A method of preparing an adsorbent for CO2 capture at high temperature

An adsorbent, CO2 technology, applied in the direction of adsorption, separation methods, chemical instruments and methods, etc., can solve problems such as reducing reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention is described below primarily with reference to the inert porous metal support being MgO. However, as will be understood by those skilled in the art, other materials may be used in place of or in combination with MgO.

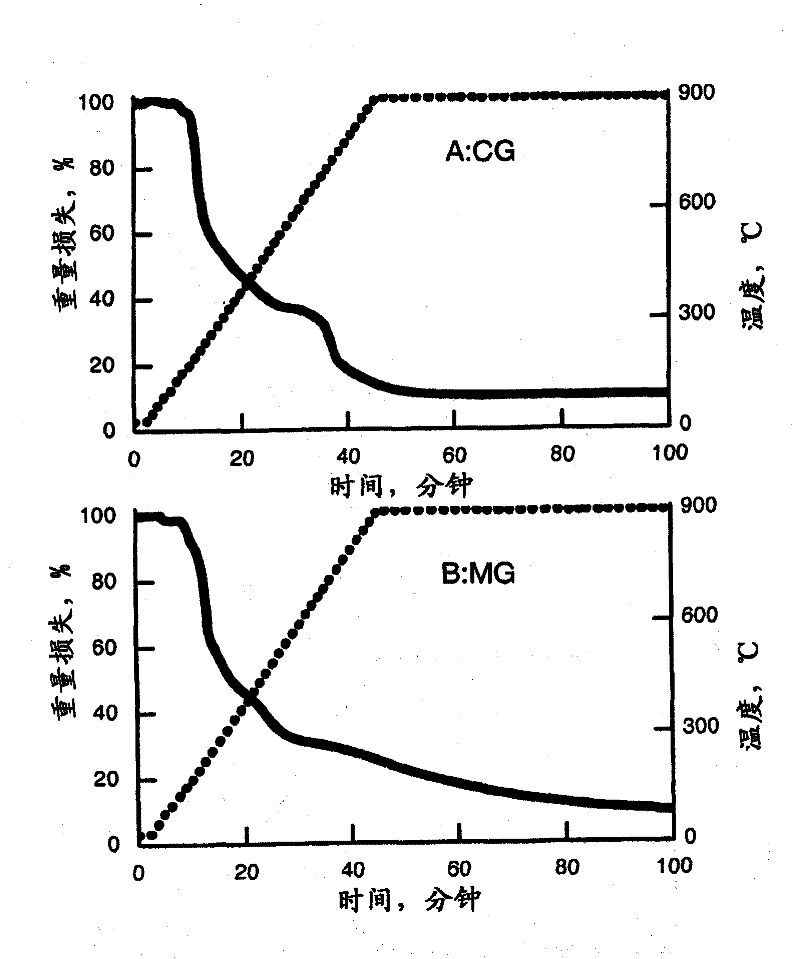

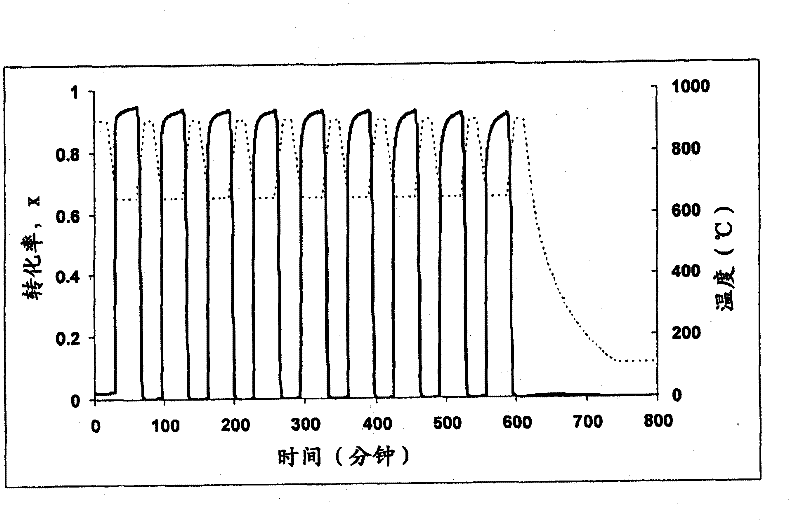

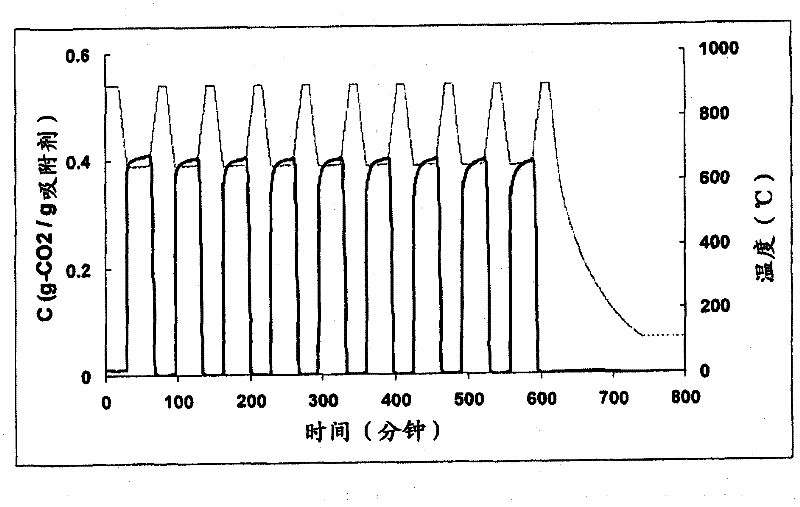

[0063] A CMO adsorbent with CaO supported on MgO was synthesized. Without wishing to be bound by theory, it is believed that the MgO component in the adsorbent is the one that does not interact with CaCO under the reaction conditions. 3 reactive, and thus acts as an inert porosity separating the CaO (ie, its crystals or grains). The inventors believe that loading CO 2 CaCO in the adsorbent 3 The sintering of is largely hindered because the CaO grains in the adsorbent are separated by MgO. That is, the process of the present invention produces ultrafine CaO particles that are uniformly separated from the inert support material. Such CMO sorbents can be reliably used for multiple cycles with less reversible loss than state-of-the-art CaO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com