Manufacturing method of heterojunction solar cell and heterojunction solar cell

A technology for solar cells and manufacturing methods, applied in the directions of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., capable of solving the problems of reduced efficiency of heterojunction solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

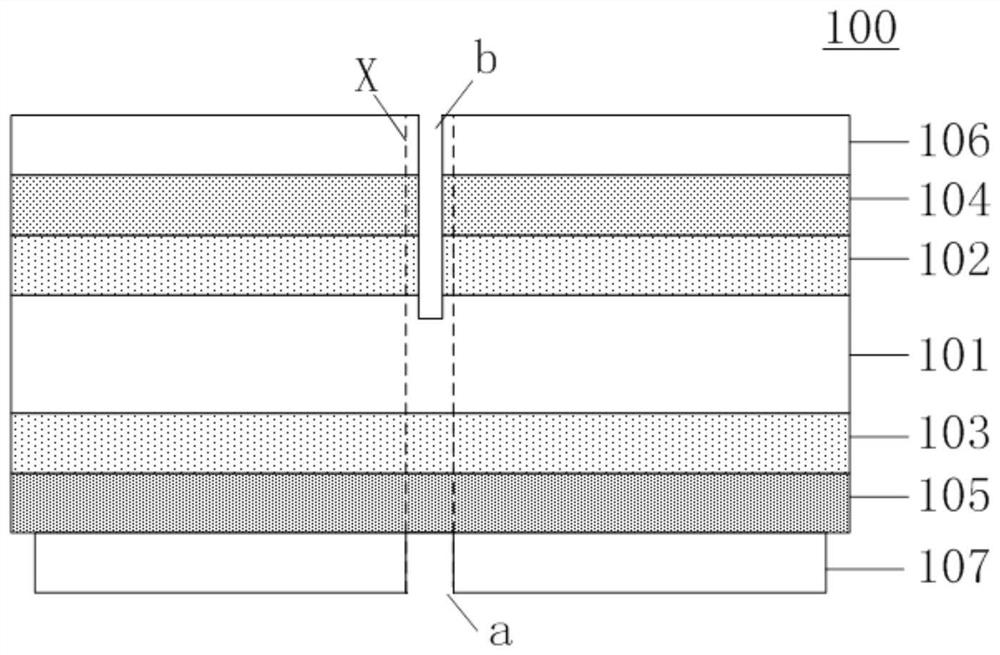

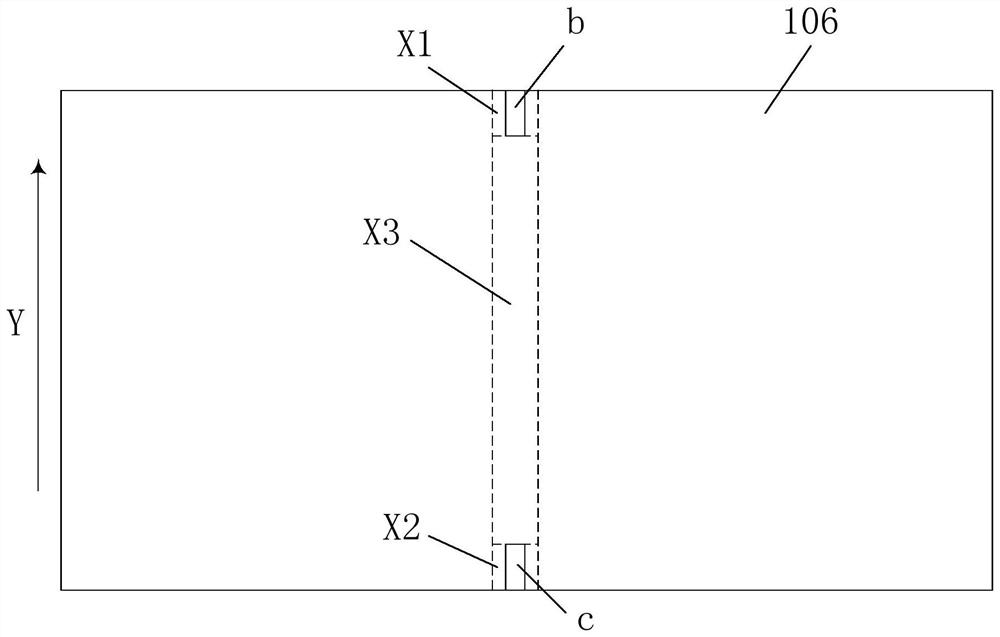

[0052] refer to Figure 1-Figure 4 , this embodiment provides a method for manufacturing a heterojunction solar cell, characterized in that it includes:

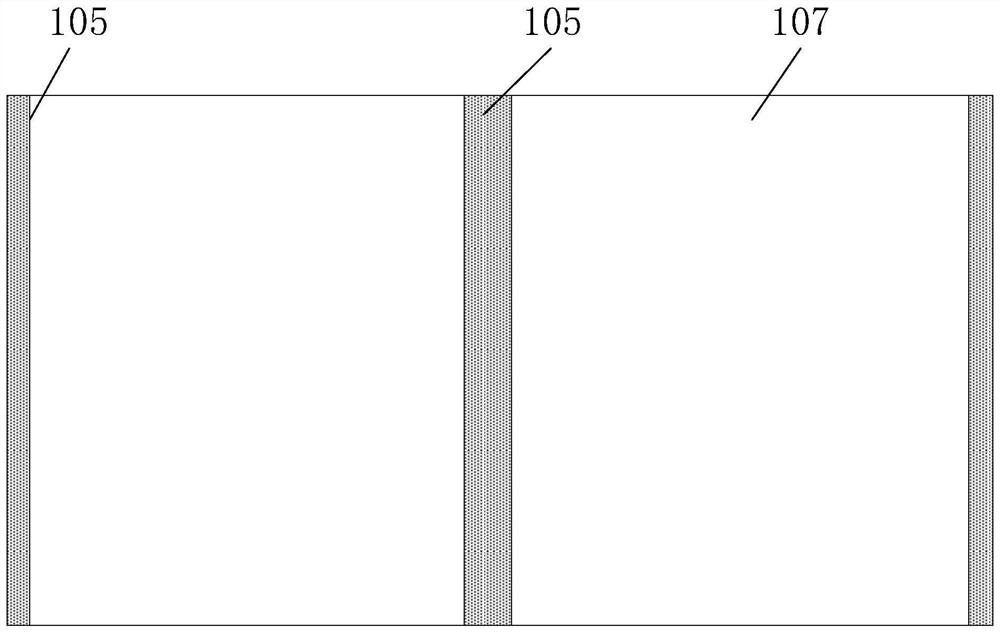

[0053] The initial solar cell sheet 100 is formed, the initial solar cell sheet has a cutting area X, and the step of forming the initial solar cell sheet 100 includes: providing a semiconductor substrate layer 101 . A first conductivity type semiconductor layer 105 is formed on one side of the semiconductor substrate layer 101 , and the conductivity type of the first conductivity type semiconductor layer 105 is opposite to that of the semiconductor substrate layer 101 . A first transparent conductive layer 107 is formed on a side of the first conductive type semiconductor layer 105 facing away from the semiconductor substrate layer 101 .

[0054] A first cutting groove a penetrating through the thickness of the first transparent conductive layer 107 is formed in the first transparent conductive layer 107 in the cutting reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com