Resource utilization method of Fenton iron sludge

A recycling and iron slime technology, applied in the field of solid waste recycling, can solve the problems of occupying land, polluting water bodies, destroying soil structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

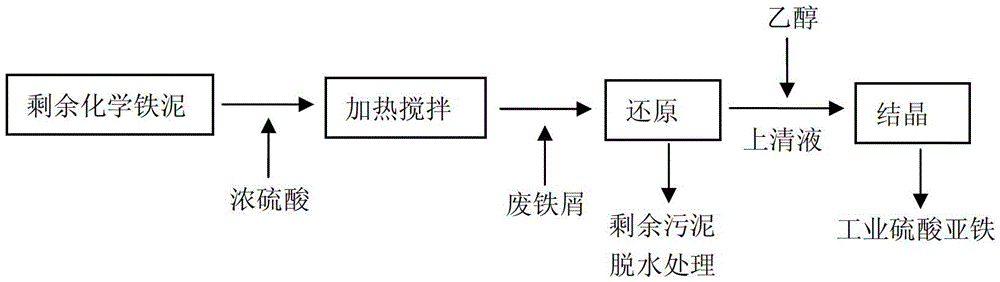

Method used

Image

Examples

Embodiment 1

[0024] Raw materials: Fenton technology for advanced treatment of pulp and papermaking wastewater remaining iron sludge, Fe 2 o 3 The content is 53.2%, and the organic matter content is 28.5%.

[0025] Processing steps:

[0026] (1) Take the above-mentioned Fenton iron mud and concentrate to obtain 1m of chemical iron mud with a moisture content of 95.5% 3 According to the volume ratio of chemical iron slime: sulfuric acid = 10: 1, add industrial concentrated sulfuric acid with a mass concentration of 98%, and heat to 70°C, and fully stir for 30 minutes to form an iron slime solution;

[0027] (2) To the 1.1m obtained in step (1) 3 Add 24kg scrap iron filings to the iron slime solution for reduction, and after the reduction time is 70min, detect Fe with phenol solution 3+ , Fe 3+ is completely reduced to Fe 2+ , after the completion of static precipitation for 30 minutes, the supernatant was extracted, and the lower sediment was dehydrated and landfilled;

[0028] (3) A...

Embodiment 2

[0030] Raw materials: Fenton technology for advanced treatment of alcohol wastewater remaining iron sludge, Fe 2 o 3 The content is 55.8%, and the organic matter content is 25.4%.

[0031] Processing steps:

[0032] (1) Take the above-mentioned Fenton iron pollution and concentrate to obtain 1m of chemical iron sludge with a water content of 94.8% 3 According to the volume ratio of chemical iron sludge: sulfuric acid = 10: 1, add industrial concentrated sulfuric acid with a mass concentration of 98%, control the temperature at 75°C, and fully stir for 30 minutes to form an iron sludge solution;

[0033] (2) To the 1.1m obtained in step (1) 3 Add 22kg of waste iron filings to the iron slime solution for reduction. After reduction for 60 minutes, detect Fe with phenol solution. 3+ , Fe 3+ is completely reduced to Fe 2+ , after the completion of static precipitation for 30 minutes, the supernatant was extracted, and the lower sediment was dehydrated and landfilled;

[0034...

Embodiment 3

[0036] Raw materials: Fenton technology for advanced treatment of pharmaceutical wastewater remaining iron sludge, Fe 2 o 3 The content is 55.1%, and the organic matter content is 26.9%.

[0037] Processing steps:

[0038] (1) Take the above-mentioned Fenton iron mud and concentrate it to obtain 1m of chemical iron mud with a moisture content of 93.5%. 3 According to the volume ratio of chemical iron sludge: sulfuric acid = 10: 1, add industrial concentrated sulfuric acid with a mass concentration of 98%, control the temperature at 73°C, and fully stir for 30 minutes to form an iron sludge solution;

[0039] (2) To the 1.1m obtained in step (1) 3 Add 23kg of waste iron filings to the iron slime solution for reduction. After reduction for 65 minutes, detect Fe with phenol solution. 3+ , Fe 3+ is completely reduced to Fe 2+ , after the completion of static precipitation for 30 minutes, the supernatant was extracted, and the lower sediment was dehydrated and landfilled;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com