A method for fabricating a shape-controllable flexible micro-nano pillar array

A manufacturing method, micro-nano technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high manufacturing cost, geometric deformation of nanostructure, low output, etc., to avoid easy breakage, simple operability, and reliability Controlled and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for manufacturing a shape-controllable flexible micro-nano pillar array, comprising the following steps:

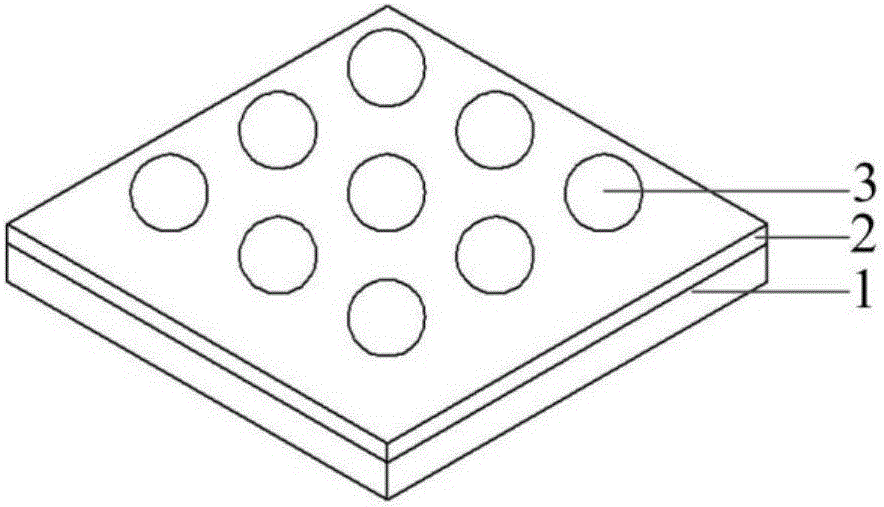

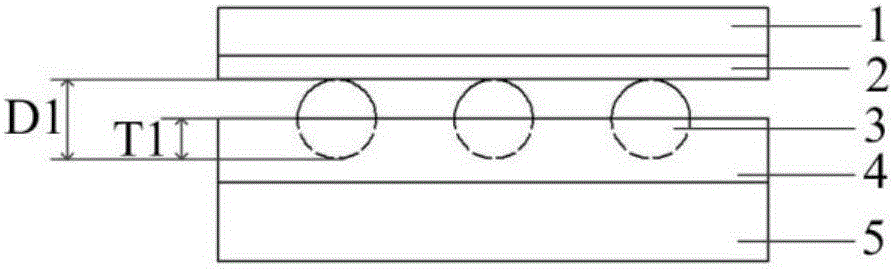

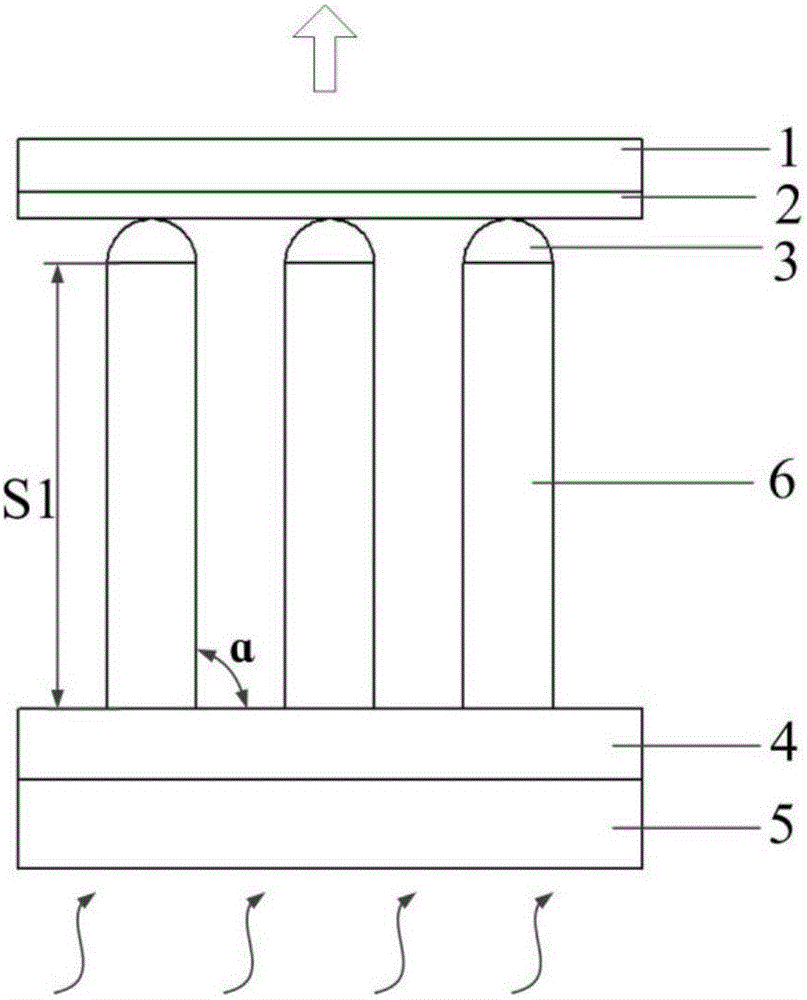

[0029] 1) Refer to figure 1 and figure 2 , first coat the surface of the substrate 1 with a hydrosol adhesion layer 2, then obtain a micro-nano patterned photoresist on the hydrosol adhesion layer 2 through a photolithography process; then obtain the particle size on the surface of the photoresist by scraping D1 = patterning of micro-nanoparticles 3 of 5 μm, and then removing the photoresist to obtain a patterned template of micro-nanoparticles 3, wherein the micro-nanoparticles 3 are spherical polystyrene;

[0030] 2) Refer to figure 2 , coating the polymer 4 on the surface of the substrate 5, and then preheating the substrate 5, the preheating parameters: the temperature is 60°C, the time is 10 minutes, the polymer 4 is PDMS (polydimethylsiloxane) ;

[0031] 3) Refer to figure 2 , contacting and embedding the micronanoparticles 3 on the surface o...

Embodiment 2

[0036] A method for manufacturing a shape-controllable flexible micro-nano pillar array, comprising the following steps:

[0037] 1) Coating a hydrosol adhesion layer 2 on the surface of the substrate 1 first, and then obtaining a micro-nano patterned photoresist on the hydrosol adhesion layer 2 through a photolithography process; Patterning of micro-nanoparticles 3 with a diameter D2=10 μm, and then removing the photoresist to obtain a patterned template of micro-nanoparticles 3, where the micro-nanoparticles 3 are cubic indium trioxide;

[0038] 2) Coating the polymer 4 on the surface of the substrate 5, and then preheating the substrate 5, the preheating parameters: the temperature is 75°C, the time is 6 minutes, and the polymer 4 is PS (polystyrene);

[0039] 3) Refer to Figure 6 (a), contacting and embedding the micronanoparticles 3 on the surface of the patterned template into the polymer 4, the embedding depth T2=5 μm;

[0040] 4) Refer to Figure 6 (b), pull the pa...

Embodiment 3

[0044] A method for manufacturing a shape-controllable flexible micro-nano pillar array, comprising the following steps:

[0045] 1) Refer to Figure 7 (a), first coat the hydrosol adhesive layer 2 on the surface of the substrate 1, then obtain the micro-nano patterned photoresist on the hydrosol adhesive layer 2 by a photolithography process; then pass the scraping method on the photoresist surface Obtain the patterning of micro-nano particles with a 3-shaped pattern of particle diameter D3=200 μm; remove the photoresist to obtain a patterned template of 3-shaped micro-nano particles, and the micro-nano particles 3 are columnar sodium chloride;

[0046] 2) Coating the polymer 4 on the surface of the substrate 5, and then preheating the substrate 5, the preheating parameters: the temperature is 90°C, the time is 2 minutes, and the polymer 4 is PTT (polyurethane);

[0047] 3) Refer to Figure 7 (b), contacting and embedding the micro-nano particles 3 on the surface of the pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com