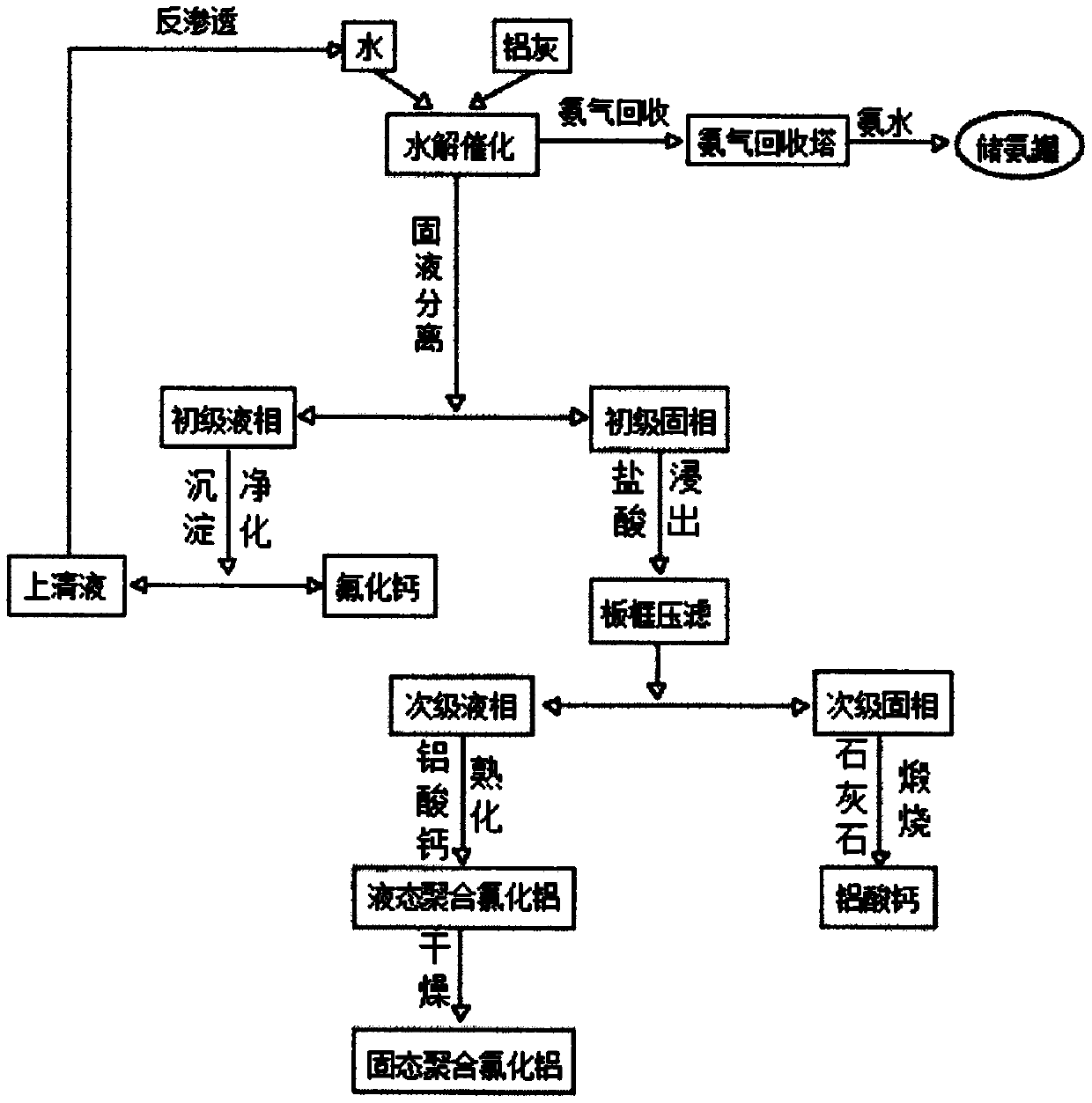

Process method for preparing high-purity calcium aluminate and polyaluminum chloride

A technology of polyaluminum chloride and a process method is applied in the field of preparation of high-purity water purifying agents, can solve problems such as aluminum ash pollution, and achieve the effects of low cost, high product purity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

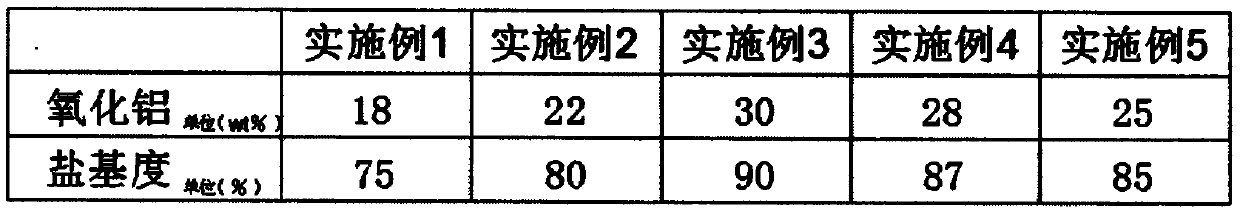

Embodiment 1

[0024] Example 1: During the hydrolysis catalytic reaction step of the secondary aluminum ash: the liquid-solid ratio of the secondary aluminum ash to water is 7ml / g, the heating temperature is 100°C, the hydrolysis catalytic reaction time is 6h, and the acidolysis reaction of the primary solid phase In the step: the ratio of the primary solid phase to hydrochloric acid and water is 1:2:4, the reaction temperature is maintained at 60° C., and the reaction is fully stirred for 4 hours. In the secondary liquid phase polymerization step: the solid-to-liquid ratio is 20:1, and the solution Keep the pH between 2.5 and 4.5, keep heating to keep the reaction temperature at 60°C, and the aging time is 10h. In the secondary solid phase calcination step: the ratio of secondary solid phase to limestone in the ball mill is 1:2, and it must go through 2 stages After crushing, the particle size is 5-13mm, fully mixed in the ball mill and the grinding fineness reaches 200 mesh, and sent to th...

Embodiment 2

[0025] Example 2: During the hydrolysis catalytic reaction step of the secondary aluminum ash: the liquid-solid ratio of the secondary aluminum ash to water is 6ml / g, the heating temperature is 95°C, the hydrolysis catalytic reaction time is 5.5h, and the acidolysis of the primary solid phase In the reaction step: the ratio of the primary solid phase to hydrochloric acid and water is 1:2.5:4.5, the reaction temperature is maintained at 70°C, and the reaction is fully stirred for 11 hours. In the secondary liquid phase polymerization step: the solid-to-liquid ratio is 20:1, The pH of the solution is kept between 2.5 and 4.5, and the reaction temperature is maintained at 70°C by continuous heating, and the aging time is 11 hours. After grade crushing, the particle size is 5-13mm, fully mixed in the ball mill and the grinding fineness reaches 200 mesh, and sent to the rotary kiln, the kiln temperature is kept at 1100-1300°C, and calcined at high temperature for 3 hours to obtain c...

Embodiment 3

[0026] Example 3: During the hydrolysis catalytic reaction step of the secondary aluminum ash: the liquid-solid ratio of the secondary aluminum ash to water is 3ml / g, the heating temperature is 80°C, the hydrolysis catalytic reaction time is 4h, and the acidolysis reaction of the primary solid phase In the step: the ratio of the primary solid phase to hydrochloric acid and water is 1:3:5, the reaction temperature is maintained at 100° C., and the reaction is fully stirred for 12 hours. In the secondary liquid phase polymerization step: the solid-to-liquid ratio is 20:1, and the solution Keep the pH between 2.5 and 4.5, keep heating to keep the reaction temperature at 100°C, and the slaking time is 12 hours. In the secondary solid phase calcination step: the ratio of secondary solid phase to limestone in the ball mill is 7:13, and it must go through 2 stages After crushing, the particle size is 5-13mm, fully mixed in the ball mill and the grinding fineness reaches 200 mesh, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com