Method for annealing simplified, efficient, low-cost and high-temperature superconductive long band

A high-temperature superconducting, low-cost technology, used in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as being unsuitable for large-scale production requirements of kilometer-scale strips, long annealing time, and unstable quality. Annealing time, short annealing time, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

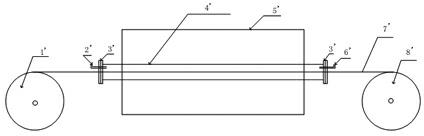

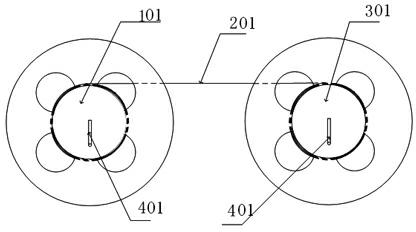

[0035] Step 1. Put the long superconducting tape to be annealed on the manual winding machine, and manually wind it on the annealing disk;

[0036] Properly control the manual winding speed (<60 turns / min) during the winding process to avoid excessive pressure between each turn of the strip in the annealing reel, so that there is a certain micro-gap between each layer of the superconducting strip;

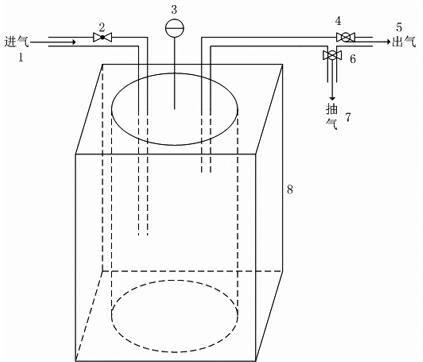

[0037] Step 2. Put the annealing tray into the vacuum box furnace and close the furnace door;

[0038] Open the exhaust valve to vacuum;

[0039] At room temperature of 25°C, turn on the mechanical pump to evacuate to 5×10 -2 Torr;

[0040] When the vacuum degree in the annealing box reaches 5×10 -2 After Torr, close the pumping valve, open the intake valve to feed high-purity oxygen with a purity of 99.95%;

[0041] The oxygen flow is controlled by a mass flow meter, and the oxygen flow is controlled within the range of 5-20SCCM;

[0042] When the oxygen pressure gauge inside...

Embodiment 2

[0048] Step 1. Put the long superconducting tape to be annealed on the manual winding machine, and manually wind it on the annealing disk;

[0049] Properly control the manual winding speed (<60 turns / min) during the winding process to avoid excessive pressure between each turn of the strip in the annealing reel, so that there is a certain micro-gap between each layer of the superconducting strip;

[0050] Step 2. Put the annealing tray into the vacuum box furnace and close the furnace door;

[0051] Open the exhaust valve to vacuum;

[0052] At room temperature of 25°C, turn on the mechanical pump to evacuate to 5×10 -2 Torr;

[0053] When the vacuum degree in the annealing box reaches 5×10 -2 After Torr, close the pumping valve, open the intake valve to feed high-purity oxygen with a purity of 99.95%;

[0054] The oxygen flow is controlled by a mass flow meter, and the oxygen flow is controlled within the range of 5-20SCCM;

[0055] When the oxygen pressure gauge inside...

Embodiment 3

[0061] Step 1. Put the long superconducting tape to be annealed on the manual winding machine, and manually wind it on the annealing disk;

[0062] Properly control the manual winding speed (<60 turns / min) during the winding process to avoid excessive pressure between each turn of the strip in the annealing reel, so that there is a certain micro-gap between each layer of the superconducting strip;

[0063] Step 2. Put the annealing tray into the vacuum box furnace and close the furnace door;

[0064] Open the exhaust valve to vacuum;

[0065] At room temperature of 25°C, turn on the mechanical pump to evacuate to 5×10 -2 Torr;

[0066] When the vacuum degree in the annealing box reaches 5×10 -2 After Torr, close the pumping valve, open the intake valve to feed high-purity oxygen with a purity of 99.95%;

[0067] The oxygen flow is controlled by a mass flow meter, and the oxygen flow is controlled within the range of 5-20SCCM;

[0068] When the oxygen pressure gauge inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com