Preparation method of monoclinic phase yttrium oxide

A technology of yttrium oxide and monoclinic phase, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of incapable mass production and high pressure, and achieve the effect of simple and efficient synthesis method, low preparation conditions and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of yttrium-based coordination polymer: 0.5mmol Y(NO 3 ) 3 ·6H 2 O and 1.5mmol oxalic acid were dissolved in 40ml of DMF solvent, and reacted in a household microwave reaction device for 15min with a power of 240W;

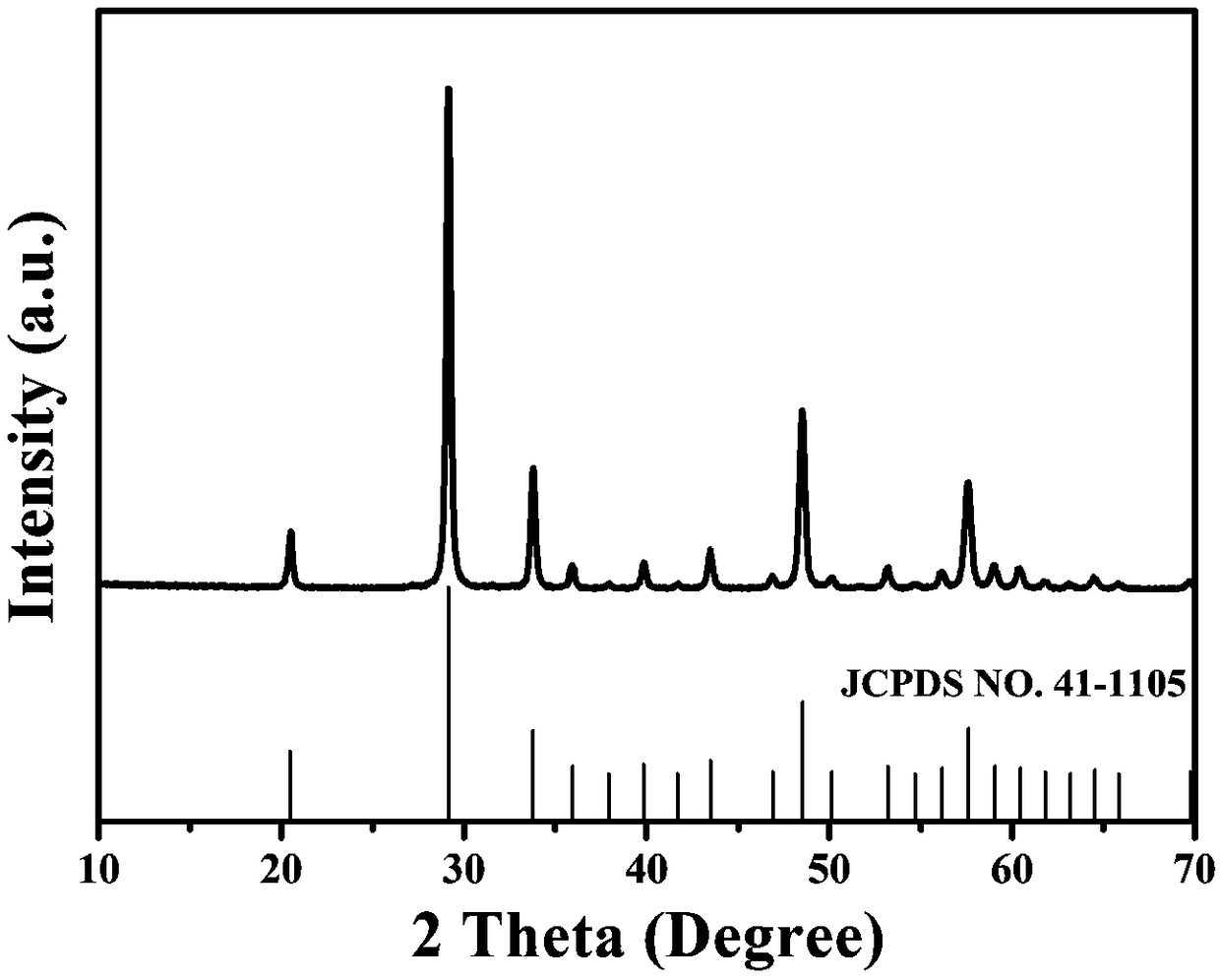

[0023] (2) Cubic phase Y 2 o 3 Preparation: The yttrium-based coordination polymer obtained by microwave reaction was calcined in a muffle furnace for 4 hours, and the calcination temperature was 800°C;

[0024] (3) Cubic phase Y 2 o 3 The precompression of: the cubic phase Y obtained after calcination 2 o 3 Put it into Mo package and pre-press, and the loading pressure is 10MPa;

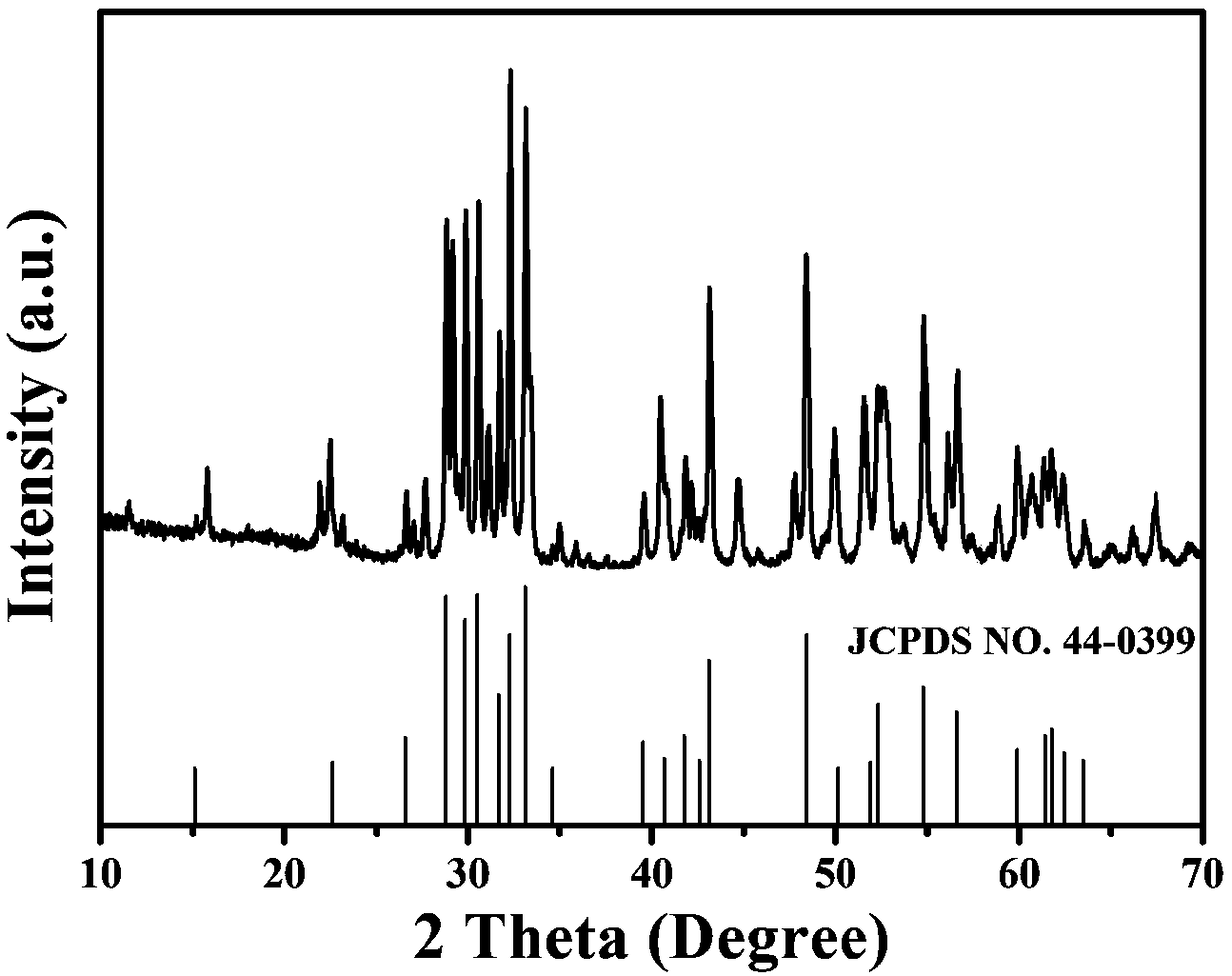

[0025] (4) High temperature and high pressure reaction: the pre-pressed cubic phase Y 2 o 3 , the reaction was carried out in a domestic hinged 1400-ton six-sided top press. First, the pressure was raised to 3GPa at a rate of 0.3GPa / min. After the pressure was stabilized, the temperature was raised to 1000°C at a rate of 100°C / min and kept for 0.5h. , th...

Embodiment 2

[0028] (1) Preparation of yttrium-based coordination polymer: 0.1mmol Y(NO 3 ) 3 ·6H 2 O and 0.3 mmol terephthalic acid were dissolved in 40 ml DMF and H 2 In a mixed solvent of O, react in a household microwave reaction device for 20min with a power of 240W;

[0029] (2) Cubic phase Y 2 o 3 Preparation: The yttrium-based coordination polymer obtained by microwave reaction was calcined in a muffle furnace for 4 hours, and the calcination temperature was 1000°C;

[0030] (3) Cubic phase Y 2 o 3 The precompression of: the cubic phase Y obtained after calcination 2 o 3 Put in Pt package and pre-press, the loading pressure is 5MPa;

[0031] (4) High temperature and high pressure reaction: the pre-pressed cubic phase Y 2 o 3 , the reaction was carried out in a domestic hinged 1400-ton six-sided top press. First, the pressure was raised to 5GPa at a rate of 0.5GPa / min. After the pressure was stabilized, the temperature was raised to 1000°C at a rate of 50°C / min and kept f...

Embodiment 3

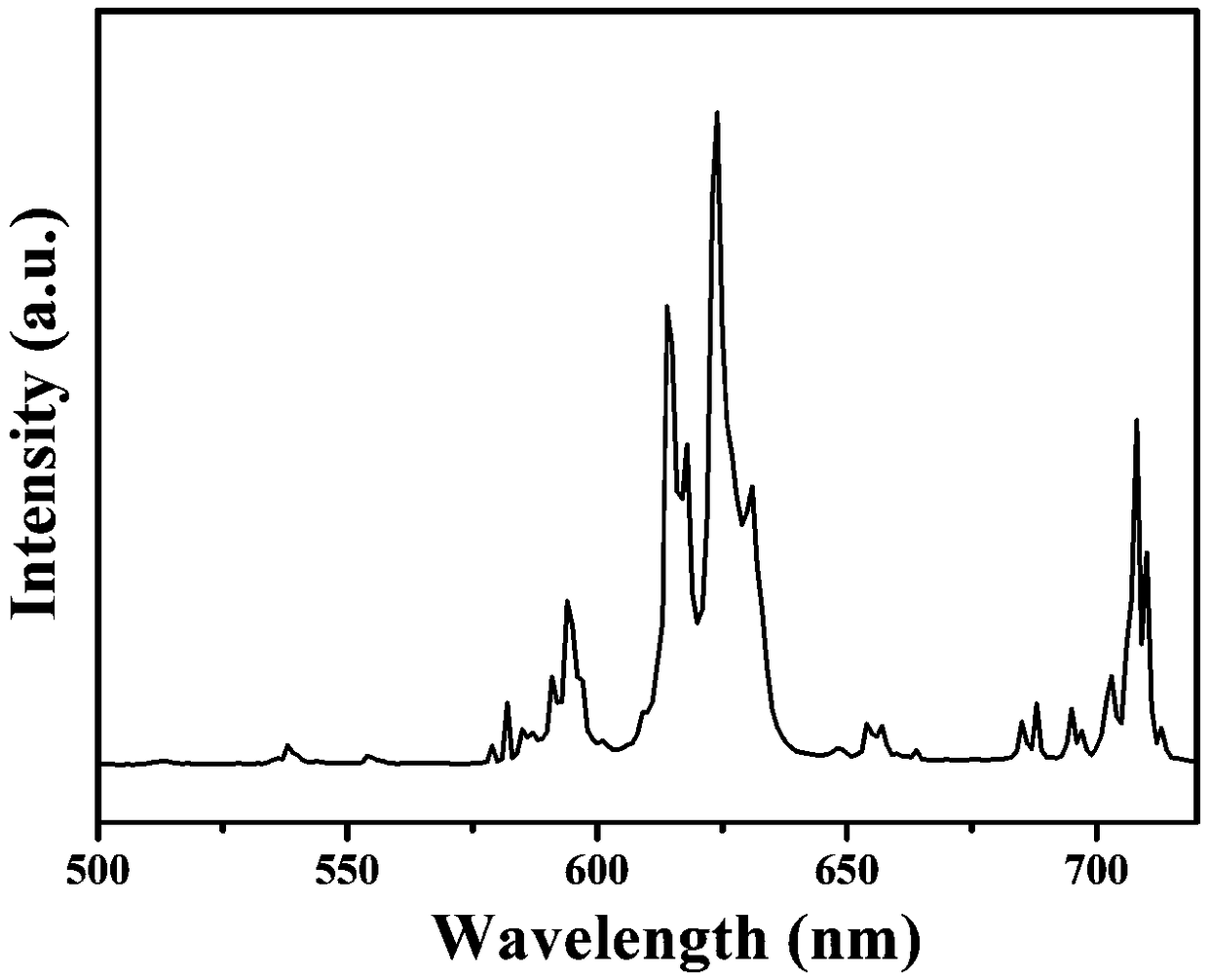

[0034] (1) Preparation of yttrium-based coordination polymer: 0.475mmol Y(NO 3 ) 3 ·6H 2 O, 0.025mmolEu(NO 3 ) 3·6H 2 O and 0.3mmol pimelic acid were dissolved in 40ml of DMF solvent, and reacted in a household microwave reaction device for 15min with a power of 240W;

[0035] (2) Cubic phase Y 2 o 3 : Eu 3+ Preparation: The europium-doped yttrium-based coordination polymer obtained by microwave reaction was calcined in a muffle furnace for 4 hours, and the calcination temperature was 800°C;

[0036] (3) Cubic phase Y 2 o 3 : Eu 3+ The precompression of: the cubic phase Y obtained after calcination 2 o 3 : Eu 3+ Put it into Mo package and pre-press, and the loading pressure is 10MPa;

[0037] (4) High temperature and high pressure reaction: the pre-pressed cubic phase Y 2 o 3 : Eu 3+ , the reaction was carried out in a domestic hinged 1400-ton six-sided top press, and the pressure was first raised to 3GPa at a rate of 0.3GPa / min. After the pressure was stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com