Mullite whisker/fiber synergistically reinforced silicon dioxide aerogel multi-scale composite structure, preparation method and application thereof

A technology of mullite whisker and composite structure, applied in the field of ceramic compositions, can solve the problems of inability to meet large-scale mass production, complex equipment, failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

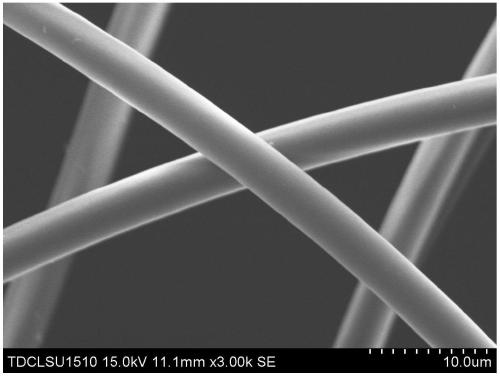

[0050] (1) Weigh the silica sol, add deionized water therein to dilute, stir to obtain the silica sol dilution, the concentration of the silica sol dilution is 0.033mol / L; then aluminum silicate fiber felt (untreated SEM image of aluminum silicate fiber felt as figure 1 Shown) immersed in the silica sol diluent, impregnated for 0.5 under vacuum conditions, then frozen below 0°C until the impregnated liquid became solid, and then placed the frozen solid in a freeze dryer for freeze-drying;

[0051] (2) weigh aluminum nitrate, take deionized water as solvent preparation aluminum nitrate solution, its concentration is 0.10mol / L; The concentration of this aluminum nitrate solution is 3 times of silica sol dilution concentration in step (1); The dried aluminum silicate fiber felt in step (1) is immersed in the aluminum nitrate solution for 0.5h under vacuum conditions, and then frozen below 0°C until the impregnation solution freezes into a solid, and then the frozen solid is place...

Embodiment 2

[0068] (1) Weigh the silica sol, add deionized water therein to dilute, stir to obtain the silica sol dilution, the concentration of the silica sol dilution is 0.10mol / L; then immerse the aluminum silicate fiber felt into the silica sol dilution, Impregnated under vacuum conditions for 0.5, then frozen below 0°C until the impregnated liquid became solid, and then placed the frozen solid in a freeze dryer for freeze-drying;

[0069] (2) weigh aluminum nitrate, take deionized water as solvent preparation aluminum nitrate solution, its concentration is 0.30mol / L; The concentration of this aluminum nitrate solution is 3 times of silica sol dilution concentration in step (1); The dried aluminum silicate fiber felt in step (1) is immersed in the aluminum nitrate solution for 0.5h under vacuum conditions, and then frozen below 0°C until the impregnation solution freezes into a solid, and then the frozen solid is placed in the freezer Freeze drying in a desiccator;

[0070] (3) Weigh...

Embodiment 3

[0088] (1) Weigh the silica sol, add deionized water therein to dilute, stir to obtain the silica sol dilution, the concentration of the silica sol dilution is 0.17mol / L; then immerse the aluminum silicate fiber felt into the silica sol dilution, Impregnated under vacuum conditions for 0.5, then frozen below 0°C until the impregnated liquid became solid, and then placed the frozen solid in a freeze dryer for freeze-drying;

[0089] (2) weigh aluminum nitrate, take deionized water as solvent preparation aluminum nitrate solution, its concentration is 0.50mol / L; The concentration of this aluminum nitrate solution is 3 times of silica sol dilution concentration in step (1); The dried aluminum silicate fiber felt in step (1) is immersed in the aluminum nitrate solution for 0.5h under vacuum conditions, and then frozen below 0°C until the impregnation solution freezes into a solid, and then the frozen solid is placed in the freezer Freeze drying in a desiccator;

[0090] (3) Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com