Apparatus and method for simulating spin printing electrolytic dissolution process of rotary parts with flat electrode

A flat electrode, electrolytic dissolution technology, applied in accessories, electric machining equipment, electrochemical machining equipment, etc., can solve the problems affecting the quality of the machined surface and machining accuracy, abnormal dissolution behavior, etc., to reduce the research cost and simplify the research process. , the effect of facilitating research work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

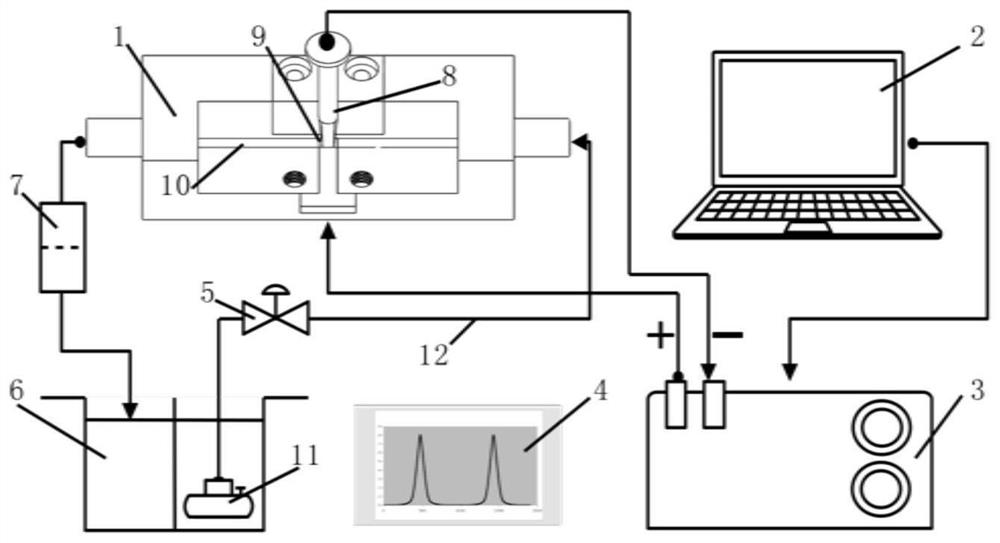

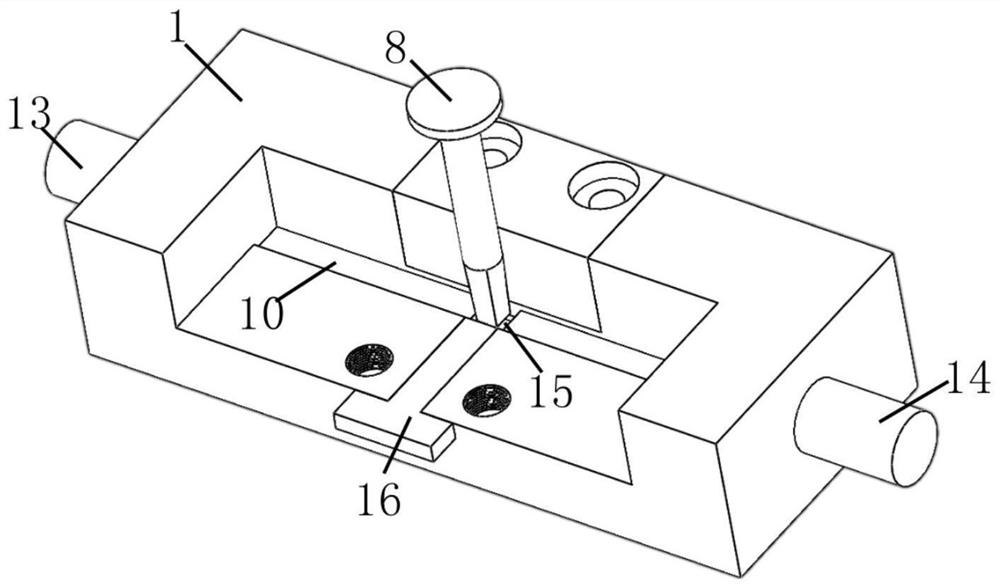

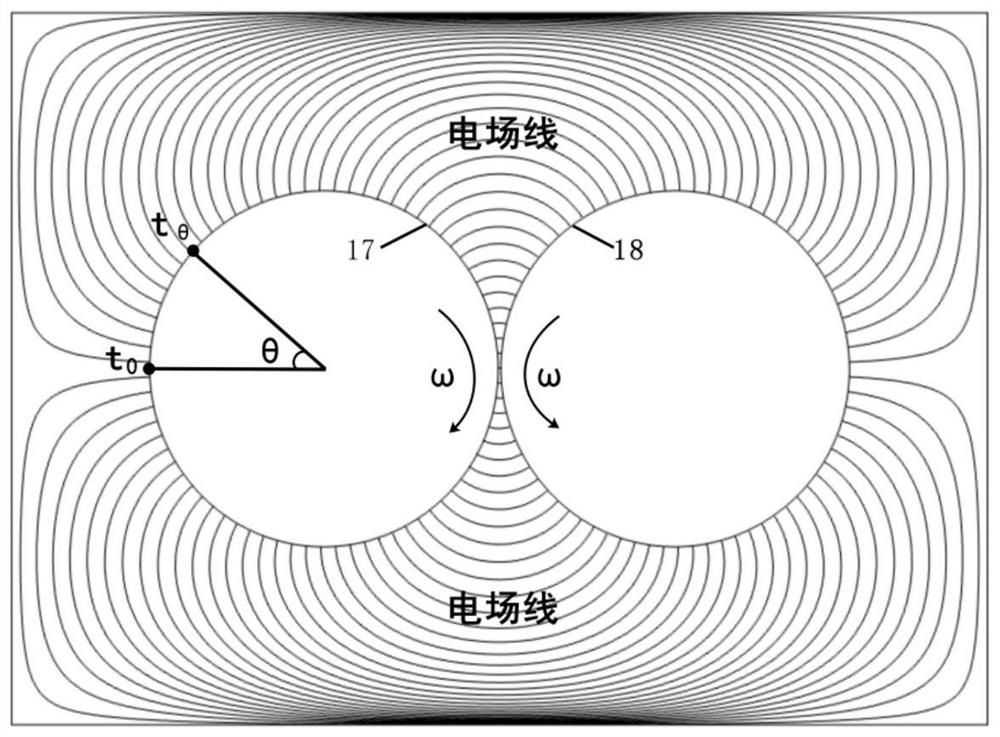

[0029] combine image 3 , 4 , 5, illustrate the implementation process of the present invention:

[0030] (1) Use electric field simulation software to build a two-dimensional model such as image 3 , the cathode and anode are circular structures with a diameter of 50mm, the minimum machining gap between the cathode and anode is 0.4mm, and the electric field enclosed space is a rectangular area with a length of 140mm and a width of 100mm. A 18V DC voltage was applied to the anode, a 0V potential was applied to the cathode, and the conductivity of the electrolyte was set to 14.5M / S.

[0031] (2) Use the electric field simulation software to carry out numerical simulation to obtain the current density value i at different angle positions θ on the anode rotating surface θ ; Set the rotational angular velocity of the anode workpiece in spin printing electrolytic machining w = 2πrad / min, the initial angular position θ of a certain point on the anode workpiece 0 , to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com