A method for forming a textured pattern on a metal surface

A metal surface and textured technology, applied in the direction of electrophoretic plating, unsaturated alcohol copolymer adhesives, adhesive types, etc., can solve the troublesome screen switching and cleaning and maintenance, the performance and appearance are greatly affected, and it is difficult to Make net pattern and other problems to achieve the effect of long appearance life, good boiling test effect and good decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

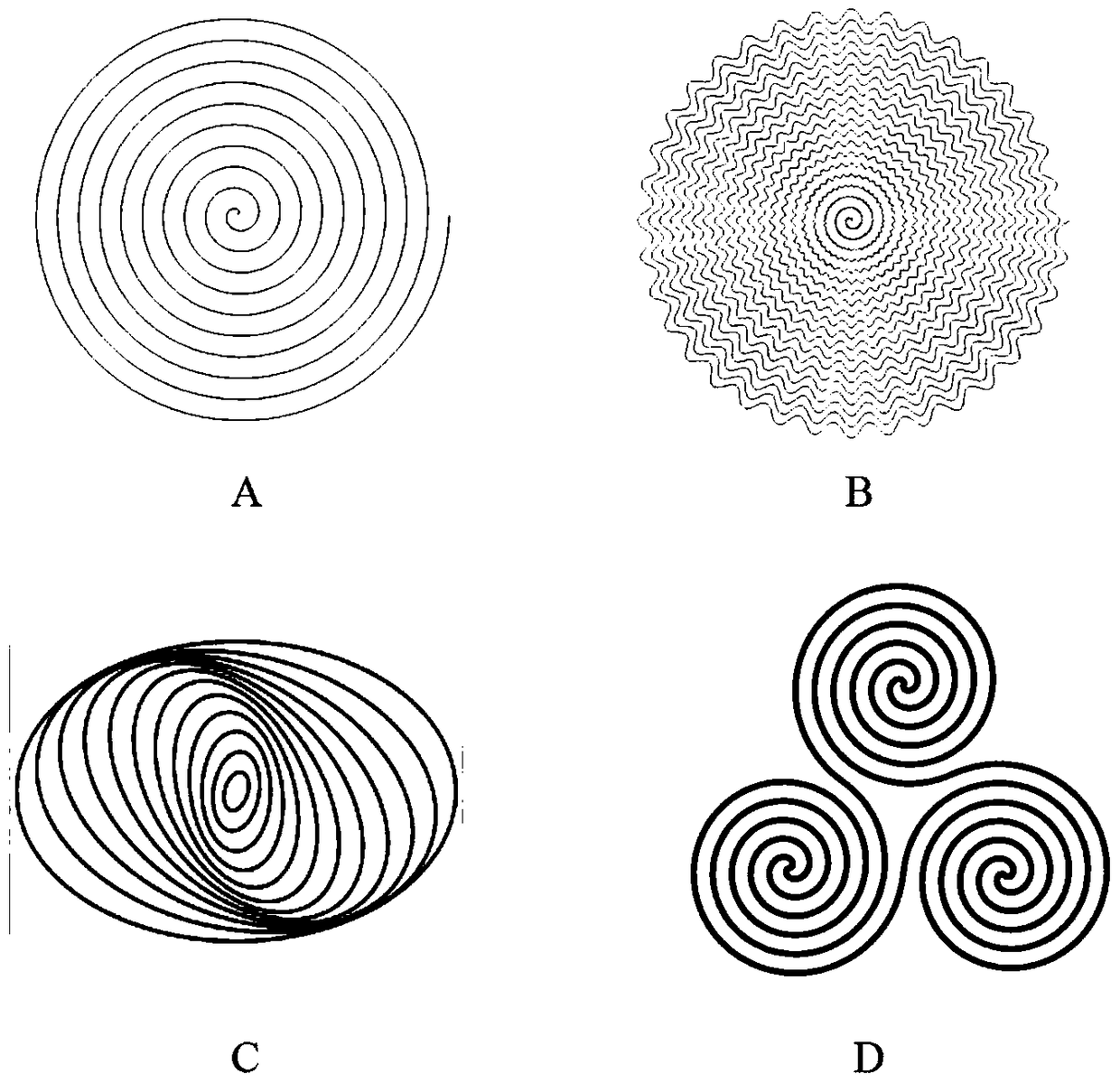

[0040] A method for forming a mesh pattern on a metal surface is to make an omentum by hot-melt adhesive wire, use the omentum as a shielding layer, and then deposit electrophoretic paints of different colors on the covered area and the uncovered area of the omentum through secondary electrophoresis, thereby A predetermined mesh pattern is formed.

[0041] The omentum is a reticulated structure formed by hot-melt adhesive filaments, with a weight range of 3g / m 2 -30g / m 2 , The softening point range of the hot melt adhesive wire is 80-180°C, and the diameter is 30μm-1000μm. In one embodiment, during production, the materials forming the hot-melt adhesive are mixed and stirred according to the proportion, extruded and granulated after melt blending; the masterbatch is heated and melted by an extruder, and then pumped into the spinneret by a melt pump Inside, the hot-melt adhesive thread ejected from the spinneret falls into the receiving plate, and the arrangement and densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com