Method for preparing ceramic nanofiltration membrane support body with gradient pores

A ceramic nanofiltration membrane and support technology are applied in the field of preparing ceramic nanofiltration membrane supports, which can solve the problems of ceramic nanofiltration membrane preparation and industrialization difficulty, and achieve the effects of less defects, low roughness, and reduced preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

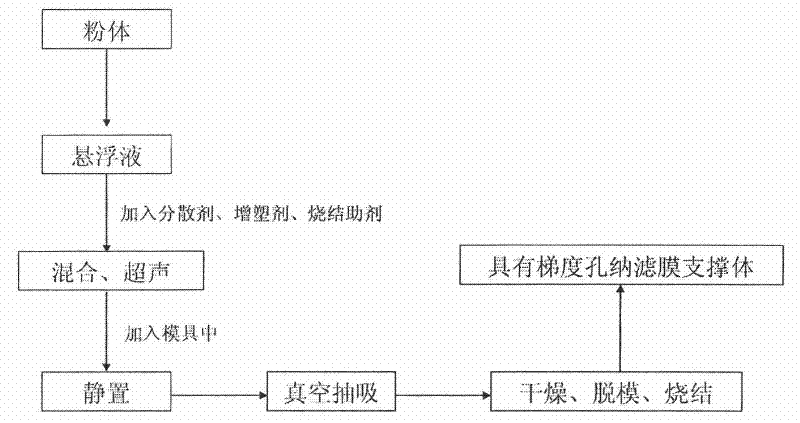

Method used

Image

Examples

Embodiment 1

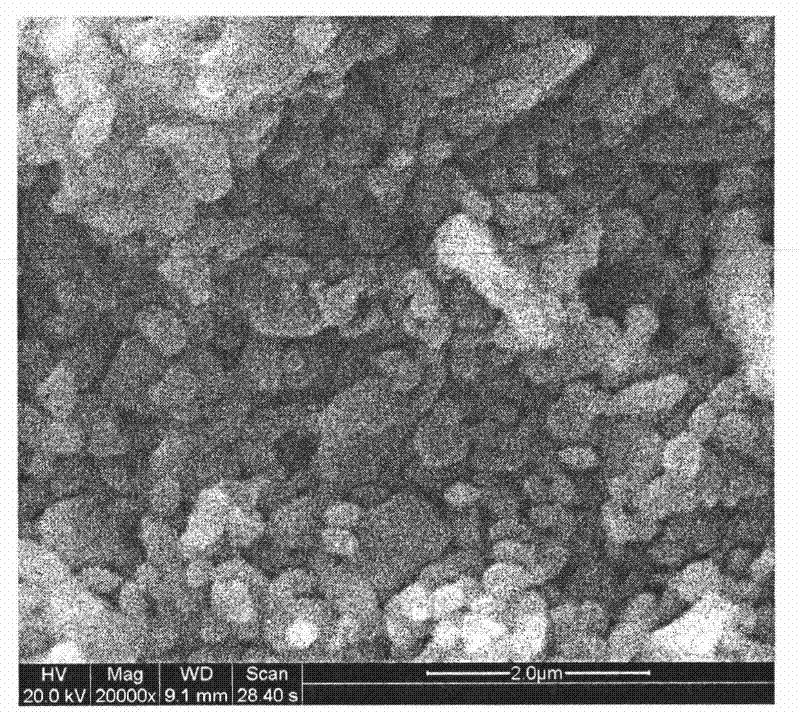

[0024] In this example, α-Al 2 o 3 Powder (the particle size distribution range is 100nm~14.2 μm, and the average particle size is 0.55 μm) 50 grams plus 50 grams of deionized water is mixed with a suspension with a mass concentration of 50%, adding nitric acid as a dispersant, adjusting the pH to 2.0, Add 1.0 g of polyvinyl alcohol with a molecular weight of 22,000 as a binder; add 2.0 g of zirconia as a sintering aid; ultrasonicate for 10 minutes, add the suspension to the mold, let it stand for 10 hours, and pump it under a pressure of 0.2 bar. Dry at 40°C for 2 hours; remove the mold to obtain a green body, then raise the temperature of the green body to 950°C at a heating rate of 2.0°C / min for 3 hours, and cool naturally to obtain a ceramic membrane support with gradient pores; the surface layer of the support Surface scanning (SEM) photographs of figure 1 shown.

Embodiment 2

[0026] In this example, α-Al 2 o 3 Powder (the particle size distribution range is 100nm ~ 4.0μm, the average particle size is 0.8μm) 40 grams plus 60 grams of deionized water to prepare a suspension with a mass concentration of 40%, adding 0.2 grams of polyammonium methacrylate as a dispersant , adding 2.3 grams of polyvinyl alcohol with a molecular weight of 55,000 as a binder; adding 1.6 grams of zirconia as a sintering aid; ultrasonication for 10 minutes, adding the suspension to the mold, standing for 15 hours, and pumping under a pressure of 0.2bar , dried at 40°C for 2 hours; demolded to obtain a green body, the green body was heated at a heating rate of 1.5°C / min to 1150°C for 1 hour, and cooled naturally to obtain a ceramic membrane support with gradient pores.

Embodiment 3

[0028] Add 40 grams of zirconia powder (the particle size distribution range is 100 nm to 4.78 μm, and the average particle size is 0.27 μm) and add 460 grams of deionized water to prepare a suspension with a mass concentration of 8%, and add 0.2 grams of polyammonium methacrylate As a dispersant, add 2.3 grams of polyvinyl alcohol with a molecular weight of 55,000 as a binder; add 1.6 grams of zirconia and 10 grams of alumina as a sintering aid; ultrasonic for 10 minutes, add the suspension to the mold, and let it stand for 15 hours. Suction at a pressure of 0.1bar, dry at 70°C for 1 hour; demould to obtain a green body, heat the green body at a rate of 1.5°C / min to 1150°C for 1 hour, and cool naturally to obtain a ceramic with gradient pores membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com