Red light semiconductor laser structure with aluminum-free waveguide layer

A waveguide layer and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as easy to form defects, high material growth requirements, and affect laser performance, so as to reduce the formation of cavity surface defects and light absorption , Improve the effect of anti-burning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

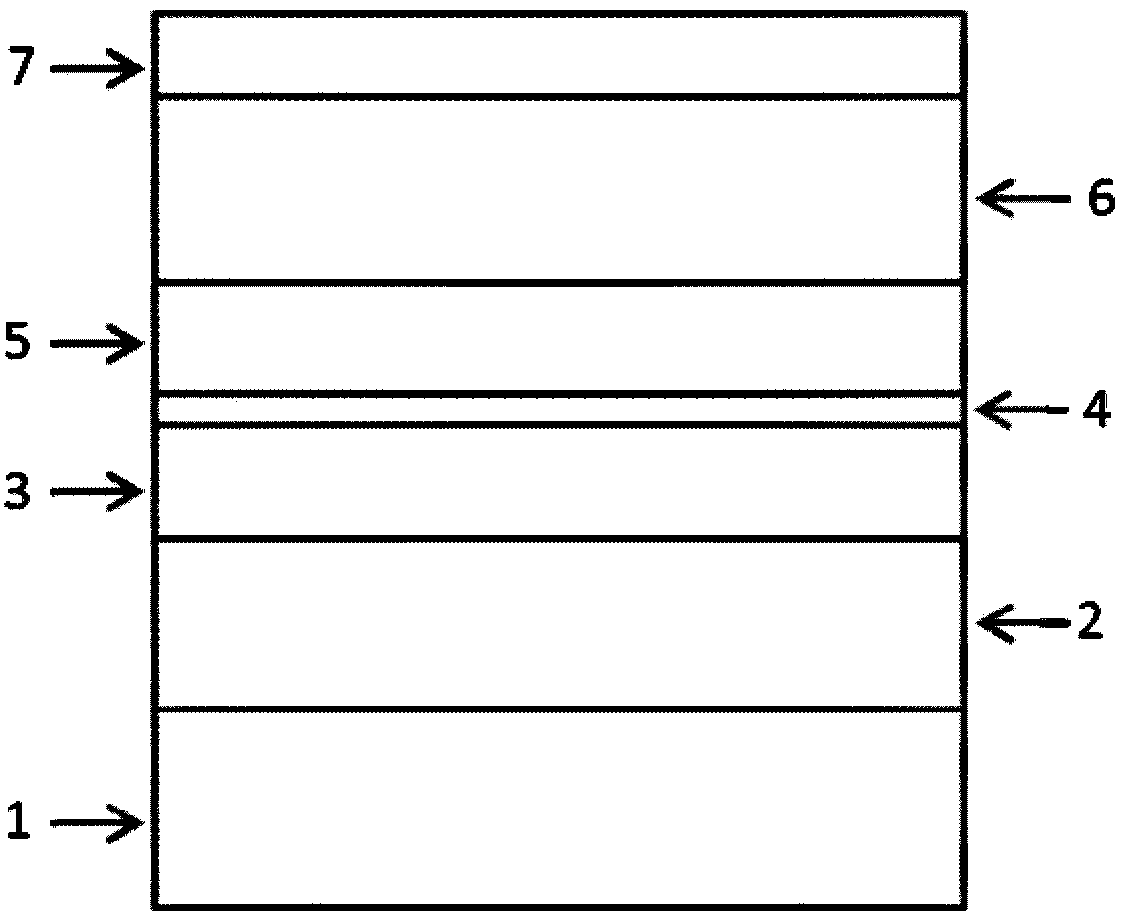

[0034] A red semiconductor laser structure without an aluminum waveguide layer, such as figure 1 As shown, it includes a substrate 1 , a lower confinement layer 2 , a lower waveguide layer 3 , a quantum well layer 4 , an upper waveguide layer 5 , an upper confinement layer 6 and an ohmic contact layer 7 from bottom to top.

[0035] The substrate 1 is an N-type GaAs (100) single crystal substrate with a orientation of 10°.

[0036] The lower confinement layer 2 is N-type (Al 0.6 Ga 0.4 ) 0.5 In 0.5 P.

[0037] The lower waveguide layer 3 is Ga with a thickness of 100nm 0.5 In 0.5 P, grown at 700°C, is a disordered structure with a band gap of 1.91eV.

[0038] The quantum well layer 4 is Ga with a thickness of 6nm 0.5 In 0.5 P, grown at a temperature of 600°C, is an ordered structure with a band gap of 1.84eV and a red light with a laser wavelength of about 660nm.

[0039] The upper waveguide layer 5 is Ga with a thickness of 100nm 0.5 In 0.5 P, grown at 700°C, is a...

Embodiment 2

[0043] According to the structure of a red light semiconductor laser without an aluminum waveguide layer described in Embodiment 1, the difference is that,

[0044] The substrate 1 is an N-type GaAs (100) single crystal substrate with a orientation of 12°.

[0045] The lower confinement layer 2 is N-type (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P.

[0046] The lower waveguide layer 3 is Ga with a thickness of 100nm 0.5 In 0.5 P, grown at 680°C, is a disordered structure with a band gap of 1.91eV.

[0047] The quantum well layer 4 is Ga with a thickness of 6nm 0.45 In 0.55 P, with a growth temperature of 620°C, is an ordered structure with a band gap of 1.79eV and a red light with a laser wavelength of about 680nm.

[0048] The upper waveguide layer 5 is Ga with a thickness of 100nm 0.5 In 0.5 P, grown at 680°C, is a disordered structure with a band gap of 1.91eV.

[0049] The upper confinement layer 6 is a P-type (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P.

[0050] The ohmic contact l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com