Method for coating surface of oxide ceramic powder with metal nanoparticles

A technology of metal nanoparticles and oxide ceramics, applied in the field of material processing engineering, can solve the problems of easy agglomeration and growth of nanoparticles, reduced hardness and strength, etc., and achieve the effects of reducing reaction time, production cost, and preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

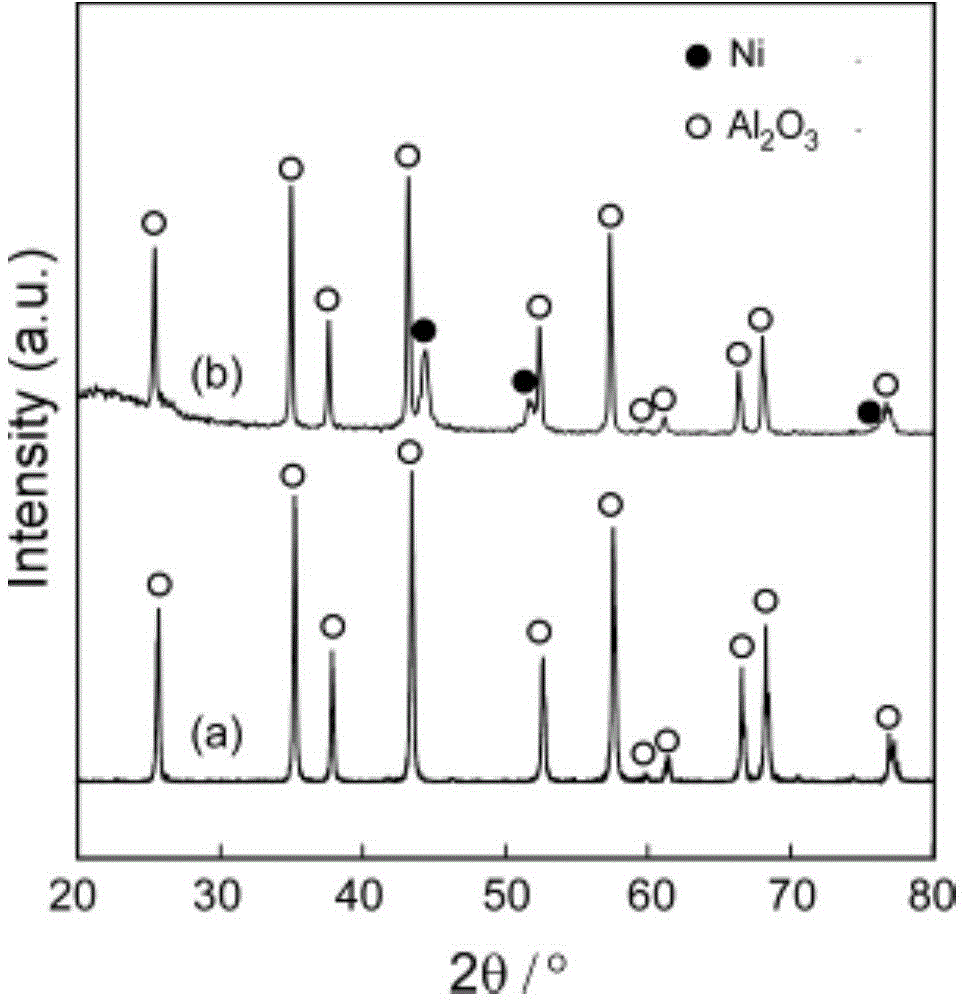

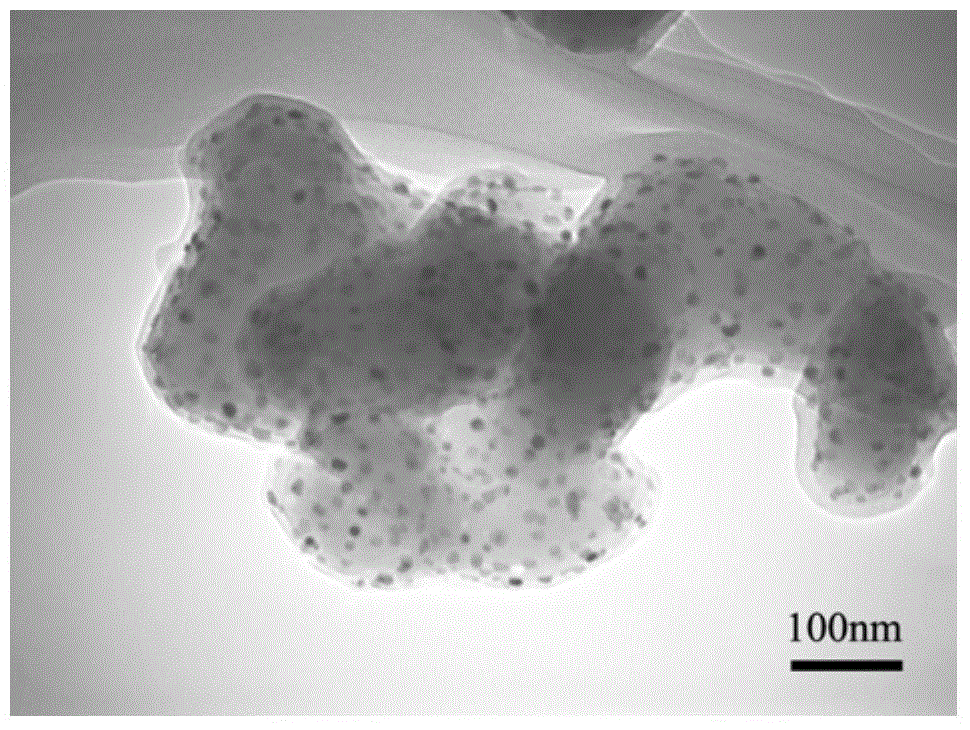

[0025] Example 1 Al 2 o 3 The surface of the powder is coated with Ni nanoparticles.

[0026] First, the common commercial 5g Al 2 o 3 Powder (particle size is 500nm) and 0.5g Ni(CO) 4 After mixing, put it into a rotary reactor, and rotate the reactor at a rotation rate of 45 r / min. The mixed gas of oxygen and Ar is introduced, the total pressure of the mixed gas is 1000Pa, and the partial pressure of oxygen is 100Pa. The heating rate is 8°C / min, and the temperature is raised to 450°C and then kept for 45 minutes to make Ni(CO) 4It is oxidized to nickel oxide, then the oxygen supply valve is closed, and carbon monoxide is introduced to reduce the metal oxide nickel oxide to metallic nanoparticles. The partial pressure of carbon monoxide is 200Pa, the reduction reaction time is 45min, and then the temperature starts to drop, and the temperature drop rate is 8°C / min. After cooling down to room temperature, close the gas valve, stop the rotation of the instrument and the h...

Embodiment 2

[0027] Example 2 Al 2 o 3 The surface of the powder is coated with Cu nanoparticles.

[0028] First, the common commercial 5g Al 2 o 3 Powder (100nm particle size) and 2g Cu(DPM) 2 (copper dipivaloylmethanate) mixed, put into the rotary reactor, close the inlet valve of the rotary reactor, start the rotary reactor to rotate, and adjust the rotation rate to 60r / min. Then feed the mixed gas of oxygen and argon, the total pressure of the mixed gas is 800Pa, and the partial pressure of oxygen is 50Pa. The heating rate was set at 5°C / min, and the temperature was raised to 400°C and kept for 60 minutes to make Cu(DPM) 2 It is oxidized to copper oxide, then the oxygen supply valve is closed, and methane is introduced to reduce the metal oxide CuO to metallic nanoparticles. The partial pressure of methane is 100Pa, the reduction reaction time is 60min, and then the temperature starts to drop, and the temperature drop rate is 5°C / min. After cooling down to room temperature, clos...

Embodiment 3

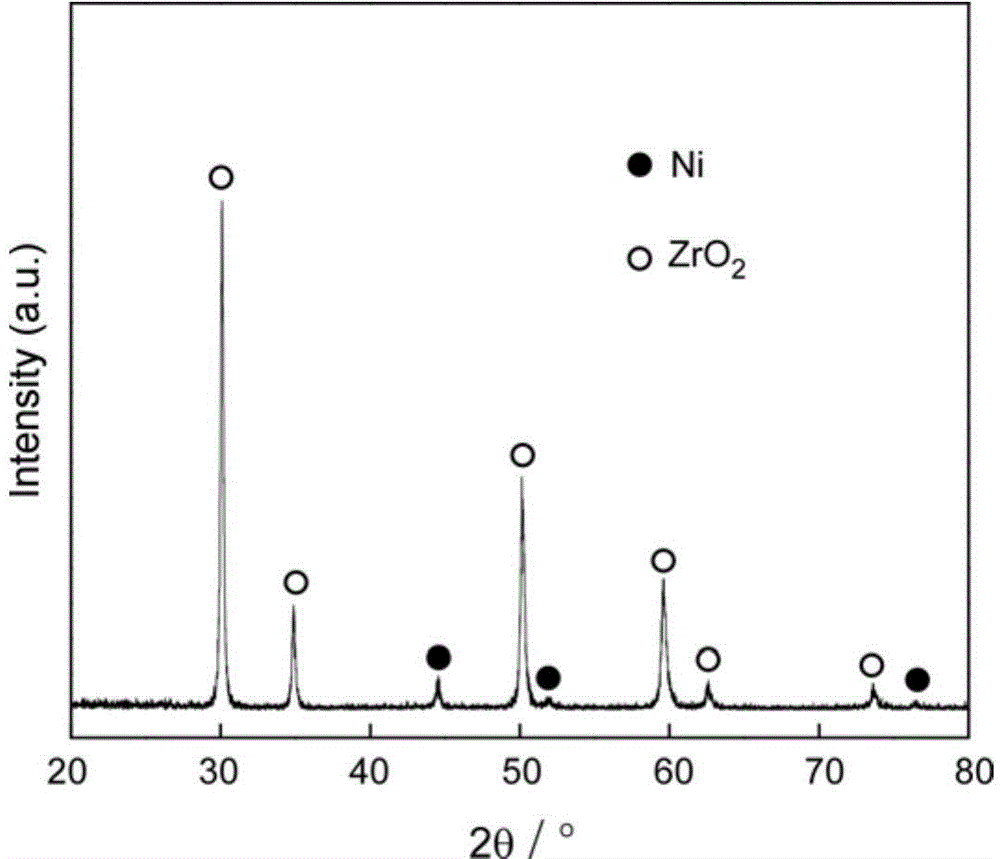

[0029] Example 3 ZrO 2 The surface of the powder is coated with Ni nanoparticles.

[0030] First, common commercial 5g ZrO 2 Powder (particle size is 10μm) and 5g NiCp 2 (nickelocene) mixed, put into the rotary reactor, the reactor is rotated, the rotation rate is 15r / min. A mixed gas of oxygen and Ar is introduced, the total pressure of the mixed gas is 800Pa, and the partial pressure of oxygen is 200Pa. The heating rate was 7°C / min, and the temperature was raised to 450°C and then kept for 30 minutes, so that the NiCp 2 It is oxidized to NiO, then the oxygen supply valve is closed, and hydrogen gas is introduced to reduce the metal oxide NiO to metallic nanoparticles. The partial pressure of hydrogen is 400Pa, the reduction reaction time is 30min, and then the temperature starts to drop, and the temperature drop rate is 7°C / min. After cooling down to room temperature, close the gas valve, stop the rotation of the instrument and the heating of the reactor, open the instr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com