Preparation method of high-purity and low-loss chalcogenide glass

A chalcogenide glass, low-loss technology, used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problem of introducing micron-scale heterogeneous inclusions, and achieve small light scattering, good uniformity, and heterogeneous packaging. body reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

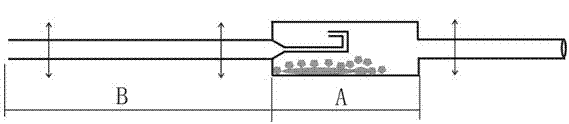

Method used

Image

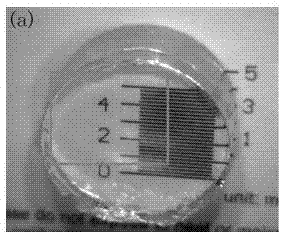

Examples

Embodiment 1

[0028] Example 1: The composition of the chalcogenide glass is Ge 12 As 24 Se 64

[0029] Using Ge with a purity of 99.999% and elements As and Se with a purity of 99.9999% as raw materials, according to the above chemical composition ratio, add 100ppm of metal Al with a purity of 99.999% and 1000ppm of ultra-dry GaCl with a purity of 99.999% 3 , weighed in a nitrogen-filled glove box with an oxygen and water content of less than 0.1 ppm and loaded into a pre-cleaned quartz ampoule with a hydroxyl content of less than 1 ppm; vacuumize the quartz ampoule containing the mixture, and when the ampoule Vacuum degree≤10 –3 At Pa, place the ampoule at 120 o Bake in a tube furnace in C for 2 hours, then seal the ampoule with an oxyhydrogen flame; put the sealed quartz ampoule with the glass mixture in a swing furnace, and slowly heat up to 900 o C, after 10 hours of heat preservation, take it out and cool it in the air, and then heat it at 200 o C annealed for 2 hours; open the ...

Embodiment 2

[0030] Example 2: The composition of chalcogenide glass is As 40 S 60

[0031] Using elements As and S with a purity of 99.9999% as raw materials, according to the above chemical composition ratio, add 200ppm of metal Mg with a purity of 99.999% and 1500ppm of ultra-dry GaCl with a purity of 99.999% 3 , weighed in a nitrogen-filled glove box with an oxygen and water content of less than 0.1 ppm and loaded it into a pre-cleaned quartz ampoule with a hydroxyl content lower than 1 ppm; vacuumize the quartz ampoule containing the mixture, and when the vacuum in the ampoule degree≤10 –3 At Pa, place the ampoule at 100 o Bake in a tube furnace in C for 3 hours, then seal the ampoule with an oxyhydrogen flame; put the sealed quartz ampoule with the glass mixture in a swing furnace, and slowly heat up to 850 o C, after 15 hours of heat preservation, take it out and cool it in the air, and then heat it at 190 o C annealed for 3 hours; the annealed ampoule filled with glass was ope...

Embodiment 3

[0032] Example 3: The composition of the chalcogenide glass is Te 20 As 30 Se 50

[0033] Using elements As, Te and Se with a purity of 99.9999% as raw materials, according to the above chemical composition ratio, add 150ppm of metal Zr with a purity of 99.999% and 500ppm of ultra-dry GaCl with a purity of 99.999% 3 In a nitrogen-filled glove box with an oxygen and water content of less than 0.1ppm, weigh the material and put it into a pre-cleaned quartz ampoule with a hydroxyl content of less than 1ppm; vacuumize the quartz ampoule containing the mixture, when the vacuum in the ampoule ≤10 –3 At Pa, place the ampoule at 150 o Bake in a tube furnace in C for 1 hour, and then seal the ampoule with an oxyhydrogen flame; put the sealed quartz ampoule with the glass mixture in a swing furnace, and slowly heat up to 800 o C, after 10 hours of heat preservation, take it out and cool it in the air, and then heat it at 132 o C annealed for 2 hours; the annealed ampoule filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com