Digital camouflage rubberized fabric and preparation method thereof

A technology of camouflage and tape, applied in the field of digital camouflage tape and its preparation, to achieve the effects of easy realization, good adaptability, and improved camouflage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

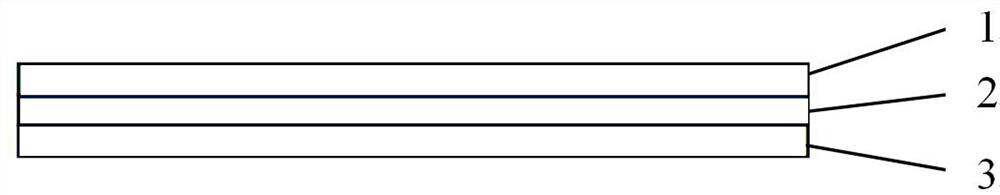

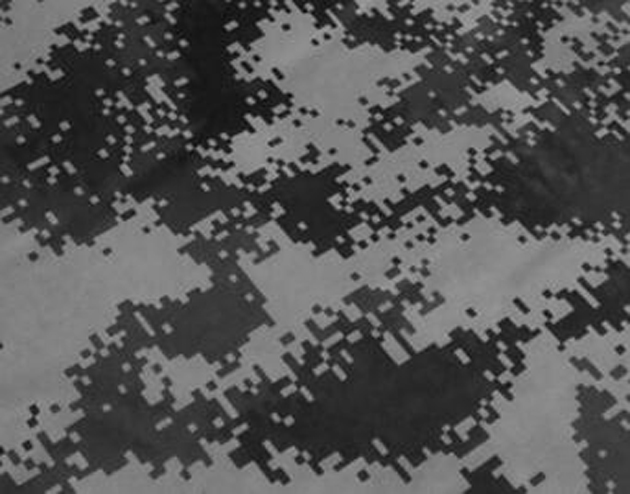

[0019] Embodiment 1: a kind of digital camouflage adhesive tape, such as figure 1 As shown, it includes the base fabric 1, the protective rubber layer 2 and the digital camouflage film 3 which are stacked and fastened in sequence; the protective rubber layer 2 has a weight ratio of 100:2:0.5:1:0.5:30:25:5 : 5:1 brominated butyl rubber, zinc oxide, sulfur, accelerator TT, accelerator DM, decabromodiphenyl ether, zinc borate, octyl diphenyl phosphate, carbon black N220 and antioxidant 4010NA The base cloth 1 is made of nylon material, and the digital camouflage tape prepared in embodiment 1 is as follows: figure 2 shown. The preparation method of the digital camouflage adhesive tape in embodiment 1 is as follows, specifically comprises the following steps:

[0020] Step 1, rubber mixing: use bromobutyl rubber as the main material and other compounding agents, and mix 30kg of rubber according to the formula in Table 1 below;

[0021] Table 1

[0022] serial number ...

Embodiment 2

[0029] Embodiment 2: a kind of digital camouflage adhesive tape, comprises the base cloth 1, protective rubber layer 2 and digital camouflage adhesive film 3 that are stacked successively and fastened connection; Protective rubber layer 2 is 100:5:1:0.5 by weight ratio: 30:25:10:5:1 Chlorobutyl rubber, zinc oxide, accelerator TT, accelerator DM, decabromodiphenyl ether, zinc borate, antimony trioxide, carbon black N220 and antioxidant 4010NA mixing Formed, the base cloth 1 is made of aramid fiber material, and the digital camouflage adhesive tape prepared in embodiment 2 is as follows image 3 shown. The preparation method of the digital camouflage adhesive tape in embodiment 2 is as follows, specifically comprises the following steps:

[0030] Step 1, rubber mixing: use chlorobutyl rubber as the main material and other compounding agents, and mix 30kg of rubber according to the formula in Table 3 below;

[0031] table 3

[0032] serial number Raw material name ...

Embodiment 3

[0039] Embodiment 3: a kind of digital camouflage adhesive tape, comprises the base cloth 1, protective rubber layer 2 and digital camouflage adhesive film 3 that are stacked successively and fastened connection; Protective rubber layer 2 is 100:3:1:1 by weight ratio: 1.5:1:1:15:30:30 Chlorine ether rubber, lead tetraoxide, accelerator NA-22, zinc stearate, magnesium oxide, anti-aging agent NBC, anti-aging agent MB, quick-extrusion carbon black, clay Formed by mixing with aluminum oxide, the base cloth 1 is made of polyester material, and the digital camouflage tape prepared in embodiment 3 is as follows: Figure 4 shown. The preparation method of digital camouflage adhesive tape in embodiment 3 is as follows, specifically comprises the following steps:

[0040] Step 1. Mixing of rubber materials: use chloroether rubber as the main material and other compounding agents, and mix 30kg of rubber materials according to the formula in Table 5 below;

[0041] table 5

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com