Method for preparing sodium aluminate solution purifying filter aid and utilizing filter cake in alumina production

A filter aid, sodium aluminate technology, applied in the field of metallurgy, can solve the problems of reducing the service life of leaf filter cloth, increasing process load, reducing alumina content, etc., to avoid pollution and waste of resources, reduce alumina Loss, effect of reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

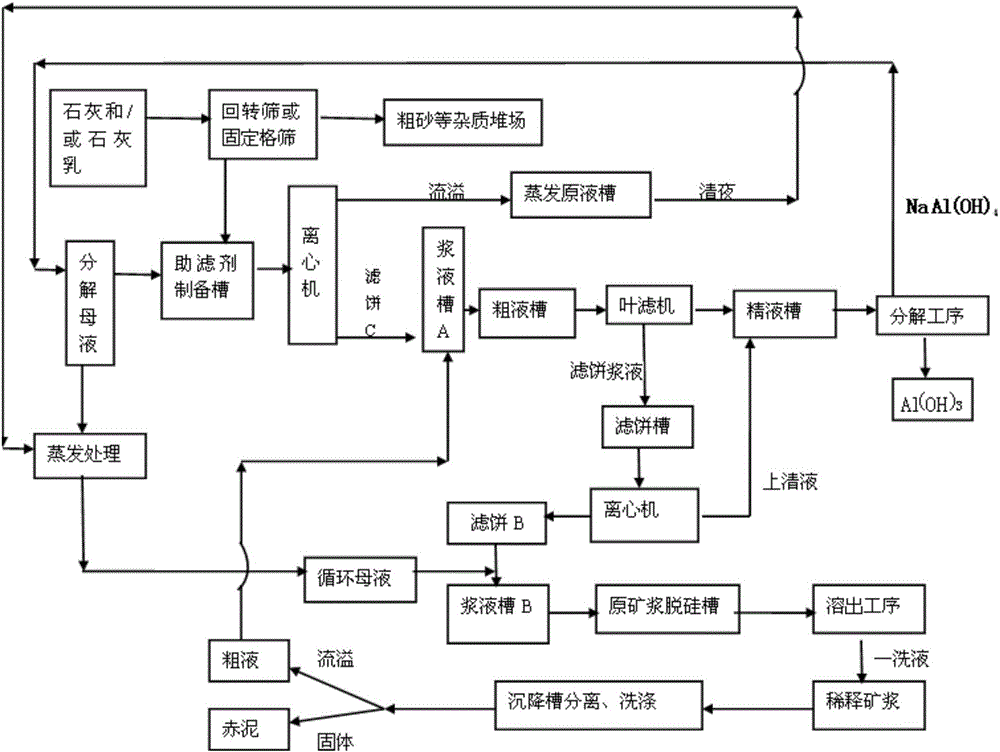

Image

Examples

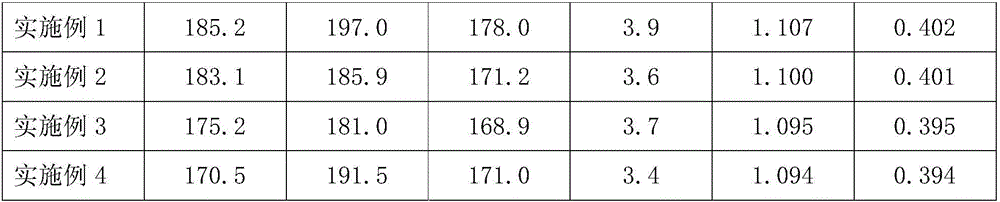

Embodiment 1

[0034] A method for preparing a sodium aluminate solution refined filter aid and utilizing a filter cake in alumina production, comprising the following specific steps:

[0035] (1) Impurity removal: pass lime milk through a rotary sieve to remove 1 mm of coarse sand impurities, and set aside;

[0036] (2) Preparation of calcium aluminate slurry: use milk of lime and decomposed mother liquor after removing impurities in step (1) (it is the solution remaining after the semen in the semen tank is extracted from aluminum hydroxide through the decomposition process, and the active ingredient is NaAl (OH) 4 ; at the beginning of the period, the raw material used in the market is enough sodium aluminate refined solution) to be put into the filter aid preparation tank according to the volume ratio of 1:2, and the temperature is 90 ° C, stirred for 1 hour, and the reaction is prepared to obtain calcium aluminate slurry, which is the aid Filter, the effective active ingredient is 3CaO...

Embodiment 2

[0041] A method for preparing a sodium aluminate solution refined filter aid and utilizing a filter cake in alumina production, comprising the following specific steps:

[0042] (1) Impurity removal: pass the lime through a rotary sieve or a fixed grid sieve to remove 1.5 mm of coarse sand impurities, and set aside;

[0043] (2) Preparation of calcium aluminate slurry: use lime after removing impurities in step (1) and decompose mother liquor (be that the semen in the semen tank passes through the solution that remains after the decomposition process extracts aluminum hydroxide, and the active ingredient is NaAl ( Oh) 4 ; At the beginning of the period, the raw material used was enough sodium aluminate refined solution on the market) to be put into the filter aid preparation tank according to the volume ratio of 1:3, and the temperature was 97°C, stirred for 2 hours, and the reaction was prepared to obtain calcium aluminate slurry, which was the filter aid preparation tank. F...

Embodiment 3

[0049] A method for preparing a sodium aluminate solution refined filter aid and utilizing a filter cake in alumina production, comprising the following specific steps:

[0050] (1) Impurity removal: pass lime milk and lime through a rotary sieve or a fixed grid sieve to remove coarse sand impurities above 1 mm, and set aside;

[0051] (2) Preparation of calcium aluminate slurry: milk of lime and lime mixture after removing impurities in step (1) and decomposed mother liquor (the semen in the semen tank is the solution remaining after the aluminum hydroxide is extracted through the decomposition process, effectively The composition is NaAl(OH) 4 ; At the beginning of the period, the raw materials used in the market were enough sodium aluminate refined solution) to be put into the filter aid preparation tank according to the volume ratio of 1:4. Filter, the effective active ingredient is 3CaO·Al 2 o 3 ·6H 2 O, CaO / Al in calcium aluminate slurry 2 o 3 molar ratio 2;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com