Method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge

A technology of calcium carbide slag and calcium aluminate, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/alumina/aluminum hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

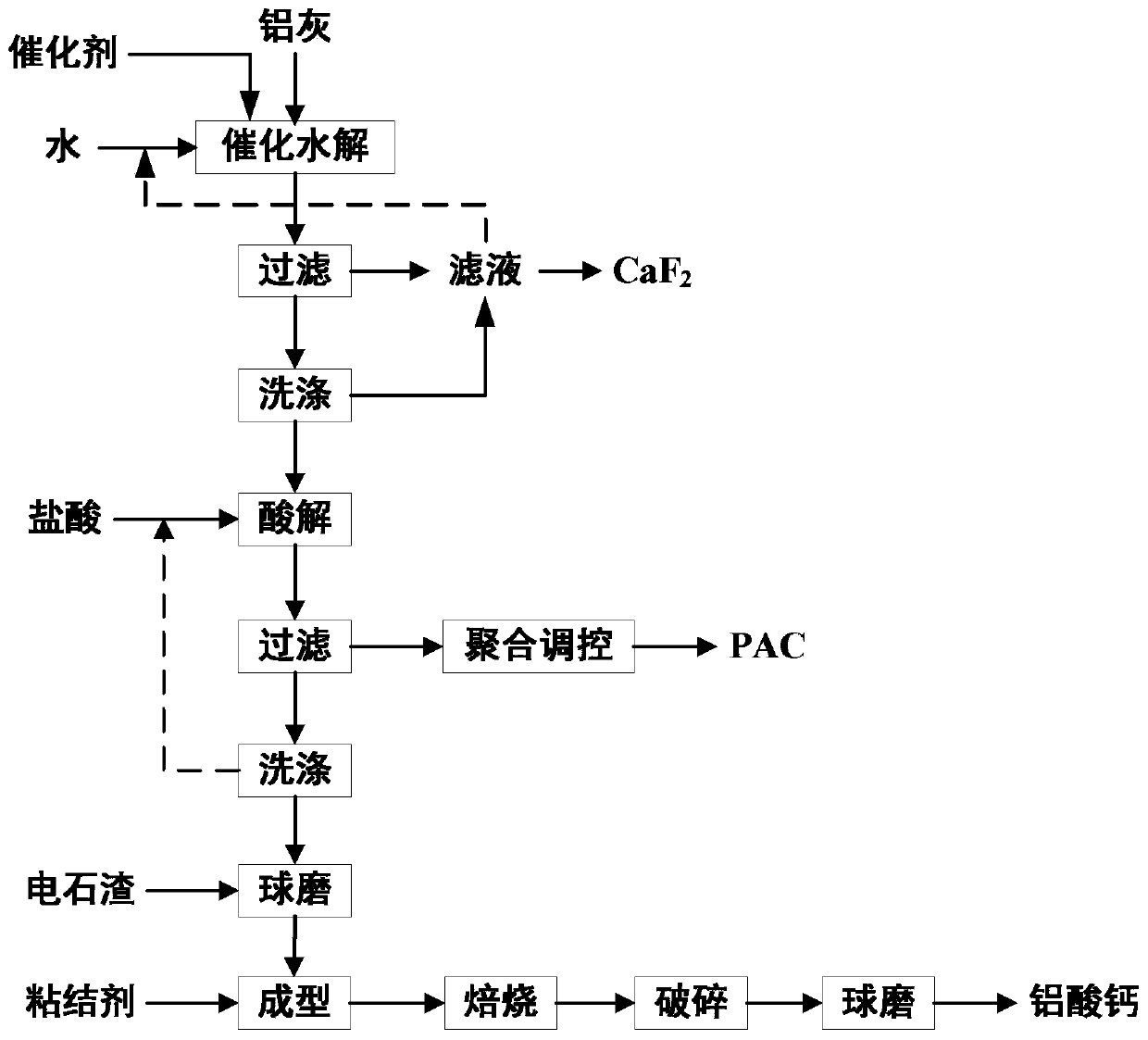

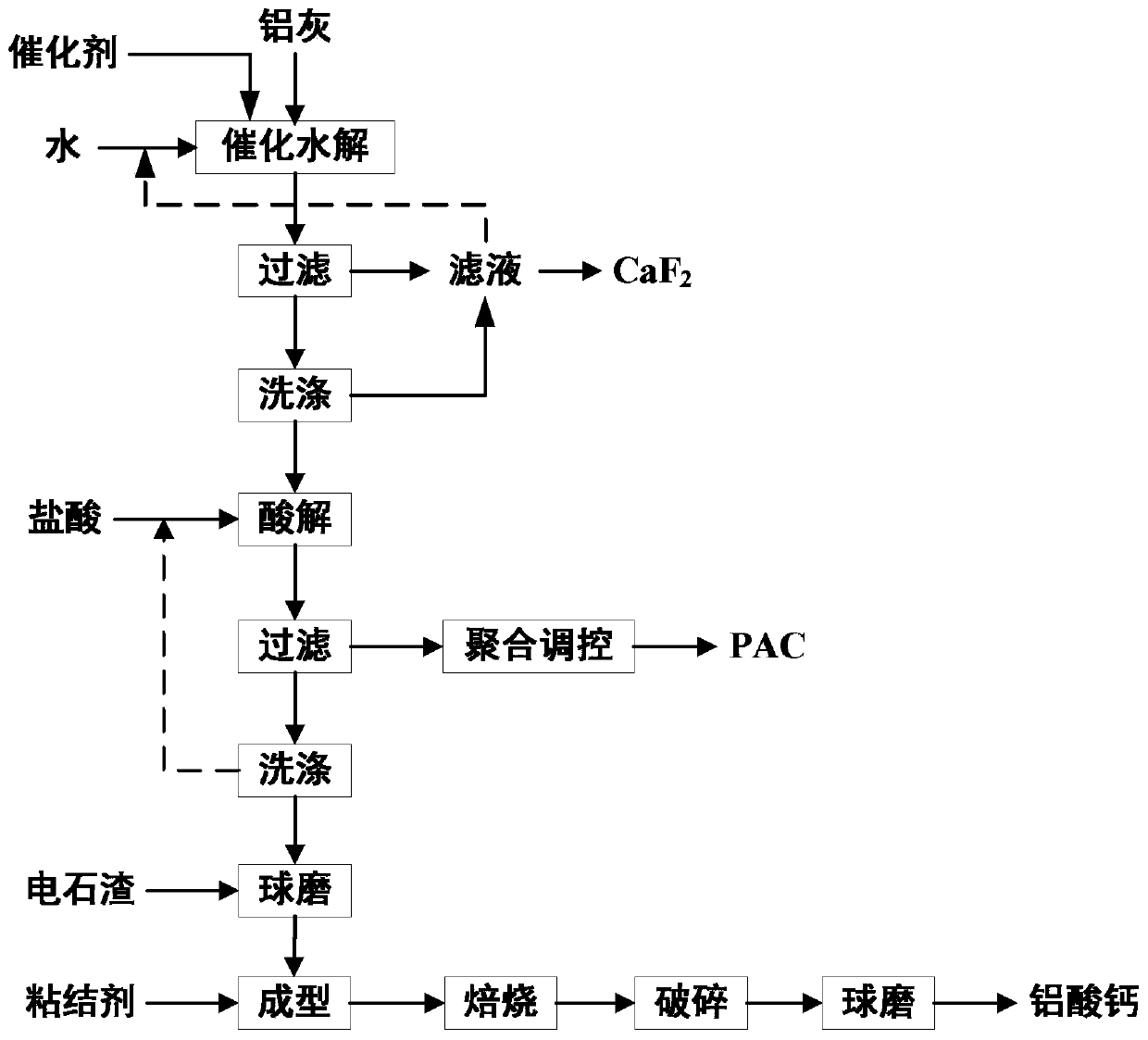

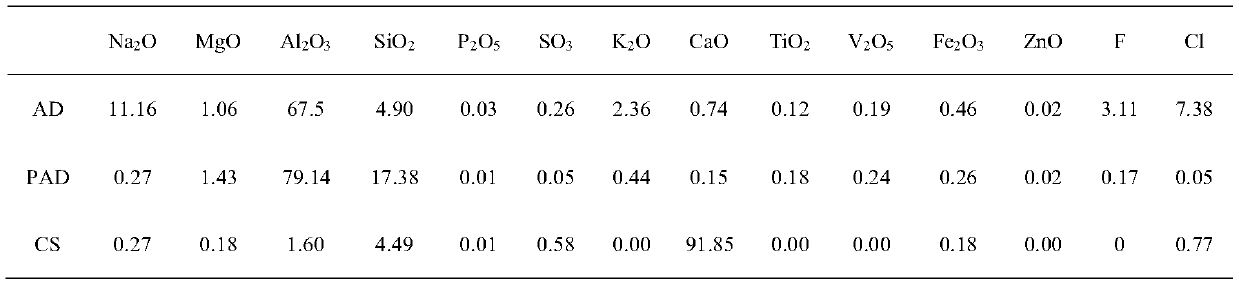

Method used

Image

Examples

Embodiment 1

[0026] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis-washing. The catalytic hydrolysis section: the liquid-solid ratio is 2ml / g, the reaction temperature is 70°C, the reaction time is 1h, and the cycle times of the hydrolyzate is 3 times; the acidolysis section: the liquid-solid ratio is 3ml / g, reaction temperature 80℃, reaction time 1h, hydrochloric acid concentration 100g / l; sintering section: molding pressure 20MPa, calcination temperature 1000℃, calcination time 0.5h. The prepared calcium aluminate has 90% soluble alumina, 54% alumina content and 34% calcium oxide.

Embodiment 2

[0028] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis-washing. The catalytic hydrolysis section: the liquid-solid ratio is 3ml / g, the reaction temperature is 85°C, the reaction time is 2h, and the cycle times of the hydrolyzate is 5 times; the acidolysis section: the liquid-solid ratio is 4ml / g, reaction temperature 80℃, reaction time 1h, hydrochloric acid concentration 150g / l; sintering section: molding pressure 100MPa, calcination temperature 1100℃, calcination time 1h. The prepared calcium aluminate has 92% soluble alumina, 56% alumina content and 22% calcium oxide.

Embodiment 3

[0030] The aluminum ash is treated according to the process of catalytic hydrolysis-acidolysis-washing. The catalytic hydrolysis section: the liquid-solid ratio is 3ml / g, the reaction temperature is 95°C, the reaction time is 3h, and the cycle times of the hydrolyzate is 6 times; the acidolysis section: the liquid-solid ratio is 5ml / g, reaction temperature 95°C, reaction time 2h, hydrochloric acid concentration 200g / l; sintering section: molding pressure 120MPa, calcination temperature 1200°C, calcination time 1h. The prepared calcium aluminate has 96% soluble alumina, 60% alumina content and 28% calcium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com