Desulfurized ash reduction-oxidation two-stage treatment method

A technology for desulfurization ash and carbon monoxide, applied in chemical instruments and methods, sulfur compounds, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of difficult comprehensive treatment of desulfurization ash, and achieve significant economic and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

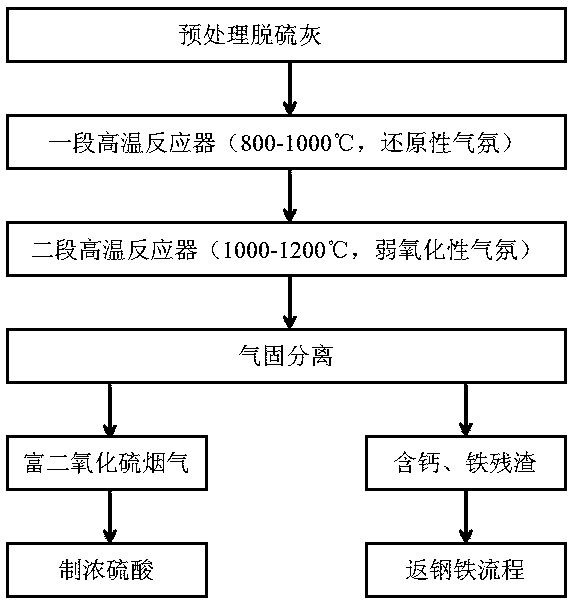

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

[0017] The desulfurization ash used in this example is a dry desulfurization ash with a moisture content of less than 10%. The main components of the dry desulfurization ash are shown in Table 1.

[0018] Table 1. Main components of dry desulfurization ash (%)

[0019] SiO 2

[0020] Such as figure 1 As shown, the dry desulfurization ash is sent to a high-temperature reactor after grinding, and a reducing atmosphere is introduced. The carbon monoxide content (volume fraction) in the reducing atmosphere is controlled at 15%, and the oxygen content (volume fraction) is 1.5%. , and the rest are inert gases. The inert gas is preferably nitrogen or carbon dioxide or a mixed gas of nitrogen and carbon dioxide. The furnace temperature is controlled at 800-900°C, so that the calcium sulfite and calcium sulfate in the desulfurization ash are reduced to calcium su...

Embodiment 2

[0022] The desulfurization ash used in this example is the wet desulfurization ash after the dry desulfurization ash used in Example 1 has been dampened, and the moisture content of the wet desulfurization ash is 30%.

[0023] The wet desulfurization ash is sent to a high-temperature reactor after pretreatment such as drying, crushing, and grinding, and a reducing atmosphere is introduced. The carbon monoxide content (volume fraction) in the reducing atmosphere is controlled at 10%, and the oxygen content (volume fraction ) 1%, and the rest is inert gas. The inert gas is preferably nitrogen or carbon dioxide or a mixture of nitrogen and carbon dioxide. The furnace temperature is controlled at 900-1000°C, so that the calcium sulfite and calcium sulfate in the desulfurization ash are reduced to calcium sulfide; reduction The final desulfurized ash enters the second-stage high-temperature reactor, and the oxidizing atmosphere is introduced. The oxygen content (volume fraction) in ...

Embodiment 3

[0025] The wet desulfurization ash (the composition is the same as in Example 2) is pretreated by drying, crushing, and grinding, and then sent to a high-temperature reactor, and a reducing atmosphere is introduced. The carbon monoxide content (volume fraction) in the reducing atmosphere is controlled at 5%, oxygen content (volume fraction) 0.5%, and the rest is inert gas. The inert gas is preferably nitrogen or carbon dioxide or a mixture of nitrogen and carbon dioxide. Calcium is reduced to calcium sulfide; the reduced desulfurized ash enters the second-stage high-temperature reactor and is introduced into an oxidative atmosphere. The oxygen content (volume fraction) in the oxidative atmosphere is controlled at 5%, and the carbon monoxide (volume fraction) is 0.2%. The rest is inert gas. The inert gas is preferably nitrogen or carbon dioxide or a mixed gas of nitrogen and carbon dioxide. The furnace temperature is controlled at 1050-1150°C to convert the desulfurized ash calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com