One-dimensional porous carbon nanometer fiber material and preparation method and application thereof

A nanofiber, porous carbon technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of reducing the actual capacity of the electrode with sulfur utilization, reducing the utilization rate of electrochemically active sulfur, and reducing the battery cycle stability. , to achieve the effect of convenient commercial application, low cost of raw materials, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

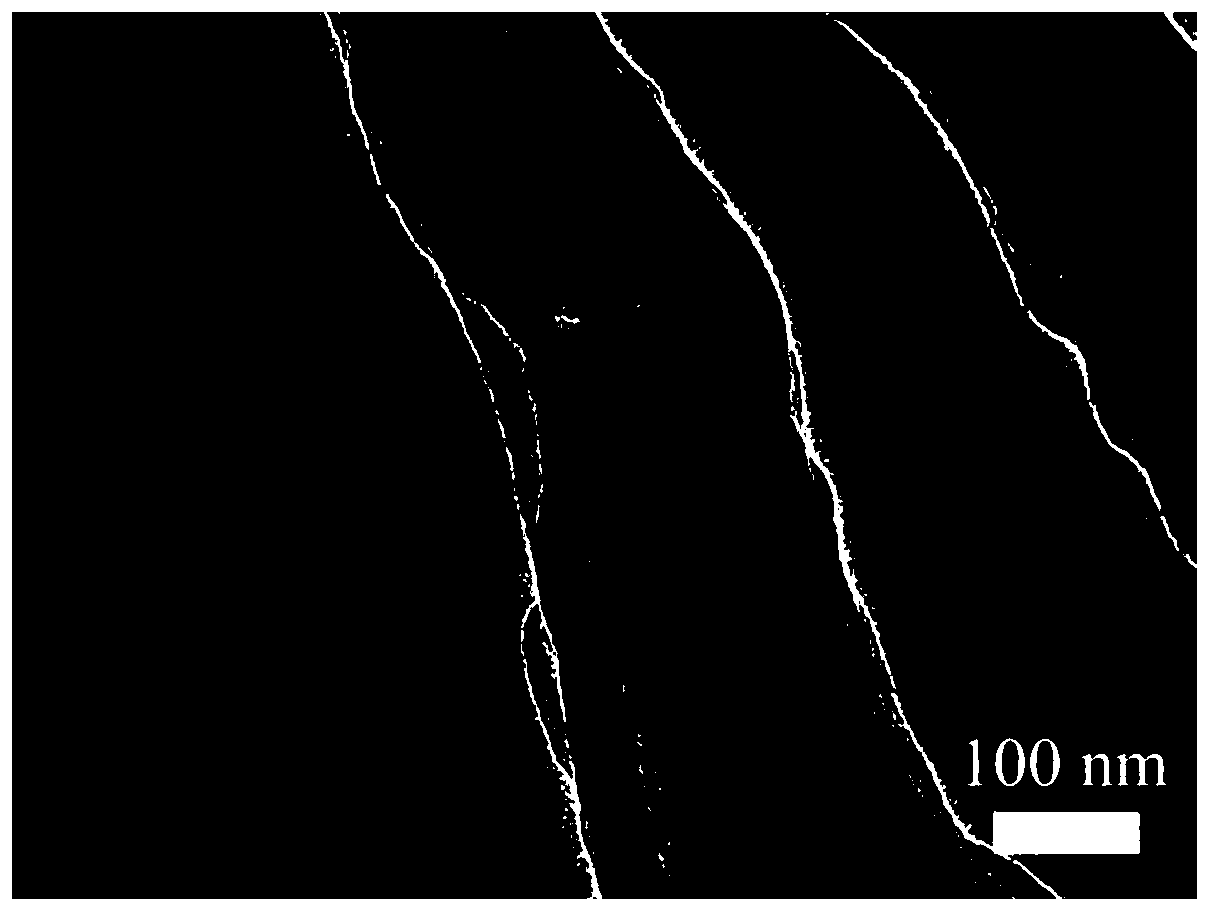

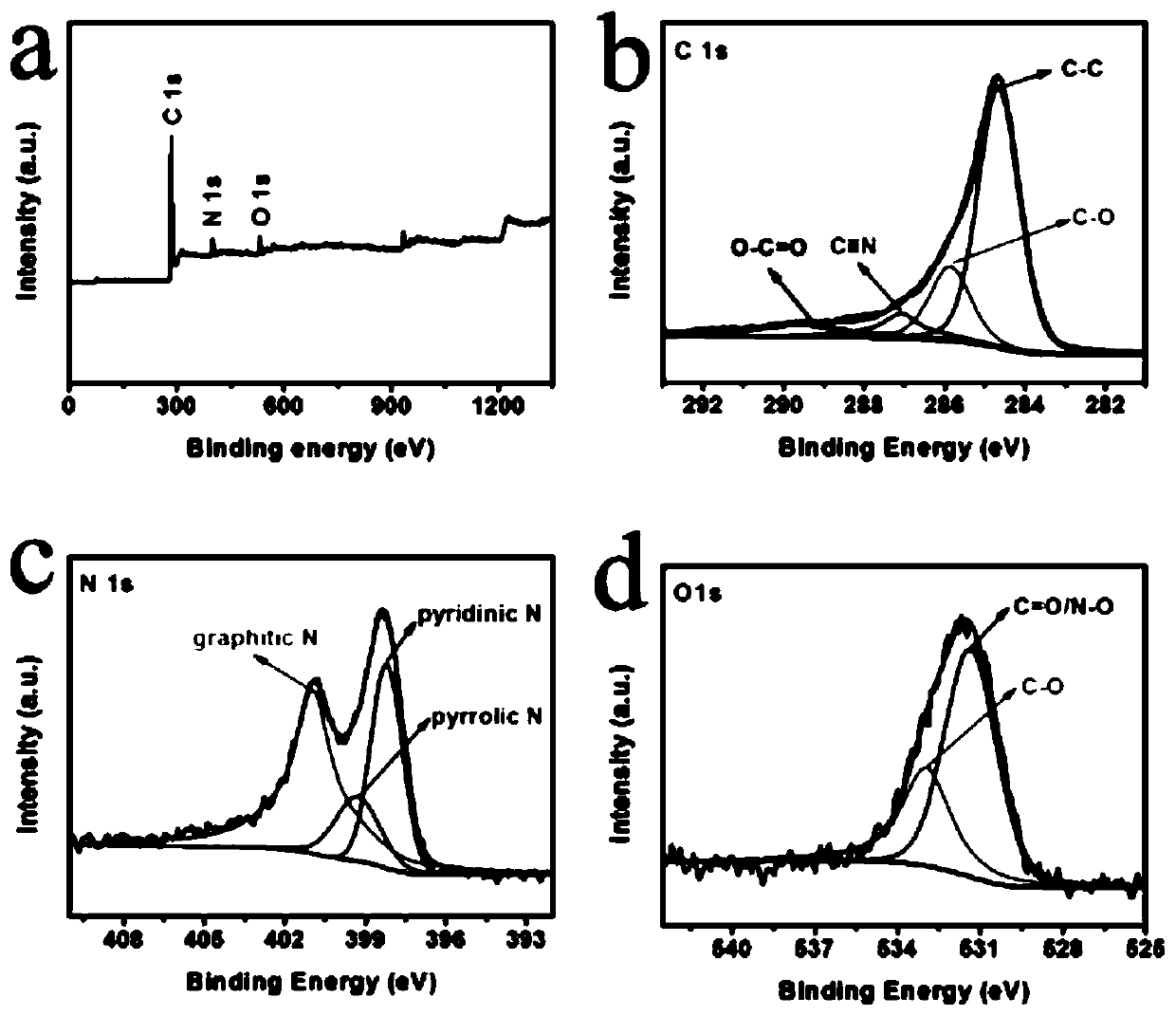

[0033] Preparation of one-dimensional porous carbon nanofiber materials

[0034] (1) The carbon source (polyacrylonitrile with a molecular weight of 150,000), the templating agent (addition polymer of polypropylene glycol and ethylene oxide) and the conductive agent (carboxylated carbon nanotubes) into a solvent (N,N-dimethylformamide), stirred at 60°C for 12 hours, and then ultrasonicated for 30 minutes at a power of 360W and a frequency of 40KHz to obtain a spinning solution;

[0035] (2) Inject the spinning solution in step (1) into a 10mL syringe for use, and then set the electrospinning parameters: the injection speed is 0.0008mm / s, the distance between the needle tip of the injection and the collecting plate is 12cm, and the working voltage is 15kV , the fiber precursor was prepared by electrospinning;

[0036] (3) Dry the fiber precursor in step (2) at 60°C for 12 hours, then raise the temperature to 280°C at a rate of 1°C / min, keep it warm for 3 hours, then lower it t...

Embodiment 2

[0038] Preparation of one-dimensional porous carbon nanofiber materials

[0039] (1) Add carbon source (polyvinyl alcohol), templating agent (addition polymer of polypropylene glycol and ethylene oxide) and conductive agent (graphene oxide) to the solvent at a mass volume ratio of 1:0.4:35:24 (ethanol), stirred at 30°C for 24h to mix, and then ultrasonicated for 5h under the condition of power of 80W and frequency of 40KHz to obtain spinning solution;

[0040] (2) Inject the spinning solution in step (1) into a 10mL syringe for use, and then set the electrospinning parameters: the injection speed is 0.0015mm / s, the distance between the needle tip of the injection and the collecting plate is 30cm, and the working voltage is 40kV , the fiber precursor was prepared by electrospinning;

[0041] (3) Dry the fiber precursor in step (2) at 100°C for 12 hours, then raise the temperature to 200°C at a rate of 3°C / min, keep it warm for 5 hours, then lower it to room temperature at a ra...

Embodiment 3

[0043] Preparation of one-dimensional porous carbon nanofiber materials

[0044] (1) The carbon source (polyvinylpyrrolidone), templating agent (addition polymer of polypropylene glycol and ethylene oxide) and conductive agent (carboxylated carbon nanotubes) were sequentially mixed according to the mass volume ratio of 1:0.2:94:18 Add it into the solvent (methanol), stir at 90°C for 10h to mix, and then ultrasonicate for 2h under the condition of power of 200W and frequency of 40KHz to obtain spinning solution;

[0045] (2) Inject the spinning solution in step (1) into a 10mL syringe for use, and then set the electrospinning parameters: the injection speed is 0.0003mm / s, the distance between the needle tip of the injection and the collecting plate is 20cm, and the working voltage is 35kV , to prepare fiber precursor by electrospinning;

[0046] (3) Dry the fiber precursor in step (2) at 80°C for 24h, then raise the temperature to 380°C at a rate of 5°C / min, keep it warm for 2h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com