Method for growing cerium fluoride crystal by non-vacuum descent process

A cerium fluoride, non-vacuum technology, applied in the field of growing CeF3 crystals, can solve the problems of high cost, low efficiency, and restrictions on the development and application of CeF crystals, and achieve the effect of removing oxygen impurities and simplifying the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In an environment with a temperature of 20°C and a relative humidity of 6.5%, 100 g of CeF with a purity of 99.9% 3 Mix the powder with 3g polytetrafluoroethylene powder evenly; put the mixed raw materials into a quartz glass container, put them in a vacuum oven, and perform vacuum drying at 300°C for 3 hours; put the dried raw materials into a In a platinum crucible with crystal taper and sealed, crystal growth is carried out under non-vacuum conditions: first heat the crucible to 1460 ° C, keep warm to fully melt the raw materials in the crucible (about 3 hours), and then at a rate of 1 mm / hour, 30 The temperature gradient of ℃ / cm was used for crystal growth; after the growth was completed, the temperature was lowered to room temperature at a rate of 30 ℃ / hour.

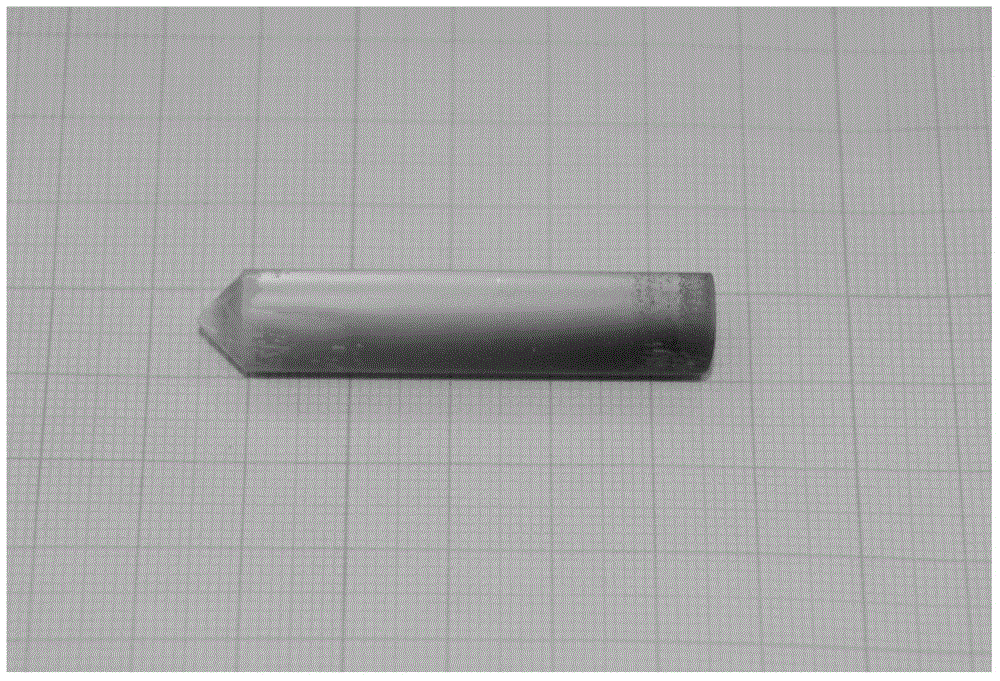

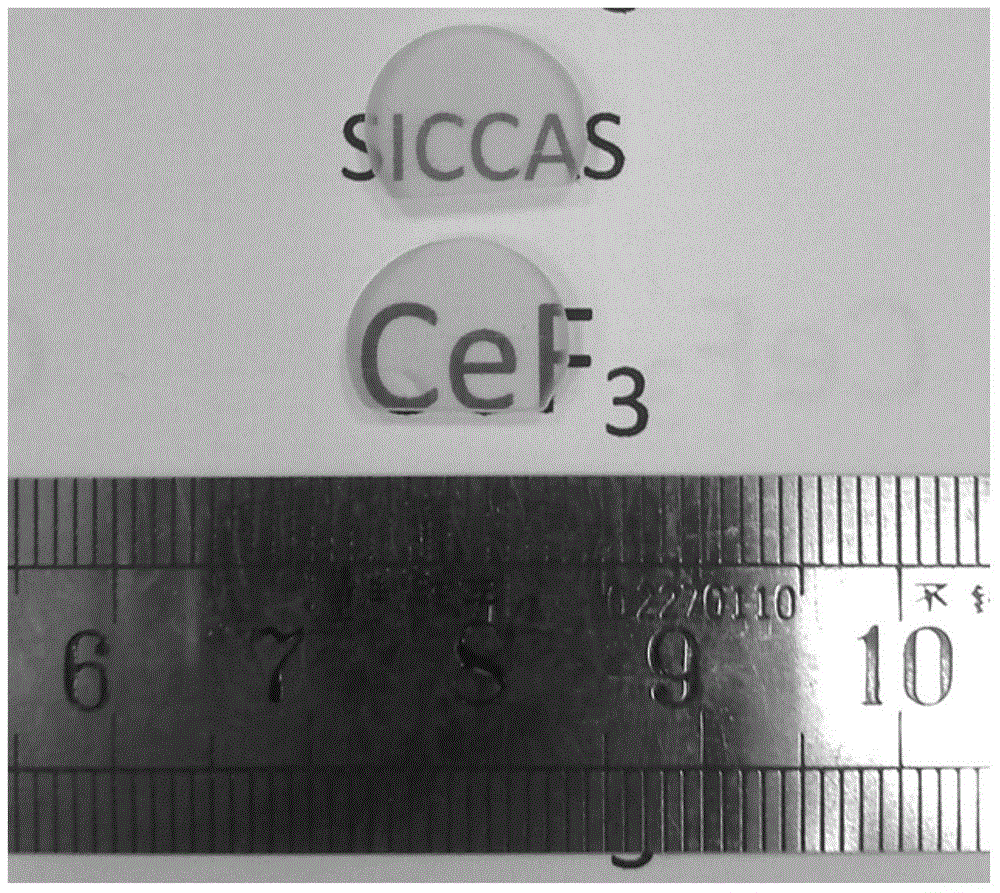

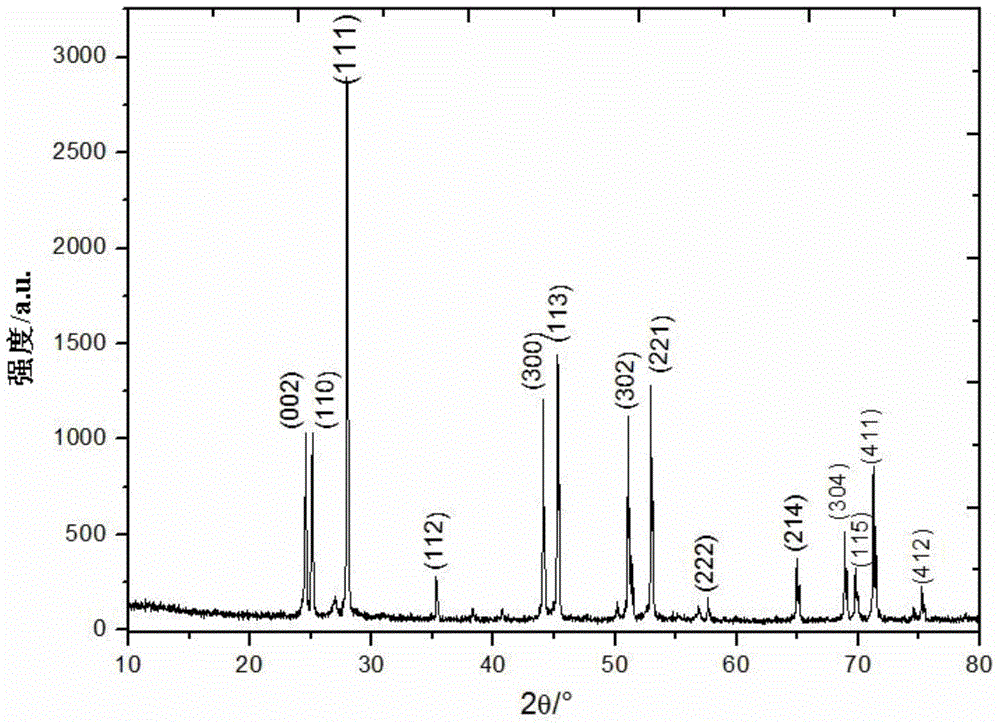

[0032] figure 1 For the CeF obtained in this embodiment 3 crystal blank, figure 2 The CeF obtained by the method described in this embodiment 3 Crystal samples, from figure 1 with figure 2 Visible: Ce...

Embodiment 2

[0036] In an environment with a temperature of 20°C and a relative humidity of 20%, 100 g of CeF with a purity of 99.9% 3 Mix the powder with 5g polytetrafluoroethylene powder evenly; put the mixed raw materials into a quartz glass container, put them in a vacuum oven, and carry out vacuum drying at 350°C for 1 hour; put the dried raw materials into a In a platinum crucible with crystal taper and sealed, crystal growth is carried out under non-vacuum conditions: first heat the crucible to 1470 ° C, keep warm to fully melt the raw materials in the crucible (about 5 hours), and then at a descending speed of 1.5 mm / hour, 40 The temperature gradient of ℃ / cm was used for crystal growth; after the growth was completed, the temperature was lowered to room temperature at a rate of 25 ℃ / hour.

[0037] CeF obtained in this embodiment 3 The crystal is transparent and complete, and has the XRD spectrum and X-ray excitation luminescence spectrum described in Example 1.

Embodiment 3

[0039] In an environment with a temperature of 20°C and a relative humidity of 15%, 100 g of CeF with a purity of 99.9% 3 Mix the powder with 1g of polytetrafluoroethylene powder evenly; put the mixed raw materials into a quartz glass container, put them in a vacuum oven, and carry out vacuum drying treatment at 150 °C for 5 hours; put the dried raw materials into a In a platinum crucible with crystal taper and sealed, crystal growth is carried out under non-vacuum conditions: first heat the crucible to 1480 ° C, keep warm to fully melt the raw materials in the crucible (about 5 hours), and then at a descending speed of 0.5 mm / hour, 60 Crystal growth was carried out with a temperature gradient of °C / cm; after the growth was completed, the temperature was lowered to room temperature at a rate of 35 °C / h.

[0040] CeF obtained in this embodiment 3 The crystal is transparent and complete, and has the XRD spectrum and X-ray excitation luminescence spectrum described in Example 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com