Water-borne epoxy resin, preparation process thereof and epoxy zinc-rich primer

A water-based epoxy resin and epoxy resin technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of low solid content and high solvent water content, achieve high solid content, reduce production costs, improve The effect of the antiseptic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

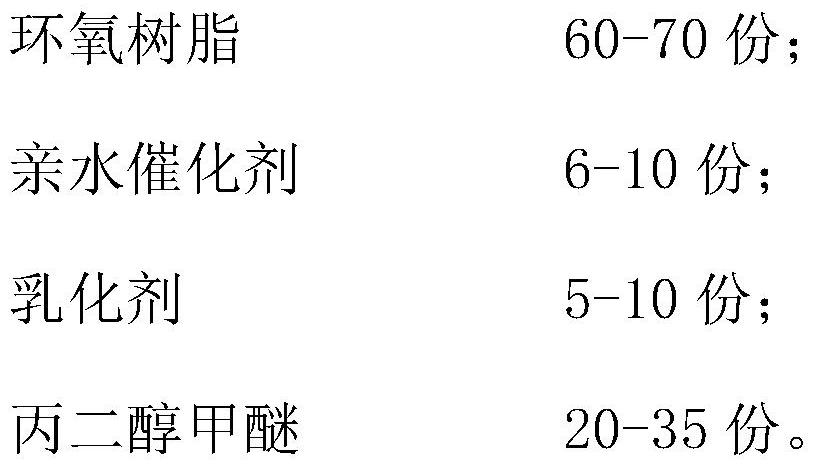

[0073] To prepare 1kg of emulsifier, the following raw materials need to be used in parts by mass:

[0074] E20 epoxy resin 90g;

[0075] N,N dimethylethanolamine 10g;

[0076] Polyethylene glycol 900g.

[0077] The preparation technology of emulsifying agent specifically comprises the following processing steps:

[0078] Weigh and mix the epoxy resin and polyethylene glycol according to the above ratio, stir at a temperature of 70±2°C at a stirring speed of 400r / min, and stir for about 10min to make the epoxy resin and polyethylene glycol mix evenly. Then add N,N dimethylethanolamine, continue to stir, and after stirring for about 10 minutes, raise the temperature to 130±2°C, and keep it warm for 5 hours to obtain the emulsifier.

[0079] Due to the severe yellowing of the emulsifier finally obtained, it was not used as an emulsifier for epoxy resin water-based modification.

preparation example 2

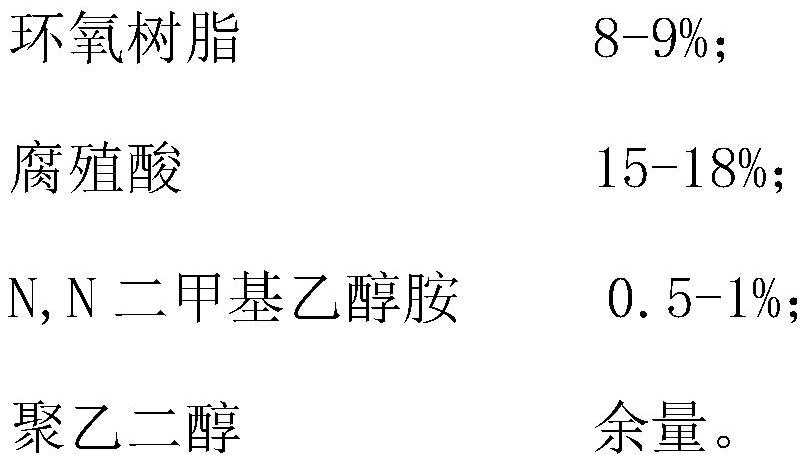

[0081] To prepare 1kg of emulsifier, the following raw materials need to be used in parts by mass:

[0082]

[0083] The preparation technology of emulsifying agent specifically comprises the following processing steps:

[0084] Step 1, esterification reaction, weigh polyethylene glycol and humic acid according to the above mass parts, mix the two evenly, pass nitrogen gas into the process for protection, and react at a temperature of 120±2°C for 2 hours to obtain an esterified product .

[0085] Step 2, grafting reaction, weigh the epoxy resin and N,N dimethylethanolamine according to the above mass parts, first add the epoxy resin to the esterified product prepared in step 1, and control the temperature to 110±2°C After stirring evenly, N, N dimethylethanolamine is added, and nitrogen gas is still passed through the whole process for protection. After reacting for 1 hour, the emulsifier is obtained.

preparation example 3-6

[0087] The difference between Preparation Example 3-6 and Preparation Example 2 is that the various compositions of the emulsifier are different, and are recorded as the following table, and the measurement units of the components in the following table are all g:

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com