Patents

Literature

41results about How to "Guaranteed precise controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

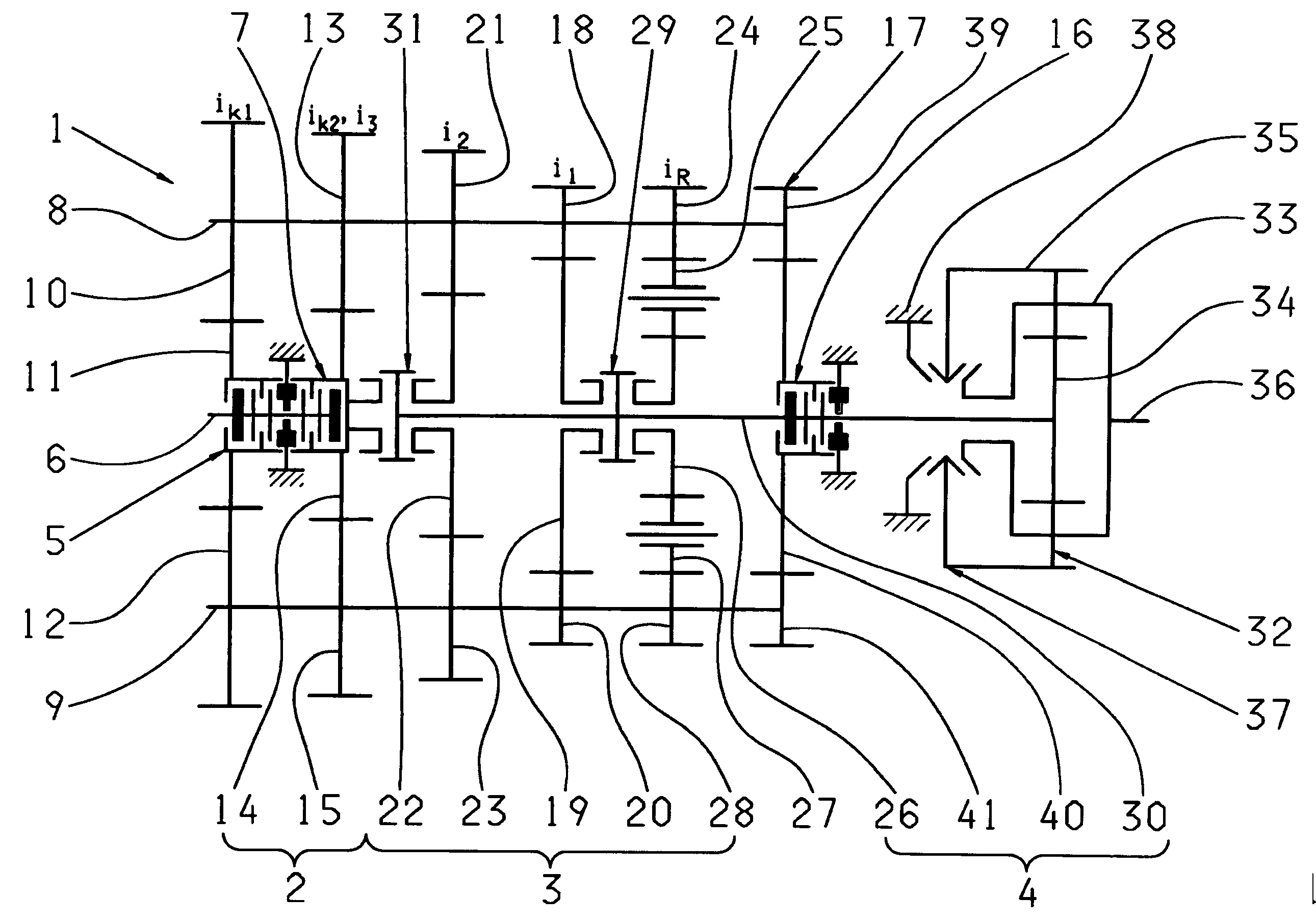

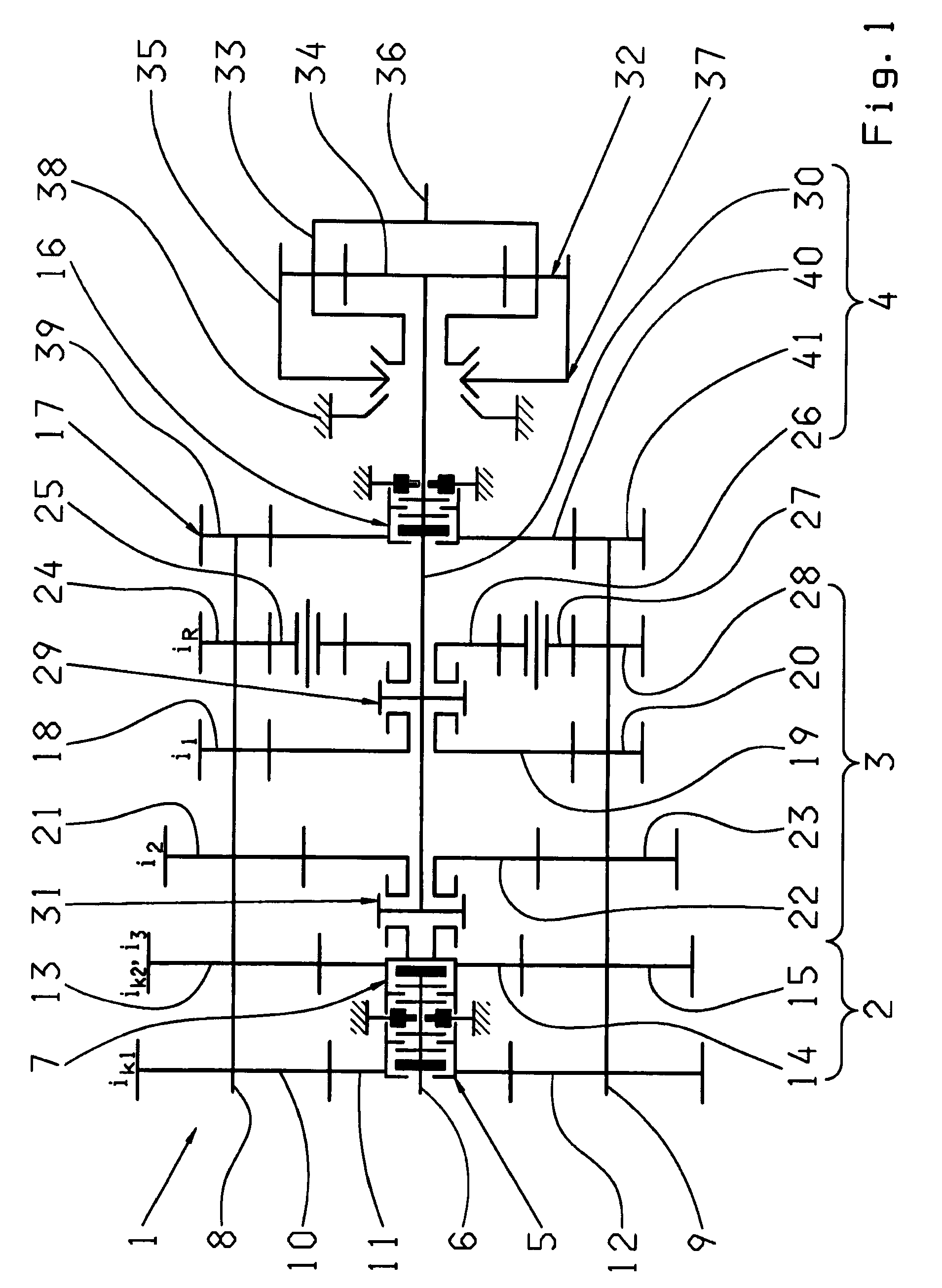

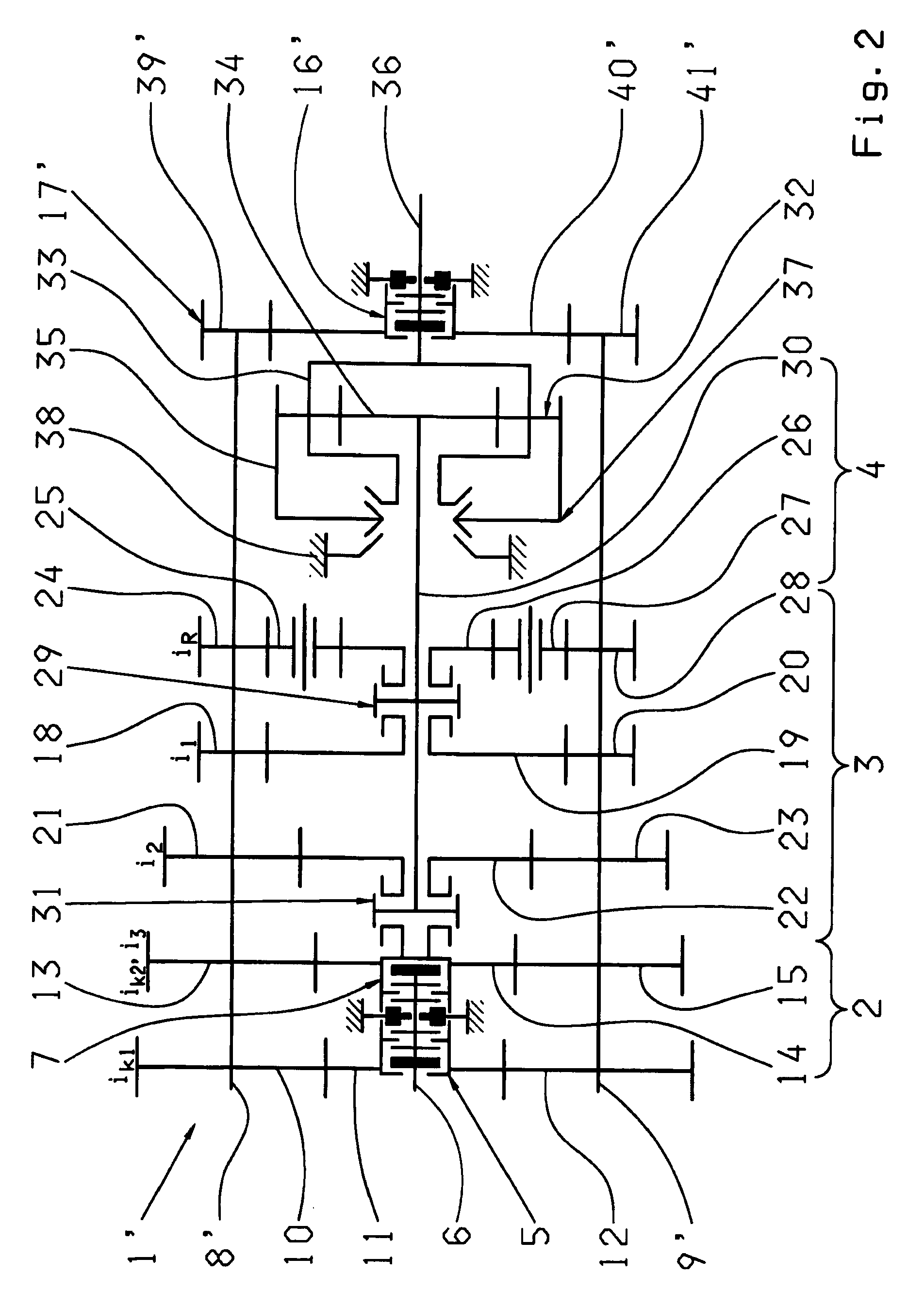

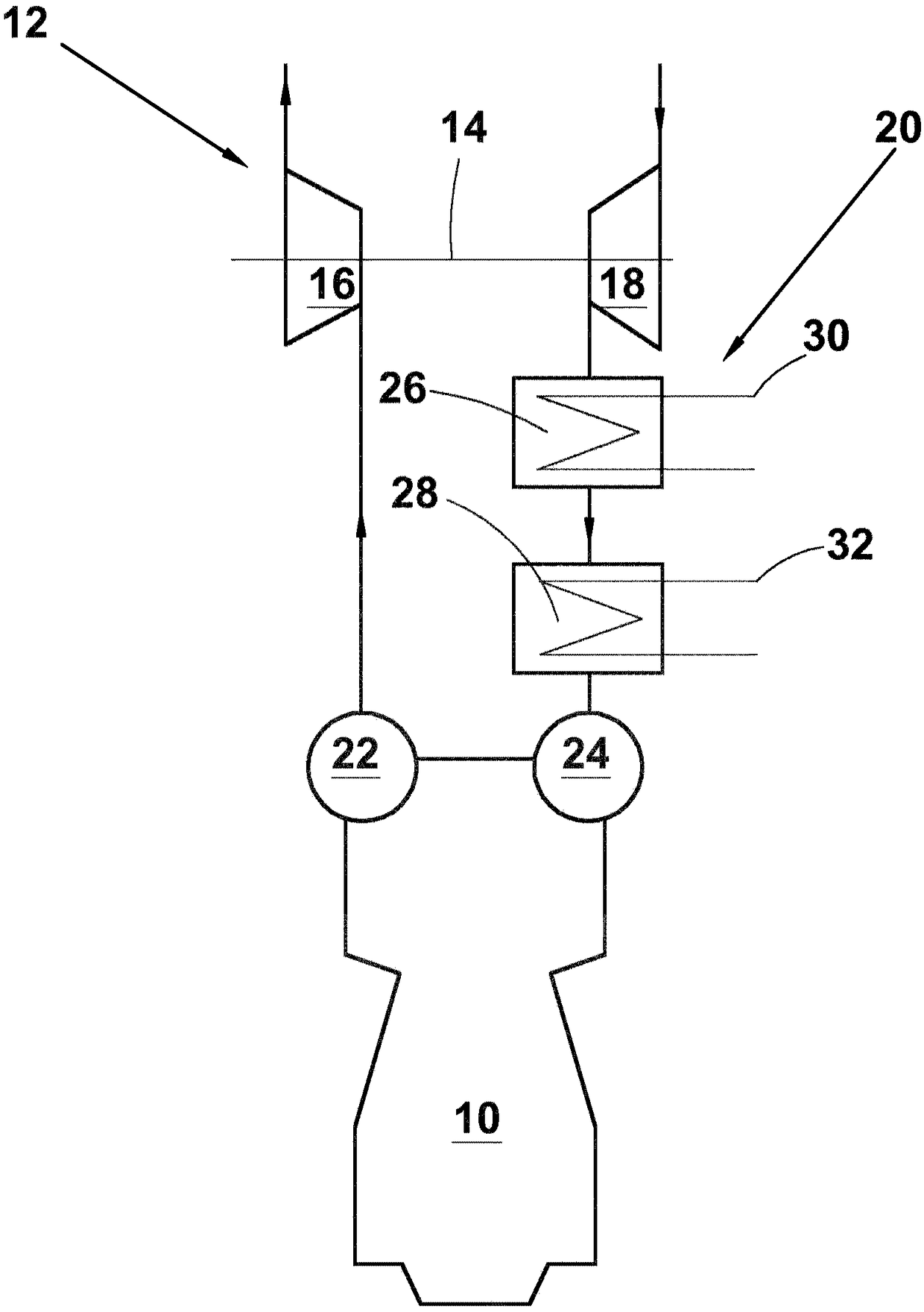

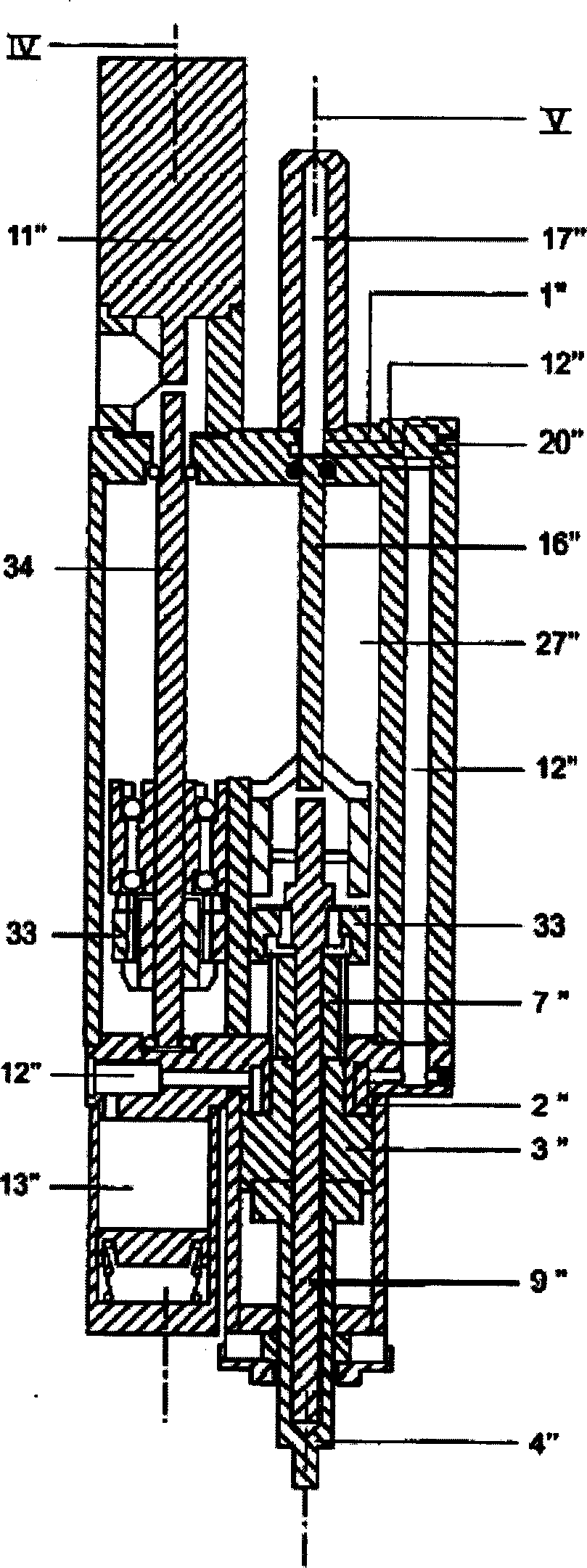

Multi-group transmission of a motor vehicle

InactiveUS20090272211A1Low costSave spaceMechanical actuated clutchesMagnetically actuated clutchesDrivetrainDrive shaft

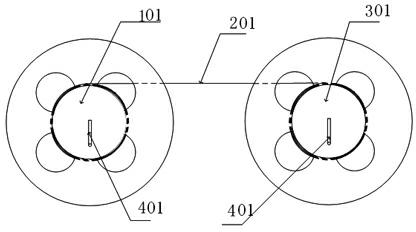

A multi-group transmission of a motor vehicle which includes at least two transmission groups arranged in a drivetrain and a way for supporting traction force during gearshifts such that traction-force gearshifts are maintained with improved shifting comfort at comparatively low cost, little design effort and compact installation space demands. At least one electromagnetic clutch is a change-under-load unit by which, bypassing the force flow of at least one main group made as a gear-change transmission, an active connection can be formed between a driveshaft and a main transmission shaft or a transmission output shaft. During a gearshift operation, an active connection is temporarily made between a driveshaft and a main transmission shaft or a transmission output shaft by way of at least one electromagnetic clutch designed as a change-under-load unit.

Owner:ZF FRIEDRICHSHAFEN AG

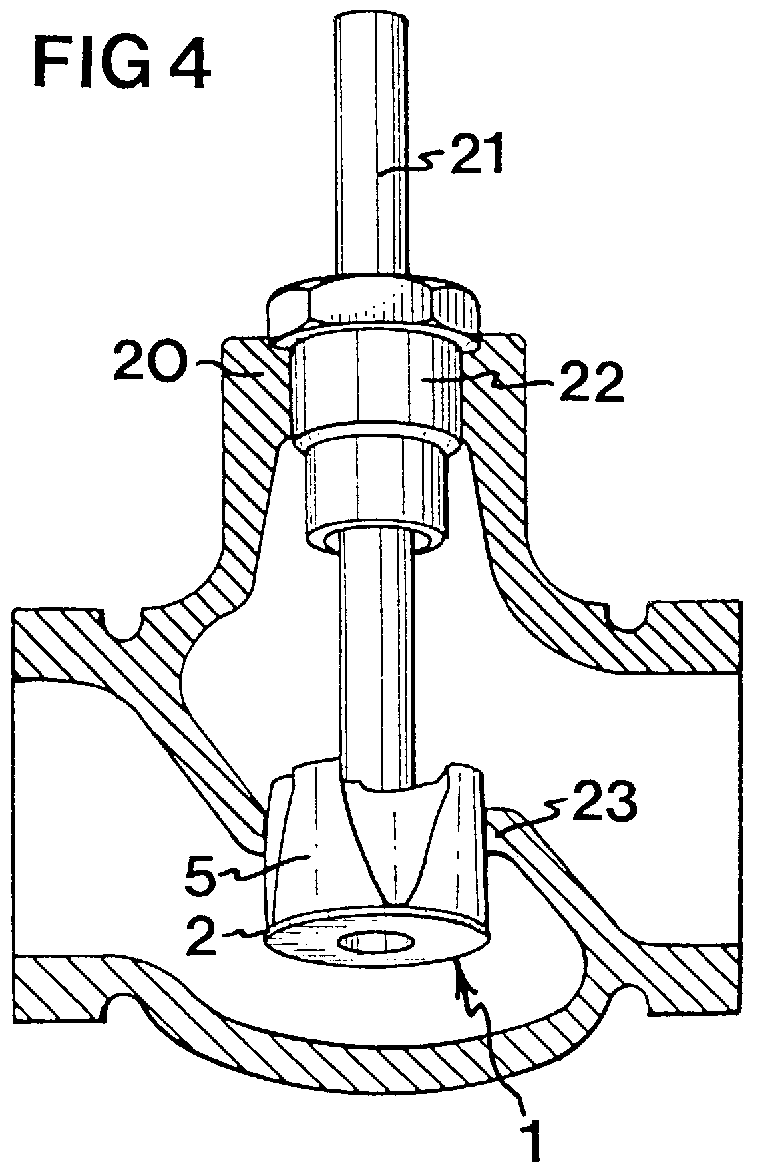

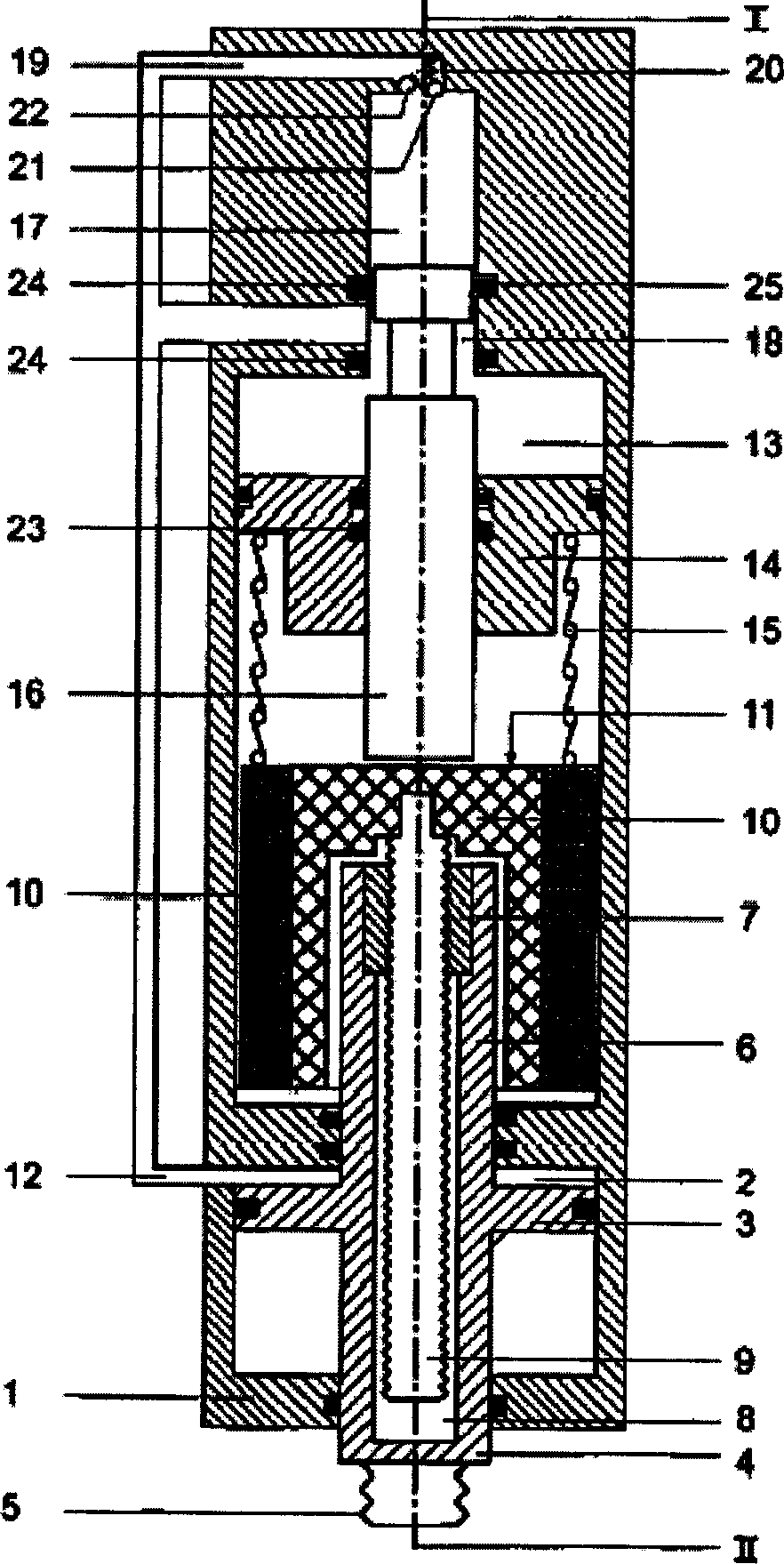

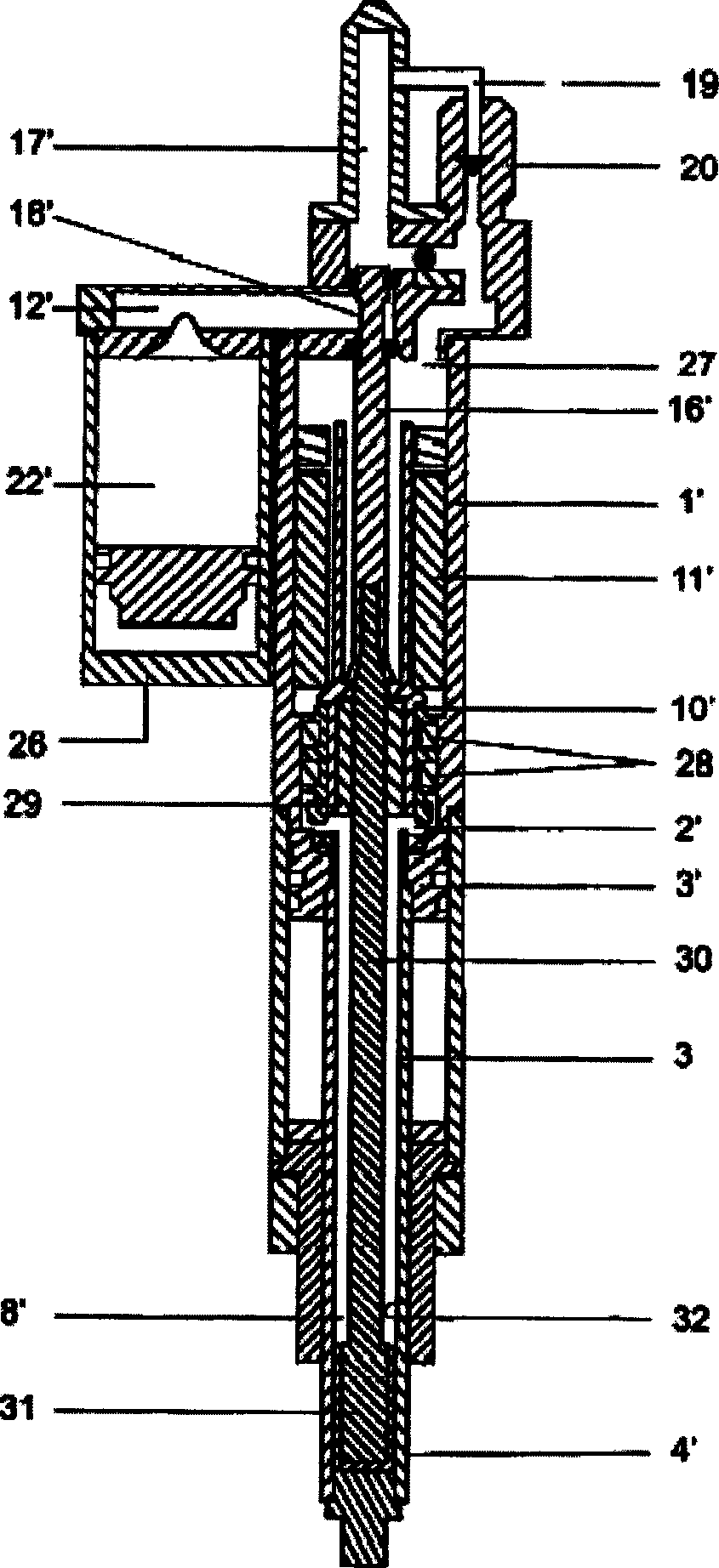

Valve cone, a valve and a valve manufacturing process

InactiveUS6082405AFunction increaseReduce wearValve members for absorbing fluid energyMachines/enginesEngineeringVALVE PORT

A valve cone comprises a cylindrical body extending along a longitudinal axis. The body has a cylindrical surface with at least one, axially extending recess. The recess extends inside a contour line between a first end position at a first end of the cylindrical body and a second end position, which is located between the first end of the body and the opposite second end of the body. The cross-sectional area of the recess, in a plane perpendicular to its longitudinal axis, gradually decreases from a maximum value close to the said first end towards the second end position. A valve cone of the type described above is arranged in a valve. In a method for manufacturing the valve cone, the radial recesses are formed by cutting in a single axial-radial cutting motion.

Owner:TAK AB

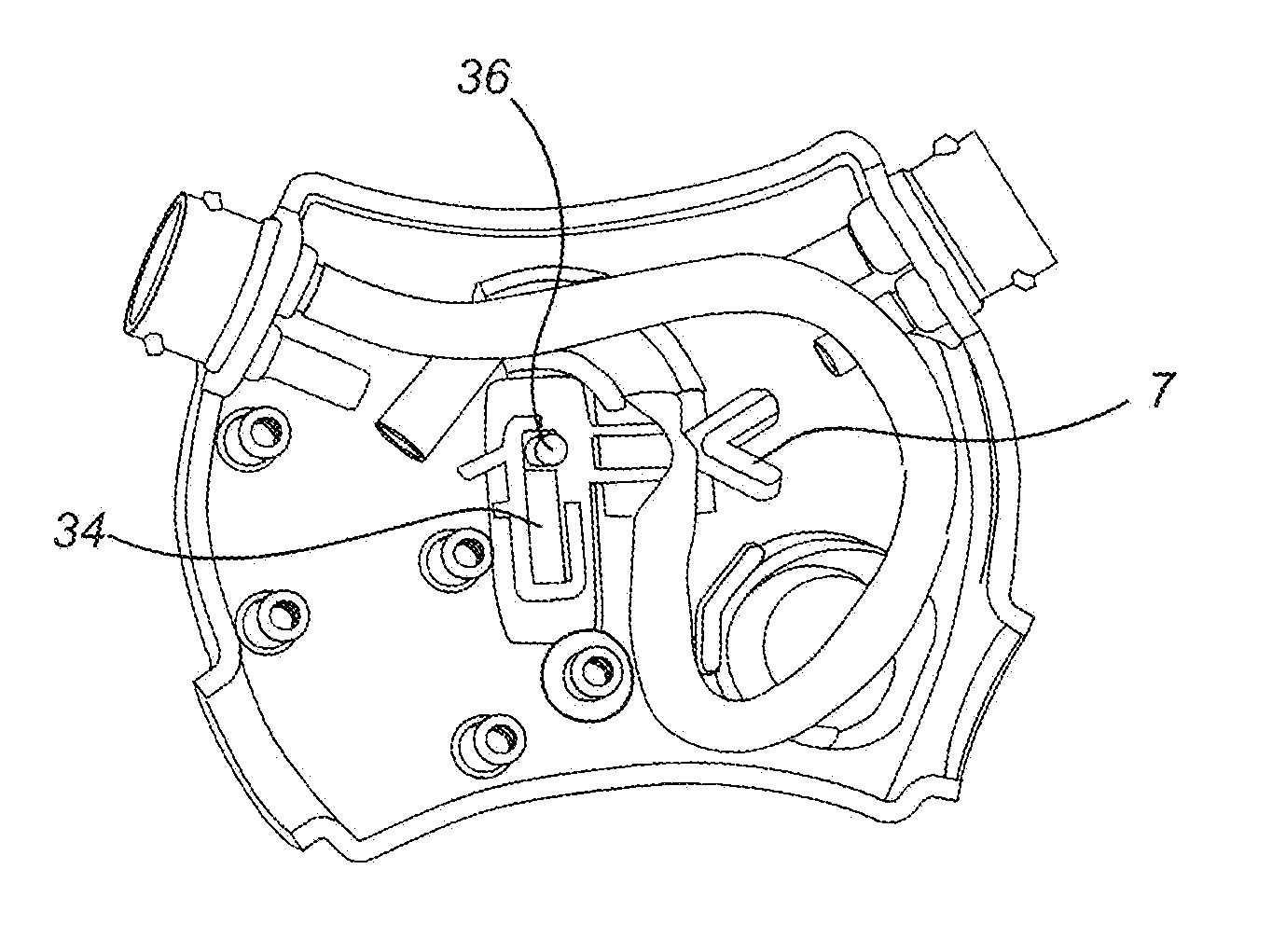

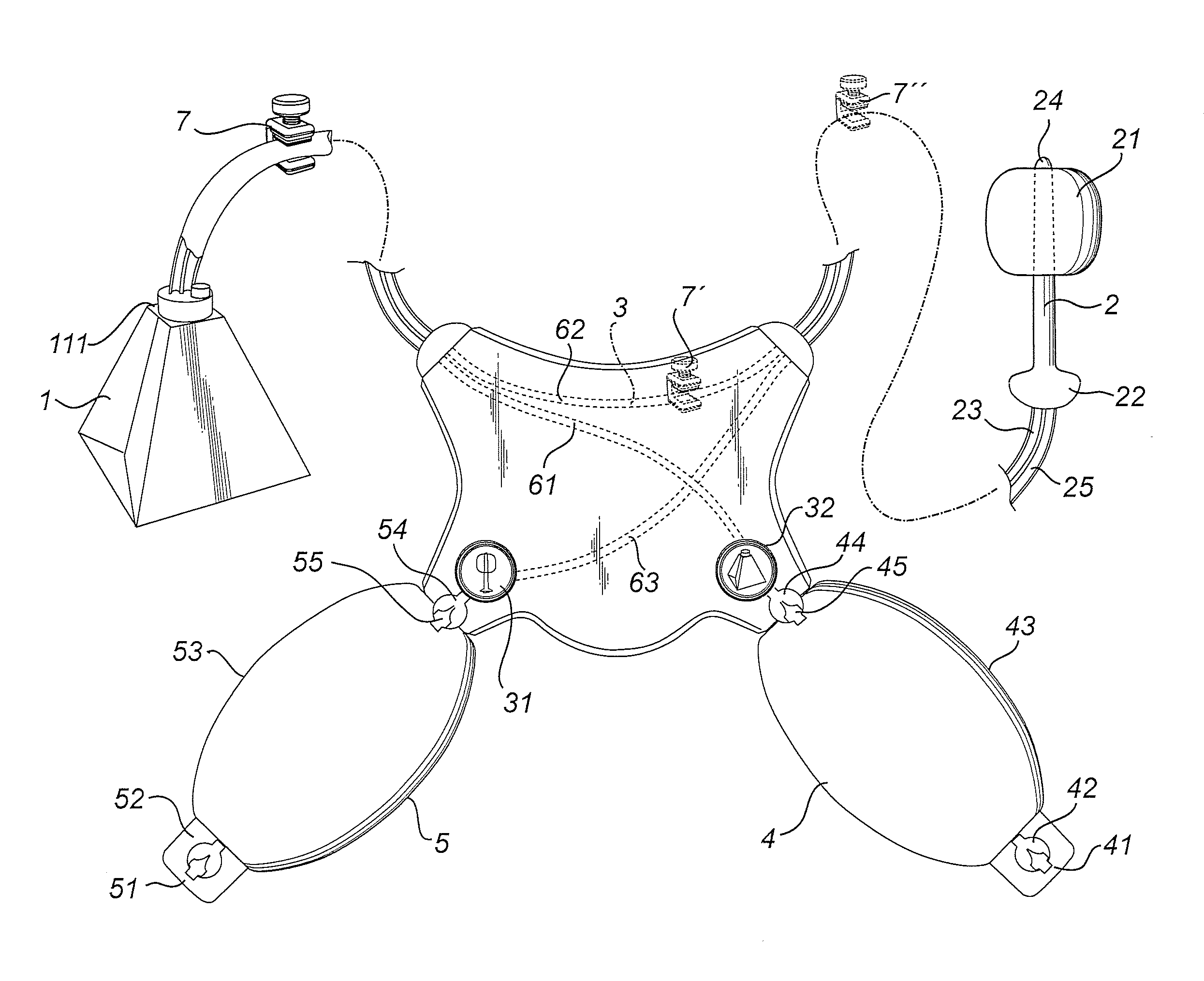

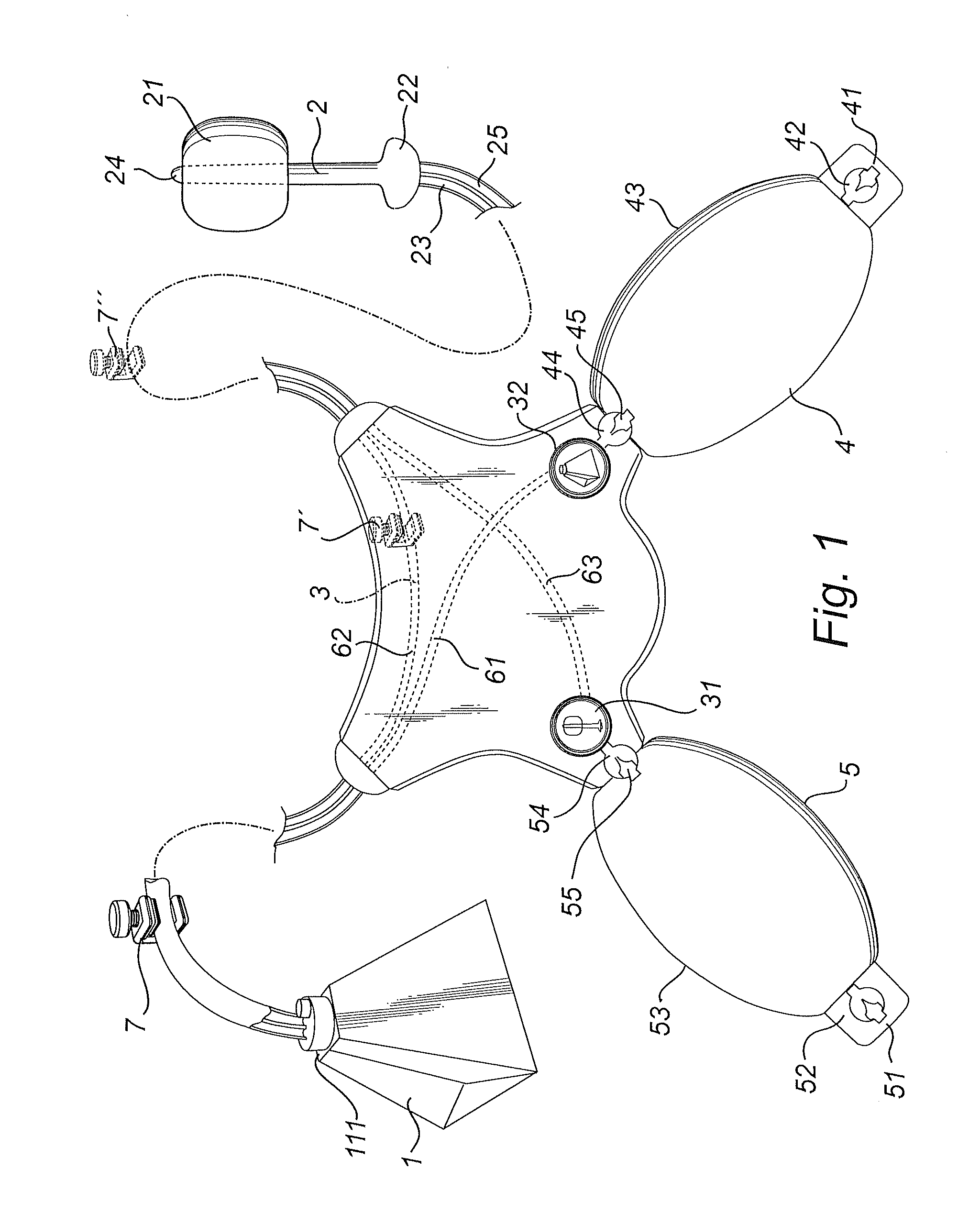

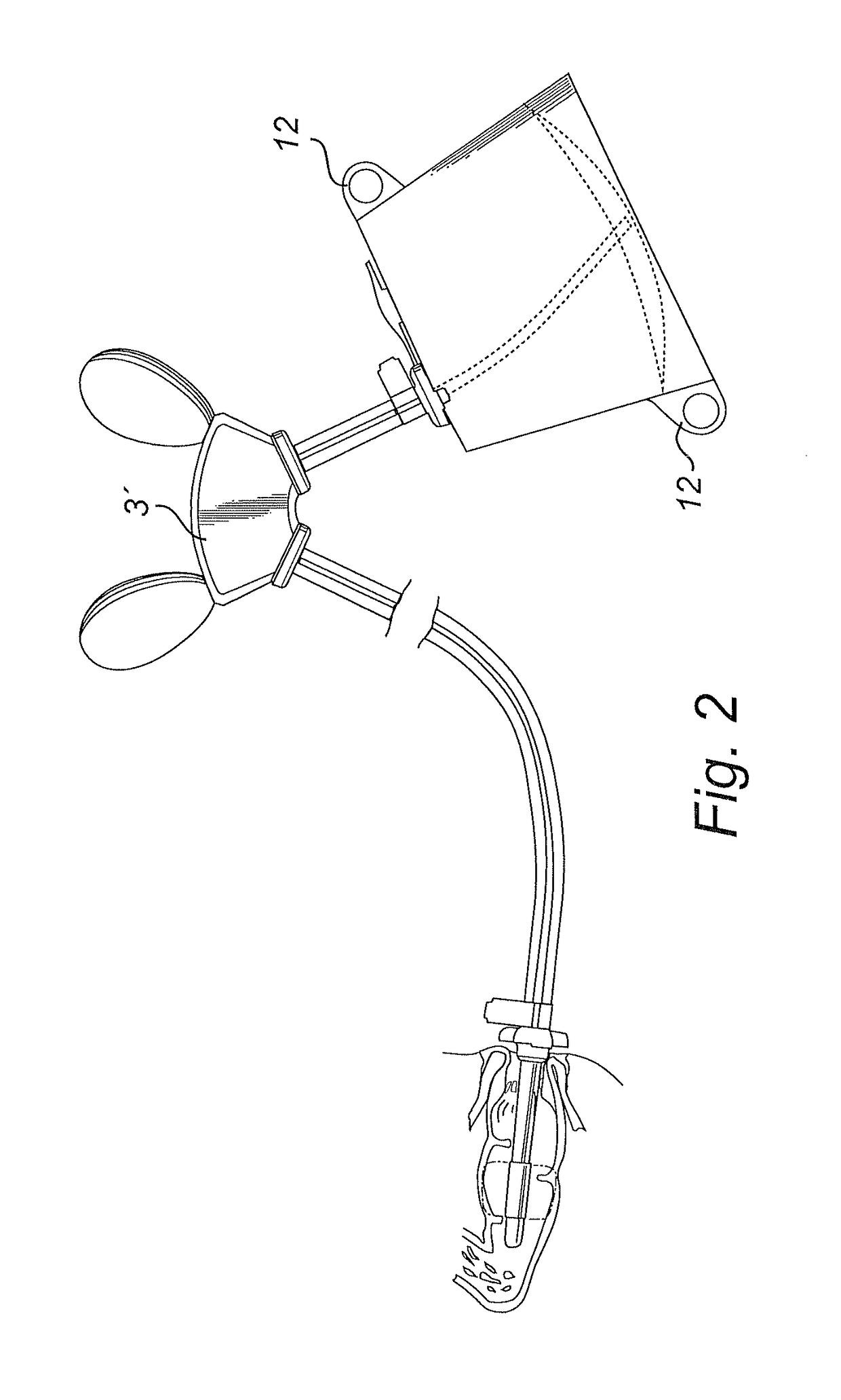

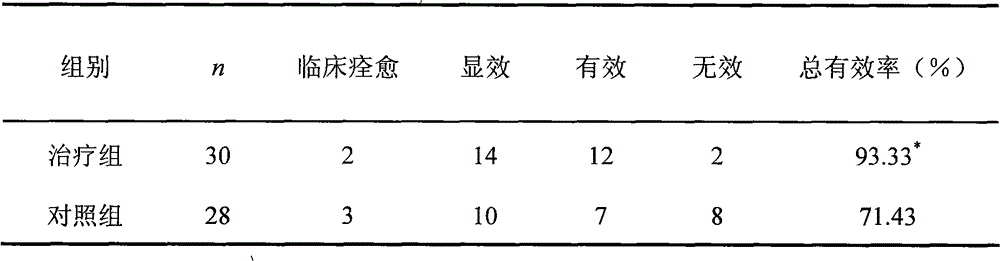

Apparatus including a conduit claimping device

An apparatus comprising a conduit clamping device with a closing mechanism for closing and opening passage of fluid or air in a flexible conduit is disclosed. The apparatus comprises a movable arm or disk that is connected to a manipulation arm or a knob; a conduit in form of a tube, that is laid flat against an abutment or protrusion; and a guide structure that constrains the movable arm or disk between the guide structure and the tube and being designed such that movement of the arm or disk will control the compression of the tube.

Owner:DENTSPLY IH

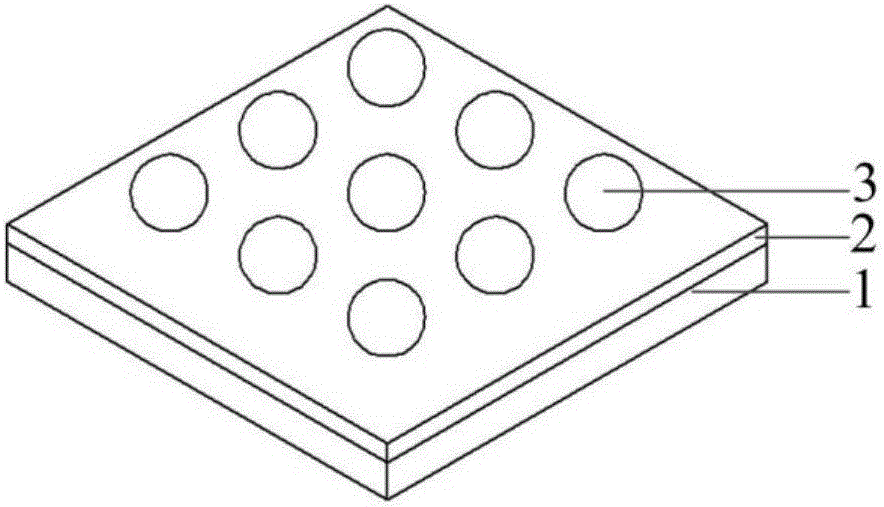

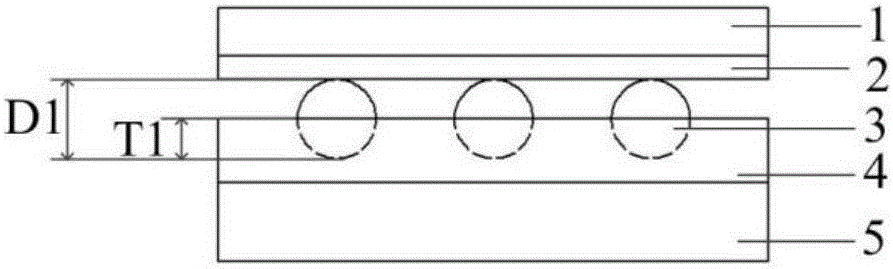

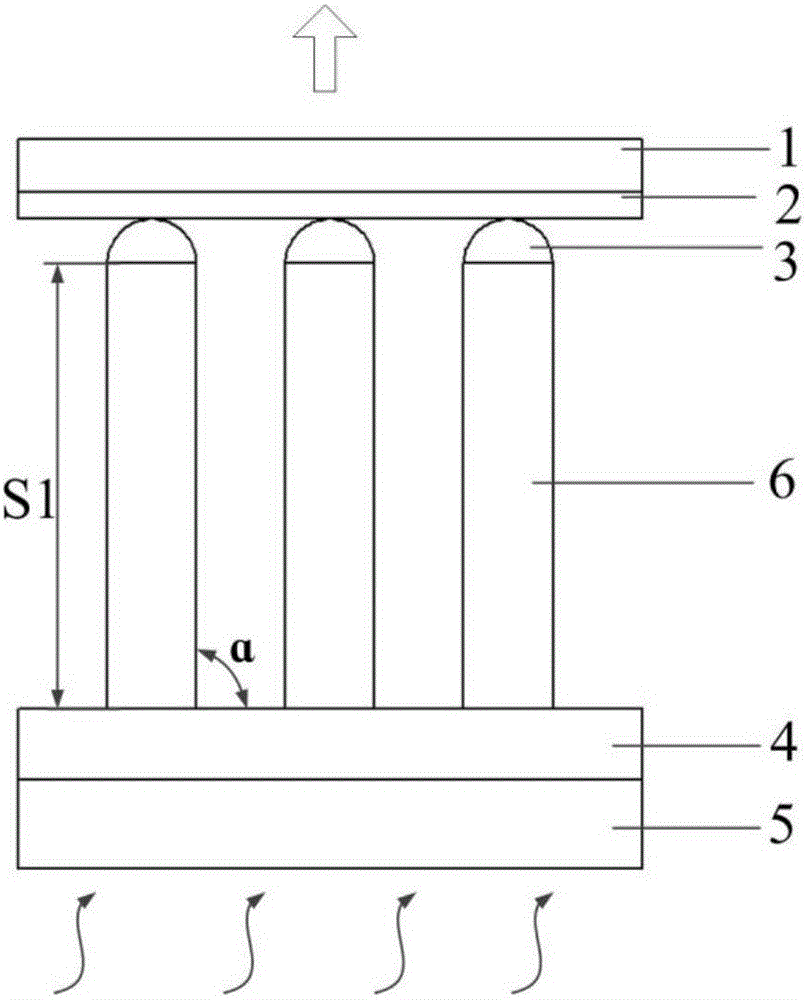

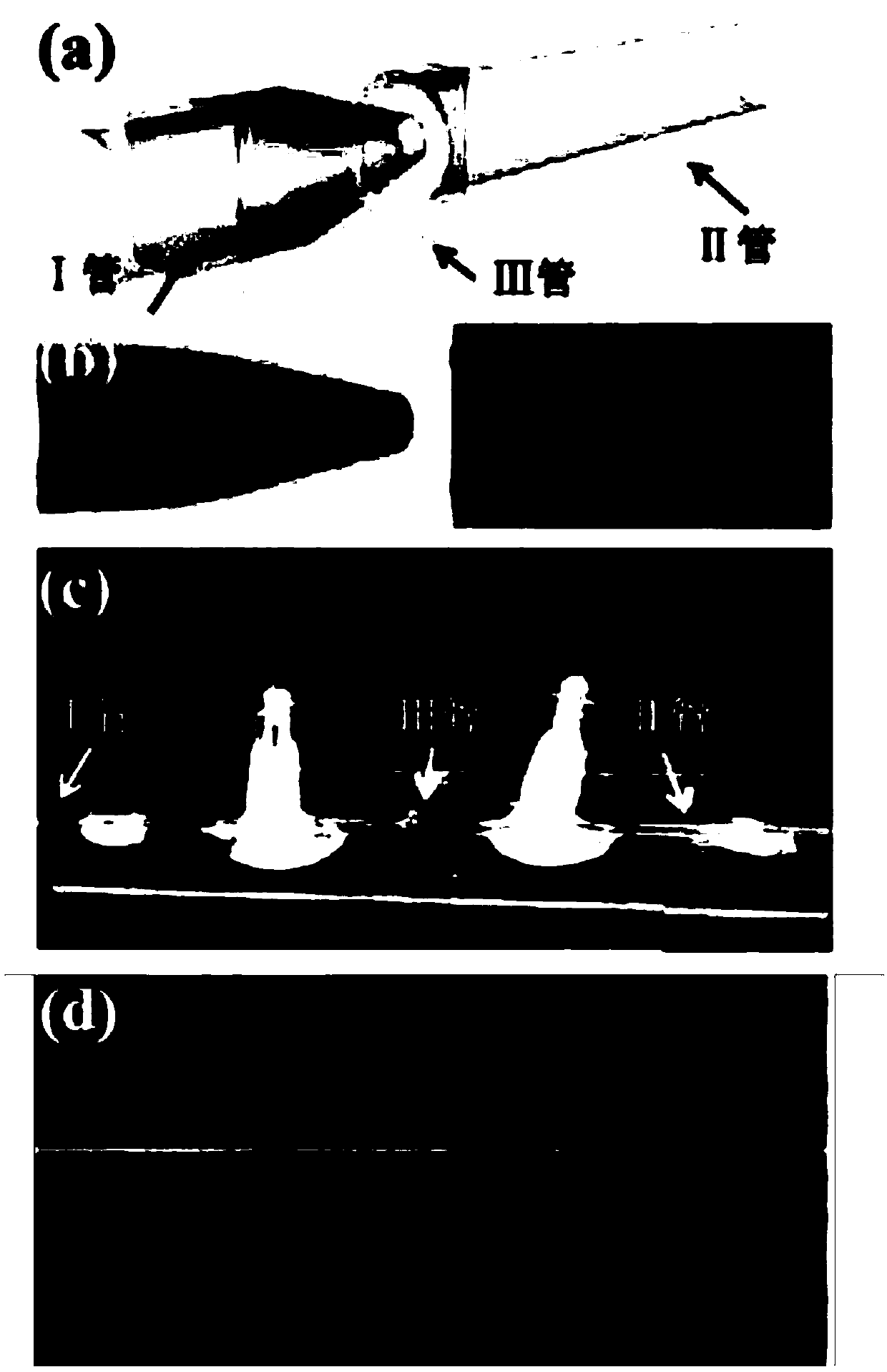

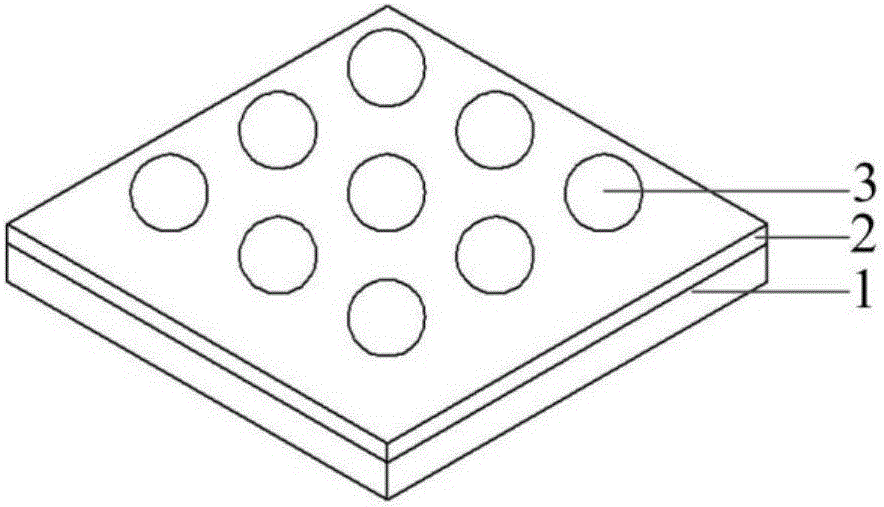

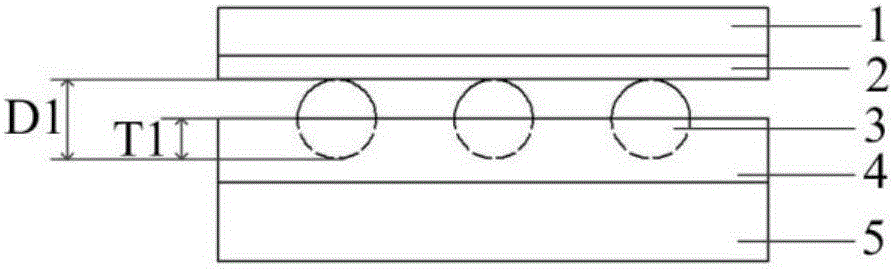

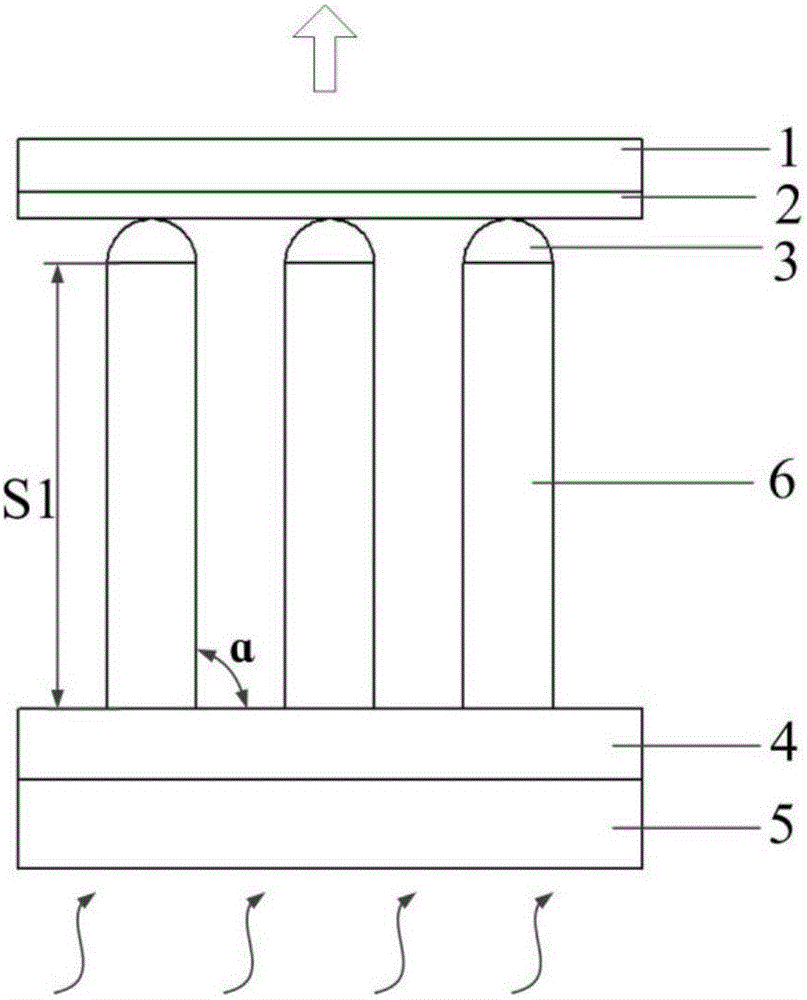

Manufacturing method of shape-controllable flexible micro-nano column array

ActiveCN105776129AControl high aspect ratioAvoid breakingNanostructure manufactureDecorative surface effectsMicro nanoMicro nanoparticles

Disclosed is a manufacturing method of a shape-controllable flexible micro-nano column array.The manufacturing method includes: coating a hydrosol adhesion layer on the surface of a substrate, obtaining a micro-nano graphical photoresist on the hydrogel adhesion layer through a photoetching process, obtaining micro-nano graphical particles on the surface of the photoresist through a scraping-coating method, and removing the photoresist to obtain a graphical template of the micro-nano particles; coating a polymer on the surface of the substrate, and pre-heating the substrate; enabling the micro-nano particles on the surface of the graphical template to contact with and to be embedded in the polymer; lifting the graphical template to enable the polymer to be drawn to be a micro-nano column array, and heating the substrate to solidify the micro-nano column array; heating the graphical template to enable the micro-nano particles to break away from the hydrogel adhesion layer to obtain a micro-nano column array with the micro-nano particles at the top end; removing the micro-nano particles at the top end of the micro-nano column array to obtain a polymer micro-nano column array.The manufacturing method has the advantages of simple operation, low cost and short period.

Owner:XI AN JIAOTONG UNIV

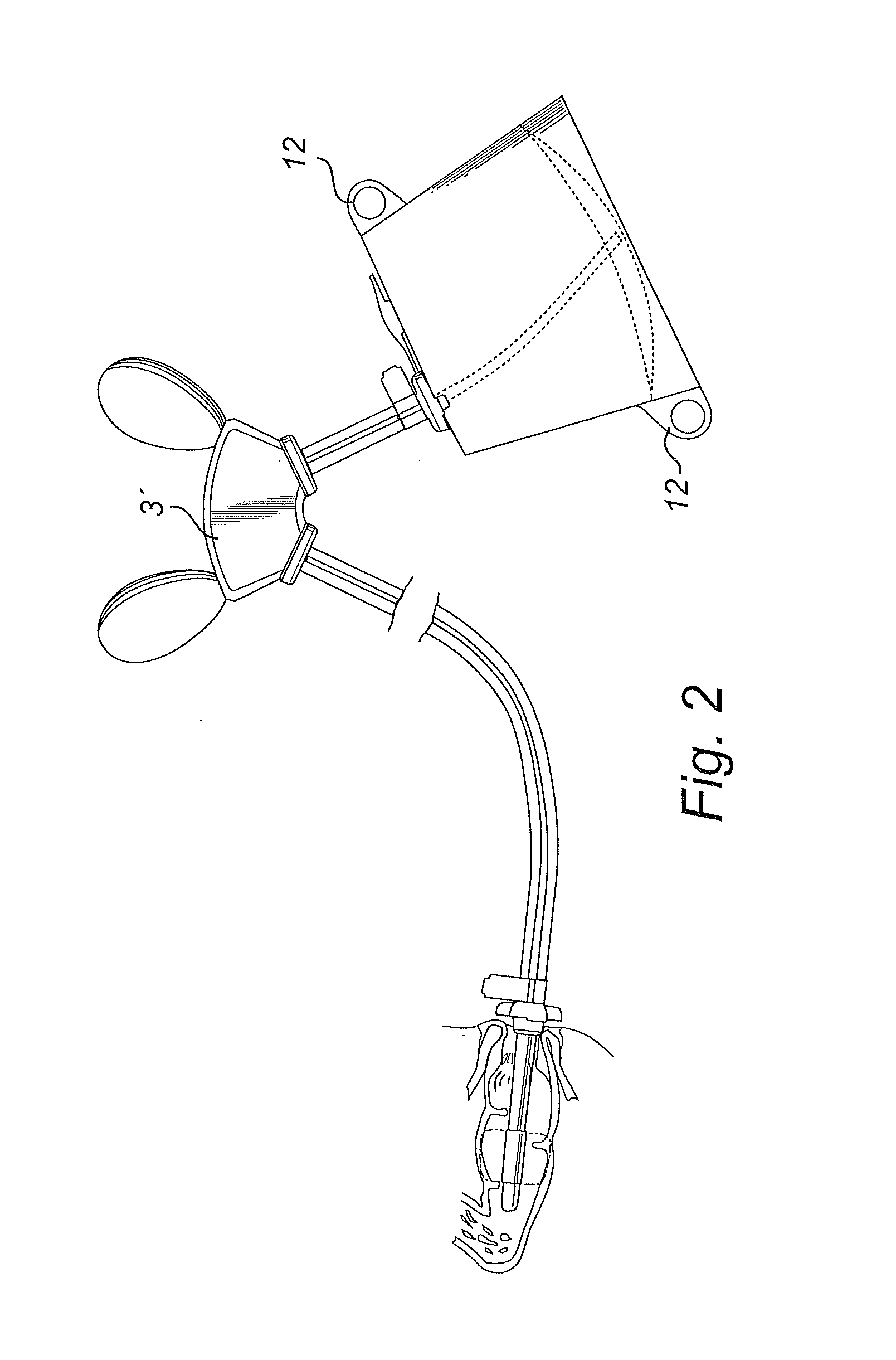

Irrigation system comprising dual pumps

ActiveUS20130331781A1Easy and cost-efficient to produceEasy to useCannulasEnemata/irrigatorsCatheterIrrigation

An irrigation system comprising a reservoir for an irrigating liquid and a probe for arrangement in a user, wherein said probe comprises an inflatable balloon for fixing the catheter in a body cavity.

Owner:DENTSPLY IH

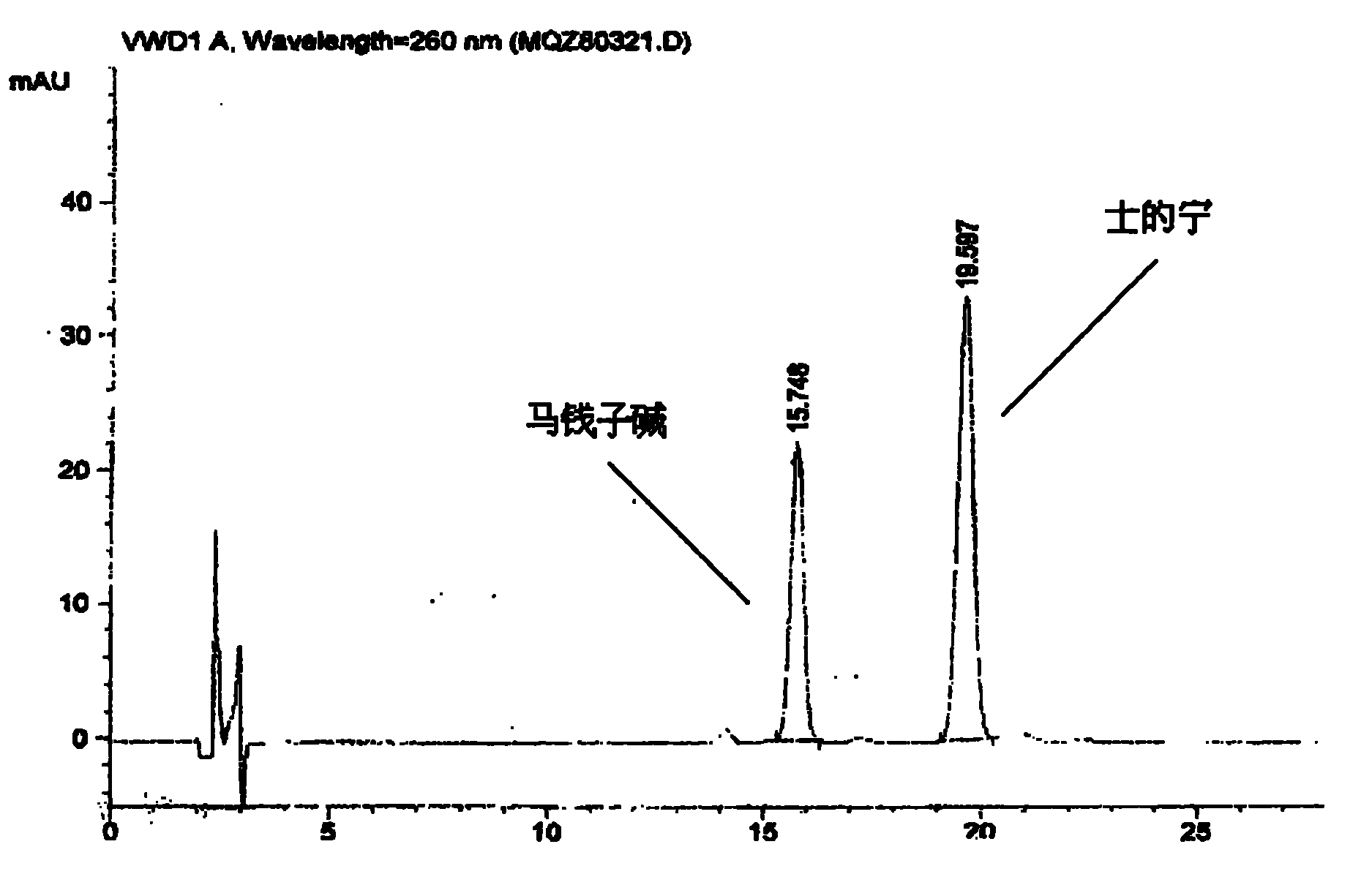

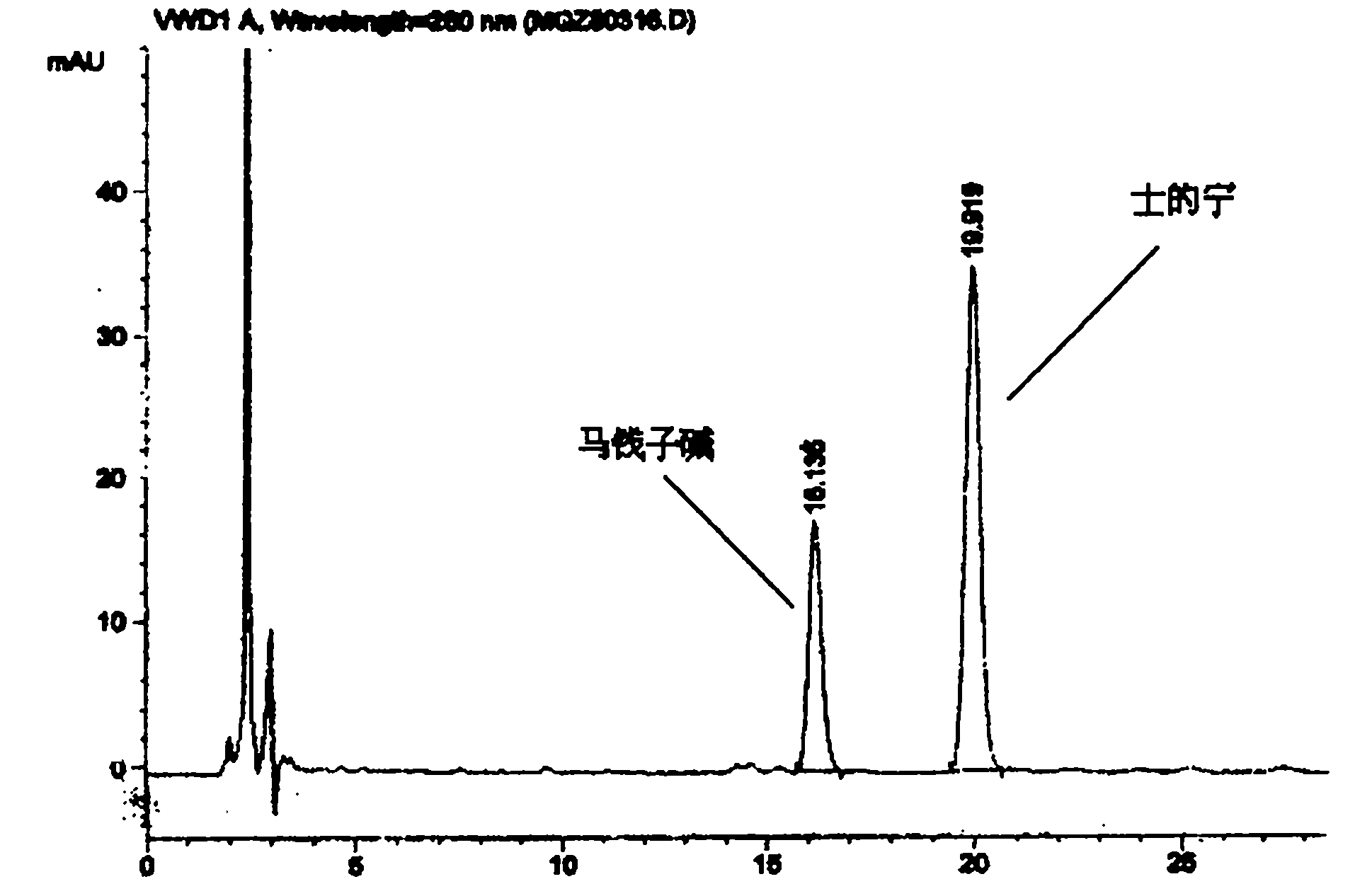

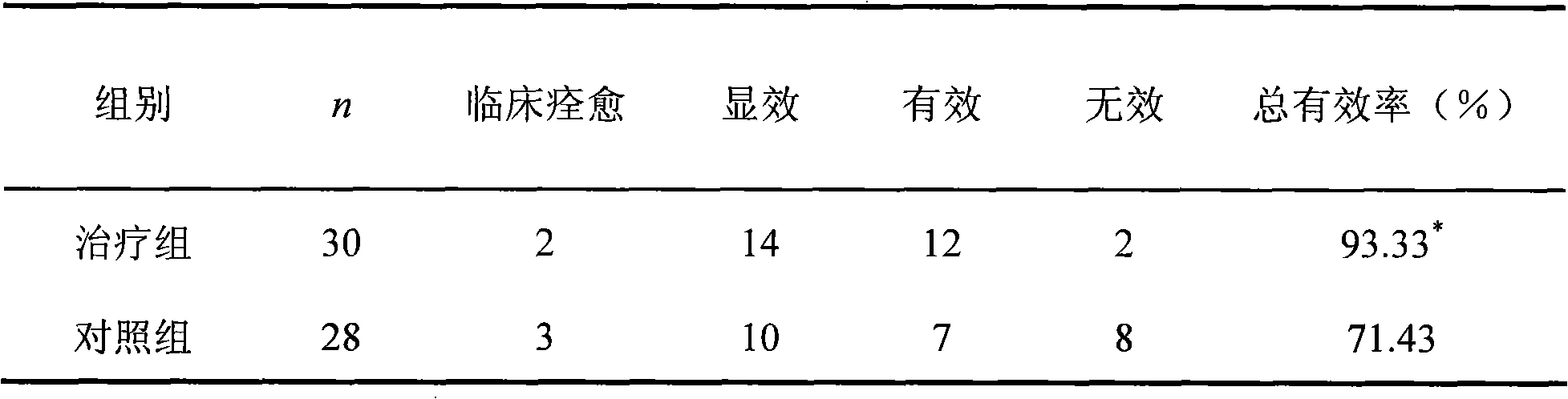

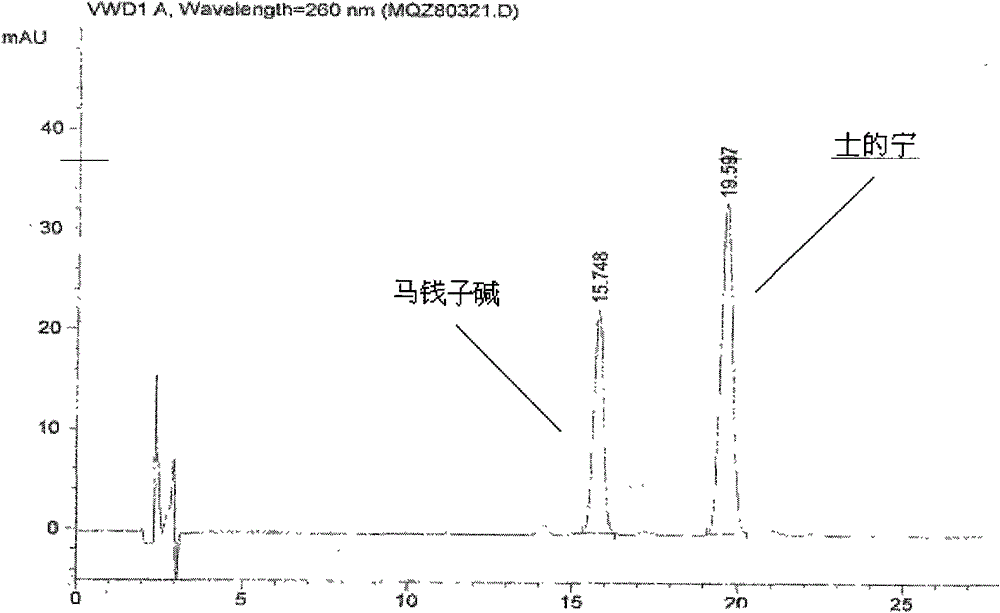

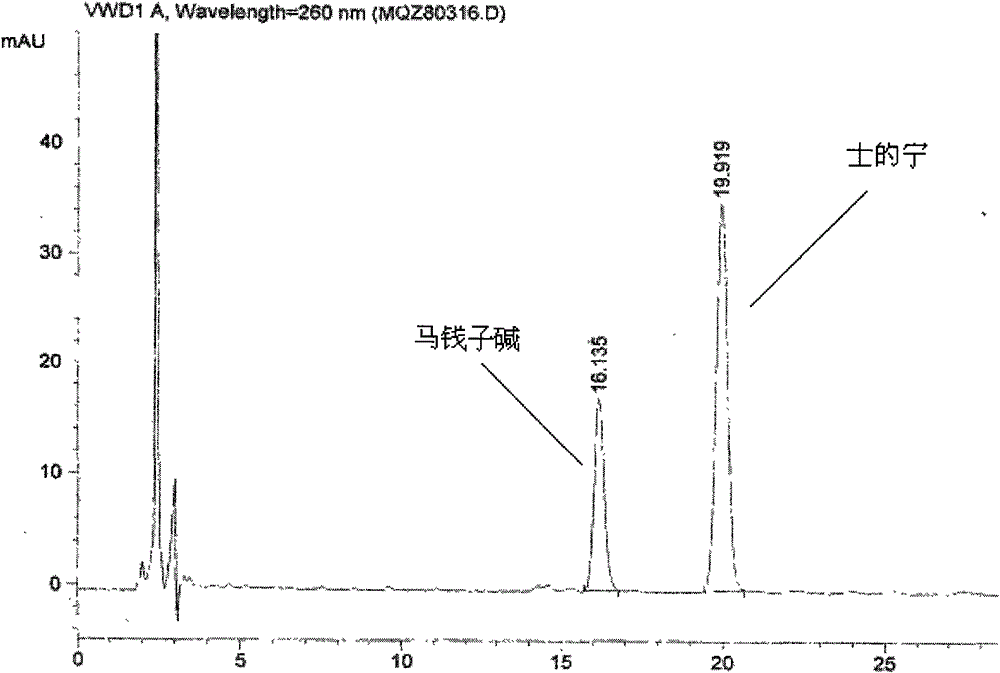

Nux vomica capsules for treating myasthenia gravis and preparation process thereof

InactiveCN102048825AReduce contentTo achieve the purpose of treatmentMuscular disorderNeuromuscular disorderWestern medicineSide effect

The invention provides Chinese medicinal nux vomica capsules for treating myasthenia gravis, which is characterized in that: processing procedures of water soaking, unhairing, frying and the like are adopted, so that the toxicity of a main active ingredient, namely strychnine is obviously reduced. The preparation process is strict and standard, easy to operate, and controllable in quality and canensure the quality stability and clinical administration safety of the nux vomica capsules. Through years of clinical observation, the capsules have satisfying curative effects and small toxic and side effects, can control slight myasthenia gravis through a single medicine, can treat severe myasthenia gravis cooperatively, can obviously reduce the using amount of western medicines and the relatedtoxic and side effects, and improve the curative effects, so the capsules have good development and clinical application prospect.

Owner:ZHEJIANG PROVINCIAL HOSPITAL OF TRADITIONAL CHINESE MEDICINE

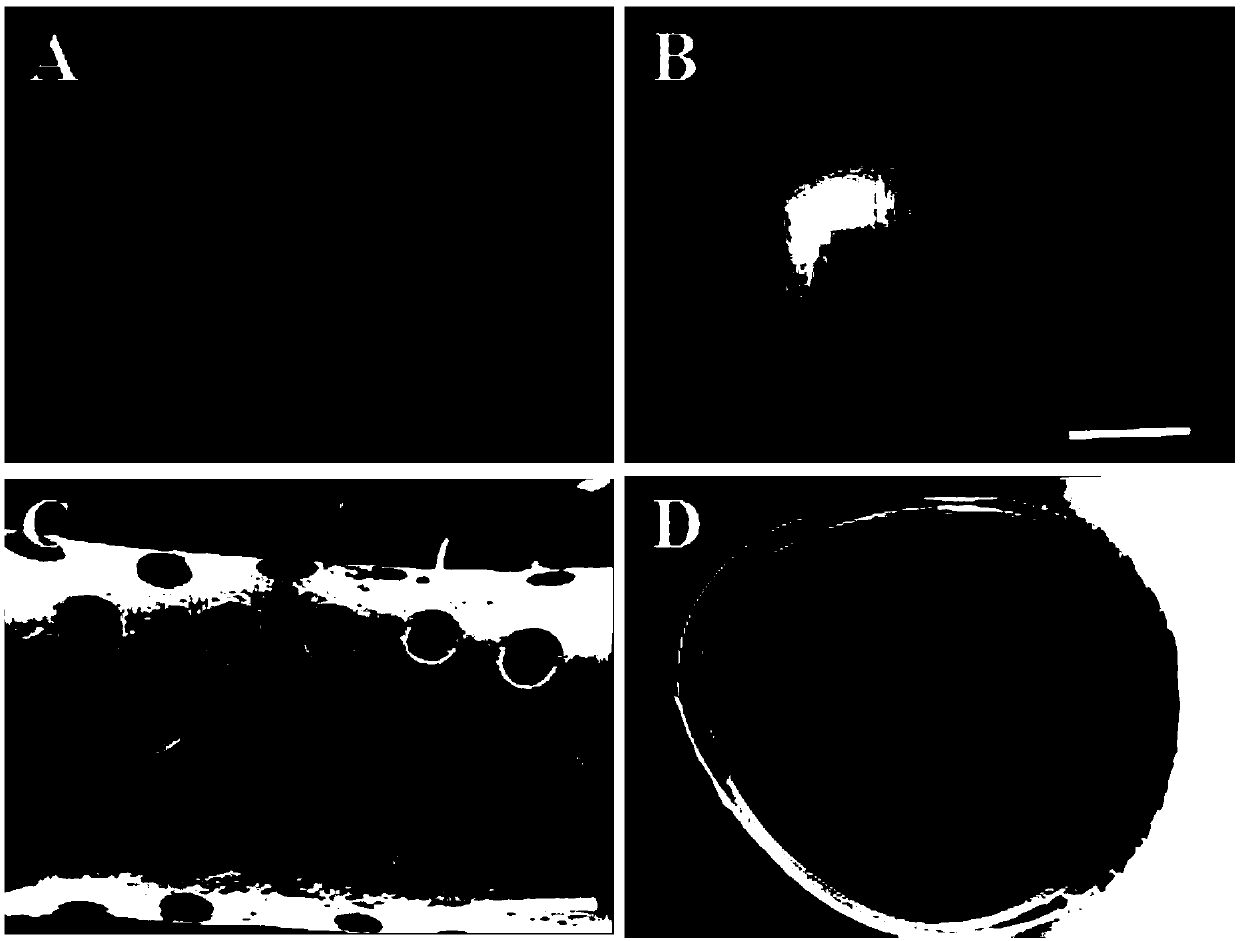

Three-dimensional porous stent and preparation method and application thereof

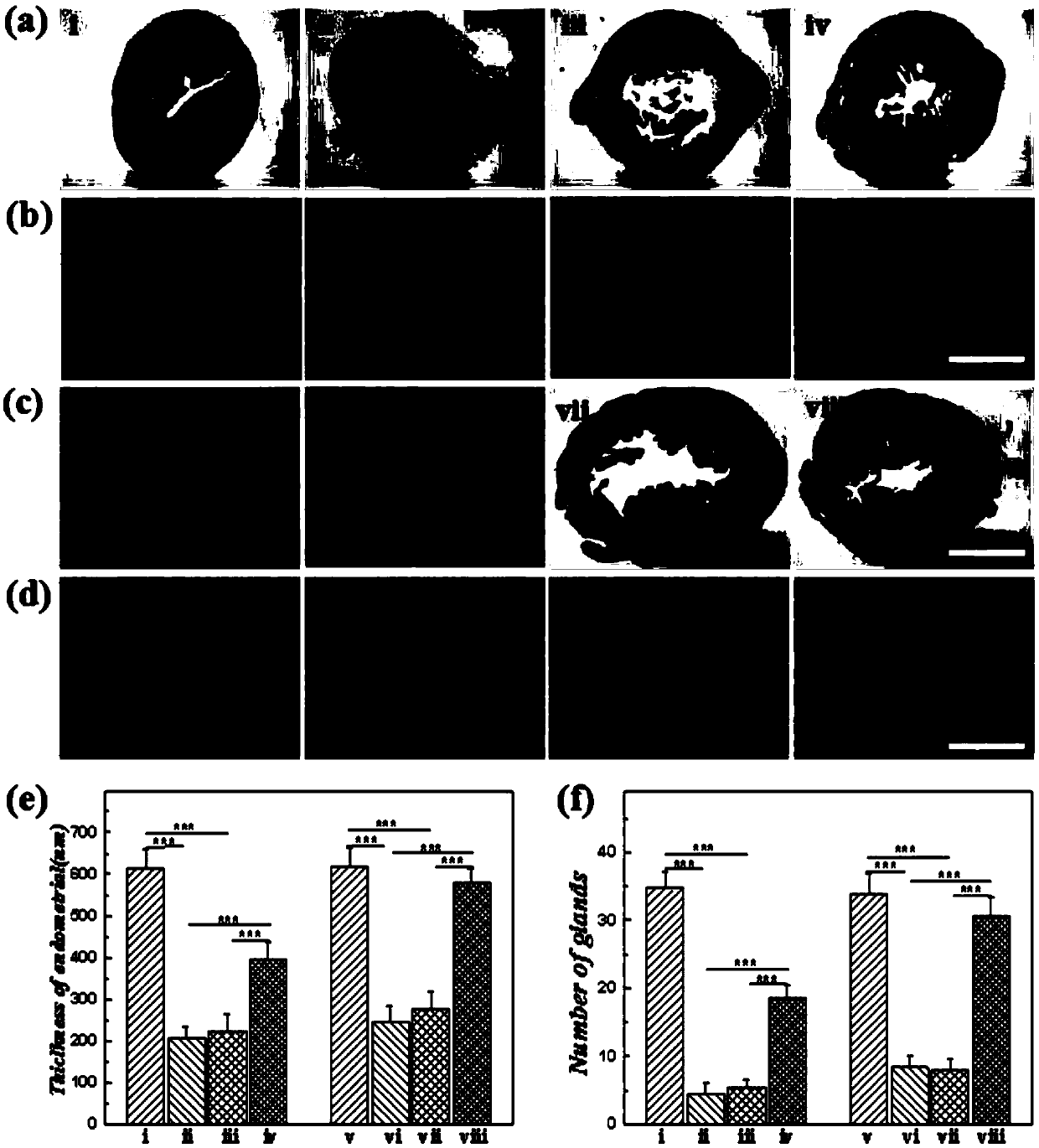

ActiveCN109091705AModerate pore sizeGood biocompatibilityAdditive manufacturing apparatusProsthesisTissue repairEmulsion

The invention discloses a three-dimensional porous stent. The three-dimensional porous stent is made from composite biomaterials consists of degradable natural biomaterials and degradable artificiallysynthesized macromolecule materials. The three-dimensional porous stent has a three-dimensional orderly porous structure in which holes are homogeneous, mutually penetrated and regular in distribution, and the hole diameter is 80-350[mu]m. The invention further discloses a preparation method and application of the three-dimensional porous stent. According to the method disclosed by the invention,the advantages of an emulsion microflow control technique and the advantages of the composite biomaterials are combined. The three-dimensional porous stent disclosed by the invention has favorable biocompatibility and biodegradability and has the characteristics that the hole diameter is appropriate, the holes are mutually penetrated, and the three-dimensional porous stent is degradable and compressible, can be shaped and can be used for performing drainage effectively, and good space is provided for medicine delivery and slow release, cell growth and metabolism and tissue repair; the proportion of ingredients of the compound materials and the holes in concentrated distribution can guarantee that the three-dimensional porous stent has favorable compression and resilience properties like sponge, so that the three-dimensional porous stent can better adapt to the shape of the uterine cavity or the shape of other positions needing prevention of adhesion, and the effect of effectively preventing the adhesion can be achieved.

Owner:南京恒华生物发展有限公司

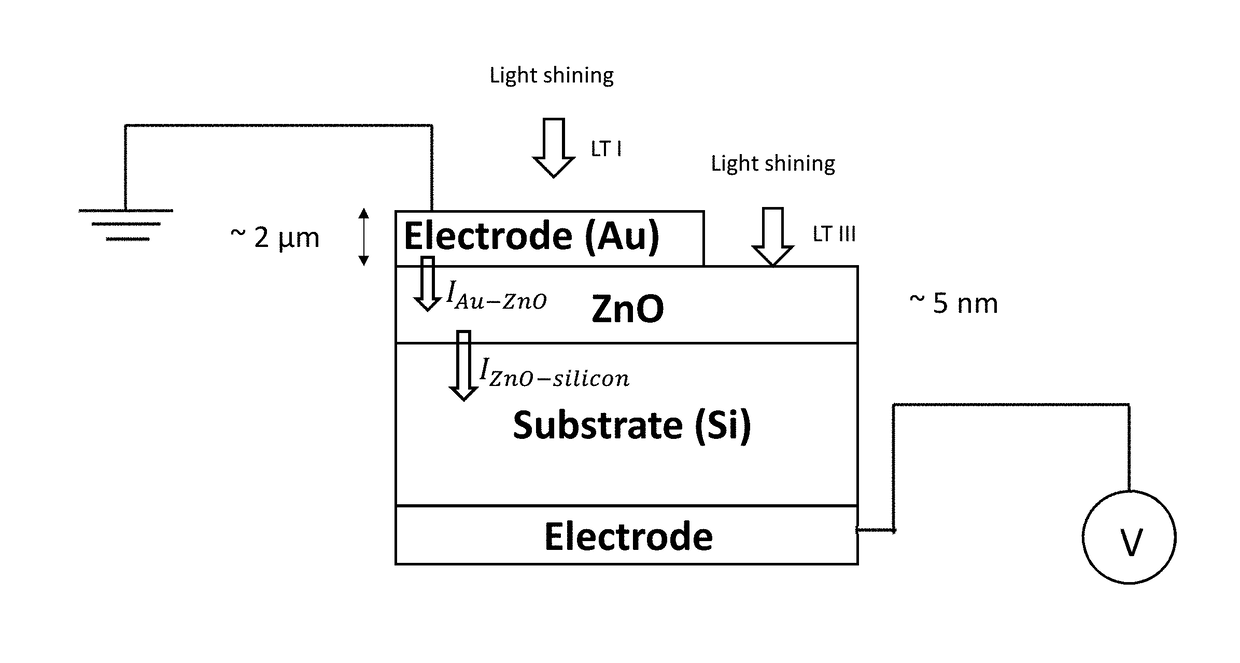

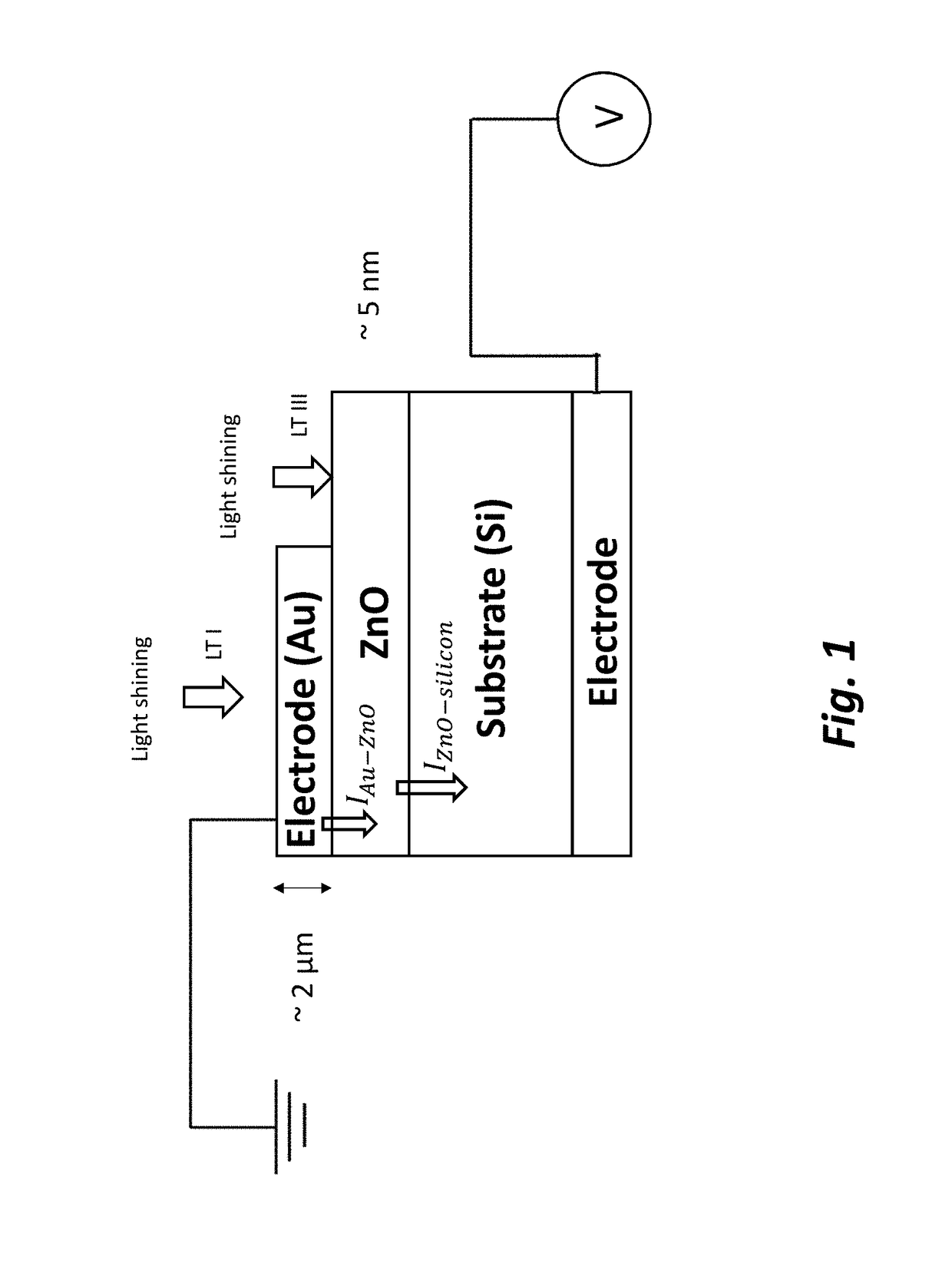

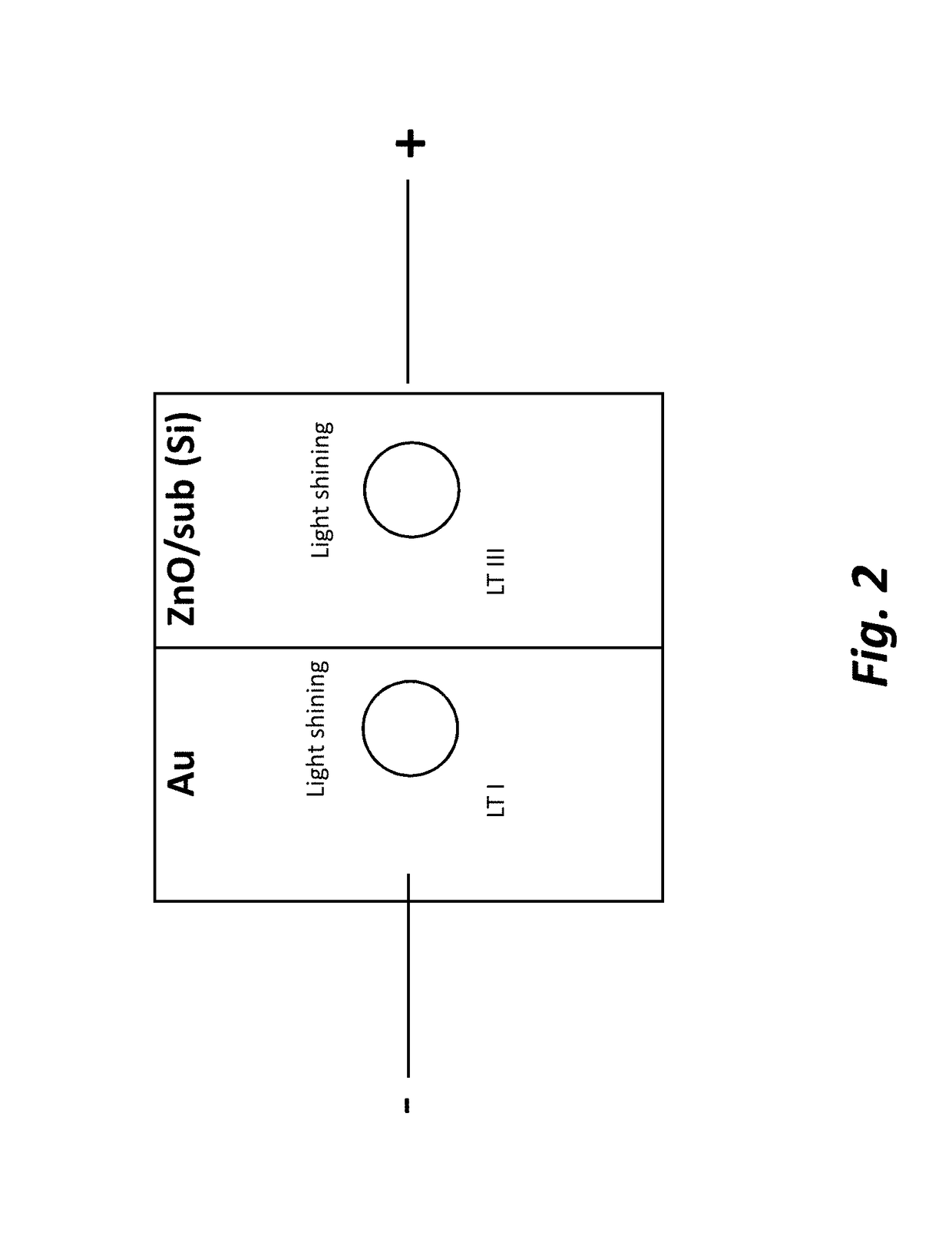

Two-dimensional electronic devices and related fabrication methods

InactiveUS20180308941A1Good conformalityImprove uniformitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationNanodotRoom temperature

Various embodiments of a semiconductor device and related fabrication methods are disclosed. In one exemplary embodiment, the semiconductor device may include a substrate and a plurality of two-dimensional semiconductor films over the substrate, where a photogain of the two-dimensional films is above about 103 when measured at room temperature. In another exemplary embodiment, a semiconductor device may comprise a substrate comprising nanorods or nanodots and a plurality of two-dimensional films disposed on the substrate.

Owner:CHANG YU CHEN

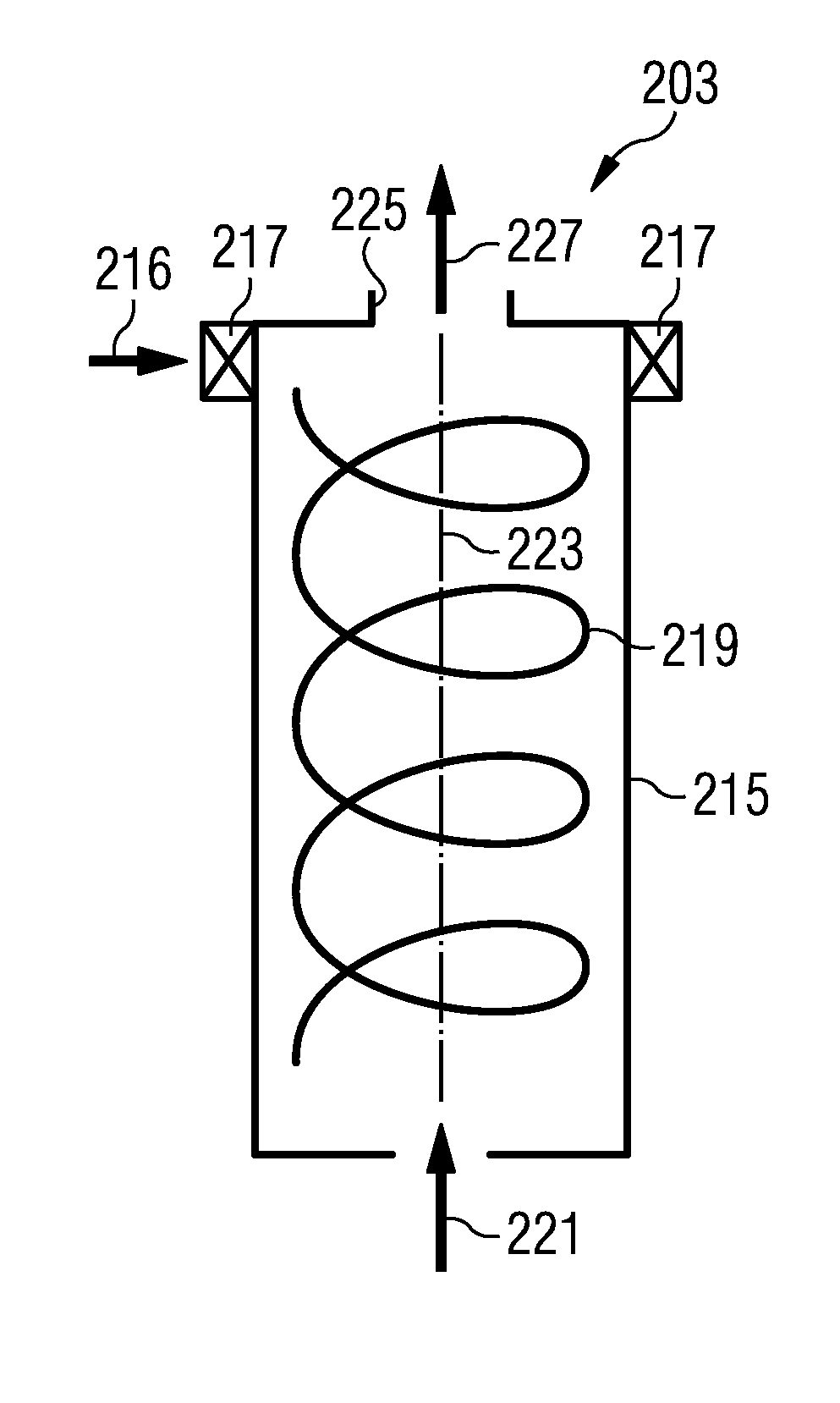

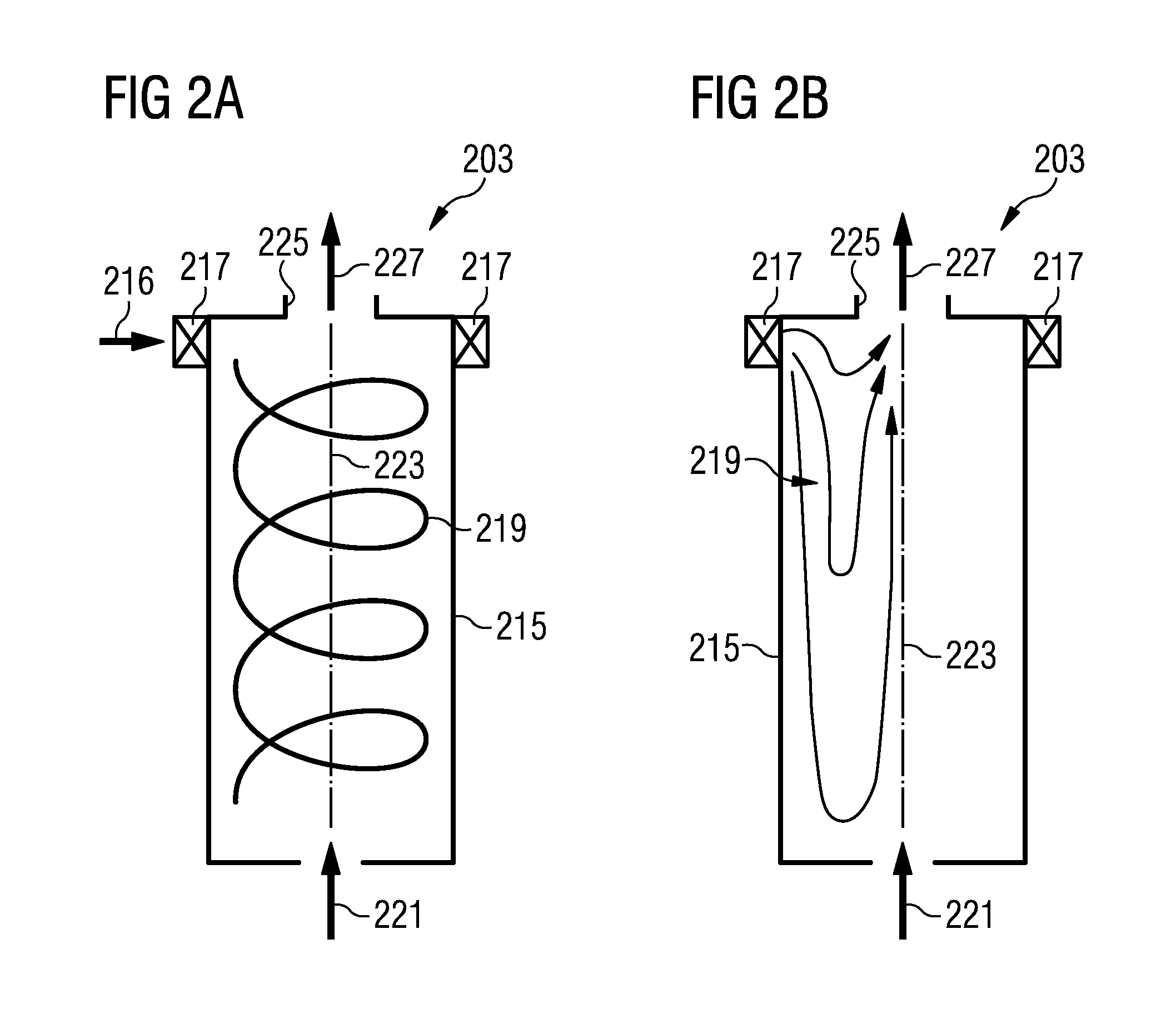

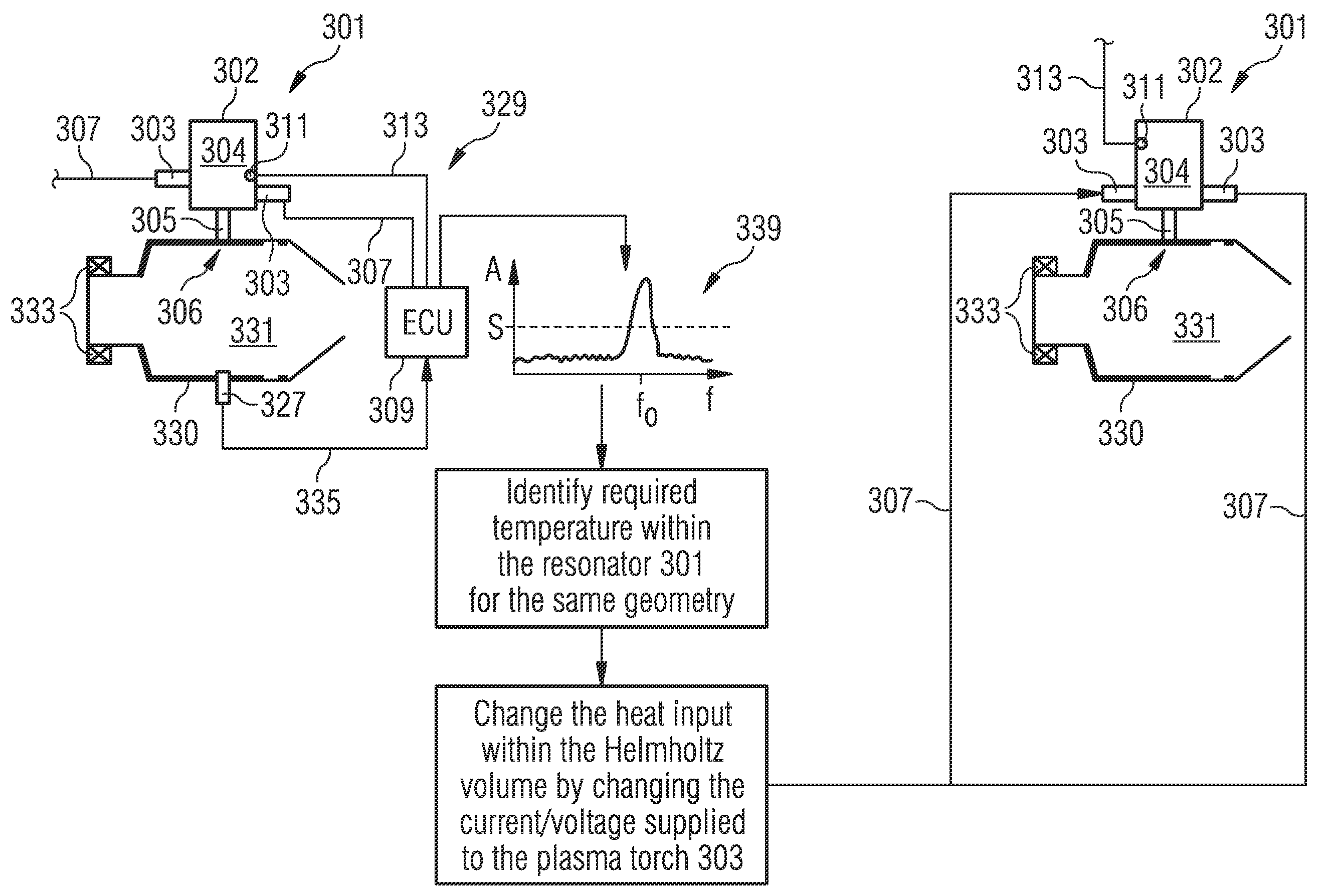

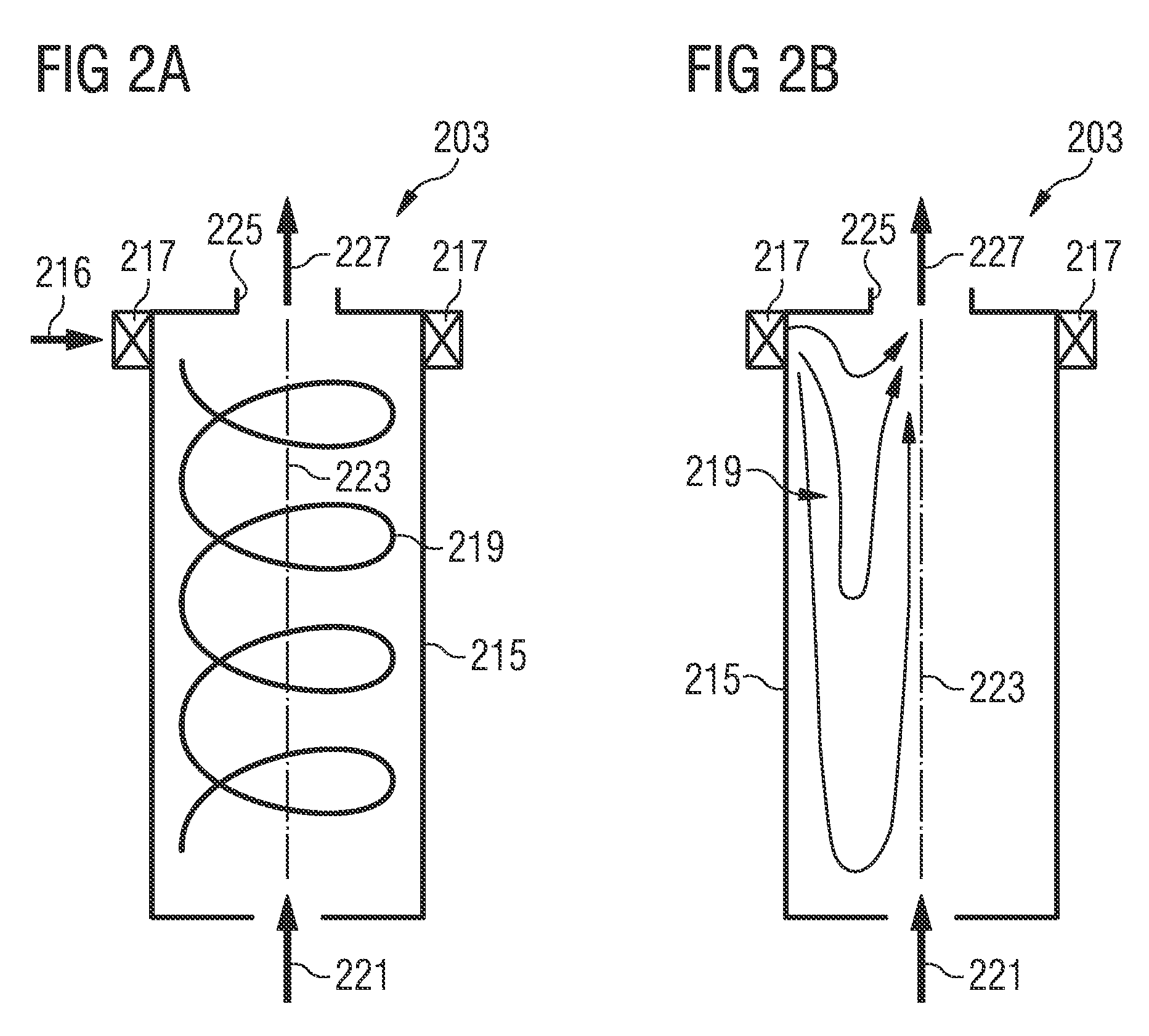

Resonator device for damping the pressure oscillation within a combustion chamber and a method for operating a combustion arrangement

InactiveUS20130025282A1Quick changeFast frequencyContinuous combustion chamberEngine fuctionsCombustion chamberNormal load

A resonator device for damping a pressure oscillation within a combustion chamber is proposed. The resonator device has a container filled with a gas, an opening in the container and a heating element adapted to generate a flame. The flame is arranged to heat the gas within the container. The resonator device is in a combustion arrangement having a combustion chamber for defining a combustion space for burning fuel. The container is connected to the combustion chamber such that an inside of the container is in communication with the combustion space via the opening. The resonator device has a resonance frequency equal to a pressure oscillation frequency within the combustion chamber under normal load conditions.

Owner:SIEMENS AG

Method for annealing simplified, efficient, low-cost and high-temperature superconductive long band

ActiveCN102682919AIncrease productivityShorten the annealing timeCable/conductor manufactureTemperature controlWinding machine

The invention provides a method for annealing a simplified, efficient, low-cost and high-temperature superconductive long band. The method comprises the following steps of: placing the superconductive long band to be annealed into a manual band winding machine, manually winding the band on an annealing plate, placing the annealing plate into a vacuum box type annealing oven, and annealing under an oxygen atmosphere according to annealing processes. The method has characteristics of low cost, short annealing time, high production efficiency, high temperature controlling precision, and capability of uniformly annealing each part of the superconductive long band. Furthermore, compared with the traditional non-vacuum annealing oven, the purity of the oxygen atmosphere in the annealing oven isgreatly increased through a vacuumizing method, so that adverse effects of N2, NO, NO2, CO, CO2 and other non-oxygen impurity gas in the residual air in an annealing furnace on the performance of thesuperconductive long band under the high temperature in the annealing process are avoided. By the method, the rare earth oxide second generation high-temperature superconductive band subjected to annealing treatment under the oxygen atmosphere has excellent superconductive performance.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

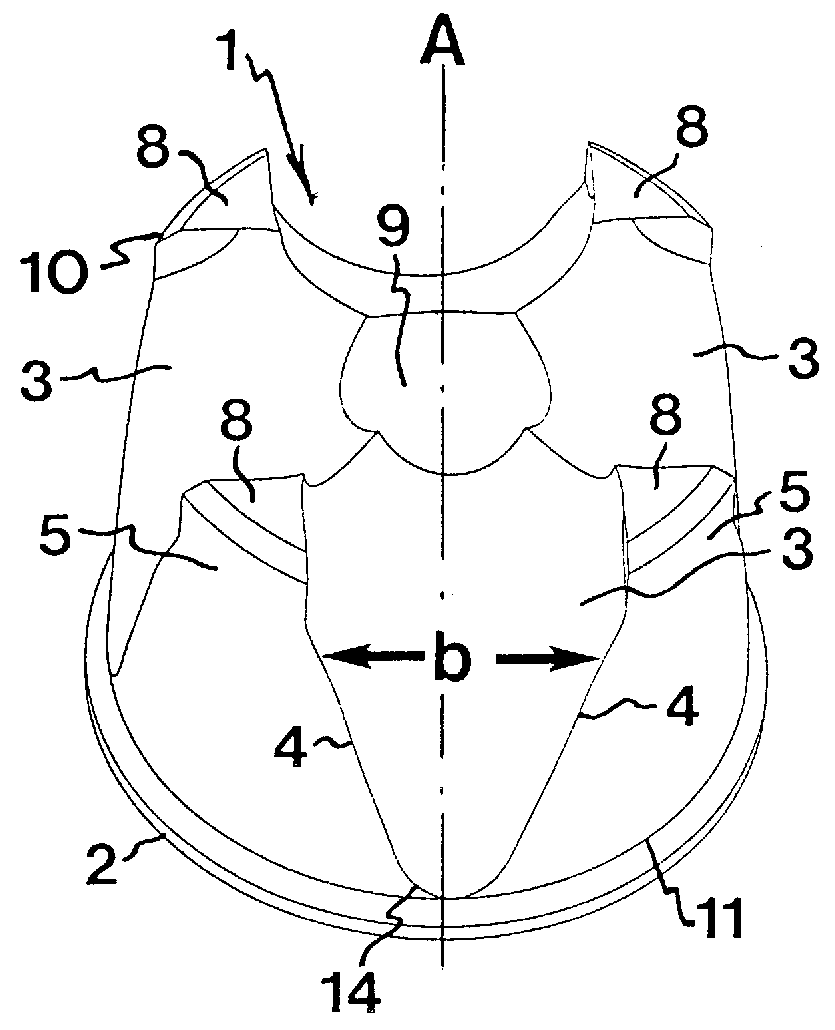

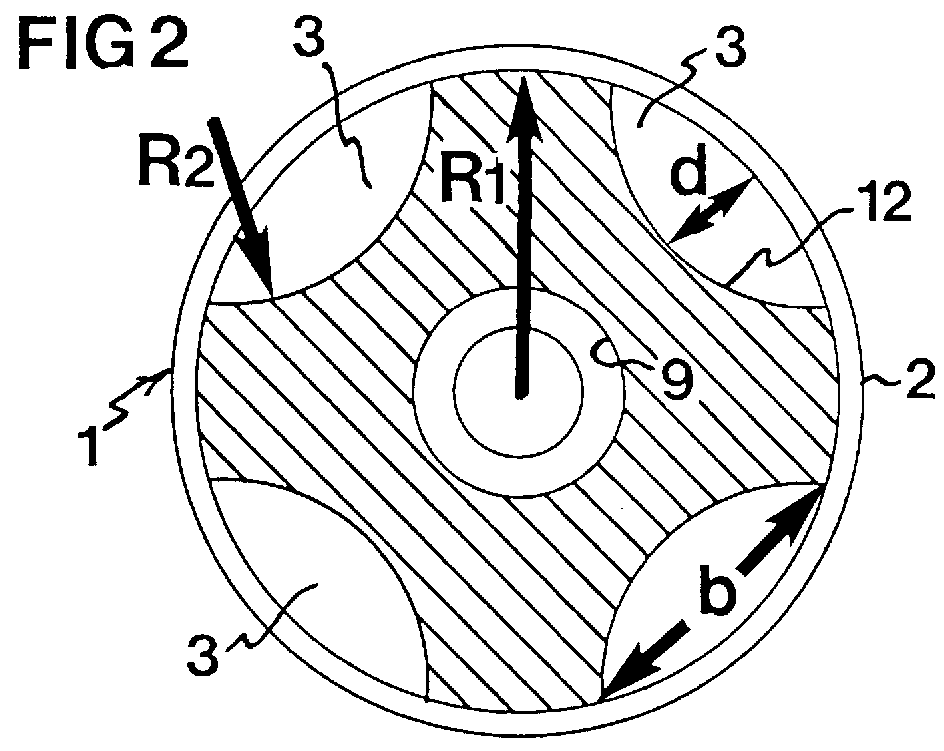

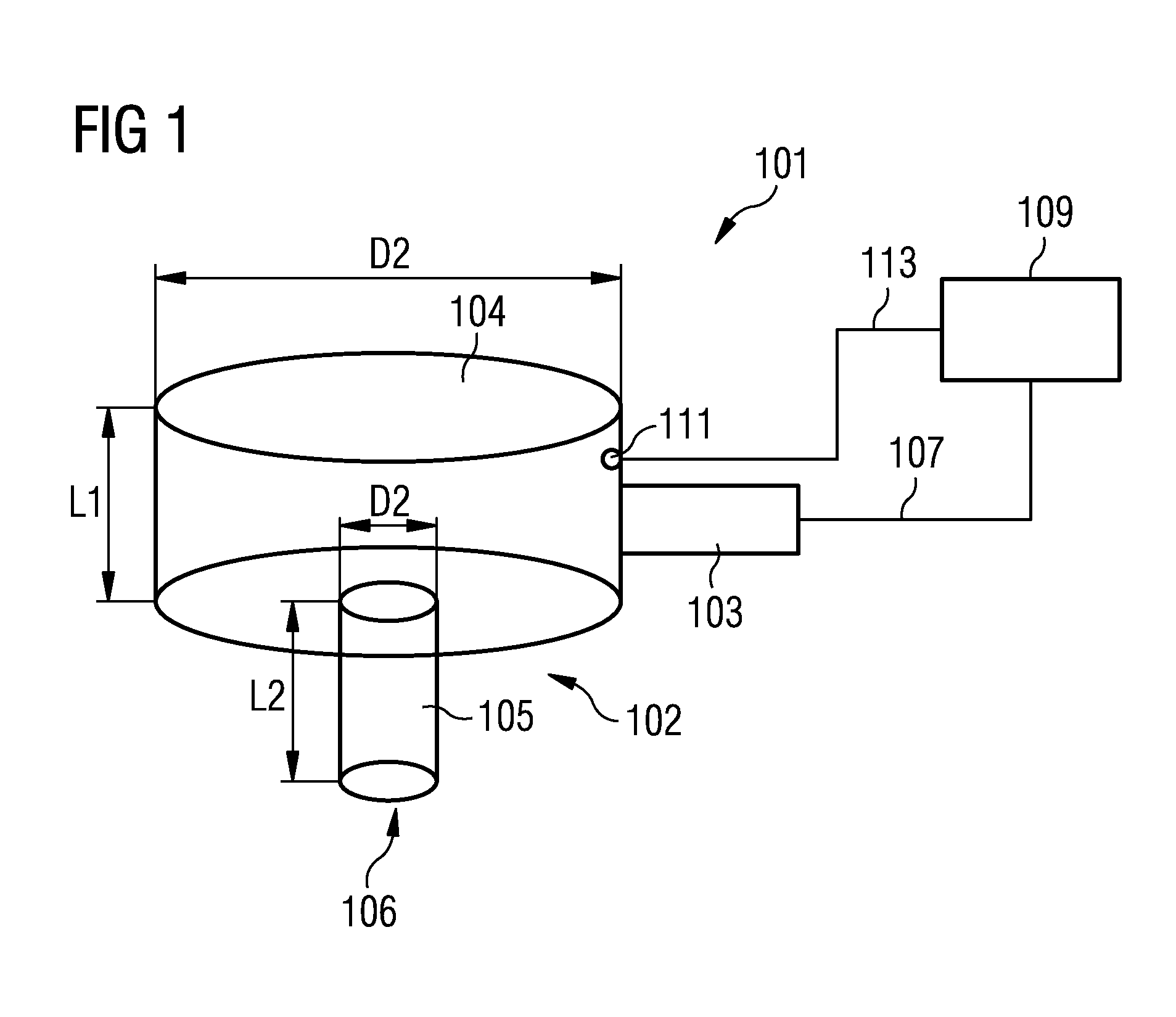

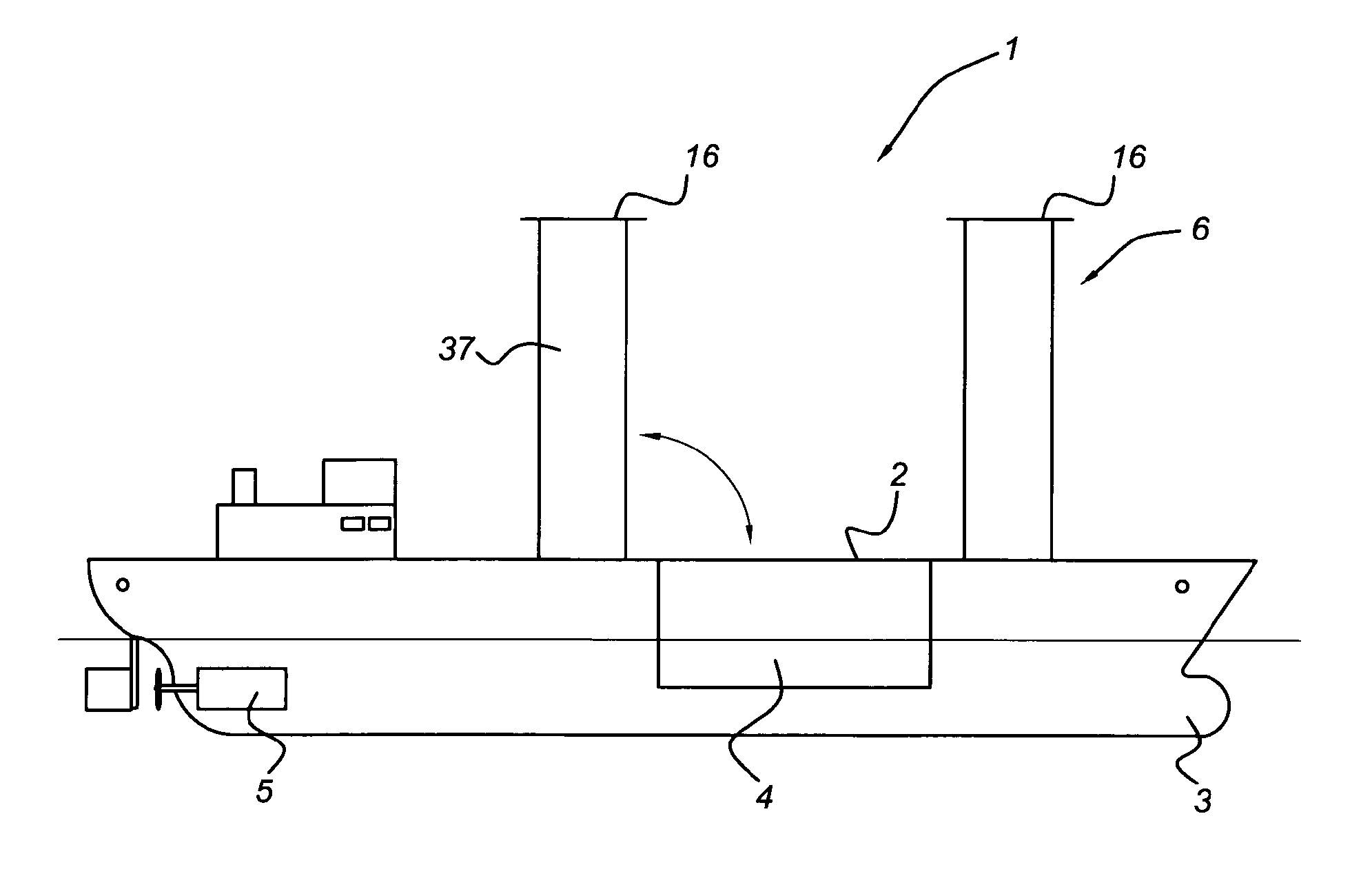

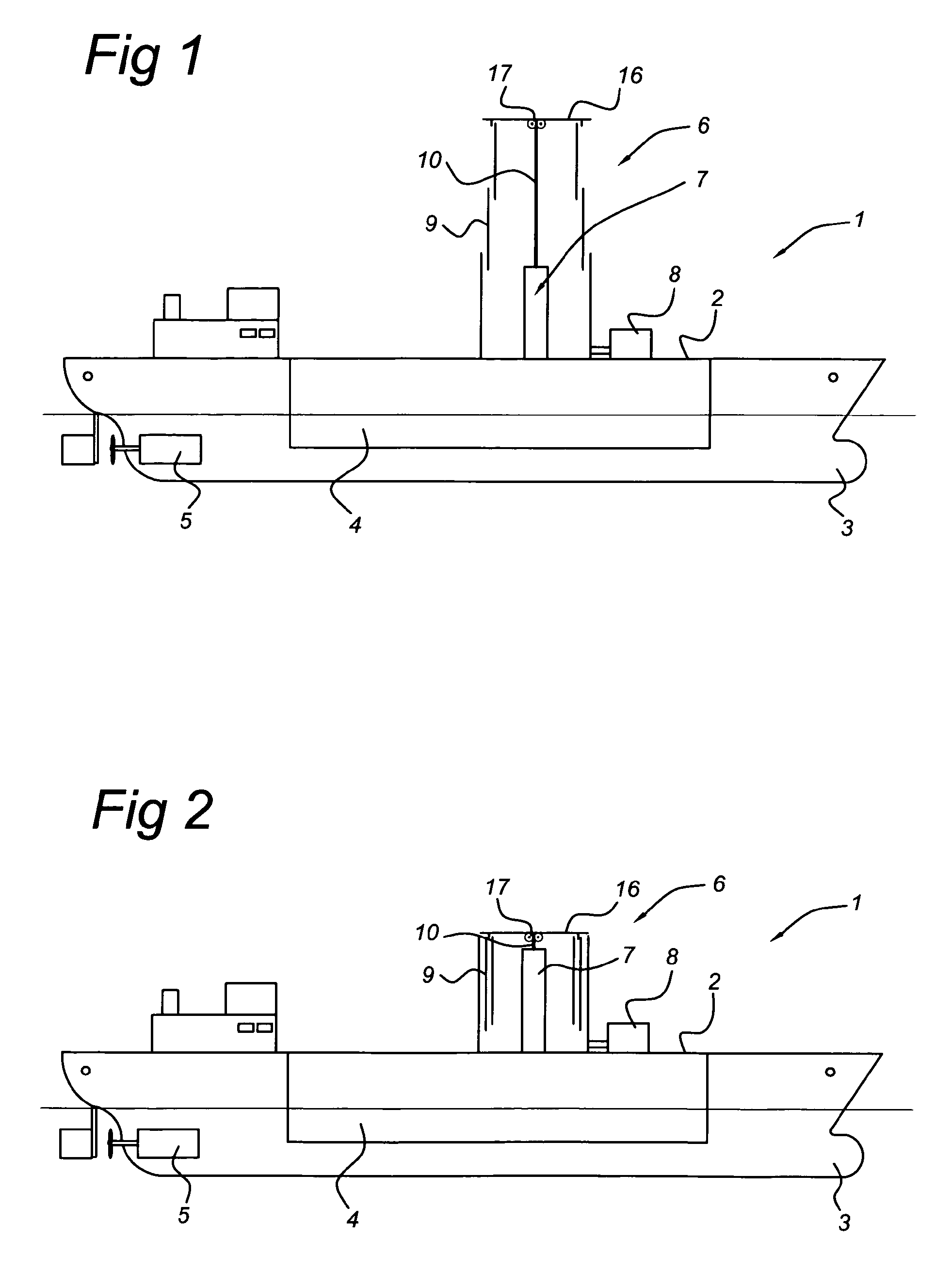

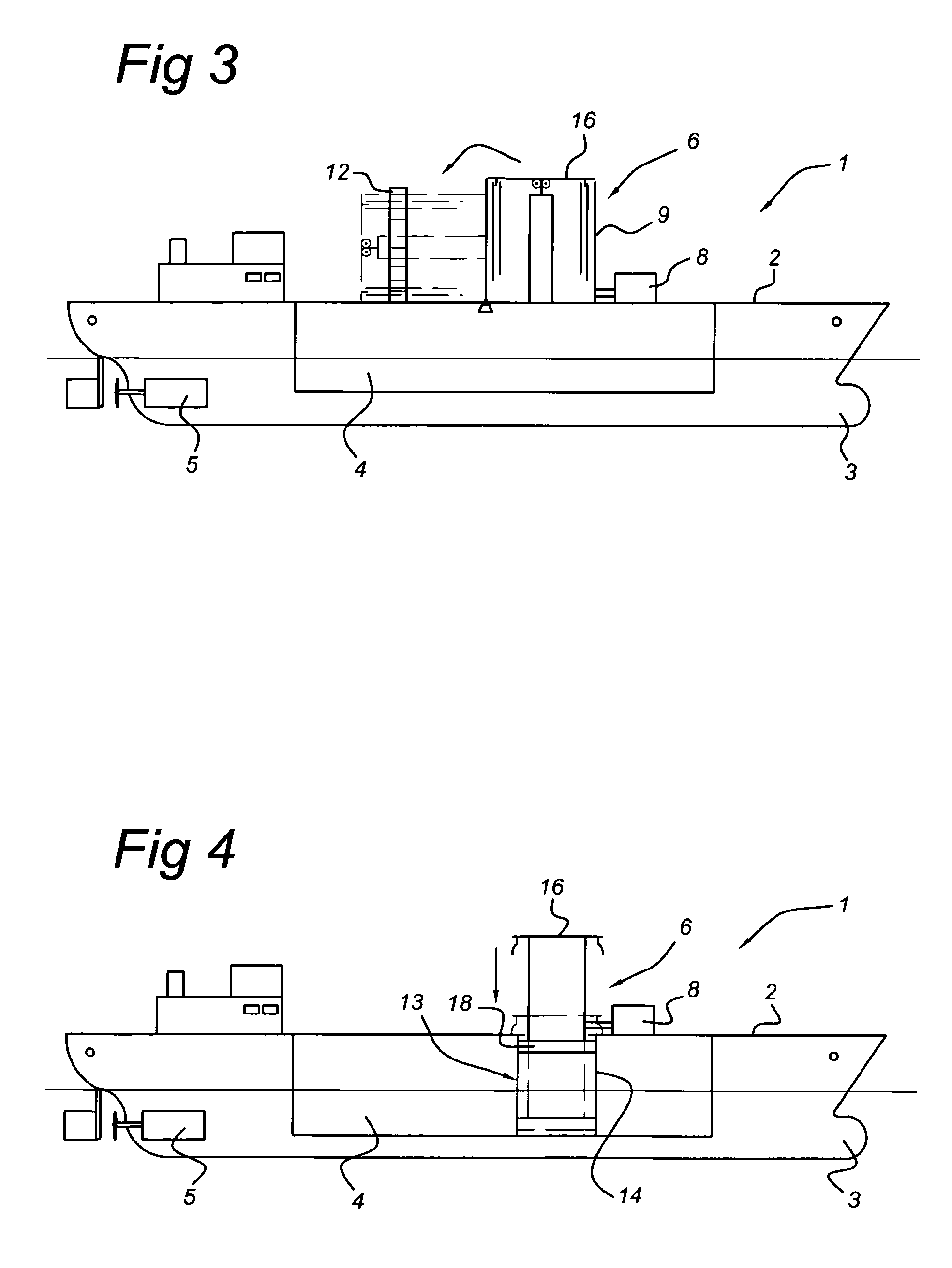

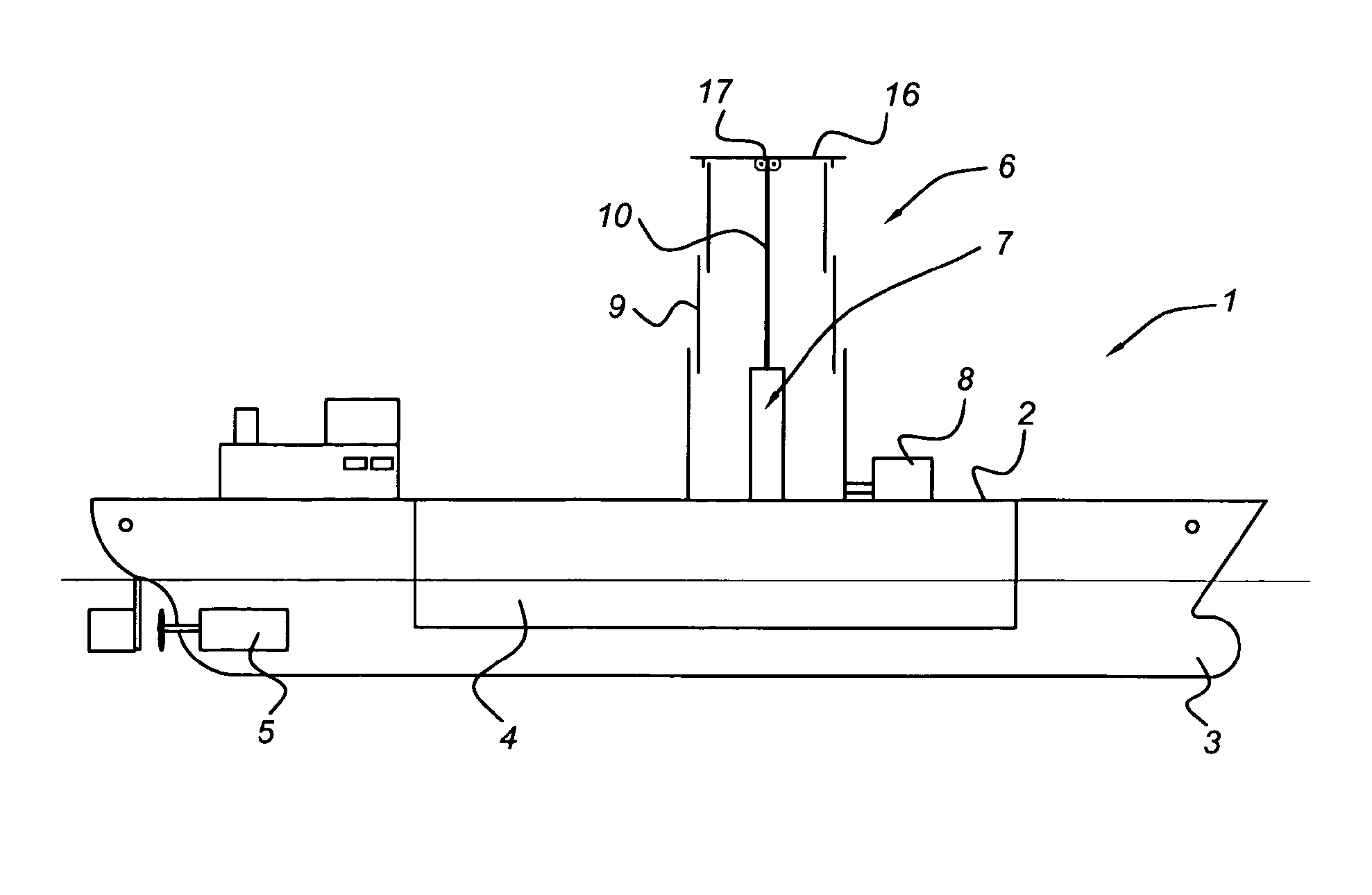

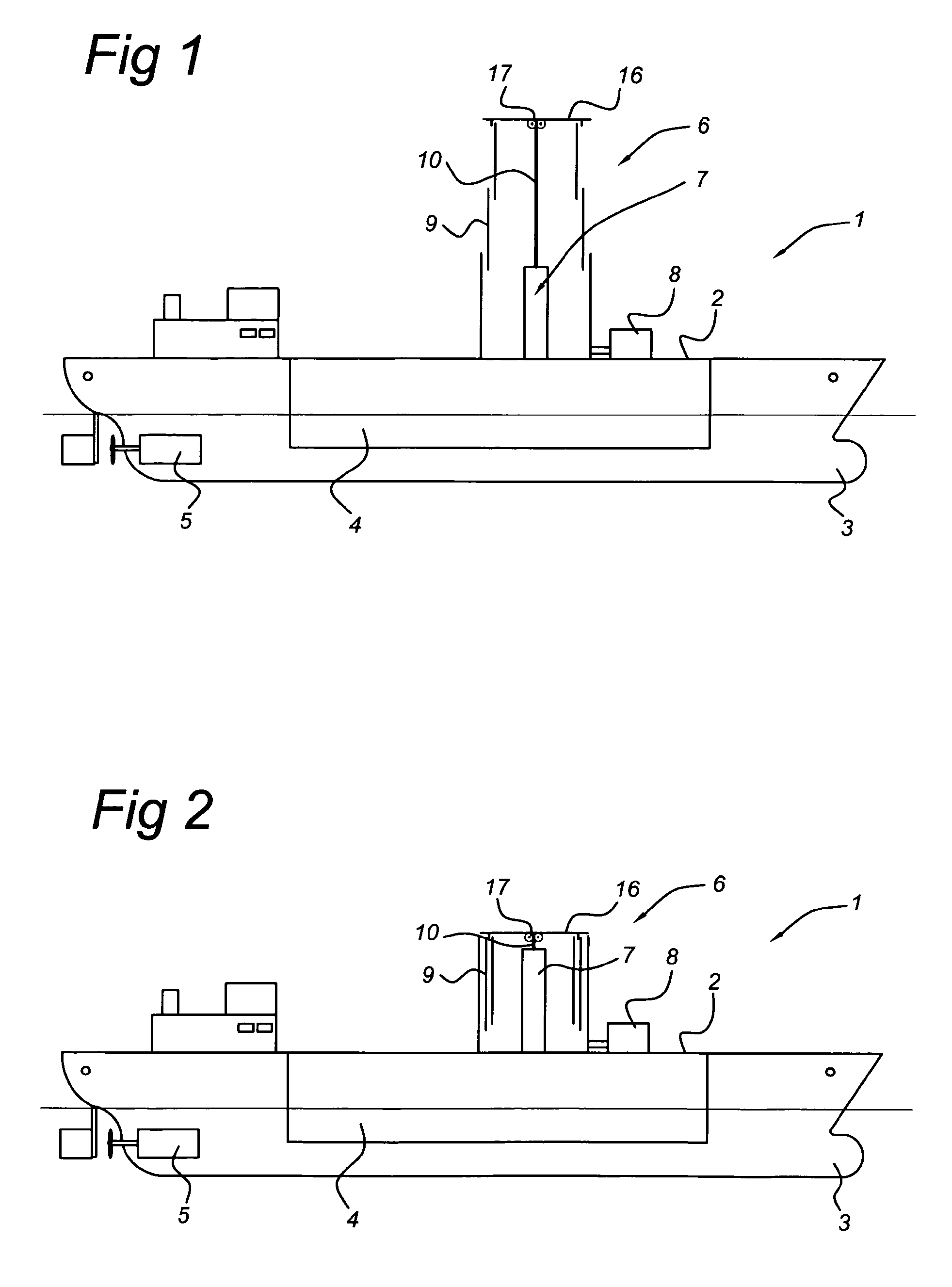

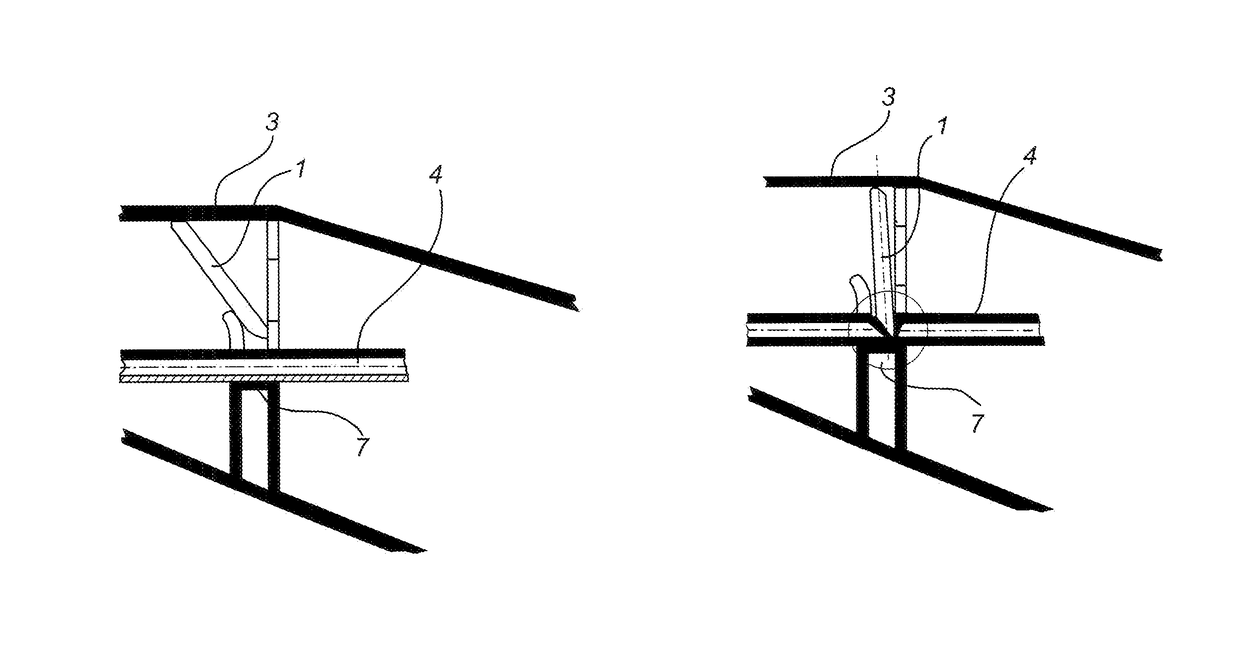

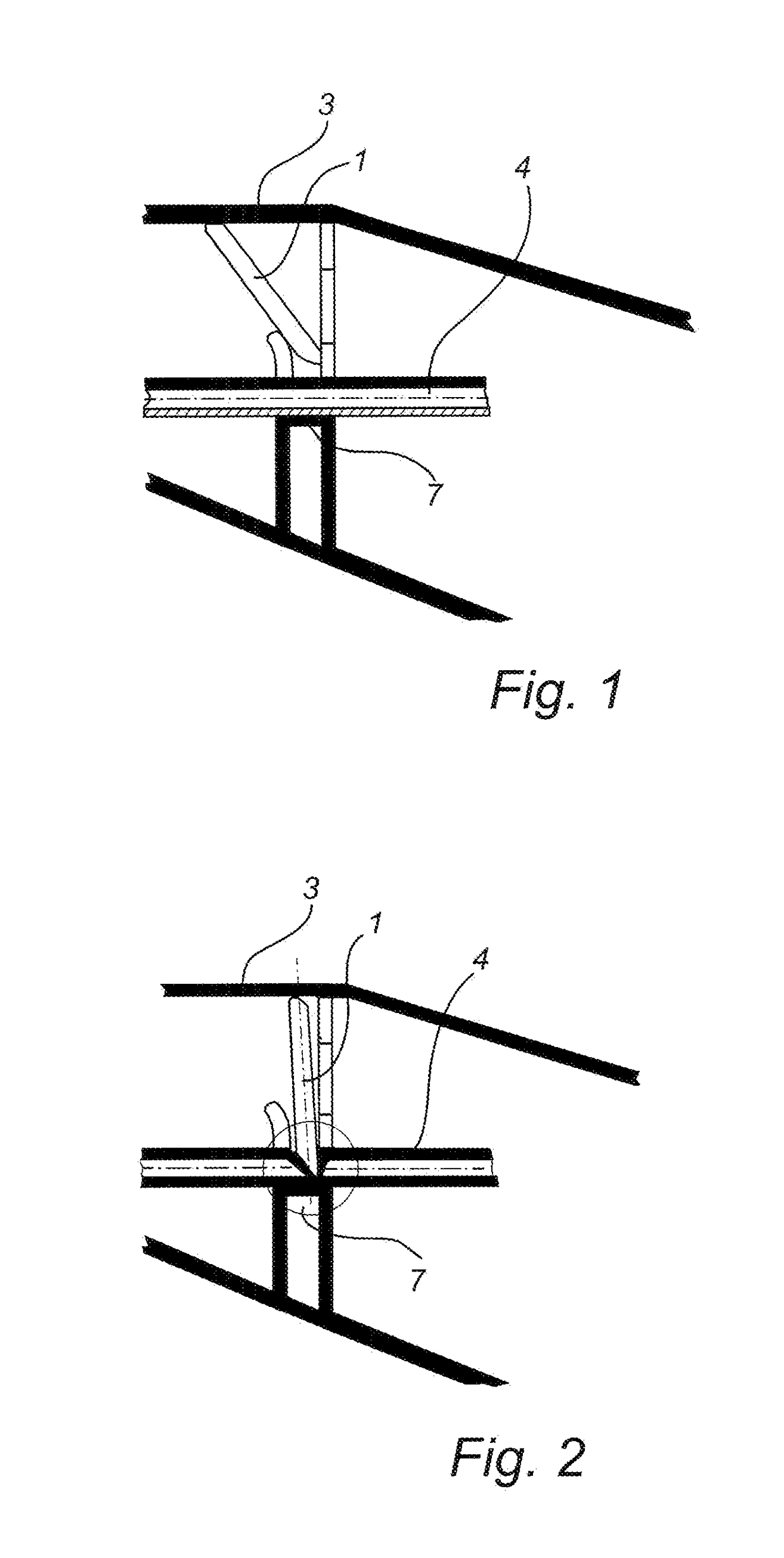

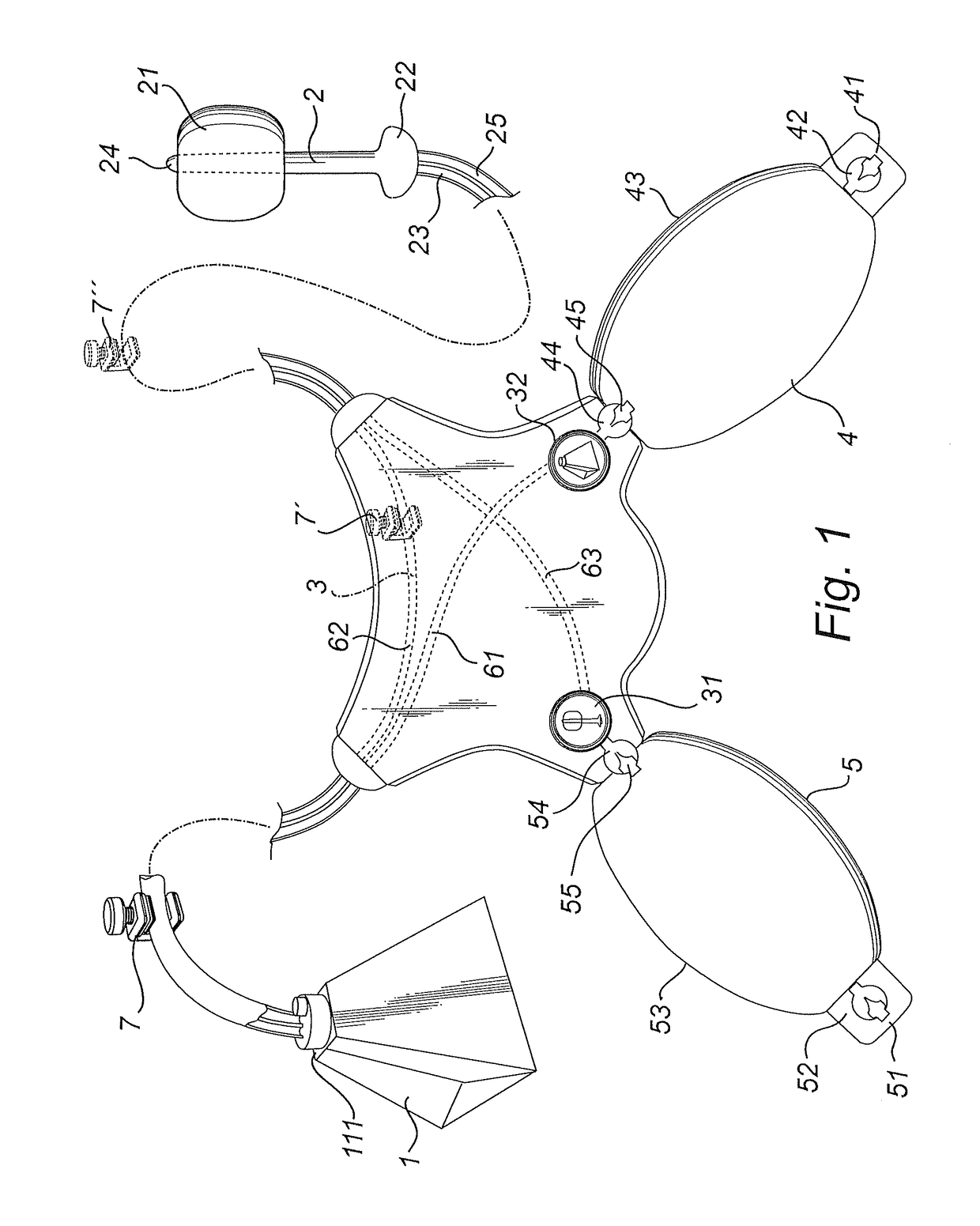

Vessel comprising a stowable magnus-effect rotor

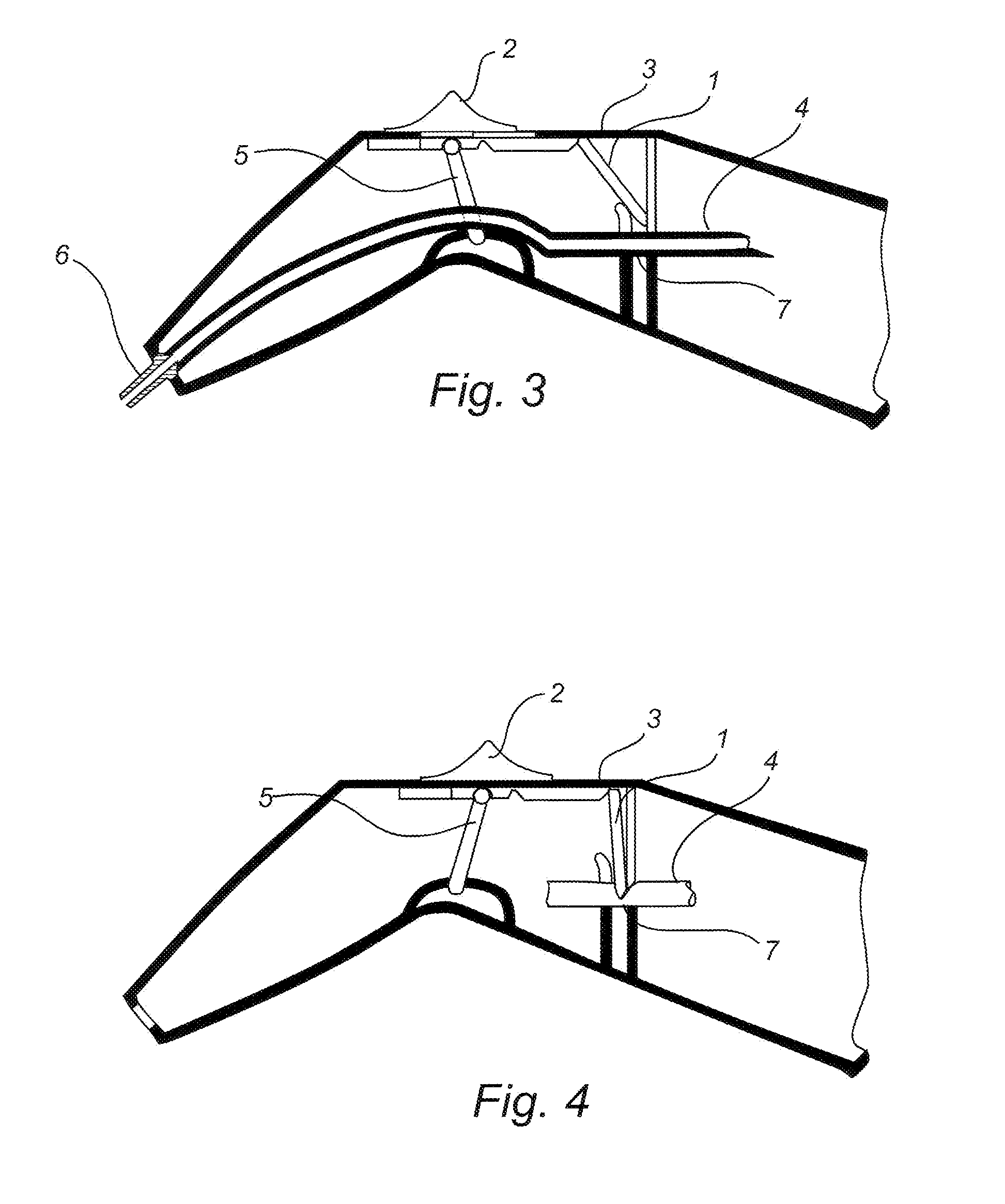

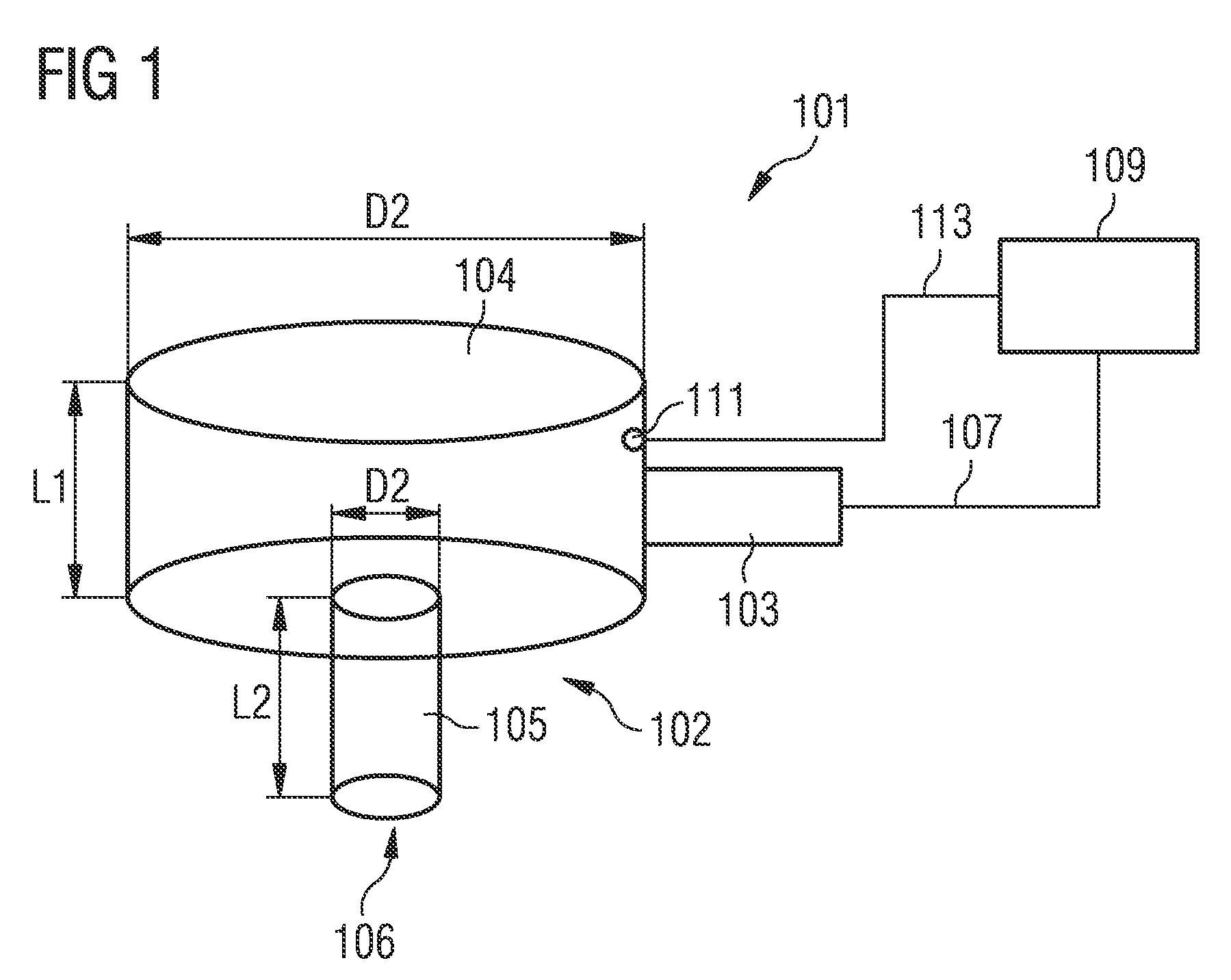

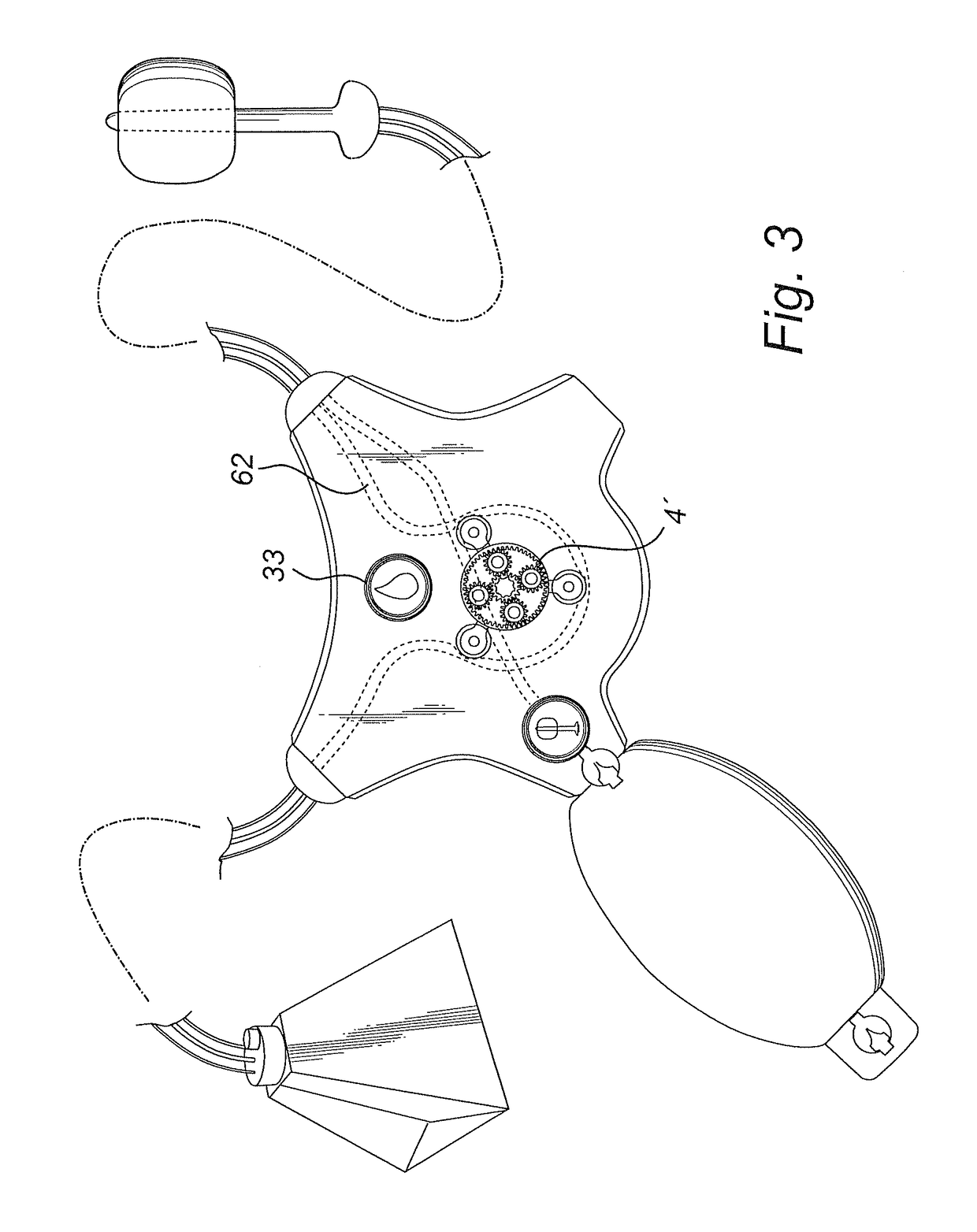

ActiveUS20130008363A1Optimize spaceGuaranteed precise controllabilityPropulsion based emission reductionWind acting propulsive elementsEdge segmentMechanical engineering

A vessel includes a hull and a deck, a substantially cylindrical rotor having a peripheral wall rotatable with respect to the deck around a longitudinal center line, the rotor being at a lower end connected to the deck and including an upper end plate, the rotor being mounted on the deck in such a manner that in an operational state the rotor is substantially vertically oriented and in an inoperational state the upper end plate is situated in the vicinity of the deck, the end plate extending transversely to the longitudinal center line, wherein the end plate is provided with movable edge segments that in the operational state of the rotor extend radially outwardly from the peripheral wall to an extended position and in the inoperational state of the rotor are moved to a retracted position that is situated closer to the peripheral wall than the extended position.

Owner:WINKLER JORN PAUL

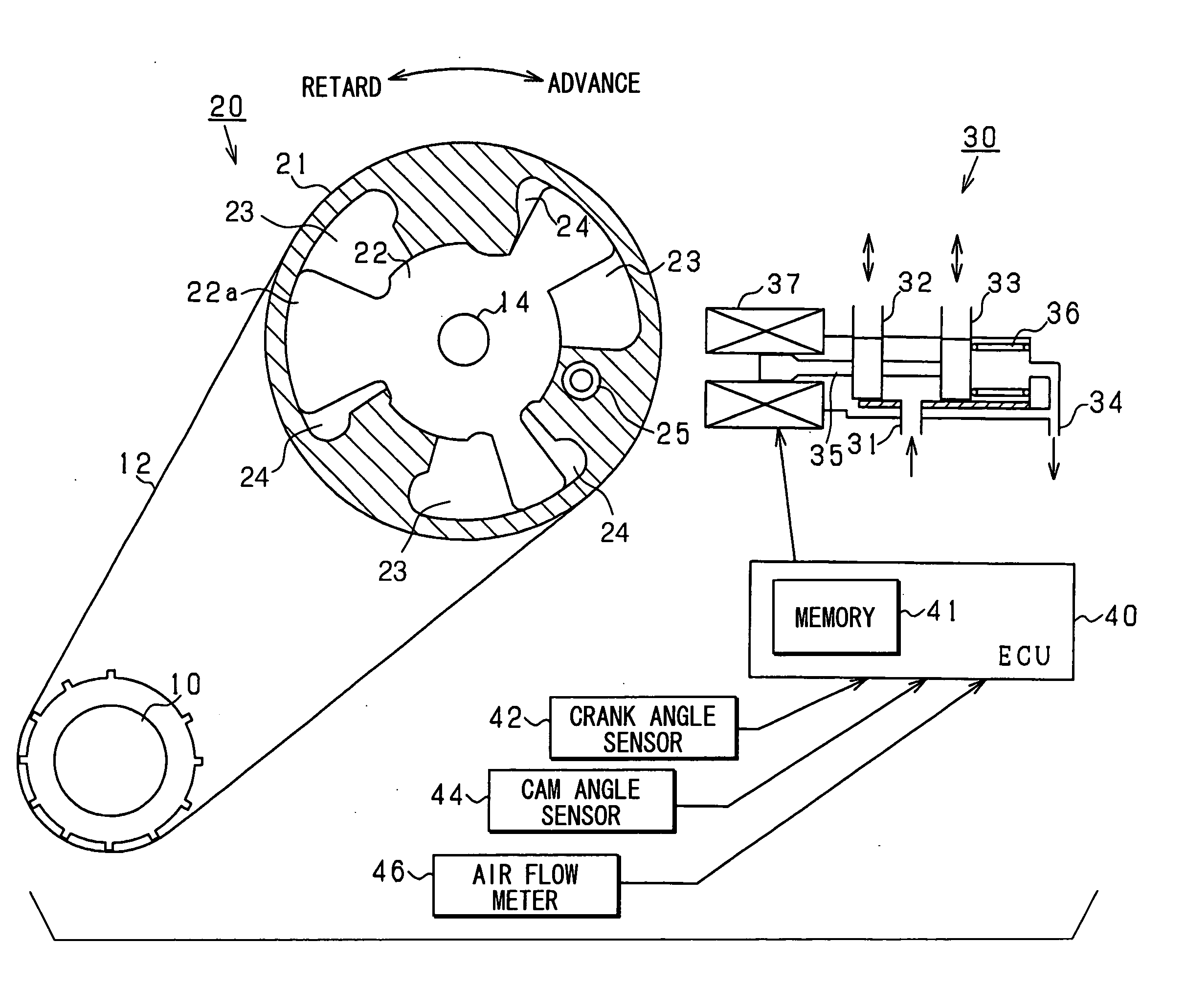

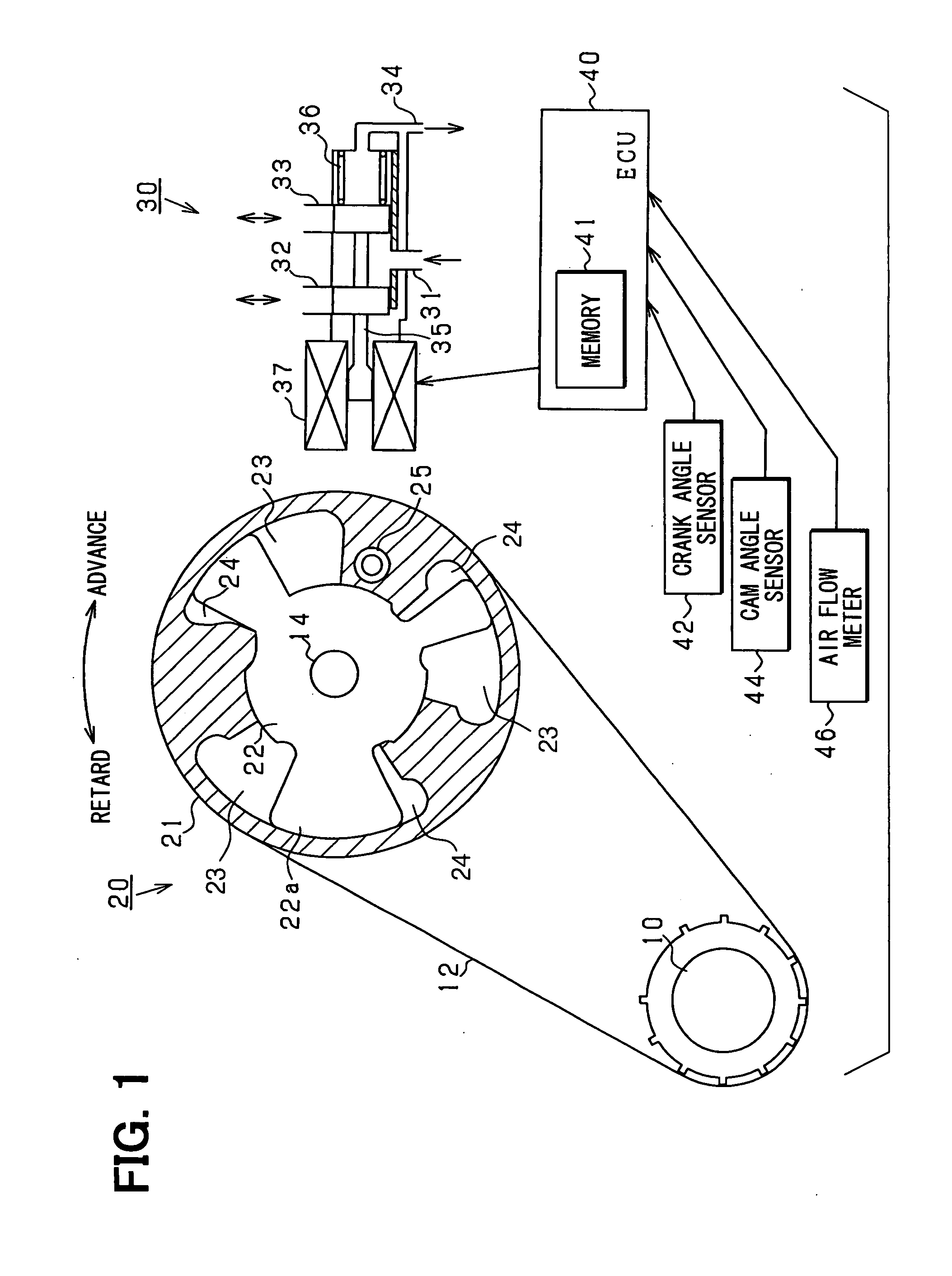

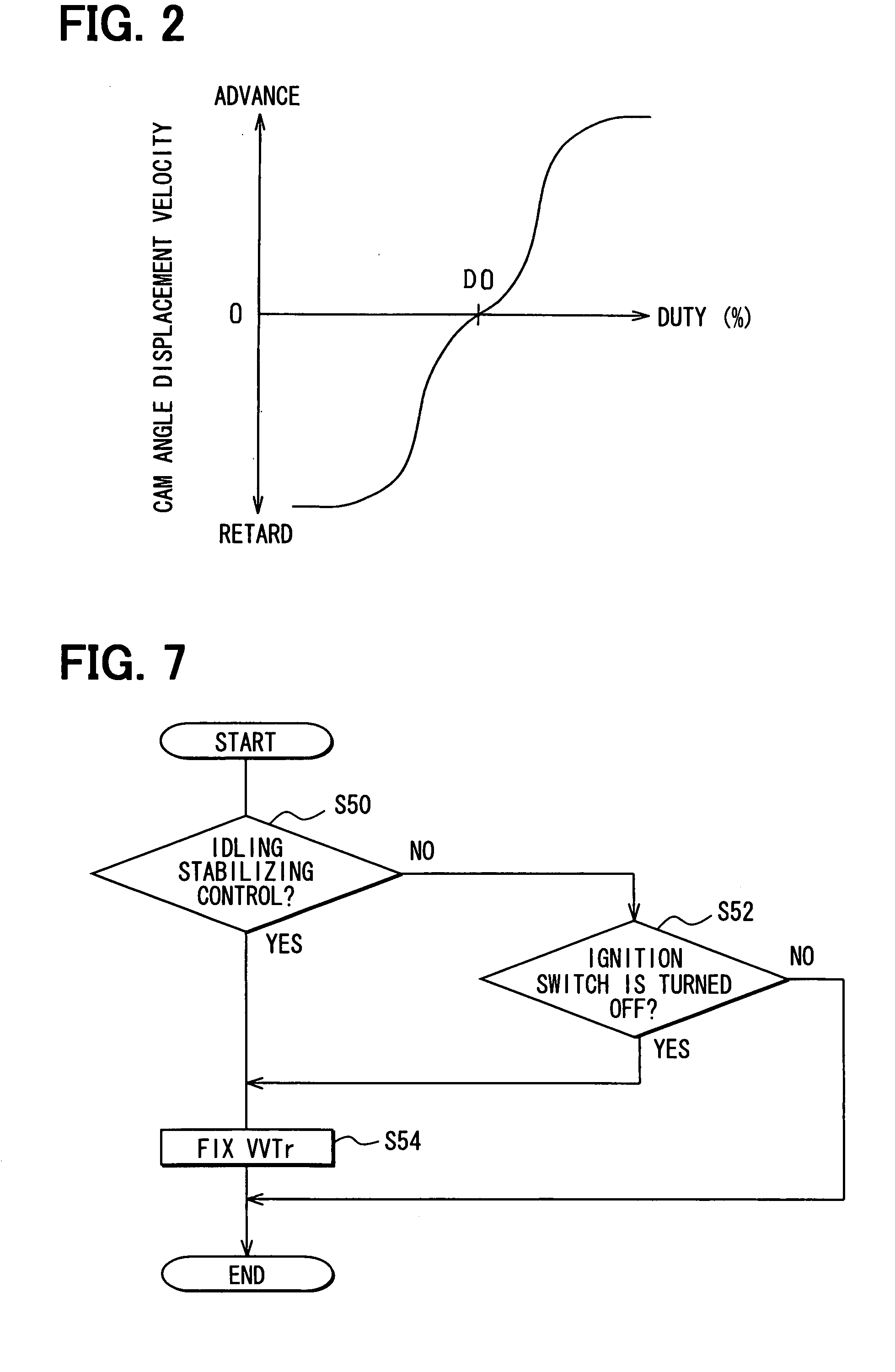

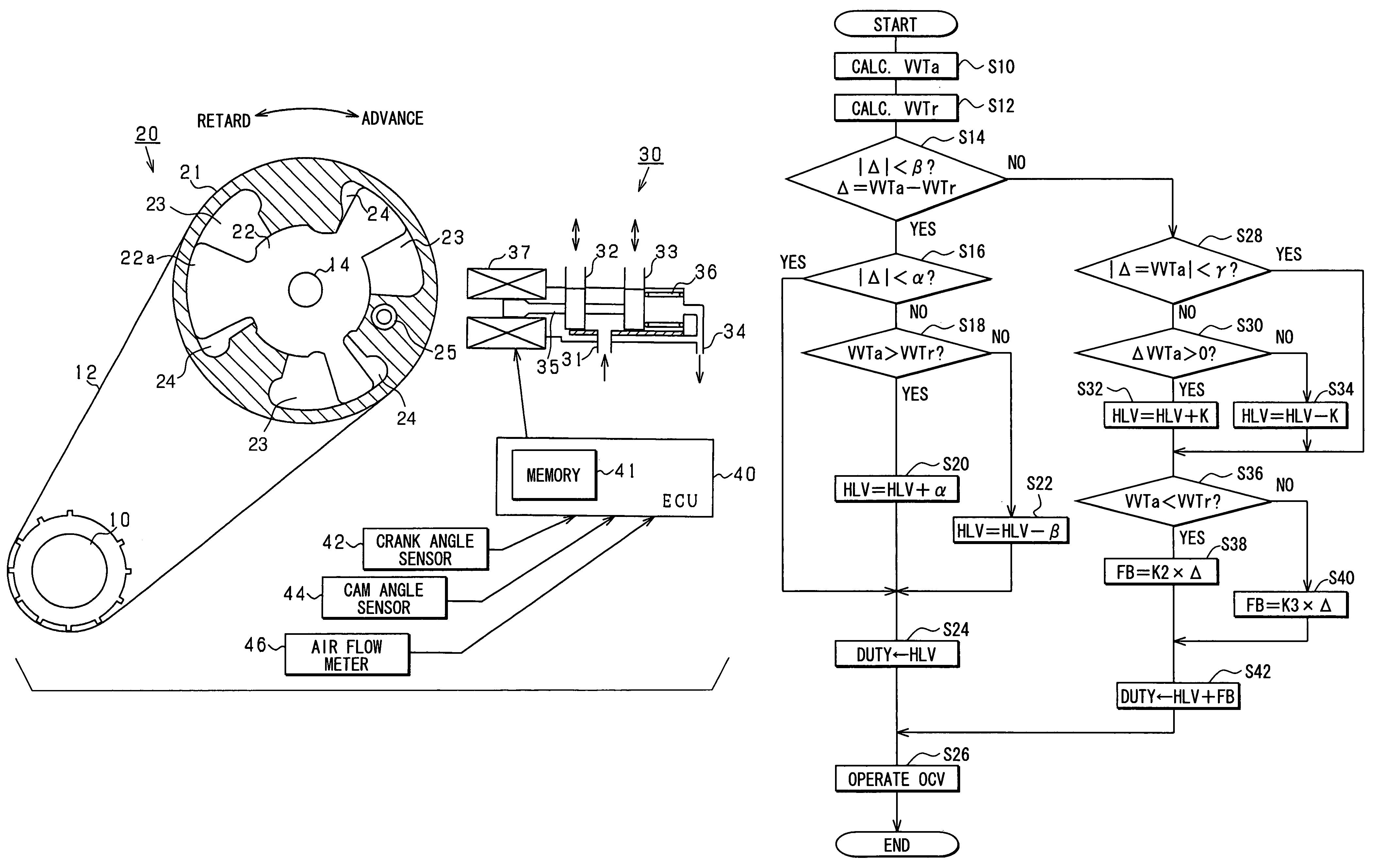

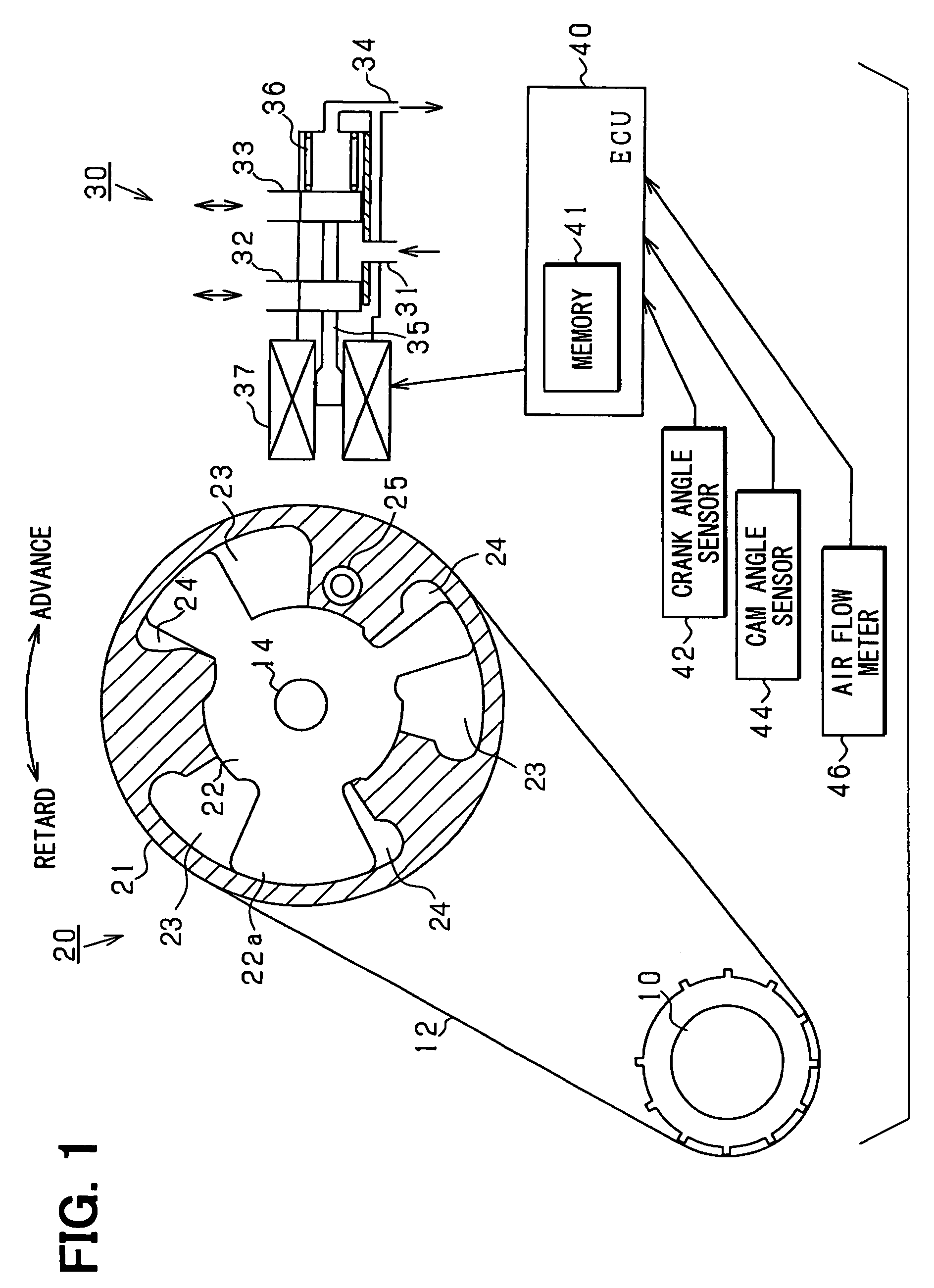

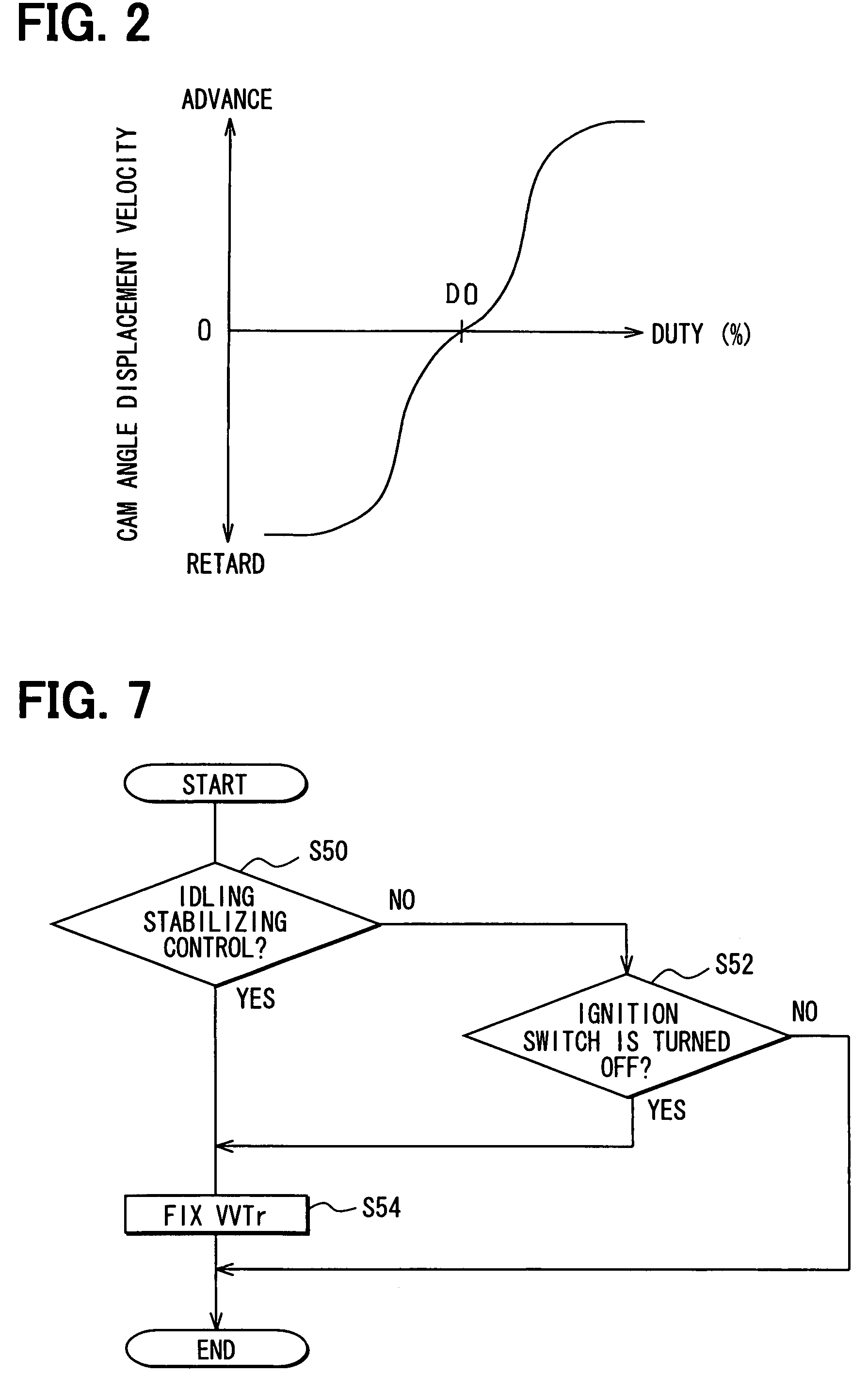

Control device for engine valve and control system for engine

InactiveUS20070221151A1Accurate controllabilityGuaranteed precise controllabilityValve arrangementsGearingCrankshaftEngine valve

A rotational phase difference of a camshaft relative to a crankshaft in a variable valve timing mechanism is controlled by an operation of an oil control valve. That is, in the oil control valve, there is outputted an operational signal which is defined by adding a feedback correction amount corresponding to a difference between an actual value and a target value of the rotational phase difference, to a holding learning value as the operational signal for holding the rotational phase difference. The holding learning value is altered only by a specified value on condition that the operational signal for holding the rotational phase difference is assumed to change.

Owner:DENSO CORP

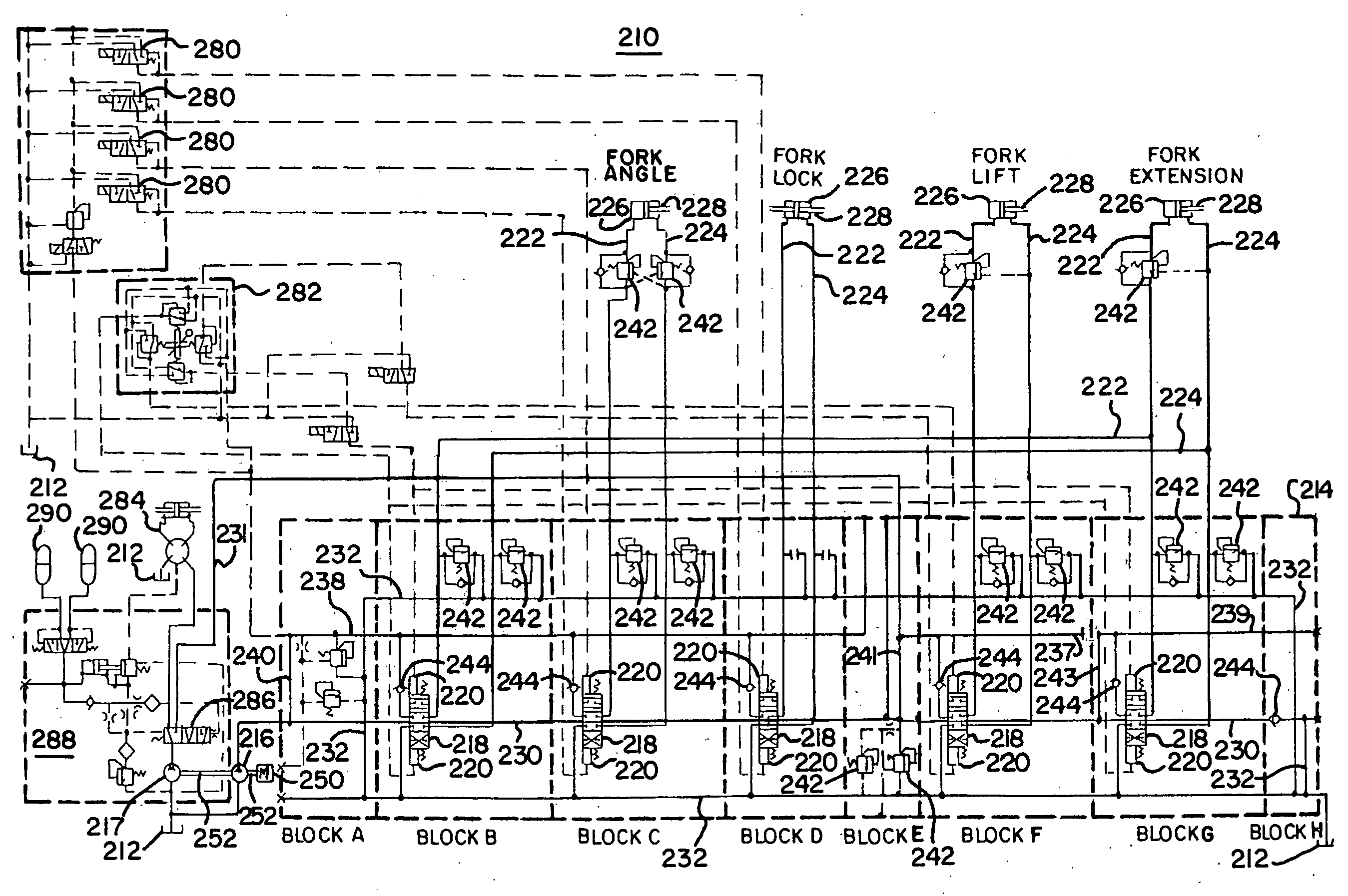

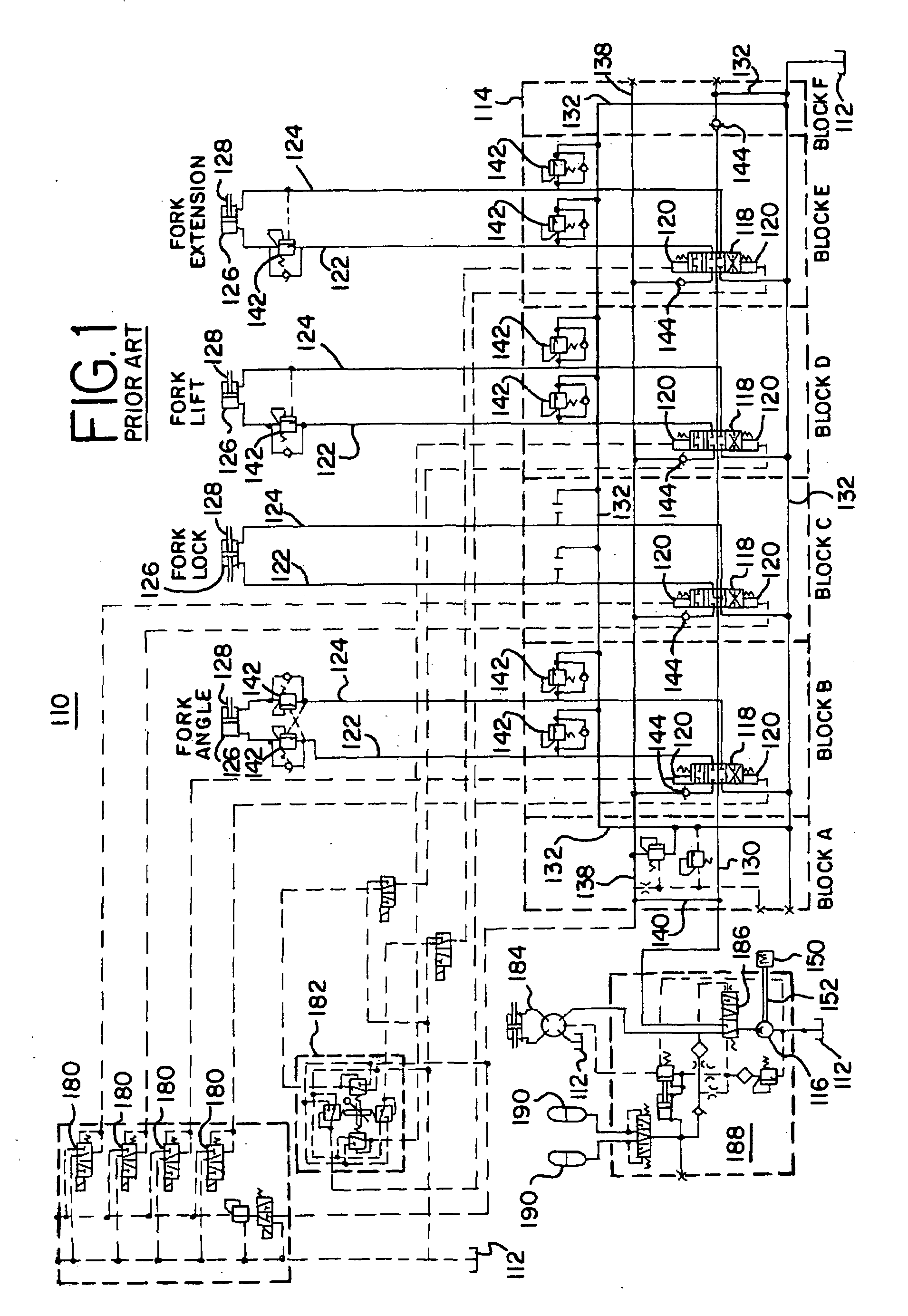

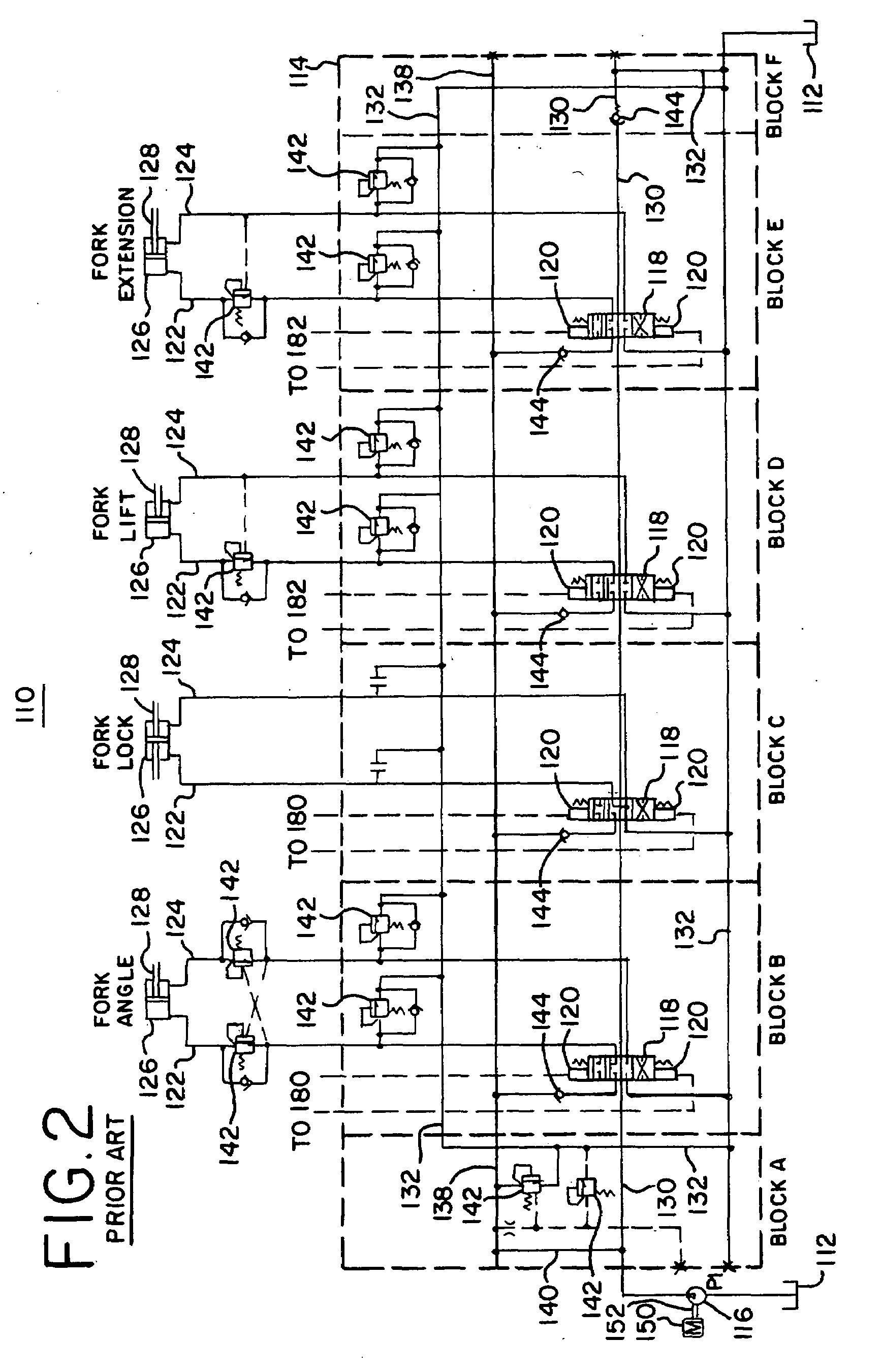

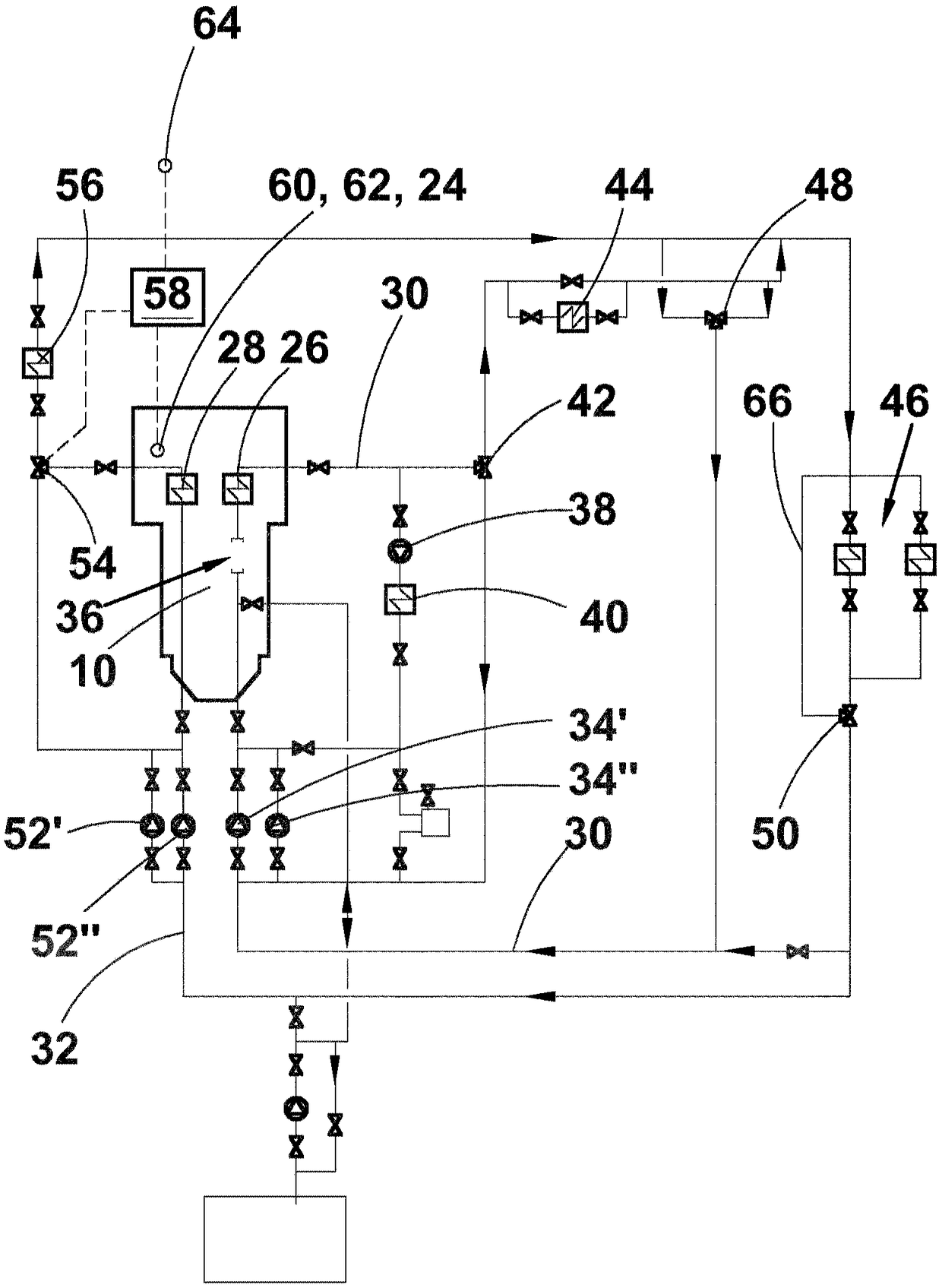

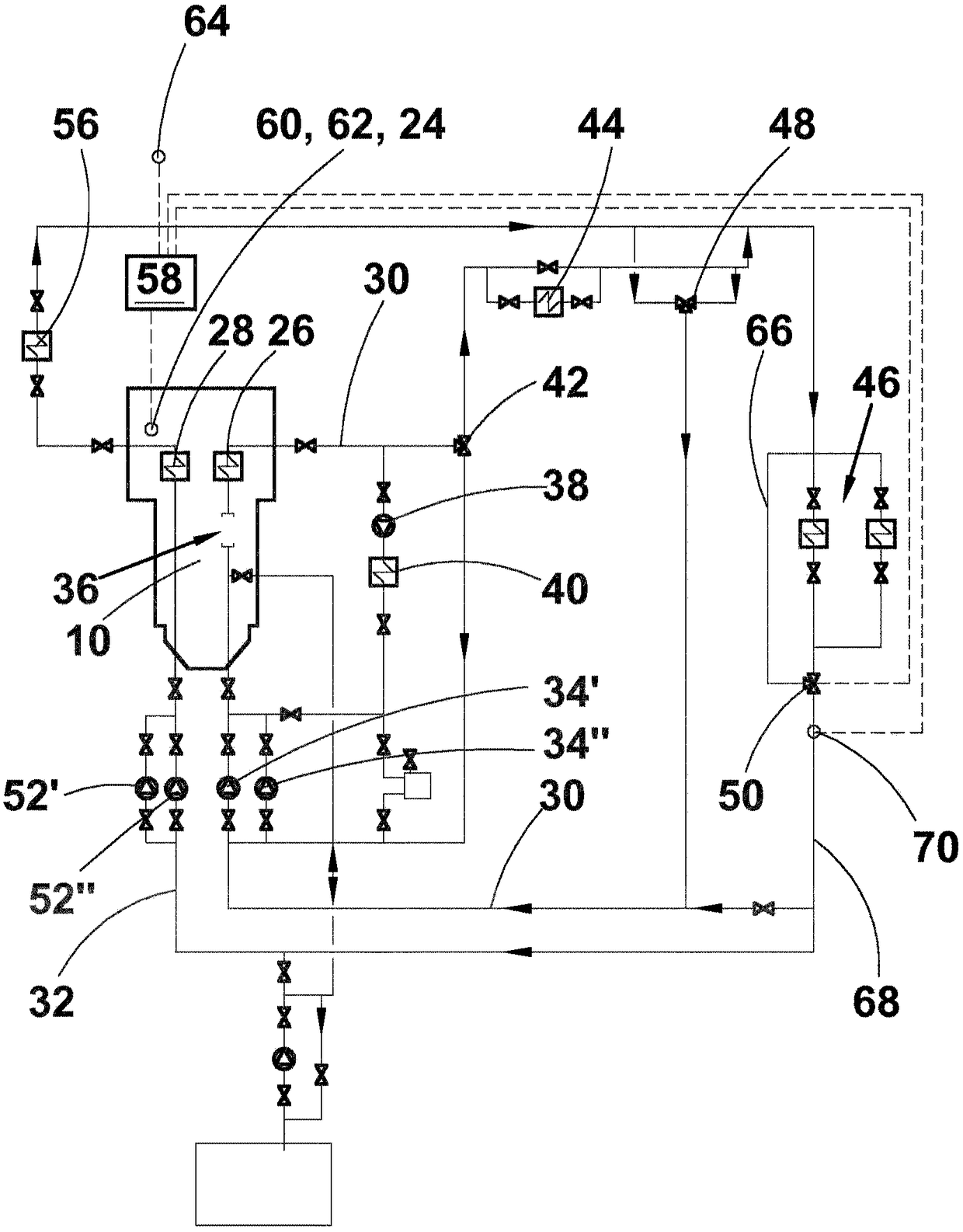

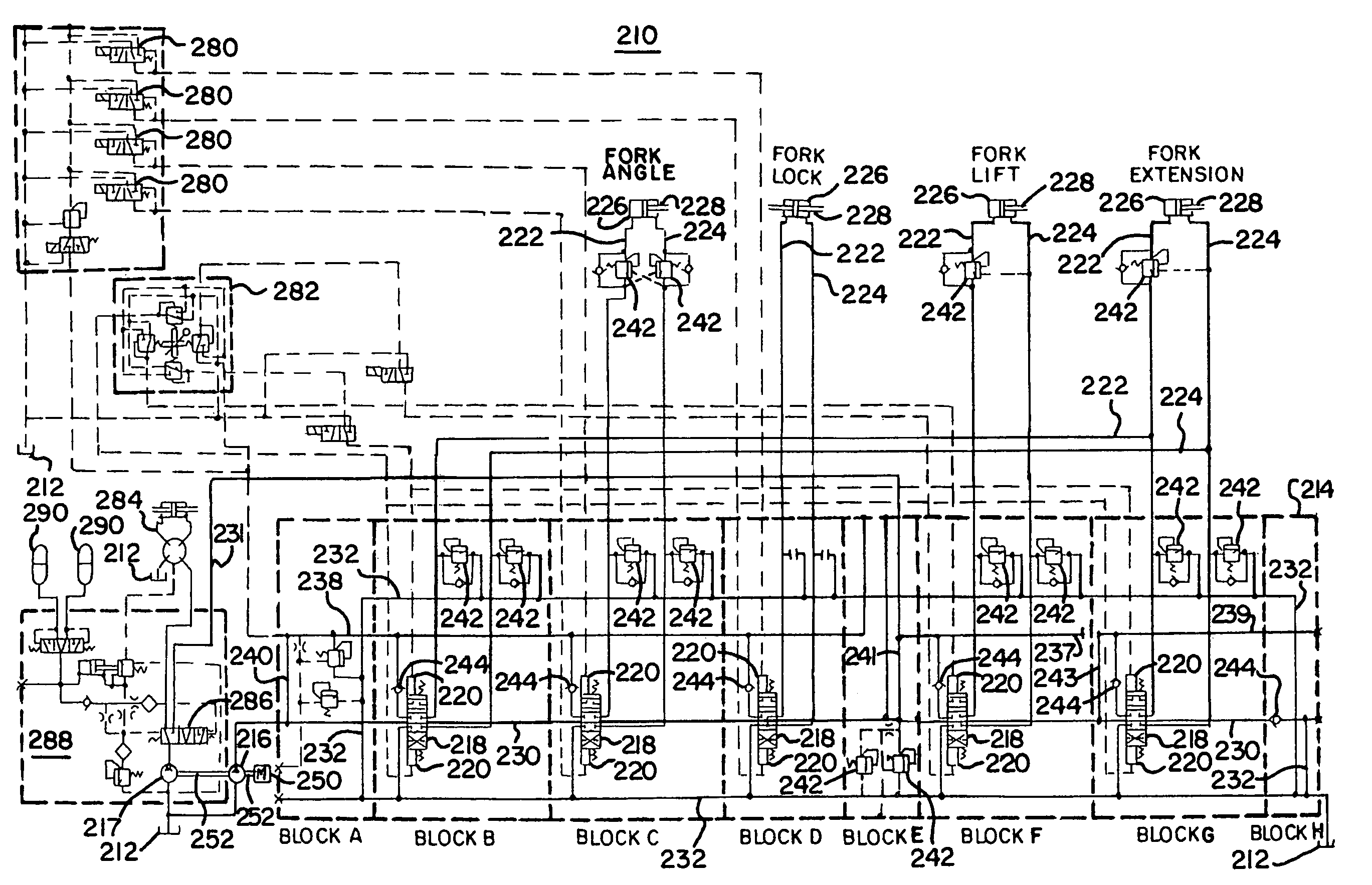

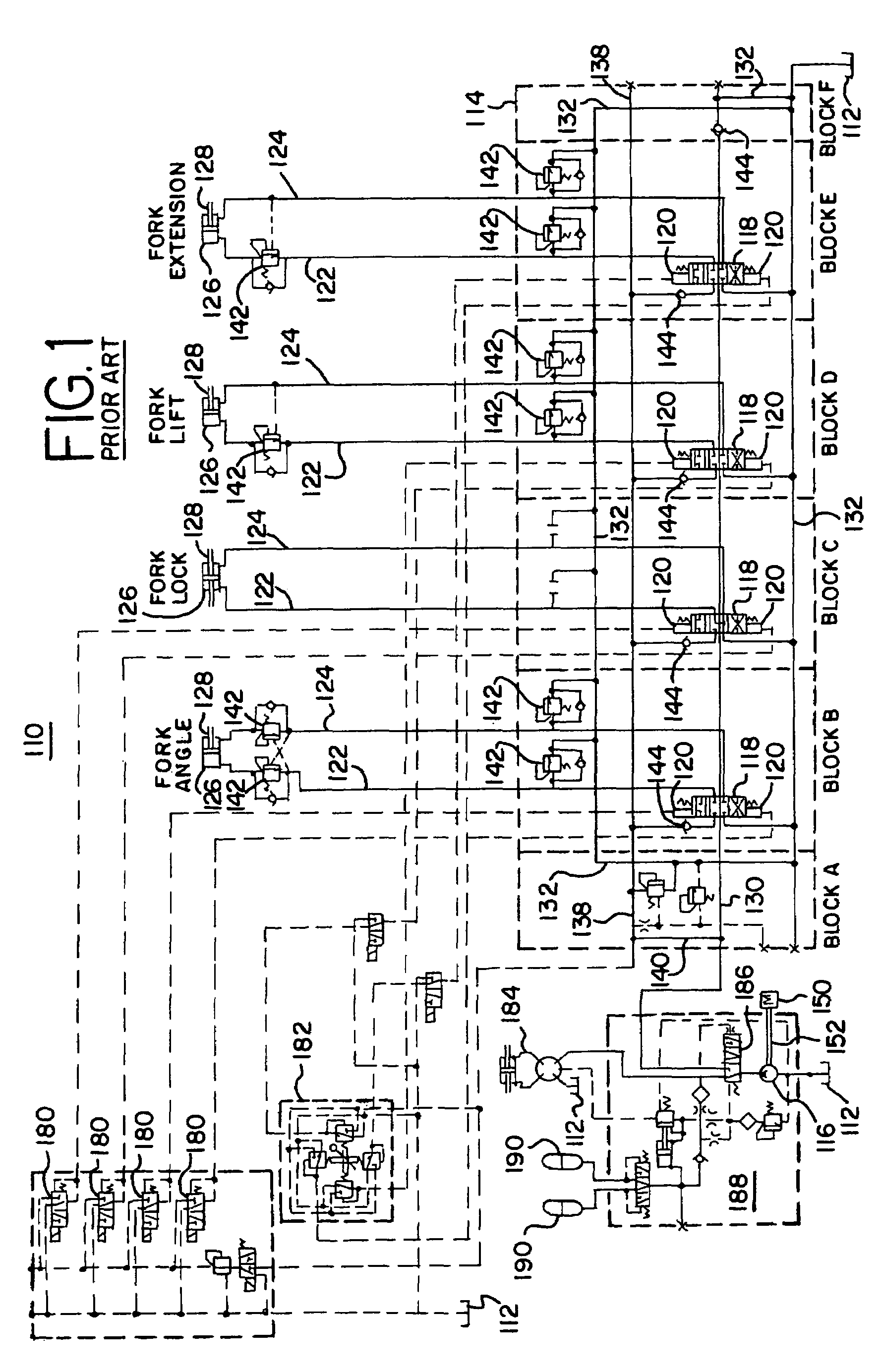

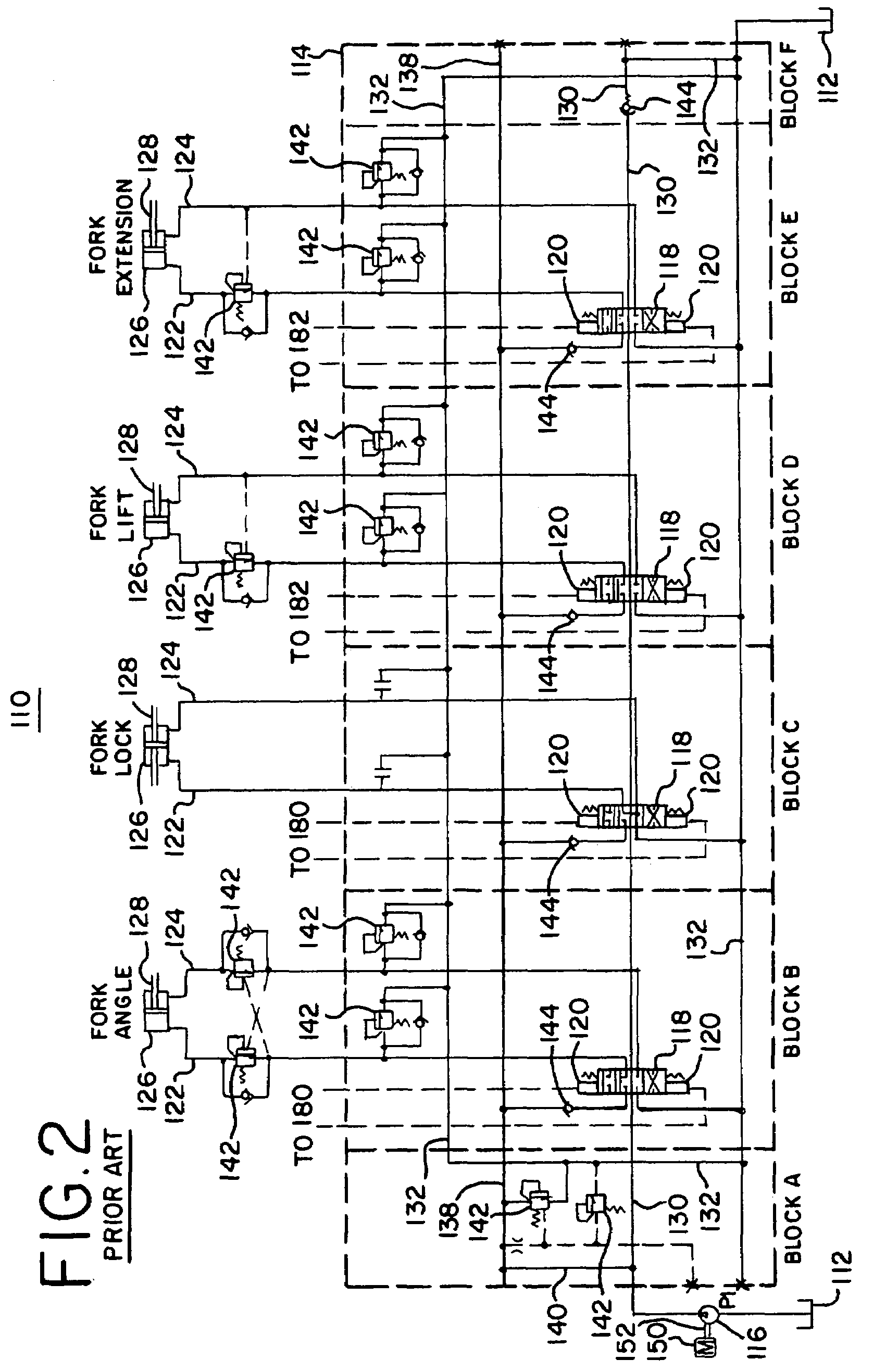

Smart flow sharing system

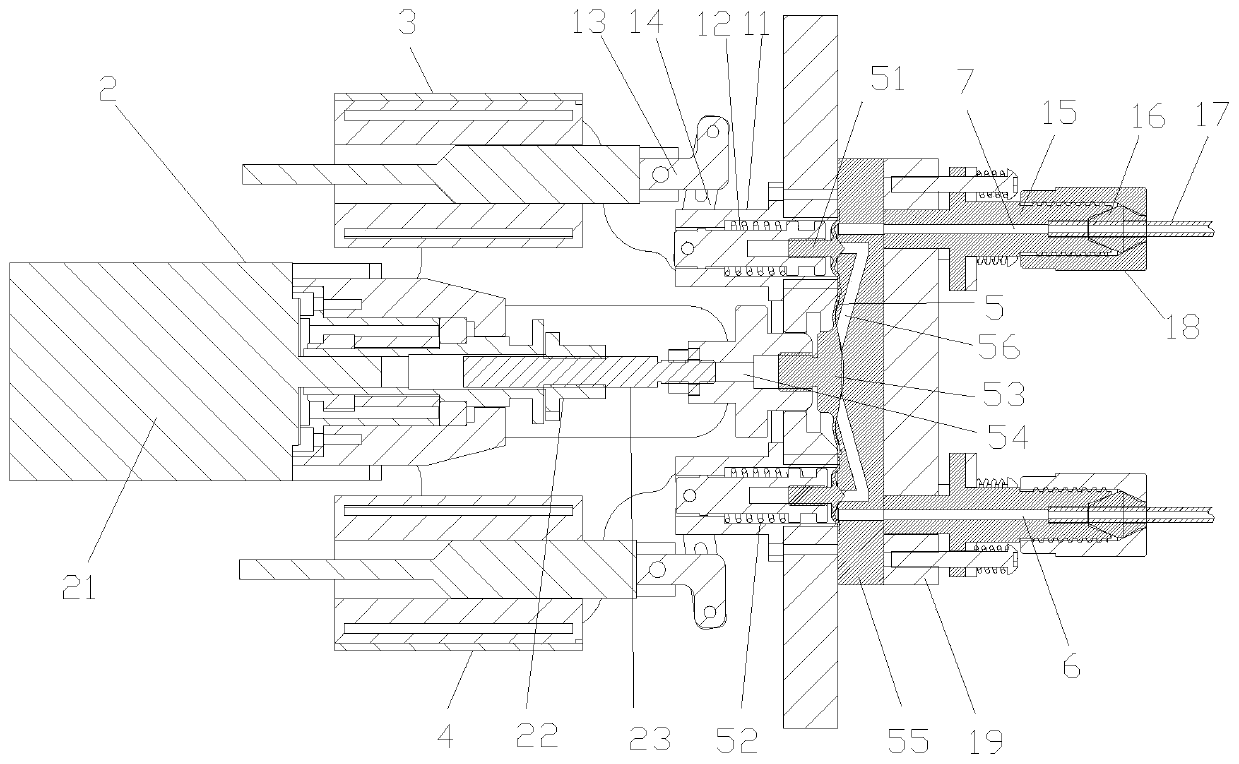

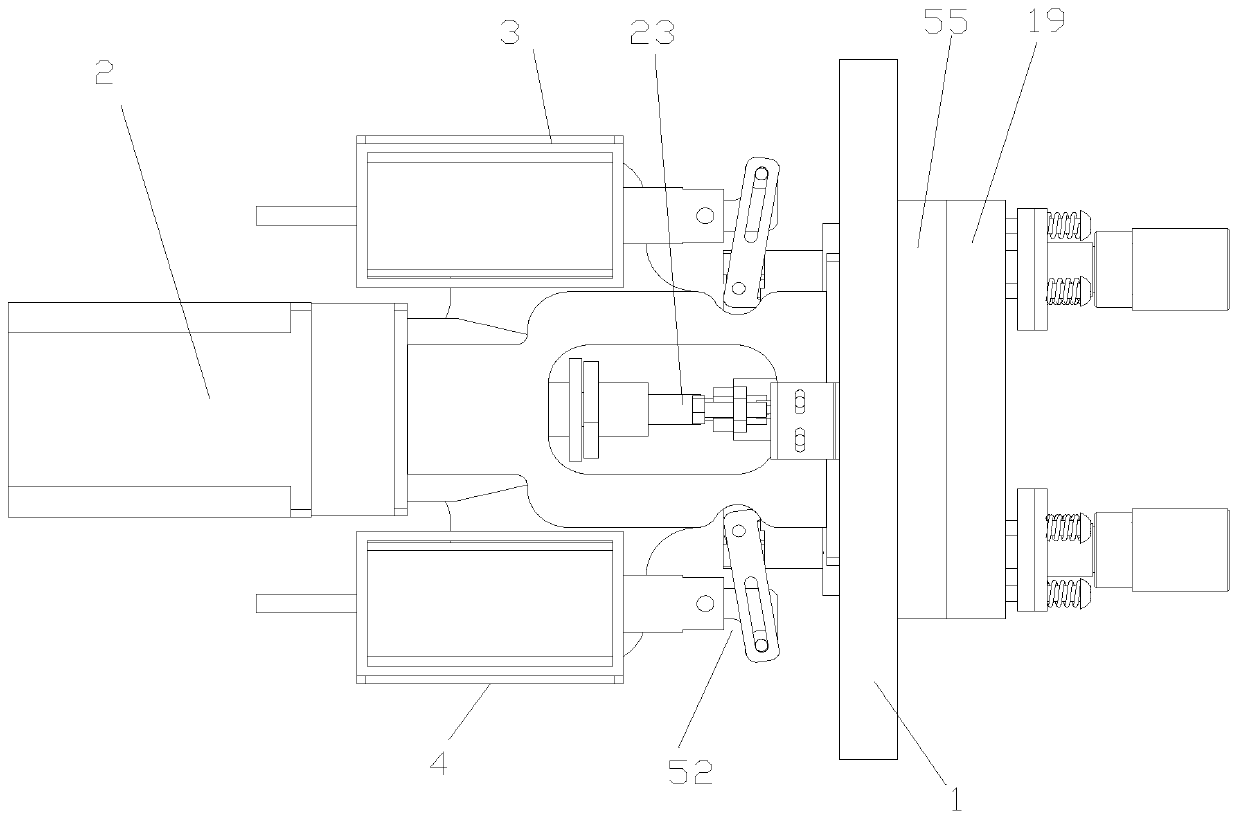

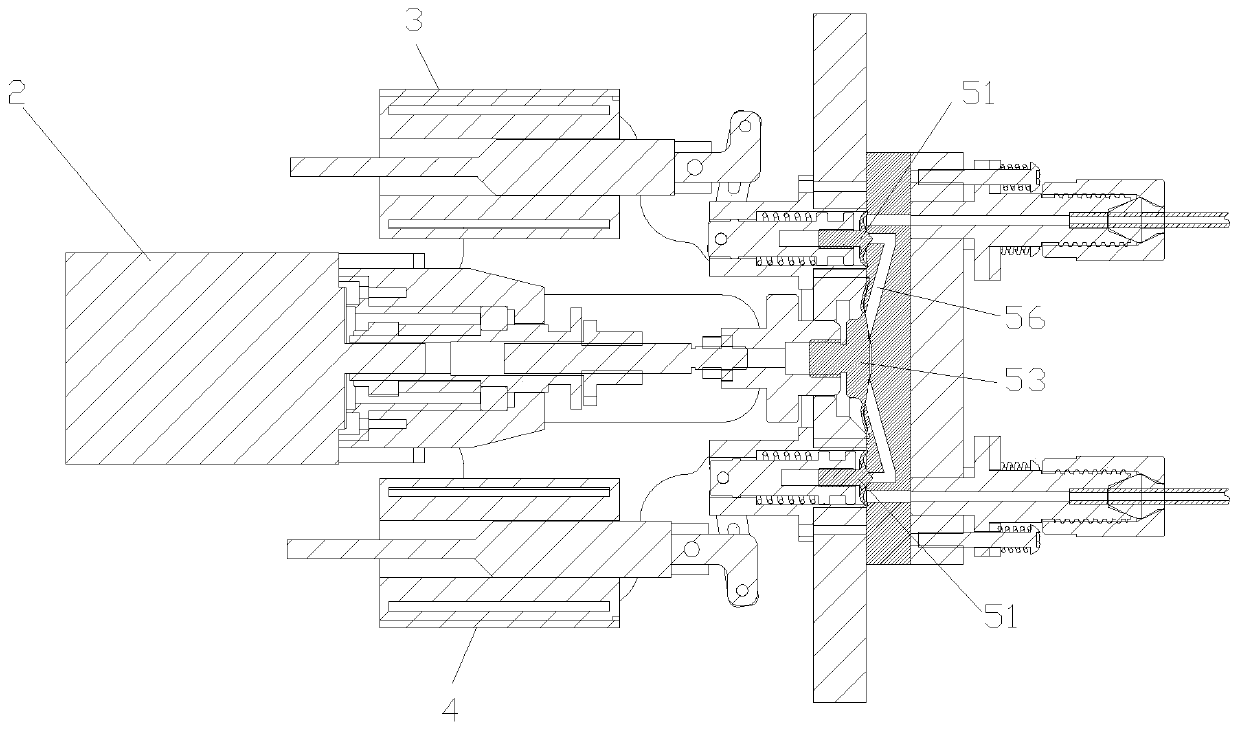

ActiveUS20090158728A1Guaranteed precise controllabilityHigh speedFluid couplingsServomotorsTraffic capacityEquipment Operator

A smart flow sharing system, useful in hydraulic systems having more than one hydraulically demanding equipment function wherein more than one of the hydraulically demanding functions are sometimes activated at the same time, has modified hydraulic passages and at least two fixed displacement pumps. The system automatically prioritizes hydraulic fluid flow so that when only one of two hydraulically demanding functions is activated by an operator, it receives the hydraulic fluid flow from both fixed displacement pumps, but when both hydraulically demanding functions are activated, one of the functions receives hydraulic fluid flow from the first fixed displacement pump, and the other function separately receives hydraulic fluid flow from the second fixed displacement pump. The smart flow sharing system accomplishes the foregoing without resorting to complex hydraulics or expensive additional components. An equipment operator advantageously achieves superior controllability and quicker movement of equipment functions using the invention.

Owner:PARKER INTANGIBLES LLC

Vessel comprising a stowable magnus-effect rotor

ActiveUS9027490B2Overlapping of adjacent segments is minimizedOptimize spacePropulsion based emission reductionWind acting propulsive elementsEdge segmentMechanical engineering

A vessel includes a hull and a deck, a substantially cylindrical rotor having a peripheral wall rotatable with respect to the deck around a longitudinal center line, the rotor being at a lower end connected to the deck and including an upper end plate, the rotor being mounted on the deck in such a manner that in an operational state the rotor is substantially vertically oriented and in an inoperational state the upper end plate is situated in the vicinity of the deck, the end plate extending transversely to the longitudinal center line, wherein the end plate is provided with movable edge segments that in the operational state of the rotor extend radially outwardly from the peripheral wall to an extended position and in the inoperational state of the rotor are moved to a retracted position that is situated closer to the peripheral wall than the extended position.

Owner:WINKLER JORN PAUL

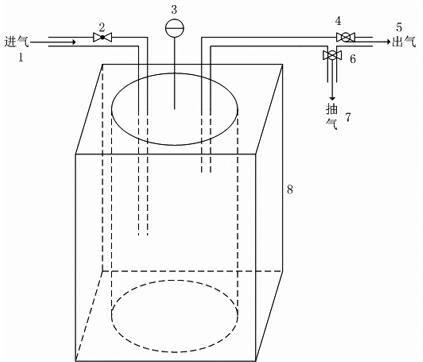

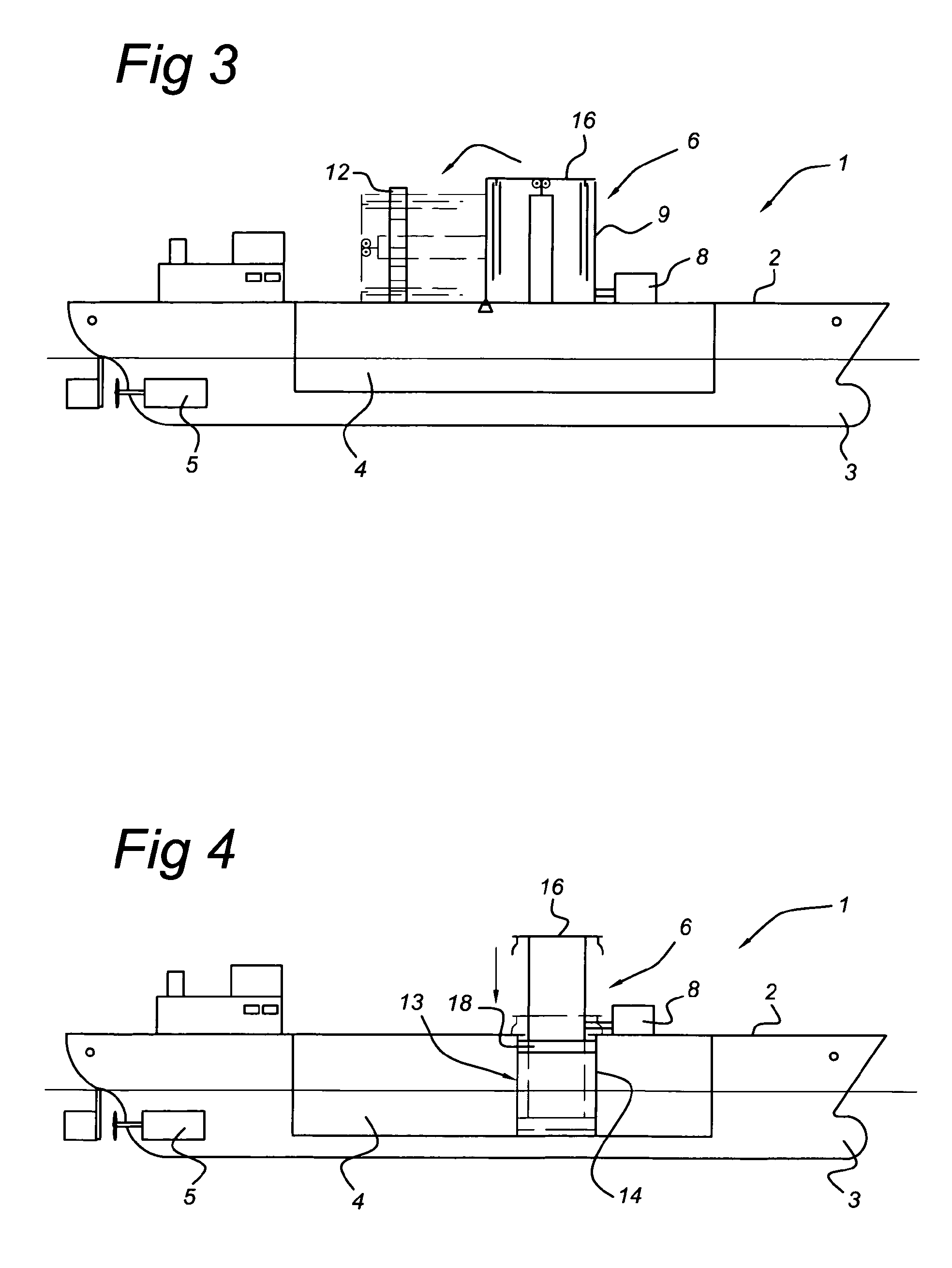

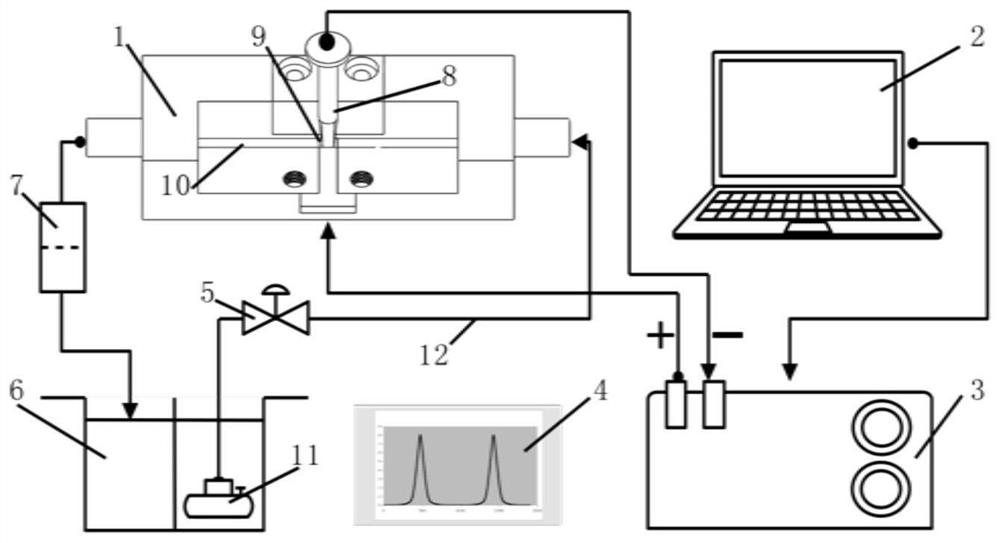

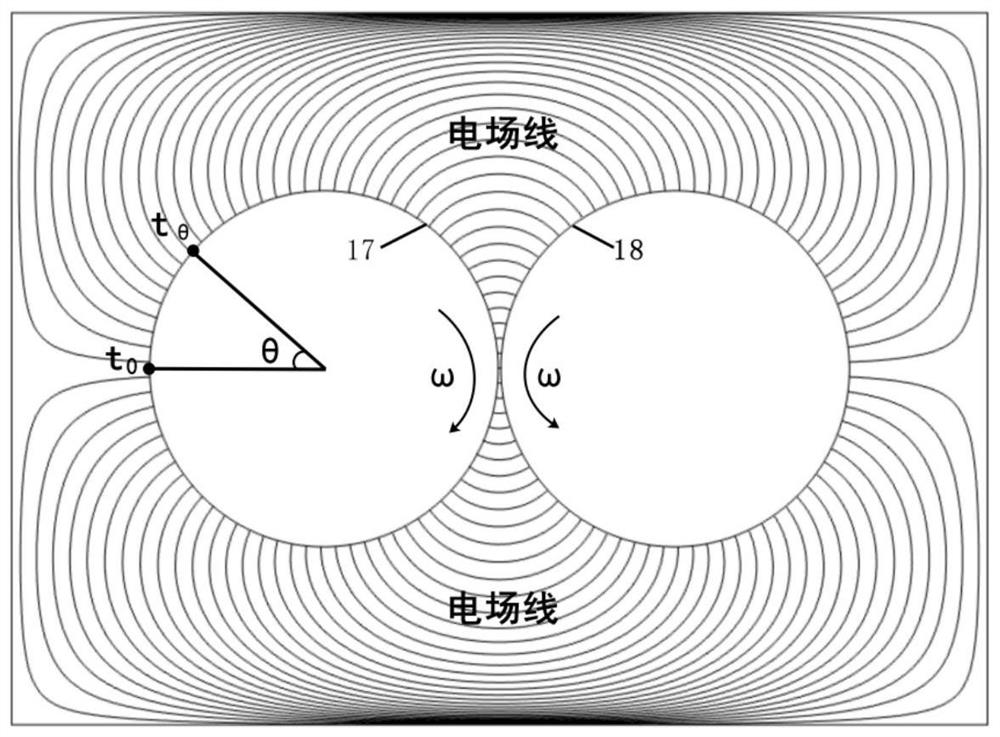

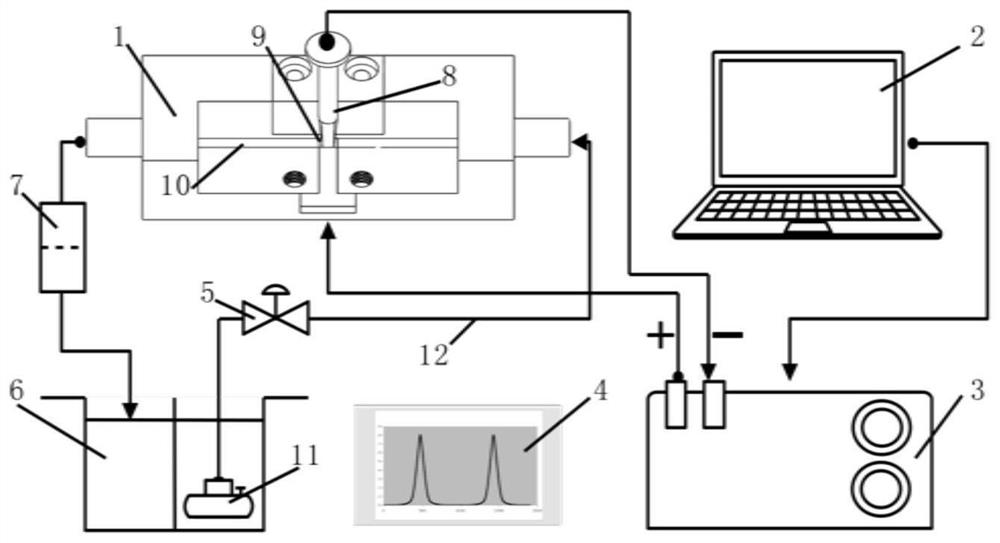

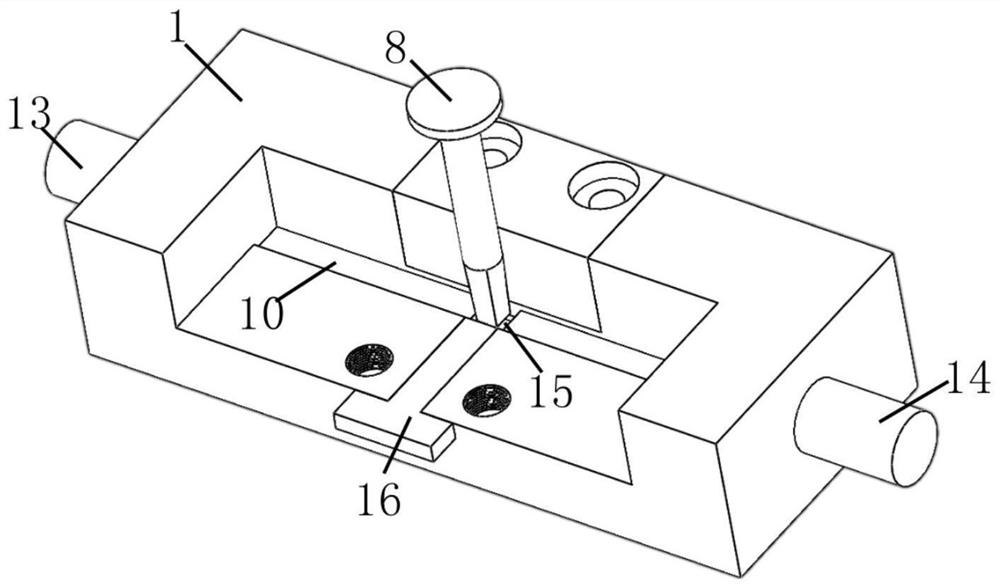

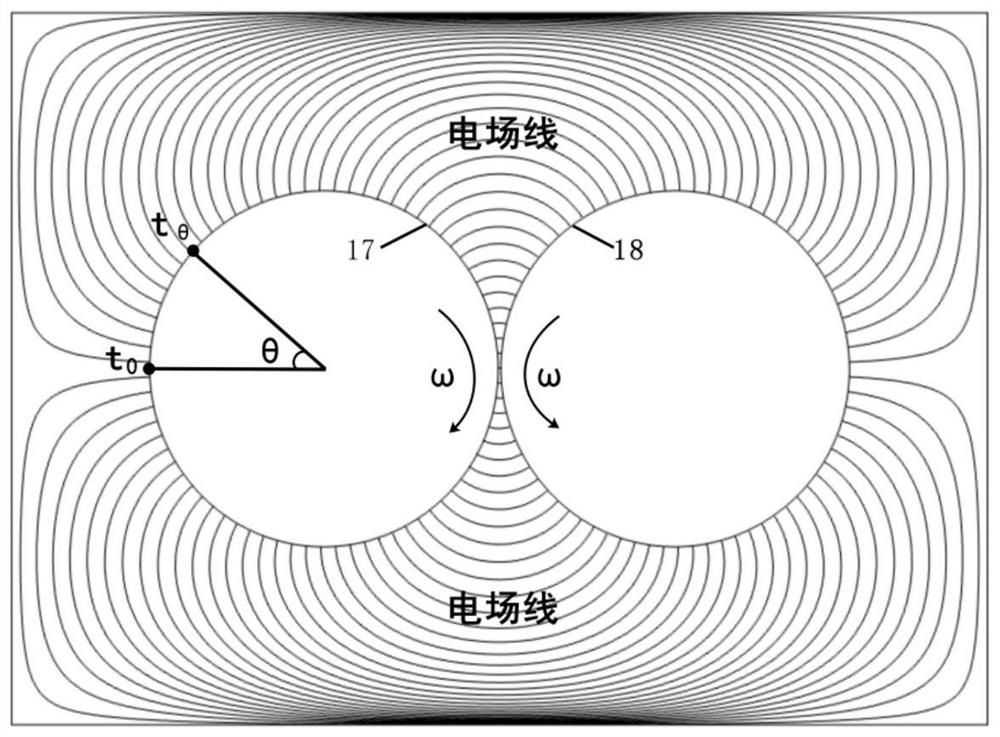

Plate electrode simulating rotation part rotary printing electrolytic dissolution process device and method

ActiveCN111822799ASimplify the dissolution study processGuaranteed precise controllabilityElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentHemt circuits

The invention relates to a plate electrode simulating a rotation part rotary printing electrolytic dissolution process device and a method, and belongs to the field of electrochemical machining. The test device has the characteristics that: a programmable power supply, an electrolytic fixture, an electrolyte filtration cycle system, a data recorder, a plate workpiece, a tool electrode and other equipment and devices are used, a static plate electrode is used instead of a rotary rotation electrode, and a related research about dissolution characteristics of rotary printing electrochemical machining is realized. The method comprises the steps that: step 1, an electric field simulation software numerical simulation is used for calculating a current density distribution waveform of an anode surface of rotary printing electrochemical machining; step 2, current waveform data corresponding to the current density distribution is calculated, and current waveform lattice data is imported into the programmable power supply; step 3, the electrolyte filtration cycle system and an electrochemical machining cathode and anode circuit are communicated; and step 4, a power is turned on and a relateddissolution test is conducted. According to the plate electrode simulating the rotation part rotary printing electrolytic dissolution process device and the method, the test cycle of the rotary printing electrochemical machining is shortened, the research process of rotary printing electrochemical machining is simplified. The device and the method are of great significance for reducing research cost and improving research accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Control device for engine valve and control system for engine

InactiveUS7398751B2Guaranteed precise controllabilityEasy to adaptValve arrangementsGearingVariable valve timingPhase difference

A rotational phase difference of a camshaft relative to a crankshaft in a variable valve timing mechanism is controlled by an operation of an oil control valve. That is, in the oil control valve, there is outputted an operational signal which is defined by adding a feedback correction amount corresponding to a difference between an actual value and a target value of the rotational phase difference, to a holding learning value as the operational signal for holding the rotational phase difference. The holding learning value is altered only by a specified value on condition that the operational signal for holding the rotational phase difference is assumed to change.

Owner:DENSO CORP

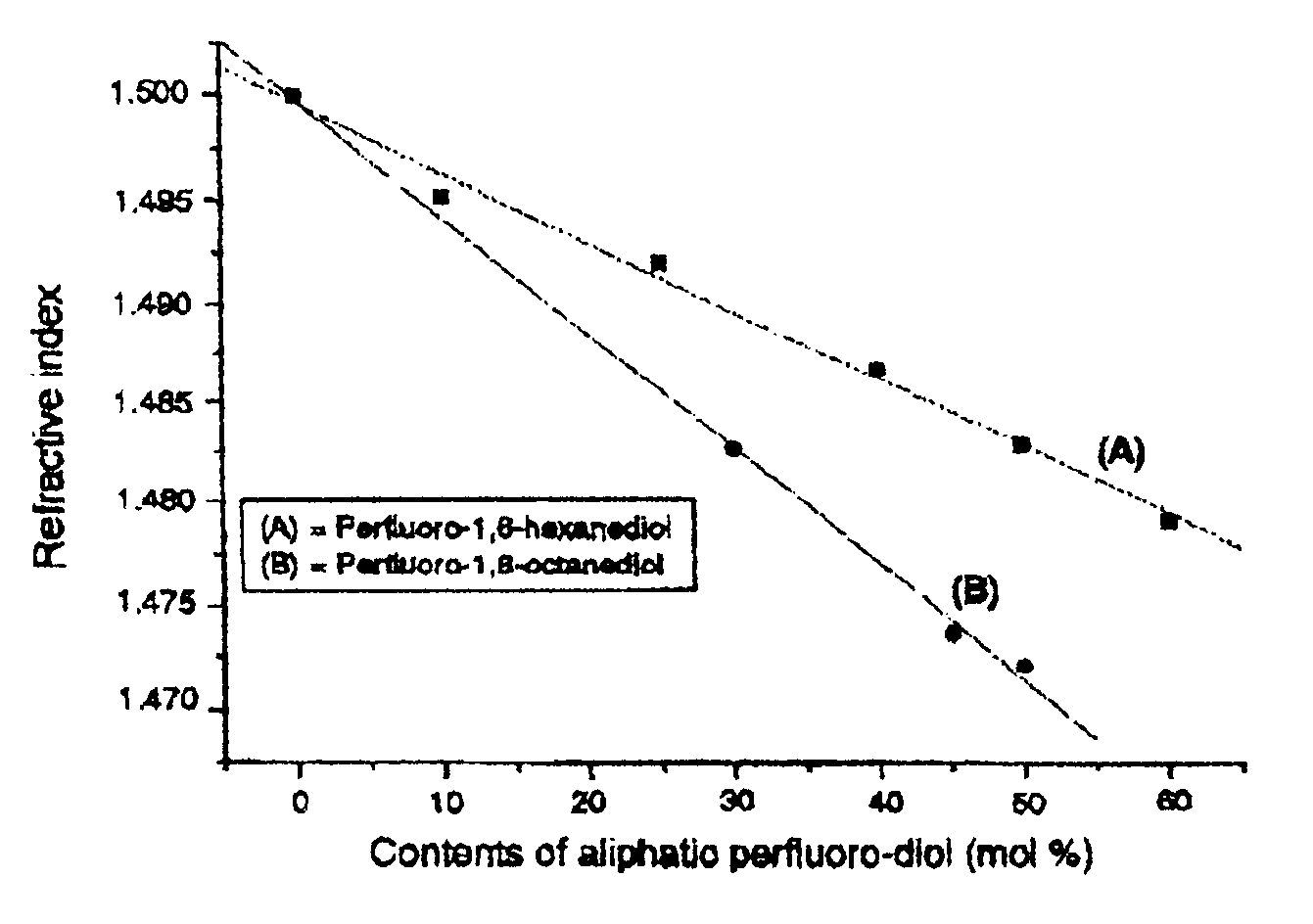

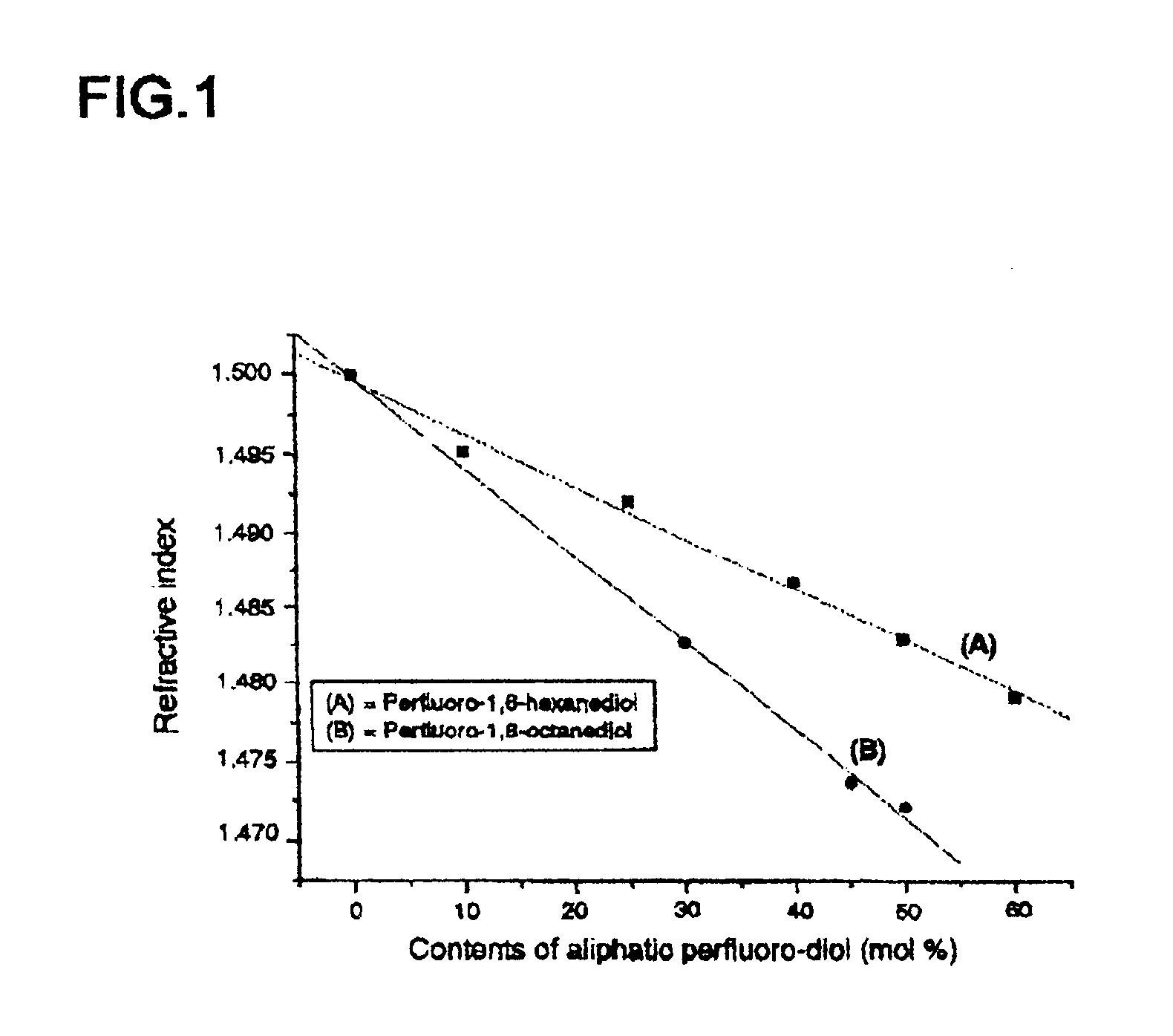

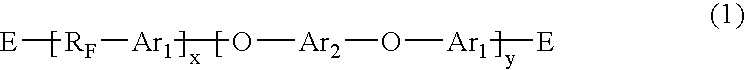

Fluorinated polyethers having perfluorinated aliphatic group and optical waveguide using the same

InactiveUS6946534B2High fluorine contentReduce bondingOrganic chemistryOrganic compound preparationWaveguidePhenyl group

The present invention relates to fluorinated polyethers having a fluorinated aliphatic group at a main chain as represented by the formula (1), as well as a waveguide fabricated using the same: where RF represents OCH2(CF2)nCH2O, or OCH2CF2O(CF2CF2O)nCF2CH2O, where n is a natural number ranging from 1 to 12;Ar1 represents where B is not present or a C═O group, orAr1 represents where Hal is one selected from F, Cl, Br and I;Ar2 represents where D is one selected from —C(CF3)2, —C(CH3)2, —CO—, —SO2—, —O— and —S—, orAr2 represents where R1 and R2 are the same or different and each independently represents a halogen atom selected from F, Cl, Br and I, and m is a natural number of 1-3, orAr2 represents E represents H, or where P is H or a substituted or unsubstituted phenyl group;x is a number ranging from 0.1 to 1.0;y is 1.0−x.

Owner:CHEM OPTICS

Resonator device for damping the pressure oscillation within a combustion chamber and a method for operating a combustion arrangement

InactiveUS9279586B2Quick changeFast frequencyContinuous combustion chamberEngine fuctionsNormal loadCombustion chamber

A resonator device is provided for damping a pressure oscillation within a combustion chamber. The resonator device may comprise: a container filled with a gas; an opening in the container; and a heating element adapted to generate a flame. The flame is arranged to heat the gas within the container. The resonator device is comprised in a combustion arrangement comprising a combustion chamber for defining a combustion space for burning fuel. The container is connected to the combustion chamber such that an inside of the container is in communication with the combustion space via the opening. The resonator device has a resonance frequency equal to a pressure oscillation frequency within the combustion chamber under normal load conditions.

Owner:SIEMENS AG

A method of cleaning a charge air cooler and an internal combustion engine

ActiveCN108431381AHeat exchange surfaces are cleanGuaranteed precise controllabilityLiquid coolingElectrical controlEngineeringInternal combustion engine

The present invention relates to a turbocharged internal combustion engine provided with means for flushing dirt periodically from the heat exchange surfaces of the LT- charge air cooler by using water condensed on the heat exchange surfaces for the flushing.

Owner:WARTSILA FINLAND OY

Apparatus including a conduit clamping device

ActiveUS9878145B2Reduced dexterityEasy to operateDiaphragm valvesEngine diaphragmsCatheterEngineering

An apparatus comprising a conduit clamping device with a closing mechanism for closing and opening passage of fluid or air in a flexible conduit is disclosed. The apparatus comprises a movable arm or disk that is connected to a manipulation arm or a knob; a conduit in form of a tube, that is laid flat against an abutment or protrusion; and a guide structure that constrains the movable arm or disk between the guide structure and the tube and being designed such that movement of the arm or disk will control the compression of the tube.

Owner:DENTSPLY IH

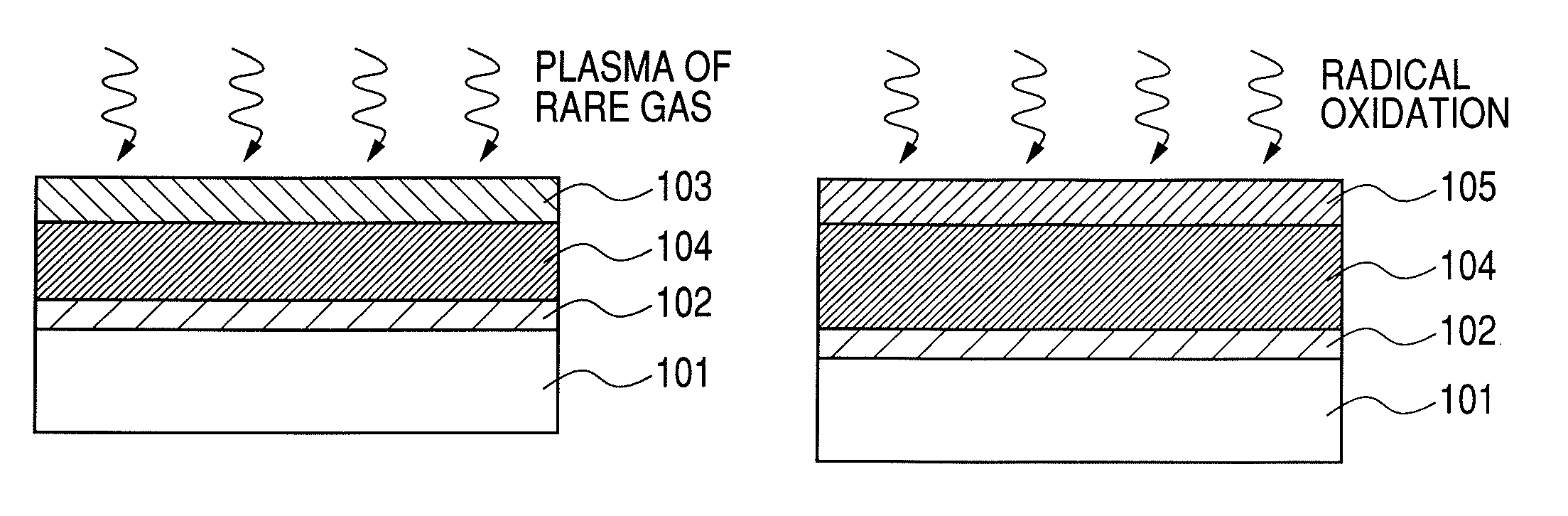

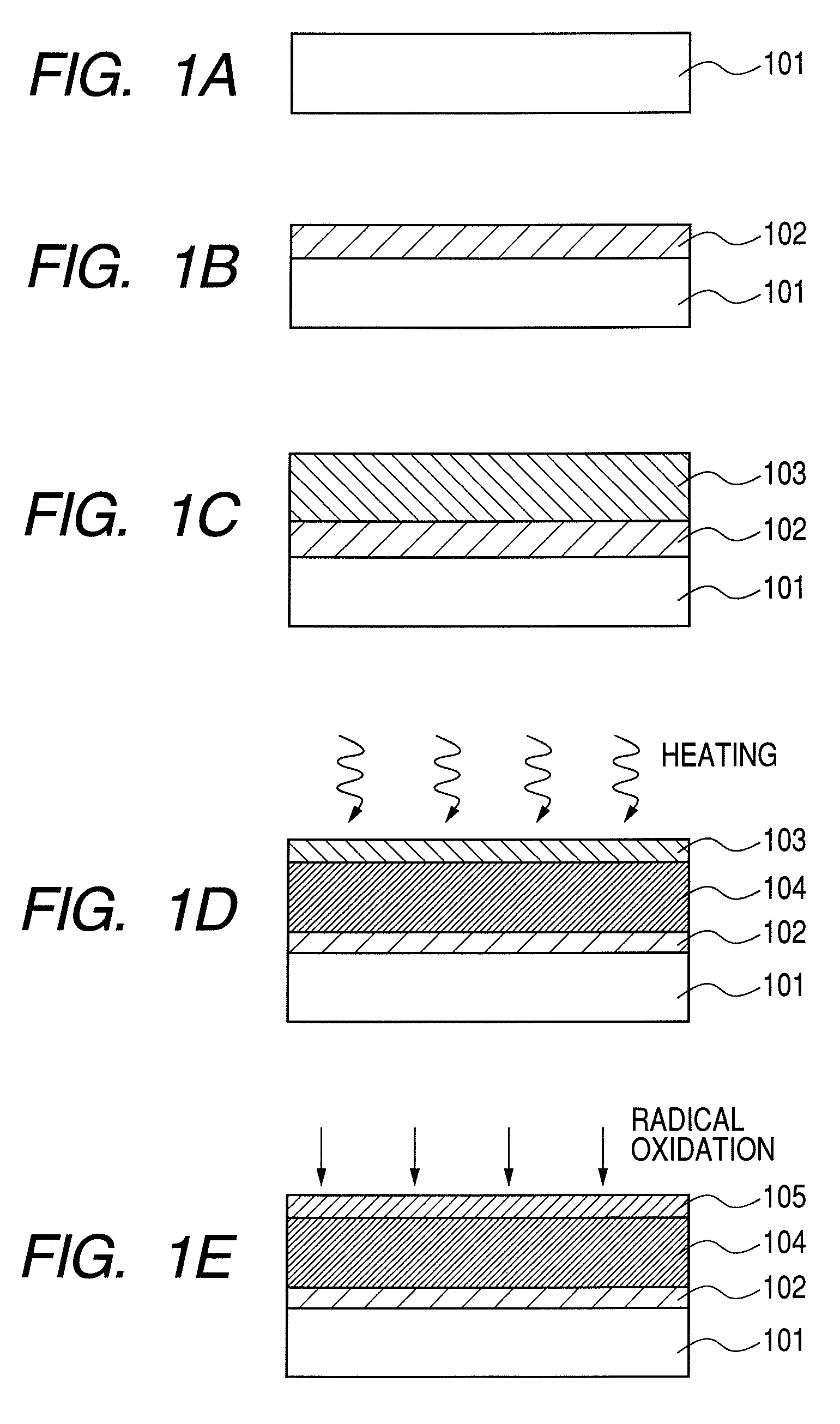

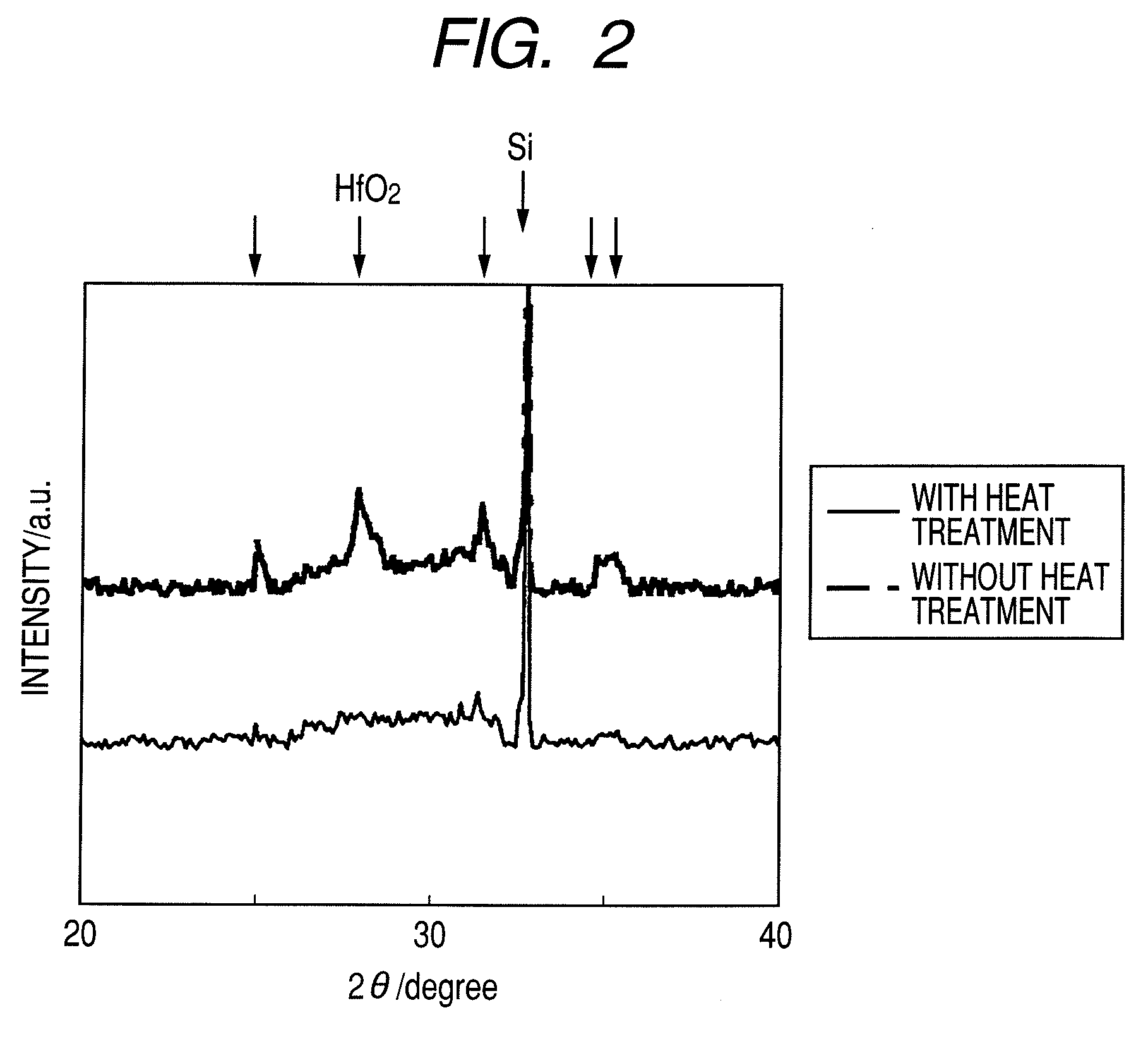

Process for forming dielectric films

ActiveUS8012822B2High dielectric constantGuaranteed precise controllabilityTransistorVacuum evaporation coatingOxygenSilicon dioxide

A process for forming dielectric films containing at least metal atoms, silicon atoms, and oxygen atoms on a silicon substrate comprises a first step of oxidizing a surface portion of the silicon substrate to form a silicon dioxide film; a second step of forming a metal film on the silicon dioxide film in a non-oxidizing atmosphere; a third step of heating in a non-oxidizing atmosphere to diffuse the metal atoms constituting the metal film into the silicon dioxide film; and a fourth step of oxidizing the silicon dioxide film containing the diffused metal atoms to form the film containing the metal atoms, silicon atoms, and oxygen atoms.

Owner:CANON KK +1

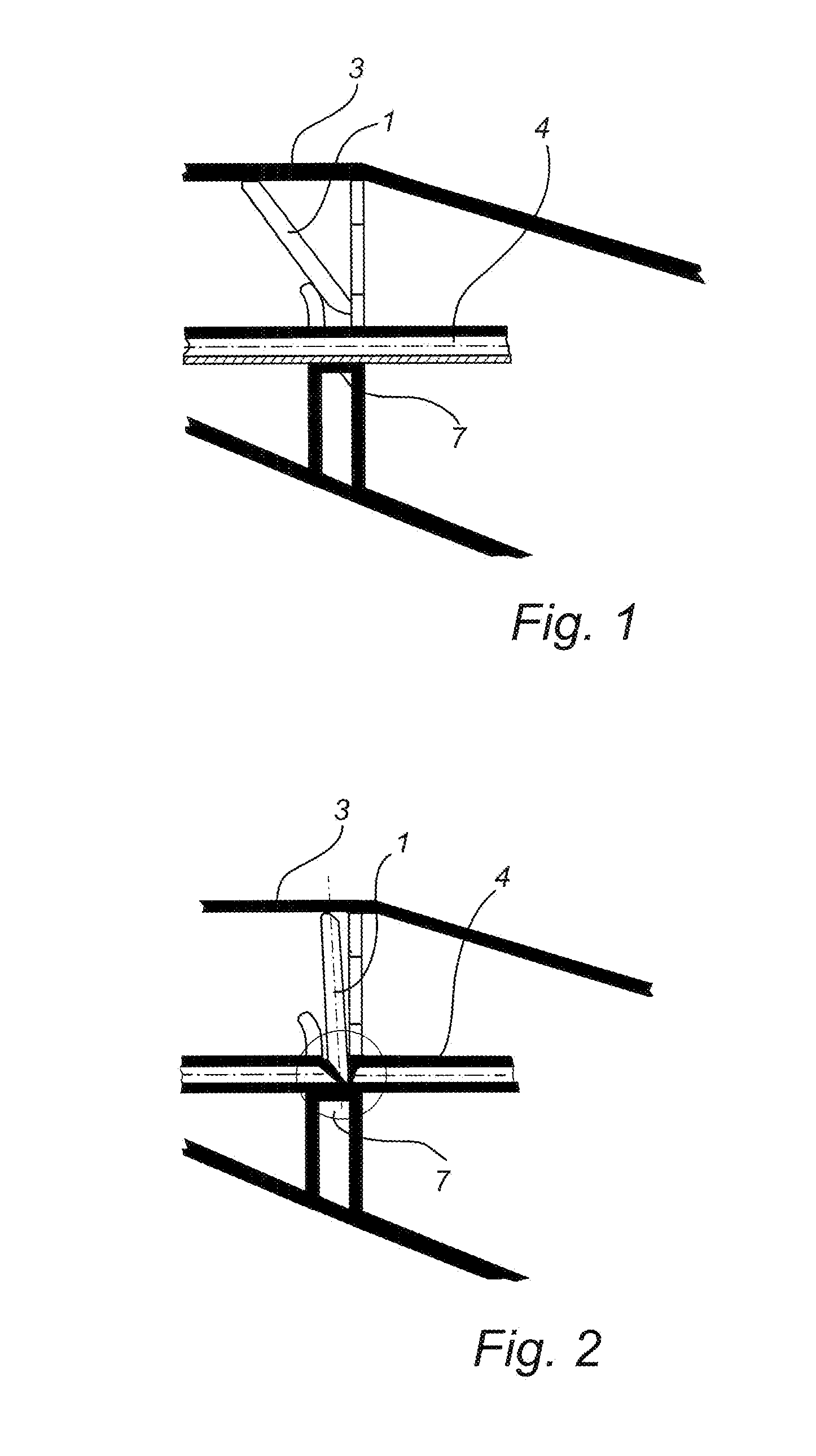

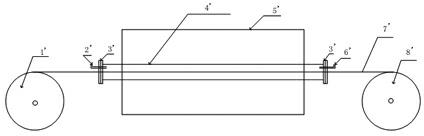

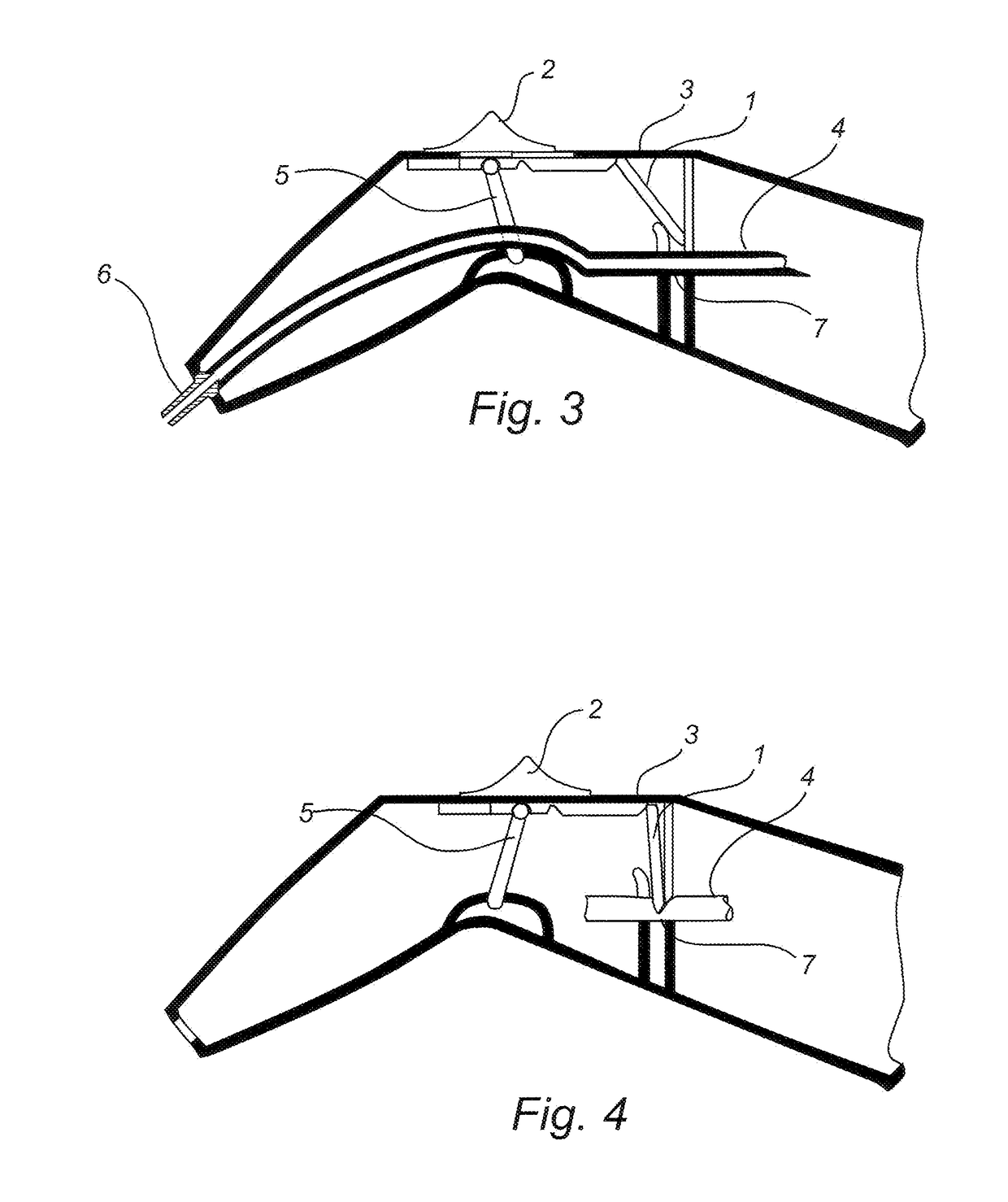

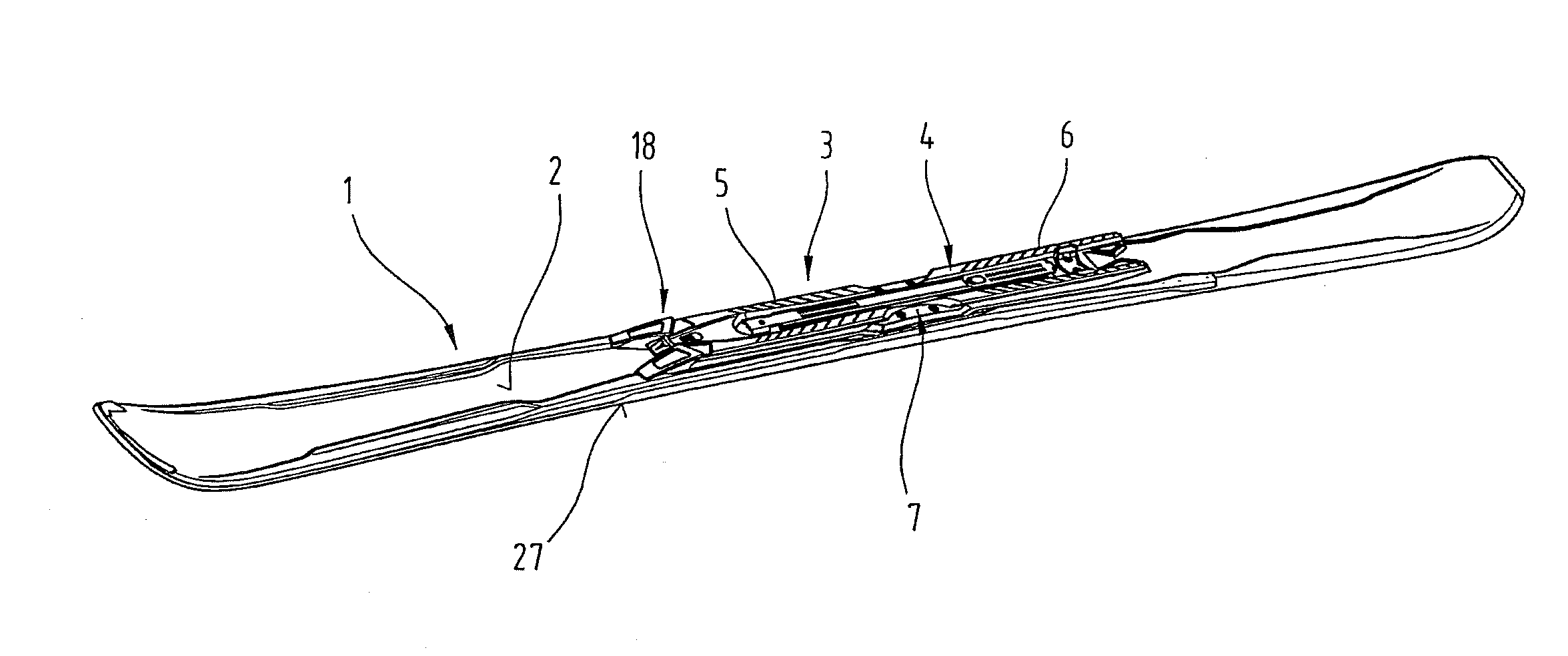

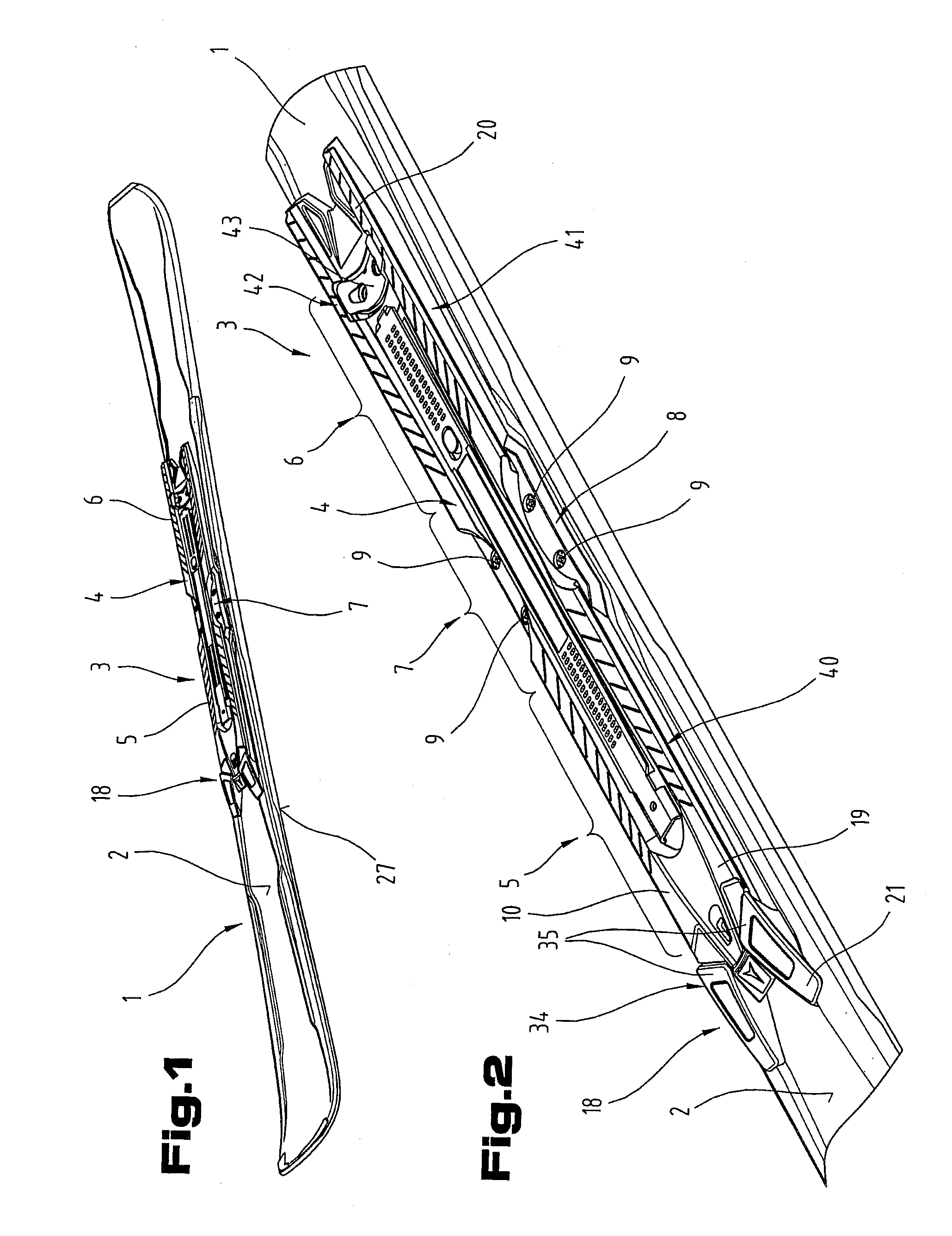

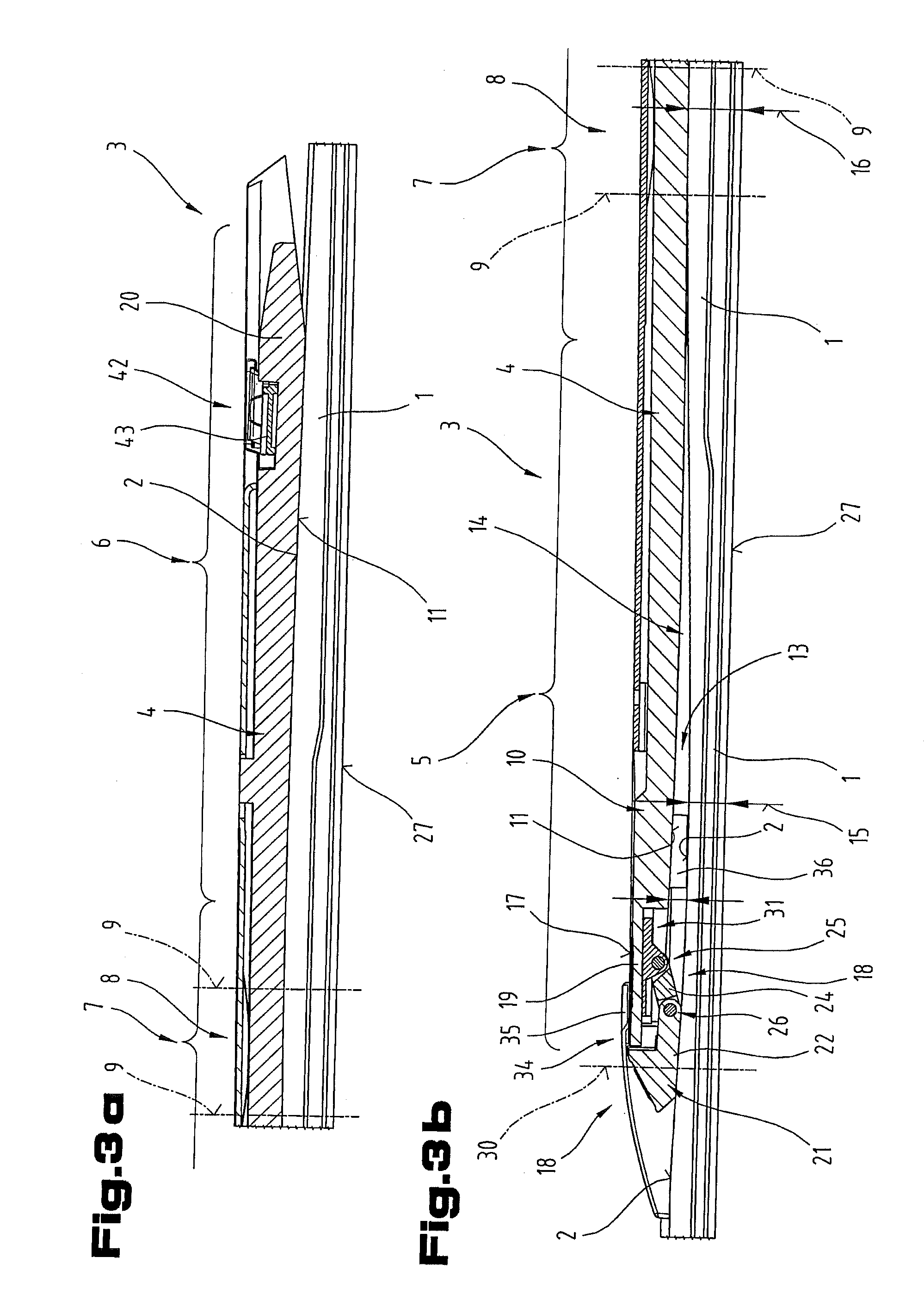

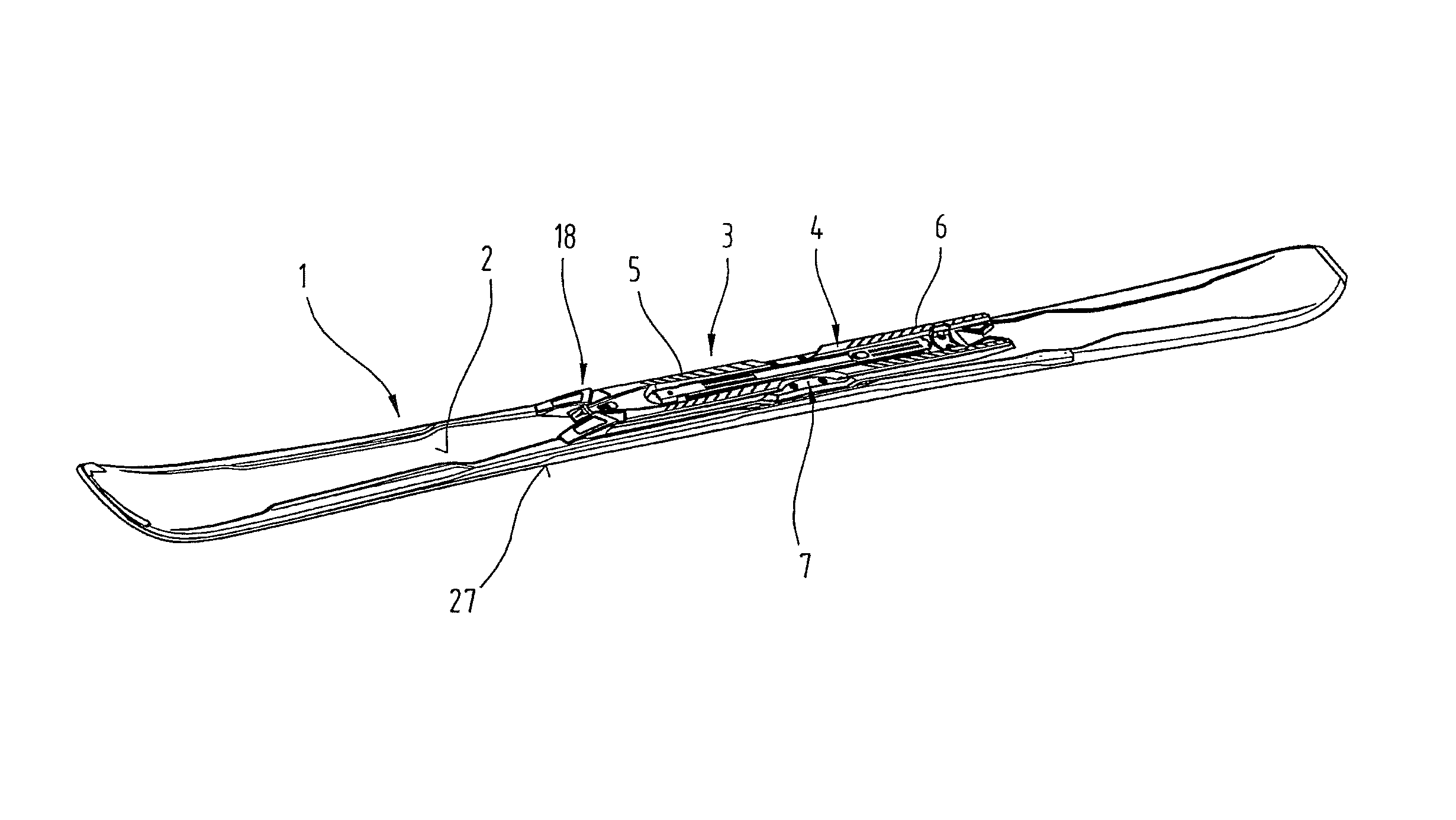

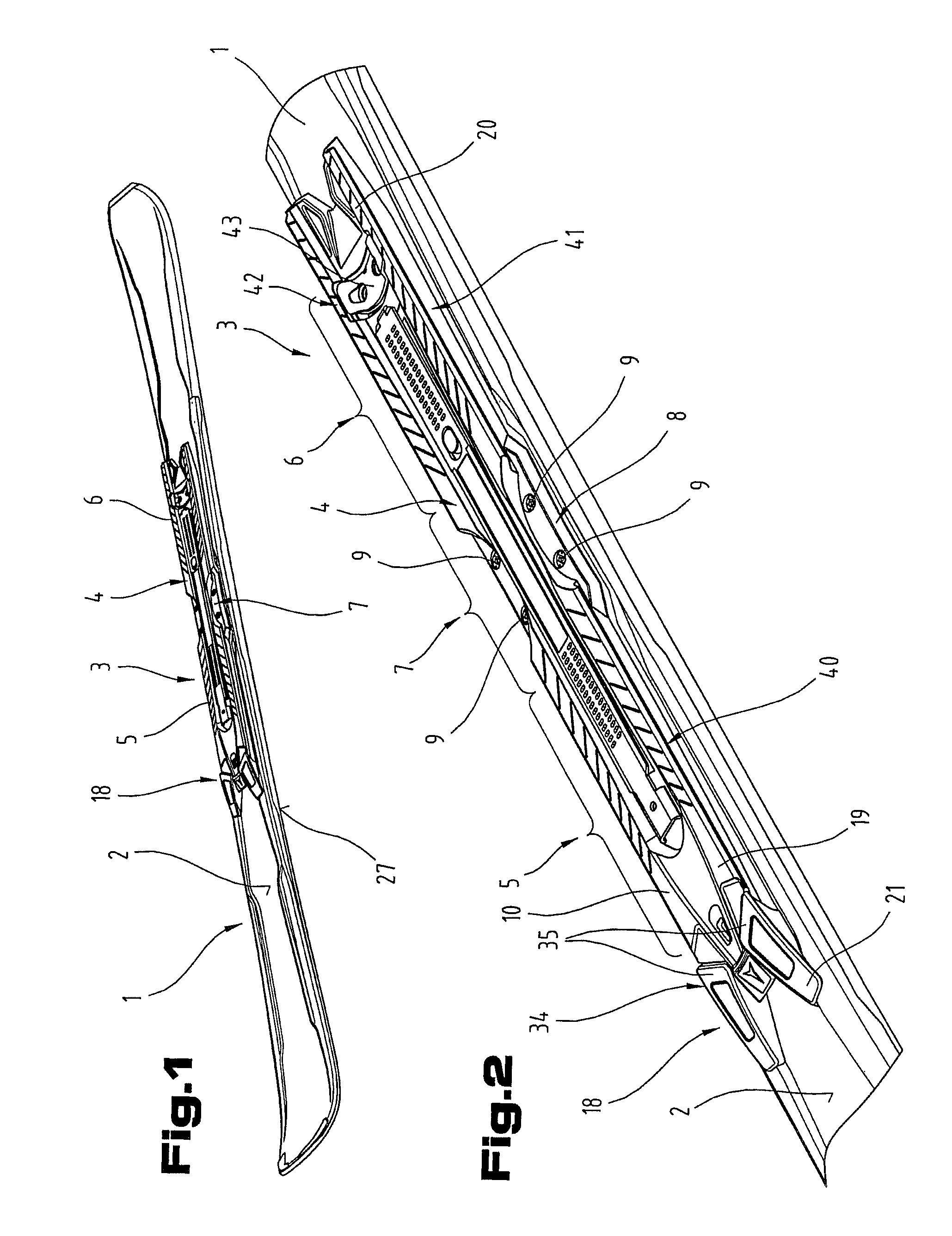

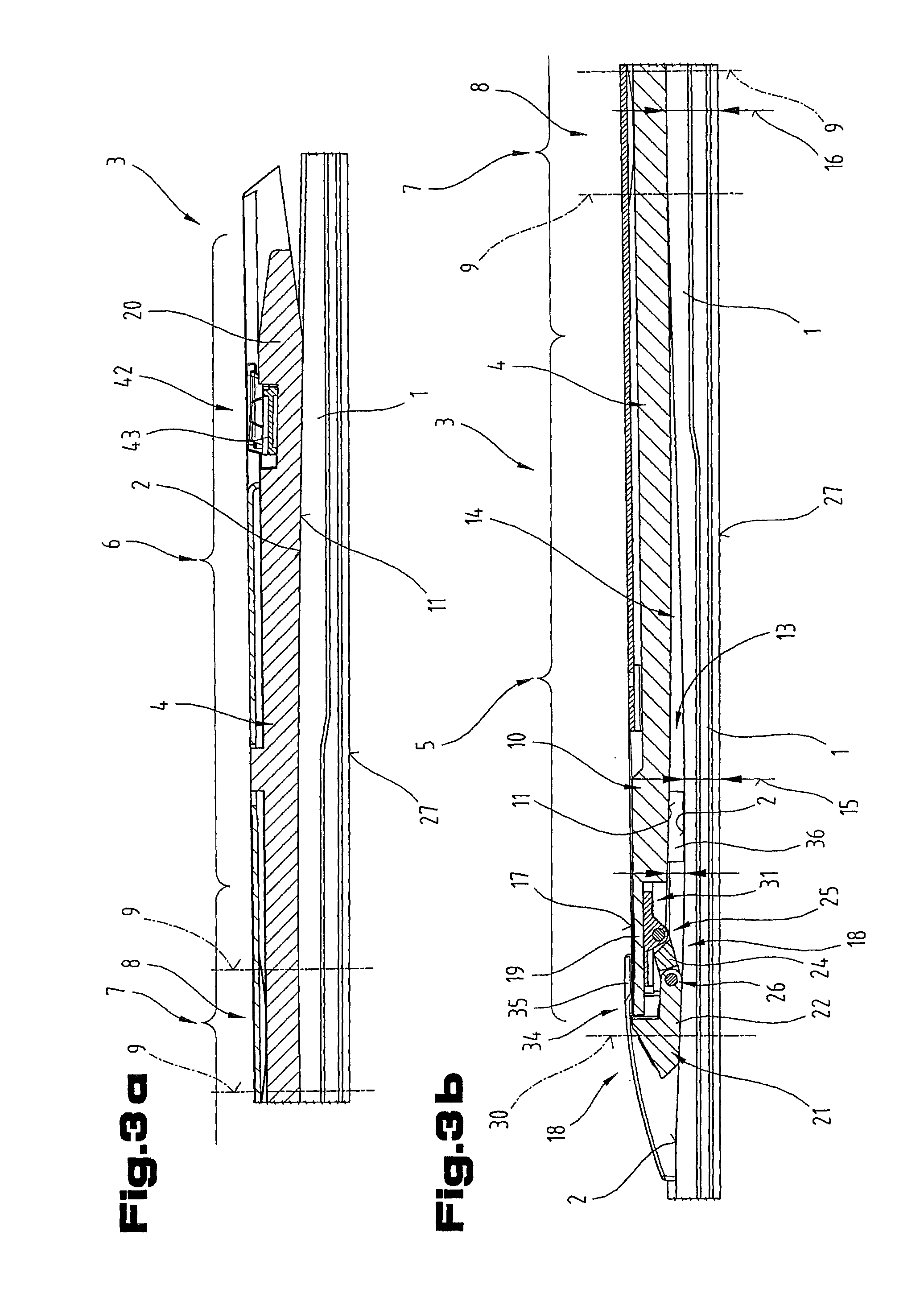

Ski with a connecting device for a ski binding

InactiveUS20130249193A1Improve performanceSmall hindranceSki bindingsEngineeringMechanical engineering

A ski with a connecting device for connecting a ski binding to the ski. The connecting device includes a plate-type support body which has a fixing zone in its longitudinal middle portion for providing a rigid connection to the ski. At least the front end portion of the support body forms a flexural element extending freely with respect to the fixing zone and to the ski. The freely extending flexural element is made from plastic and is coupled with the ski via a coupling device. This coupling device comprises a connecting arm, which has a first articulated connection to the flexural element in its first end portion and a second articulated connection to the ski in its second end portion.

Owner:ATOMIC AUSTRIA

Irrigation system comprising dual pumps

An irrigation system comprising a reservoir for an irrigating liquid and a probe for arrangement in a user, wherein said probe comprises an inflatable balloon for fixing the catheter in a body cavity.

Owner:DENTSPLY IH AB

Precise diaphragm pump

PendingCN111120278APrecise controllabilityStable and precise deliveryFlexible member pumpsPump controlElectric machineryLower upper

The invention primarily discloses a precise diaphragm pump. The technical scheme is as follows: the precise diaphragm pump comprises a PLC, a base, a driving assembly, an upper push-and-pull magneticring, a lower upper push-and-pull magnetic ring, a sealing assembly, a lower liquid channel and an upper liquid channel. The PLC controls the upper push-and-pull magnetic ring, the lower upper push-and-pull magnetic ring and the driving assembly separately. By controlling the upper push-and-pull magnetic ring or the lower upper push-and-pull magnetic ring to gain or loss electricity, separately, the driving assembly and the sealing assembly are movably matched for controlling liquid input or output. By controlling the outflow velocity of a liquid by controlling the rotating speed of a steppingmotor, the feeding amount of the liquid can be regulated, so that controllability can be seen precisely and positive and reverse flow directions of the liquid can be changed smoothly, too.

Owner:宁波斯百睿自控设备有限公司

A method for fabricating a shape-controllable flexible micro-nano pillar array

ActiveCN105776129BControl high aspect ratioAvoid breakingNanostructure manufactureDecorative surface effectsMicro nanoMicro nanoparticles

Owner:XI AN JIAOTONG UNIV

Smart flow sharing system

ActiveUS8806862B2Guaranteed precise controllabilityHigh speedFluid couplingsServomotorsTraffic capacityEquipment Operator

A smart flow sharing system, useful in hydraulic systems having more than one hydraulically demanding equipment function wherein more than one of the hydraulically demanding functions are sometimes activated at the same time, has modified hydraulic passages and at least two fixed displacement pumps. The system automatically prioritizes hydraulic fluid flow so that when only one of two hydraulically demanding functions is activated by an operator, it receives the hydraulic fluid flow from both fixed displacement pumps, but when both hydraulically demanding functions are activated, one of the functions receives hydraulic fluid flow from the first fixed displacement pump, and the other function separately receives hydraulic fluid flow from the second fixed displacement pump. The smart flow sharing system accomplishes the foregoing without resorting to complex hydraulics or expensive additional components. An equipment operator advantageously achieves superior controllability and quicker movement of equipment functions using the invention.

Owner:PARKER INTANGIBLES LLC

Method for switching a hydraulic pressure intensifier

InactiveCN1656320AReduce mechanical frictionTime optimizationServomotorsServometer circuitsTravel to workEngineering

The invention relates to a method for switching a machine tool from rapid travel to working travel and to a hydraulic pressure intensifier, especially for carrying out the inventive method. According to the invention, the machine tool is automatically switched from rapid travel to working travel when a defined counter-force occurs.

Owner:TOX PRESSOTECHNIK GMBH & CO KG

Nux vomica capsules for treating myasthenia gravis and preparation process thereof

InactiveCN102048825BReduce contentTo achieve the purpose of treatmentMuscular disorderNeuromuscular disorderWestern medicineSide effect

The invention provides Chinese medicinal nux vomica capsules for treating myasthenia gravis, which is characterized in that: processing procedures of water soaking, unhairing, frying and the like are adopted, so that the toxicity of a main active ingredient, namely strychnine is obviously reduced. The preparation process is strict and standard, easy to operate, and controllable in quality and canensure the quality stability and clinical administration safety of the nux vomica capsules. Through years of clinical observation, the capsules have satisfying curative effects and small toxic and side effects, can control slight myasthenia gravis through a single medicine, can treat severe myasthenia gravis cooperatively, can obviously reduce the using amount of western medicines and the relatedtoxic and side effects, and improve the curative effects, so the capsules have good development and clinical application prospect.

Owner:ZHEJIANG PROVINCIAL HOSPITAL OF TRADITIONAL CHINESE MEDICINE

Apparatus and method for simulating spin printing electrolytic dissolution process of rotary parts with flat electrode

ActiveCN111822799BSimplify the dissolution study processGuaranteed precise controllabilityElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentDot matrix

The invention relates to a device and a method for simulating the rotary printing electrolytic dissolution process of rotary parts with flat electrodes, which belong to the field of electrolytic processing. The test device is characterized in that it uses programmable power supply, electrolytic tooling fixture, electrolyte filtration circulation system, data recorder, flat workpiece, tool electrode and other equipment, and uses static flat electrode instead of rotating rotary electrode to realize Related research on the dissolution characteristics of spin printing electrolytic processing. It includes the following process: Step 1. Use the electric field simulation software to numerically simulate and calculate the current density distribution waveform on the surface of the spin-printed electrolytic machining anode; Step 2. Calculate the current waveform data corresponding to the current density distribution, and import the current waveform dot matrix data into the available Program the power supply; step 3. Connect the electrolyte circulating filter system and electrolytic processing cathode and anode circuits; 4. Turn on the power to conduct relevant dissolution tests. The invention shortens the test cycle of the spin printing electrolytic machining, simplifies the research flow of the spin printing electrolytic machining, and has great significance for reducing the research cost and improving the research precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ski with a connecting device for a ski binding

InactiveUS8720935B2Improve performanceLess-costly to produceSki bindingsEngineeringMechanical engineering

A ski with a connecting device for connecting a ski binding to the ski. The connecting device includes a plate-type support body which has a fixing zone in its longitudinal middle portion for providing a rigid connection to the ski. At least the front end portion of the support body forms a flexural element extending freely with respect to the fixing zone and to the ski. The freely extending flexural element is made from plastic and is coupled with the ski via a coupling device. This coupling device comprises a connecting arm, which has a first articulated connection to the flexural element in its first end portion and a second articulated connection to the ski in its second end portion.

Owner:ATOMIC AUSTRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com