Calcium aluminate powder with high dissolution rate

A technology of dissolution rate calcium aluminate and calcium aluminate powder, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/alumina/aluminum hydroxide, etc., which can solve the problem of excessive precipitation of CaLC, pollution of precipitated slag, and energy consumption Major issues, to achieve the effect of reducing environmental pollution, realizing industrial development, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

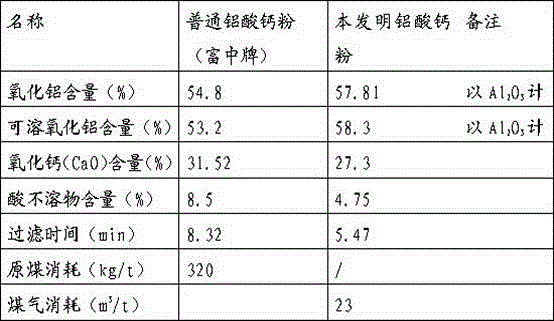

[0012] Calcium aluminate powder is an off-white powdery industrial intermediate product, mainly used in the production of aluminum salts such as polyaluminum chloride, aluminum sulfate, sodium aluminate and other water purifying agents. It can be widely used as raw materials for water purifying agents, and also Can be used for refractory materials, etc. However, ordinary calcium aluminate powder is low in aluminum and high in calcium, with poor performance and a lot of calcium carbonate precipitation, which cannot keep up with the needs of industrial production. At present, the calcium aluminate commonly used in the market is high in calcium and low in aluminum, and the content of CaO is as high as 31%. Agent manufacturers directly use high-aluminum and low-calcium calcium aluminate powder without adding other aluminum-containing substances to produce water purifiers. The yield is high, the water purification effect is good, and the slag discharge is less. It is an ideal water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com