roasted at 1200°C in the third stage, the roasting time is 0.5h, the third stage roasting flue gas is circulated to pre-oxidation, the third stage roasted product is subjected to two-stage countercurrent leaching, and the first stage countercurrent leaching uses the leachate obtained from the second stage countercurrent To extract the roasted product, the leaching solution obtained from the first-stage countercurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com