Red mud unfired aggregate

A red mud and aggregate technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high and difficult red mud treatment, high-cost processing of sintered aggregates, etc., to reduce energy consumption costs, Reduced water absorption and reduced disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

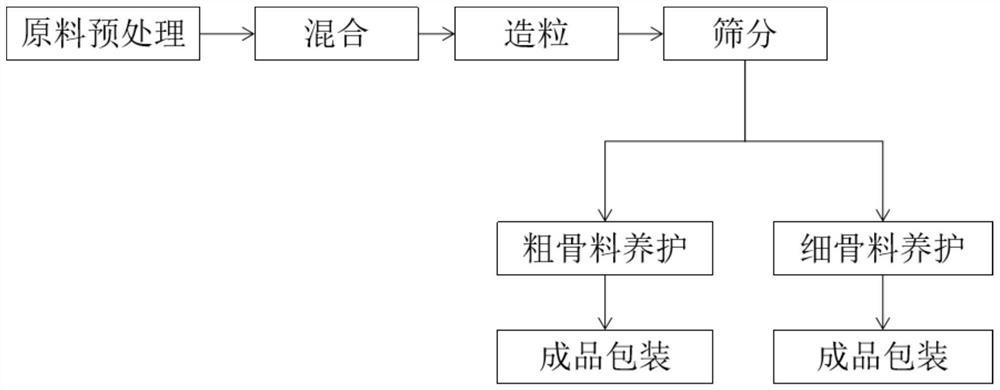

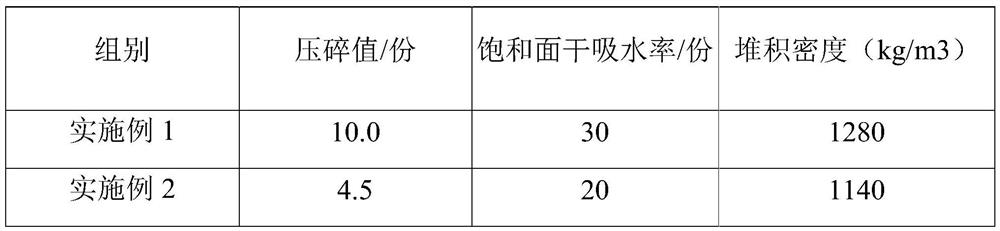

[0030] Such as figure 1 As shown, mix 80 parts of red mud, 3 parts of mineral powder, 2 parts of dihydrate gypsum of desulfurized gypsum, 3 parts of silica fume, 1 part of dispersible latex powder, 1 part of water reducer, and 10 parts of kaolin, and then pass A large granulator is used to granulate to obtain semi-finished aggregates; the semi-finished products are screened through a 4.75mm sieve to obtain coarse aggregates and fine aggregates, and the finished products are obtained after 28 days of moisturizing and curing at 20°C.

Embodiment 2

[0032] Mix 50 parts of red mud, 15 parts of mineral powder, 5 parts of desulfurized gypsum dihydrate gypsum, 10 parts of quartz powder, 3 parts of dispersible latex powder, 1 part of water reducing agent, and 22 parts of fly ash, and then pass through a large The granulator granulates to obtain semi-finished aggregates; the semi-finished products are screened through a 4.75mm screen to obtain coarse aggregates and fine aggregates respectively, and the finished products are obtained after 30°C moisturizing and curing for 14 days.

Embodiment 3

[0034] Mix 60 parts of red mud, 5 parts of steel slag, 3 parts of hemihydrate gypsum of desulfurized gypsum, 6 parts of silica fume, 2.5 parts of dispersible latex powder, 0.5 parts of water reducer, and 23 parts of kaolin, and then pass it through a large granulator Granulate to obtain the semi-finished aggregate; sieve the semi-finished product through a 4.75mm sieve to obtain coarse aggregate and fine aggregate respectively, and obtain the finished product after 7 days of moisturizing and curing at 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com