Patents

Literature

121 results about "Cerium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient composite modifying-refining agent for hypoeutectic cast aluminium-silicon alloy and treatment process

InactiveCN1936044ASimplify the melt handling processImprove performanceStrontium carbonateSilicon alloy

The invention relates to a high efficiency compounded refiner for hypoeutectic aluminum-silicon alloy and the method of application. It contains 10-30wt% NaCl, 10-15wt% KCl, 10-20wt% sodium fluoride, 1-30wt% potassium fluoborate, and 1-20wt% potassium fluotitanate, 1-20wt% strontium carbonate, 1-15wt% cerium fluoride, 5-20wt% granular lanthanum abundant mixed rare earths and 1-5% heachloroethane. After taking the process of heating, dehydrating, mixing according to the ratio to equal, pressing to molding, it could be sealed to use. The technology includes the following steps: after the magnesium alloy melting in crucible, heating to 720-740 degree centigrade and removing the slag, standing for 3-5 minutes, pressing the refiner into alloy liquid to take refining process for 5-10 minutes, standing for 5-10 minutes after process to gain hypoeutectic aluminum-silicon alloy melt. The invention simplifies melt process technology, lowers cost and improves the capability of alloy.

Owner:重庆工学院

High temperature resistant and wear resistant lubricating paint

A refractory antiwear lubricating paint is prepared from thermosetting epoxy resin, boron modified phenolic resin, MoS2, Sb2O3 and cerium fluoride. Its advantages are high antiwear, load-bearing and lubricating performance, and excellent refractory performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

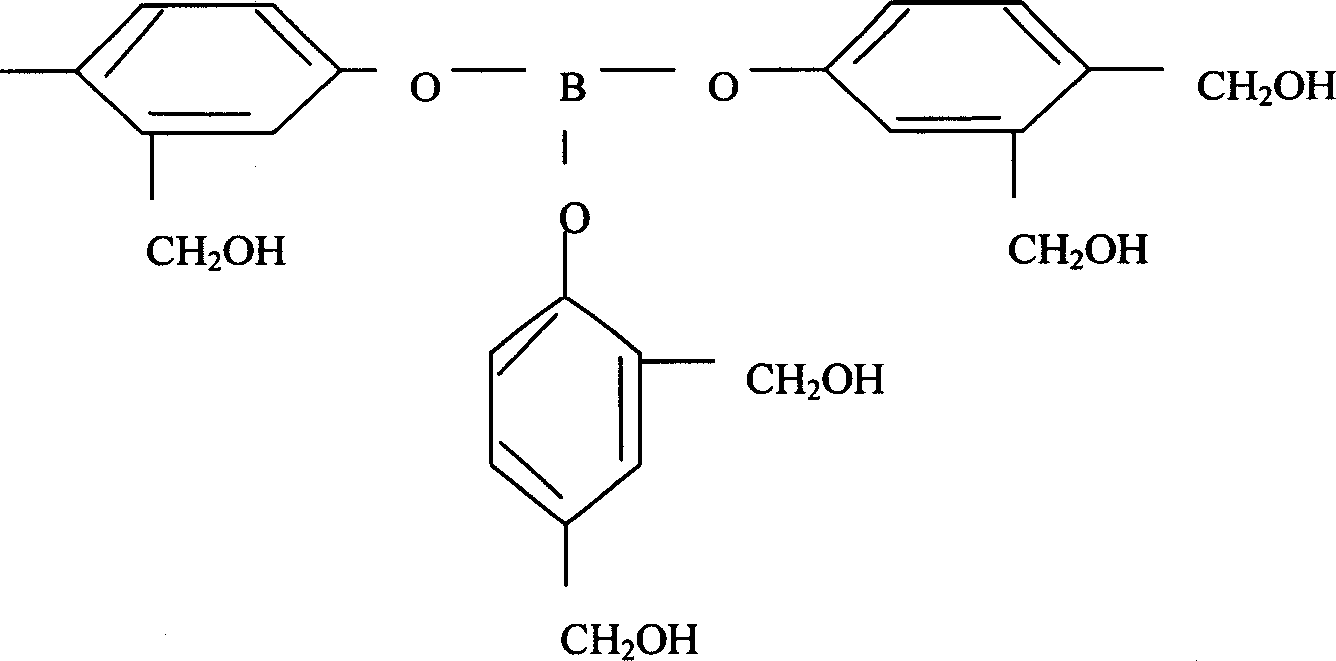

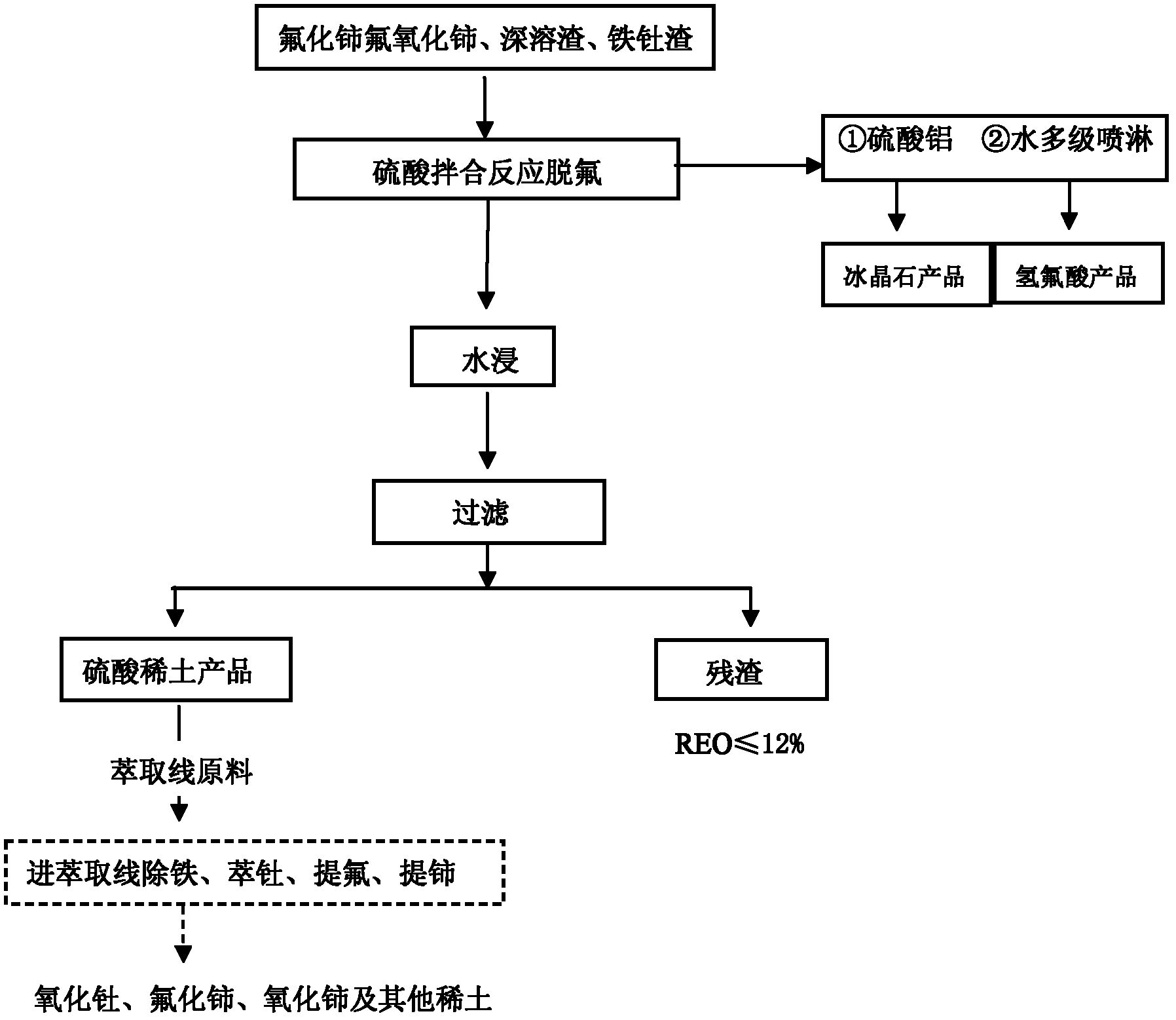

Method for comprehensively recycling various rare earth from rare earth materials containing fluorine

InactiveCN102534269ASolve environmental problemsHigh yieldProcess efficiency improvementSlagRare earth

The invention relates to a method for comprehensively recycling various rare earth from rare earth materials containing fluorine, in particular to a comprehensive utilization treatment separating method for cerium fluoride, fluorine cerium oxide, deep smelting slag and iron thorium slag, and belongs to the technical field of non-ferrous metal rare earth separation. The method for comprehensively recycling various rare earth from rare earth materials containing the fluorine comprises the following steps: a. stirring the rare earth materials containing the fluorine with sulfuric acid to generate hydrofluoric acid gas for preparing cryolite or hydrofluoric acid; and b. obtaining sulfuric rare earth solution by dipping the materials after stirring through water. The sulfuric acid directly acts on bastnaesite after roasting or other rare earth materials containing the fluorine (a cerium fluoride or fluorine cerium oxide product, the deep smelting slag and the iron thorium slag which are generated after reactions), further roasting is not required, a fluorine product is directly recycled through generated gas after the reactions at normal temperature, and the procedure in the prior art that sodium fluoride is formed by transforming alkali into fluorine and removed through washing is not required. The problem of environment protection of discharging of the fluorine is effectively solved, and the high yield of the rare earth is ensured.

Owner:LESHAN SHENGHE RARE EARTH CO LTD

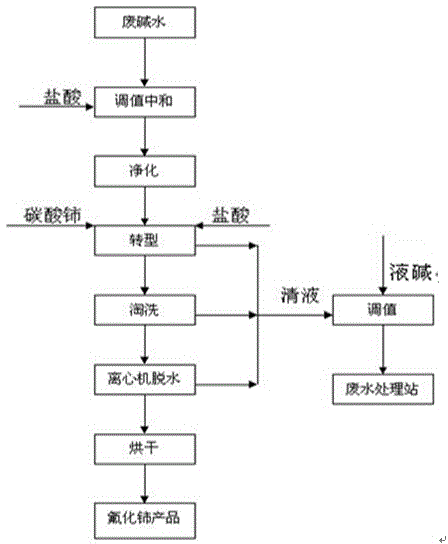

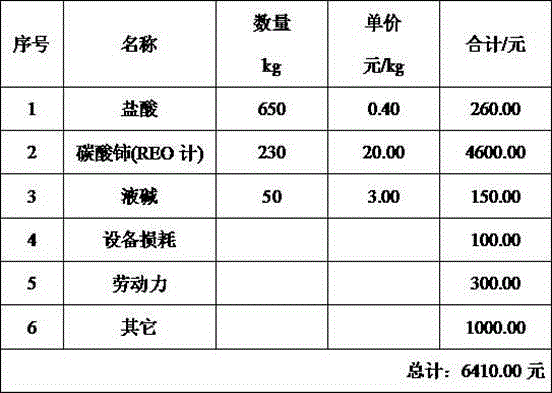

Method for fluorine removal of wastewater in bastnaesite hydrometallurgy

ActiveCN103979658AThe process is simple and flexibleEasy to operateWater contaminantsWaste water treatment from metallurgical processWastewaterHydrometallurgy

The invention relates to the field of bastnaesite hydrometallurgy, and in particular relates to a method for fluorine removal of wastewater in bastnaesite hydrometallurgy. A specific scheme comprises the following steps: A. regulating pH value of a fluorine-containing waste liquid to be acid through hydrochloric acid; B. adding cerium carbonate or lanthanum carbonate as well as hydrochloric acid to the waste liquid; C. adding a flocculant to the liquid obtained from reaction of the step B; and D. collecting a flocculating product. Through the method disclosed by the invention, chlorine in the wastewater is nearly completely turned into cerium fluoride; and therefore, the method not only reduces pollution but also facilitates operation.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

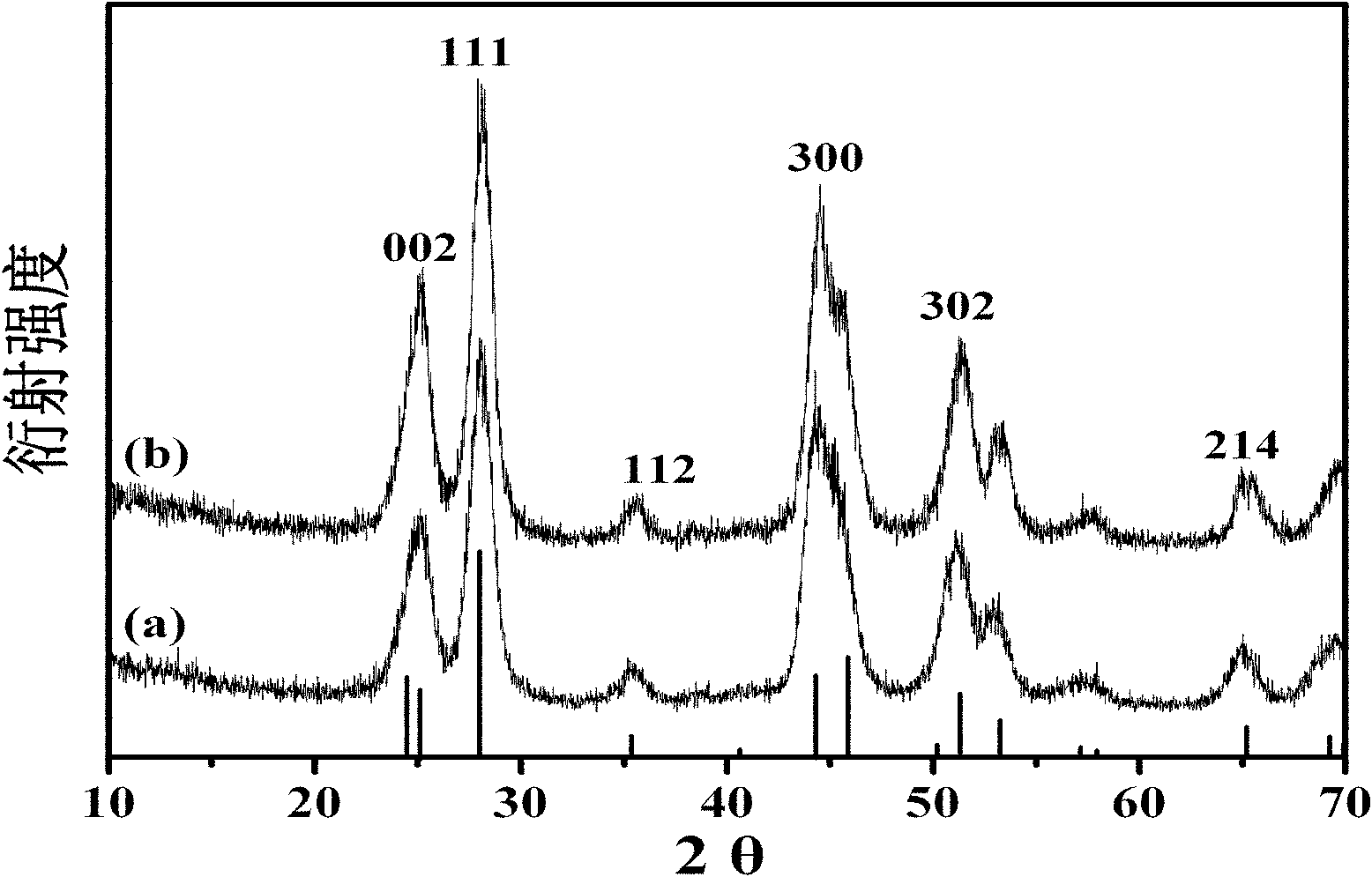

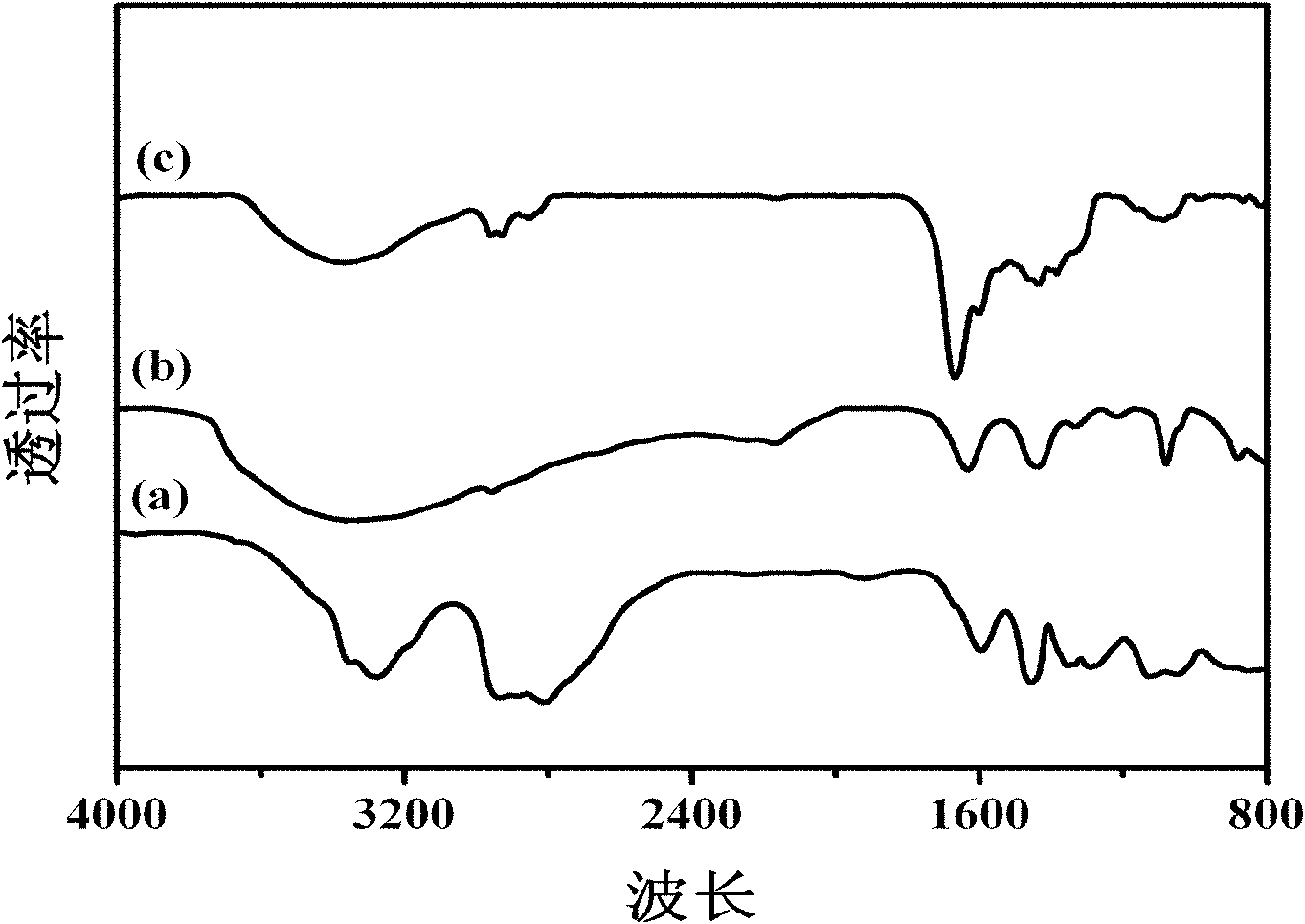

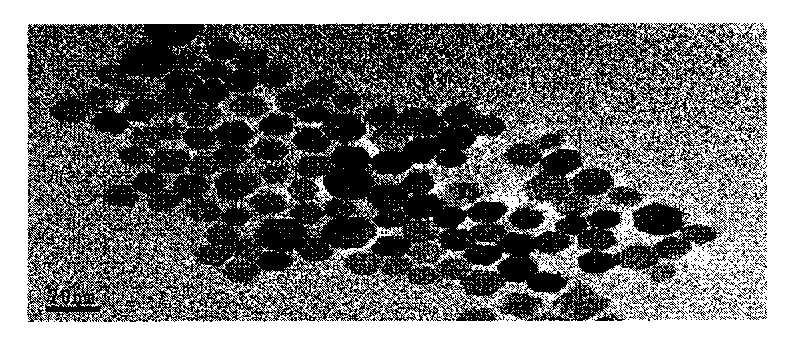

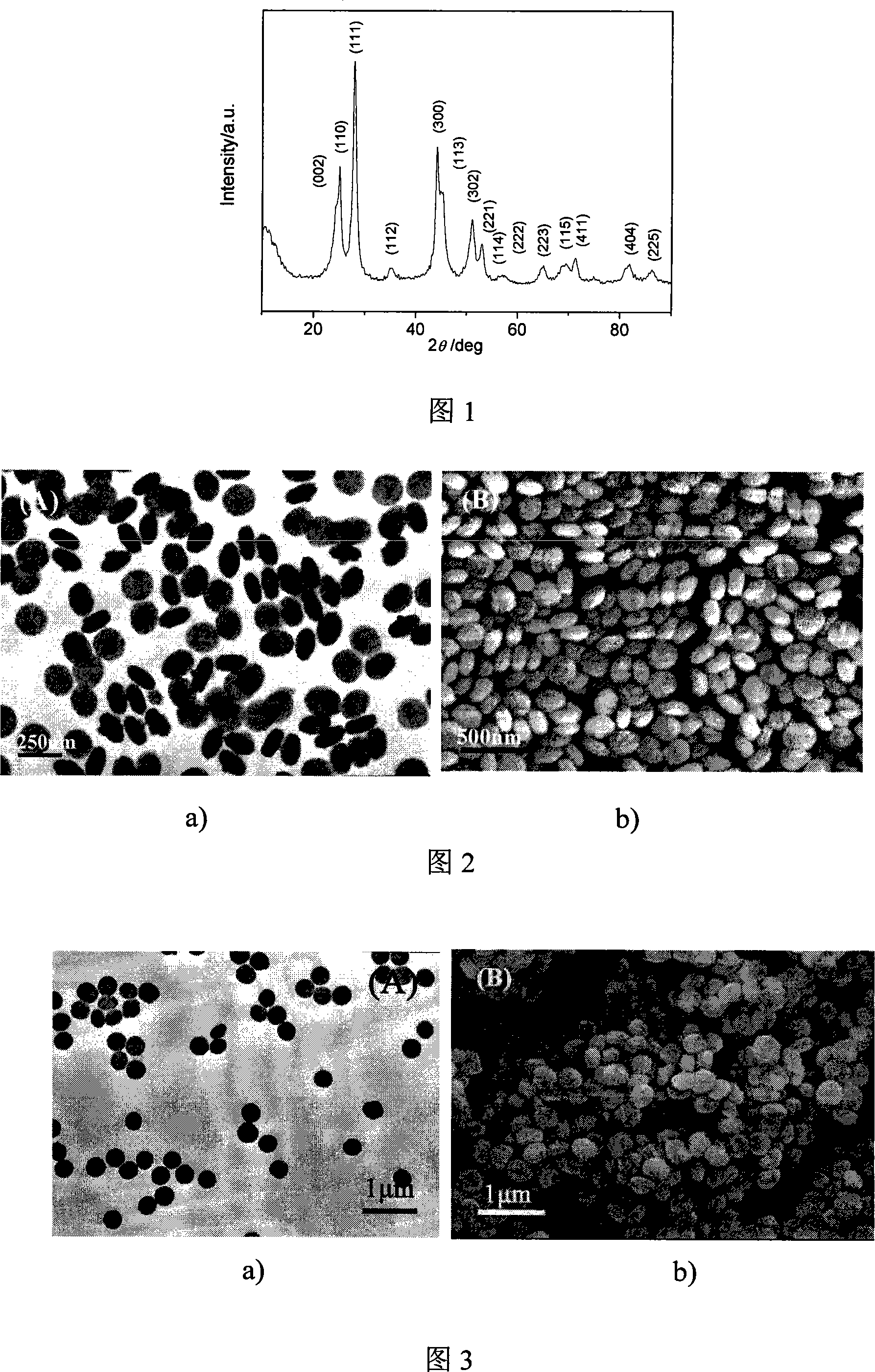

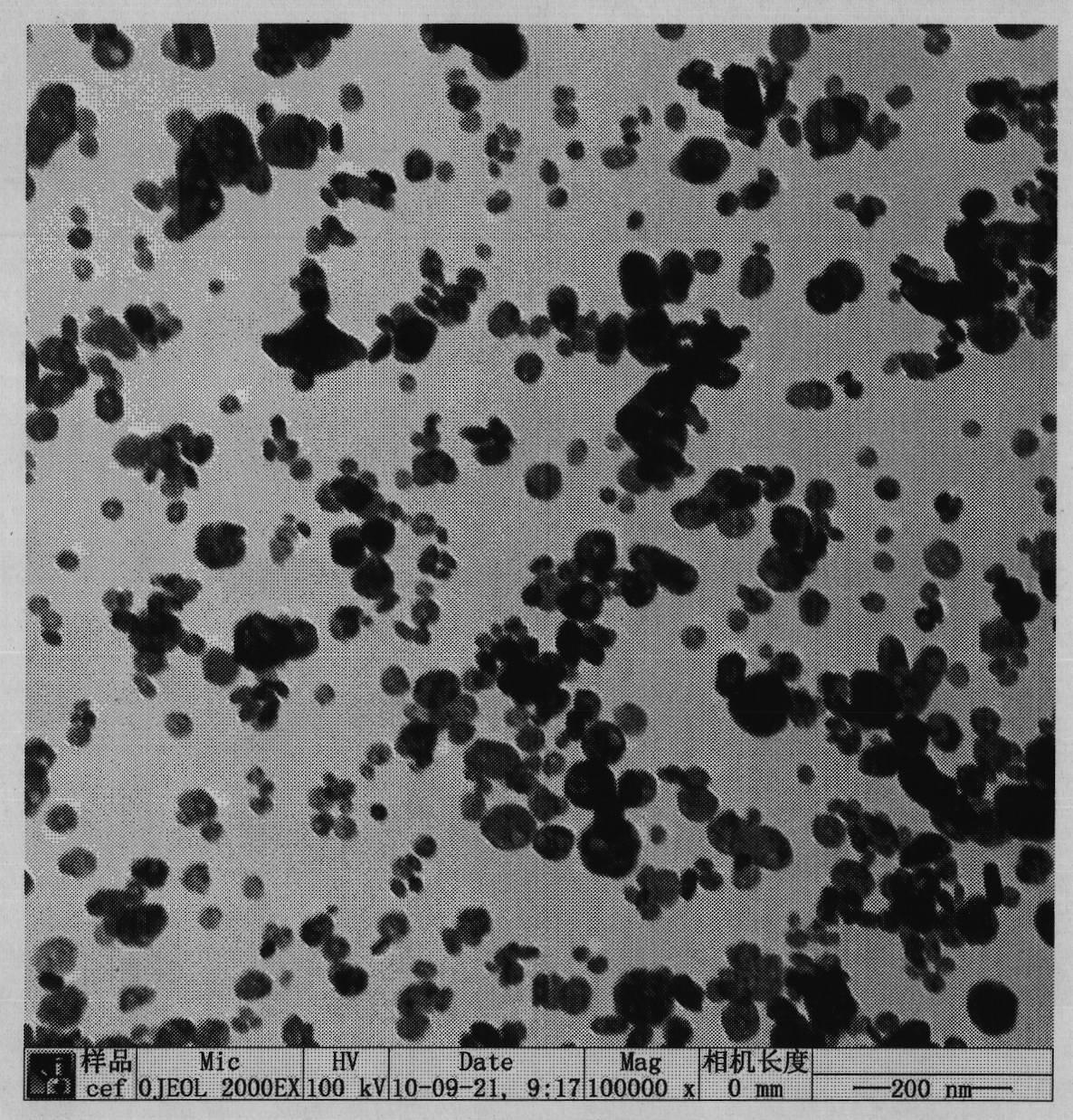

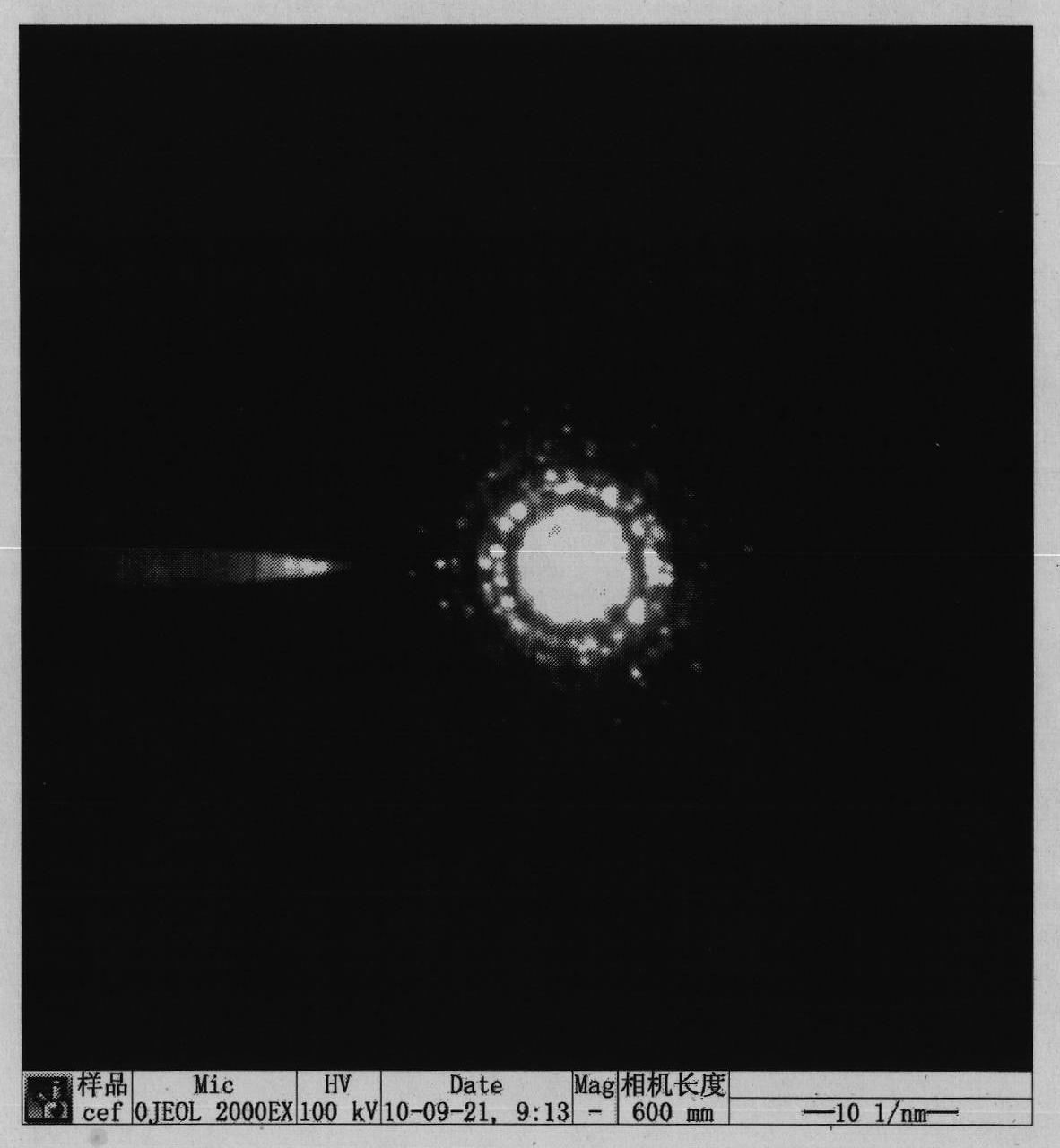

Water-soluble rare-earth terbium ion-doped cerium fluoride nanocrystallines and preparation method thereof

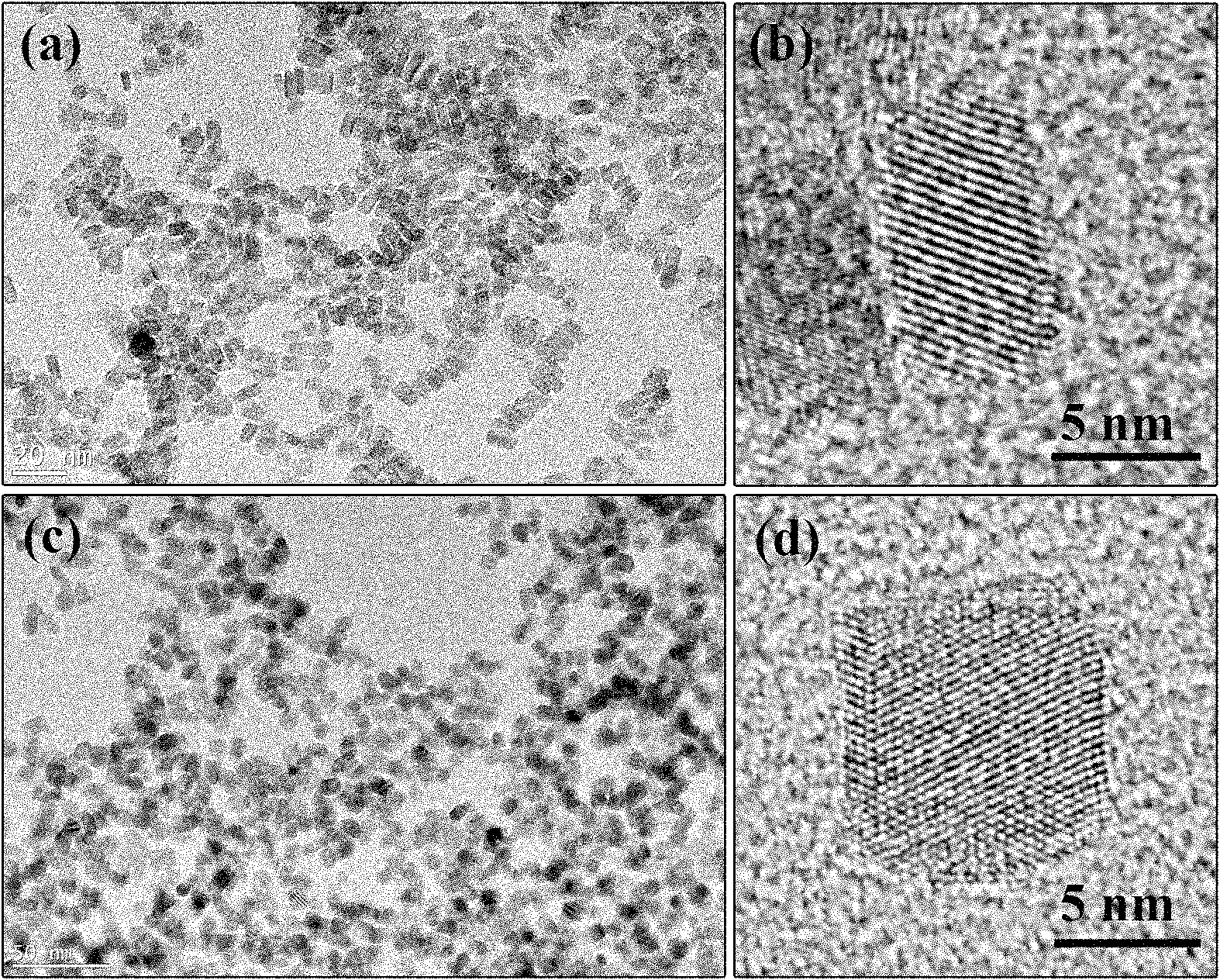

InactiveCN102071027AEvenly dispersedGood crystalMaterial nanotechnologyNanoopticsSolubilityQuantum yield

The invention discloses water-soluble rare-earth terbium ion-doped cerium fluoride nanocrystallines and a preparation method thereof, and belongs to the technical field of fluorescent nano-crystalline materials and hydrothermal chemical method synthesis thereof. The rare-earth terbium ion-doped cerium fluoride nanocrystallines are rod-shaped or cube-like; and the polyethyleneimine is coated on the surfaces of the nanocrystallines. The preparation method comprises the following steps of: mixing cerium nitrate hexahydrate, terbium chloride hexahydrate, the polyethyleneimine and ethylene glycol in a certain ratio; reacting for 1 to 12 hours in a baking oven at the temperature of 160 to 240 DEG C; cooling a reaction product; washing the reaction product with water and ethanol; and drying in vacuum. The product has very high solubility, adjustable and controllable appearance, high particle stability and high fluorescence quantum yield, and also can be dispersed in different solvents. In the method, raw materials are cheap and easy to obtain; the process is simple; the cost is low; the process repeatability is high; and the nanocrystallines have a potential application value in the field of biomarkers.

Owner:JILIN UNIV

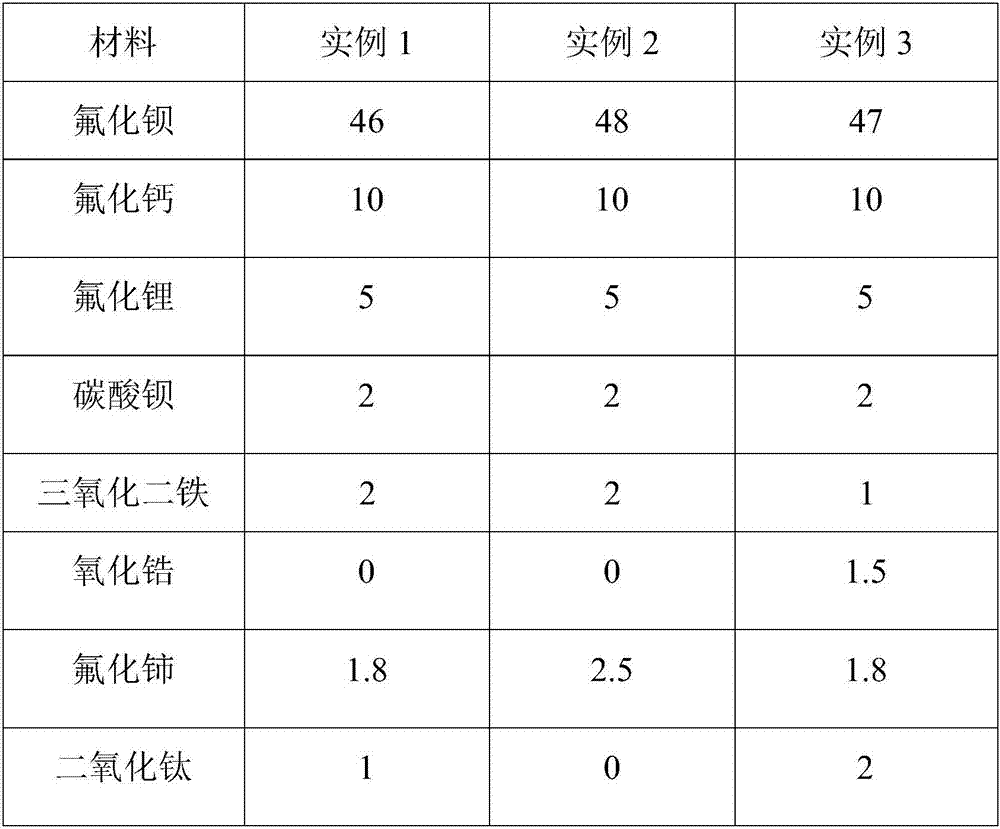

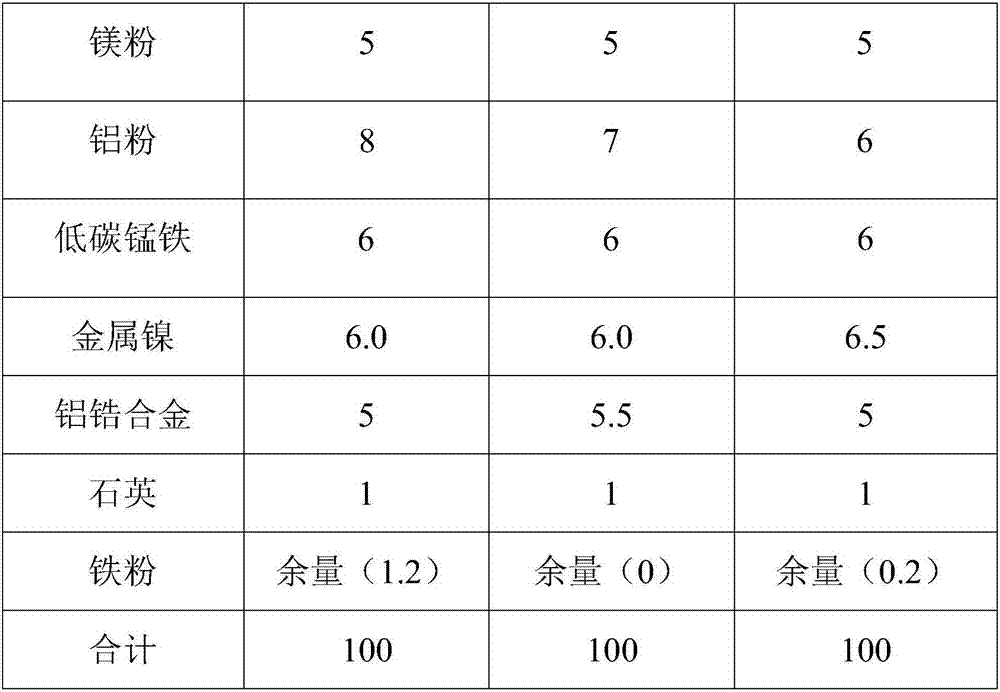

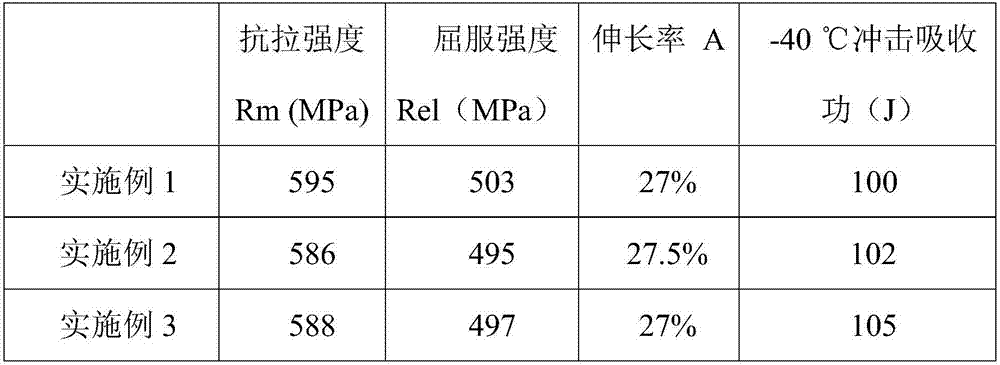

Self-shielded flux-cored wire for X80 pipeline steel

ActiveCN106944765AEasy to useImprove self-protection performanceWelding/cutting media/materialsSoldering mediaAbsorbed energyWeld seam

The invention provides a self-shielded flux-cored wire for X80 pipeline steel. The self-shielded flux-cored wire comprises wire skin made of mild-carbon steel strips and a flux core, and is characterized in that a formula of powder of the flux core comprises components in percentage by mass as follows: 40%-50% of barium fluoride, 10%-20% of calcium fluoride, 5%-10% of lithium fluoride, 2%-5% of barium carbonate, 1%-5% of cerium fluoride, 1%-2% of ferric oxide, 0%-2% of zirconium oxide, 0%-4% of titanium dioxide, 5%-8% of magnesium powder, 5%-10% of powdered aluminium, 6%-8% of low-carbon ferromanganese, 6%-8% of metallic nickel, 5%-10% of aluminium-zirconium alloy, 1%-5% of quartz and 0%-5% of iron powder. The self-shielded flux-cored wire is suitable for all-position welding of pipelines and good in welding processing property, wire deposited metal has good mechanical properties, impact absorbing energy of a V-shaped notch at the temperature of subzero 40 DEG C of the wire deposited metal reaches 100 J or higher, and the requirement of welding seam toughness is met.

Owner:WUHAN UNIV OF SCI & TECH

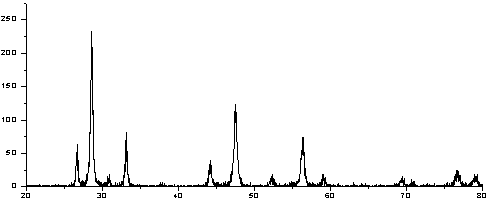

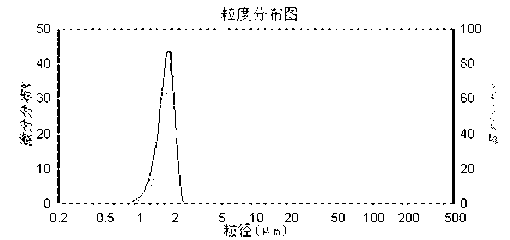

Rich cerium rare earth polishing powder and preparation method thereof

InactiveCN102936461ASimple filterReduce reunionPolishing compositions with abrasivesSpray driedRoasting

The invention discloses a preparation method of a rich cerium rare earth polishing powder. The method includes the following steps that a precipitator is added in a soluble rich cerium mixed rare earth salt solution and a pure cerium rare earth salt solution to obtain a cerium containing mixed rare earth precipitation and a pure cerium rare earth precipitation, the pure cerium rare earth precipitation is fluorated to obtain cerium fluoride, the cerium fluoride is subjected to preliminary roasting and mixed with the cerium containing mixed rare earth precipitation to obtain a mixture, and the mixture is subjected to wet ball milling, spray drying and high-temperature roasting to obtain the rich cerium rare earth polishing powder. The preparation method of the rich cerium rare earth polishing powder has the advantages that a novel process of subjecting the cerium precipitation with a single component to perfluorination, preliminary roasting and ball-milling with the cerium containing mixed rare earth precipitation is utilized, so that the volume center particle size D50 of the produced rich cerium rare earth polishing powder is smaller than or equal to 2.5mum, the maximum particle size D100 is smaller than or equal to 8mum, the specific surface area is in a range from 2m2 / g to 6m2 / g, the dispersibility is good, the particle size distribution is narrow, the product quality is easy to control, and the abrasive resistance and polishing accuracy of the polishing powder are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

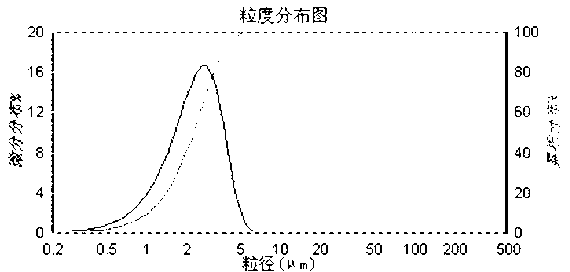

Preparation method of rare earth polishing powder

InactiveCN104017500AReduce consumptionReduce manufacturing costPolishing compositions with abrasivesLanthanum fluorideRare earth

The invention discloses a preparation method of rare earth polishing powder. The preparation method comprises the following steps of (1) precipitating mixed rare earth through an ammonium hydrogen carbonate and ammonia water mixed solution, ageing, and then, adding mixed fluorine-contained acid to fluorinate to obtain fluorinated alkaline rare earth carbonate, wherein mixed rare earth is cerium lanthanum chloride rare earth or cerium lanthanum chloride rare earth, and mixed fluorine-contained acid is mixed acid of hydrofluoric acid and fluosilicic acid; (2) carrying out multi-stage roasting on fluorinated alkaline rare earth carbonate obtained in the step (1) to obtain a mixed rare earth oxide, wherein the mixed rare earth oxide is an oxygen cerium fluoride and cerium oxide mixture or an oxygen cerium lanthanum fluoride and cerium oxide mixture; (3) smashing the mixed rare earth oxide obtained in the step (2), and grading to obtain the rare earth polishing powder with the particle size of 0.3-0.5mu m. The preparation method can be used for preparing ultrafine rare earth polishing powder which is capable of reaching the angstrom grade on a glass polished surface, uniform in dispersion and small in particle size.

Owner:山东麦丰新材料科技股份有限公司

Pollution flashover preventing insulating coating with micro-nano composite particles added and preparing technology

ActiveCN105086826AImprove stain resistanceGood oil resistanceFireproof paintsAntifouling/underwater paintsMicro nanoUltra high voltage

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Wax deposition resistant coating for oil pipeline

InactiveCN1865370ASolve anti-waxPolyurea/polyurethane coatingsEpoxy resin coatingsPolyvinylidene difluoridePolyvinylidene fluoride

Disclosed is an anti-waxing paint for internal surfaces of oil pipes, which comprises modified polyurethane 20-50%, polyvinylidene fluoride 5-30%, epoxy resin 5-20%, molybdenum sulfide 2-20%, Disclosed is an anti-waxing paint for internal surfaces of oil pipes, which comprises modified polyurethane 20-50%, polyvinylidene fluoride 5-30%, epoxy resin 5-20%, molybdenum sulfide 2-20%, cerium fluoride 2-10%.

Owner:ZHONGBEI UNIV

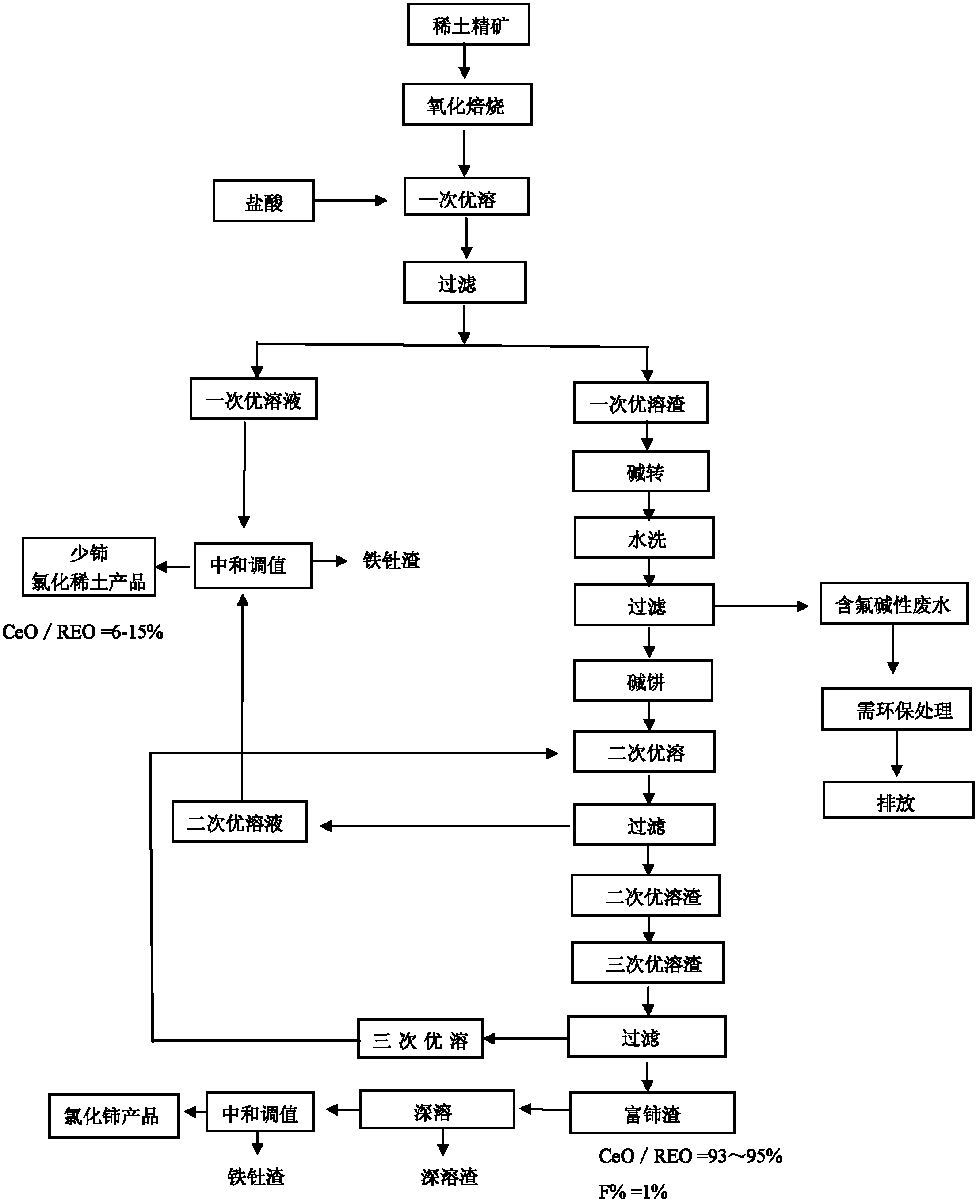

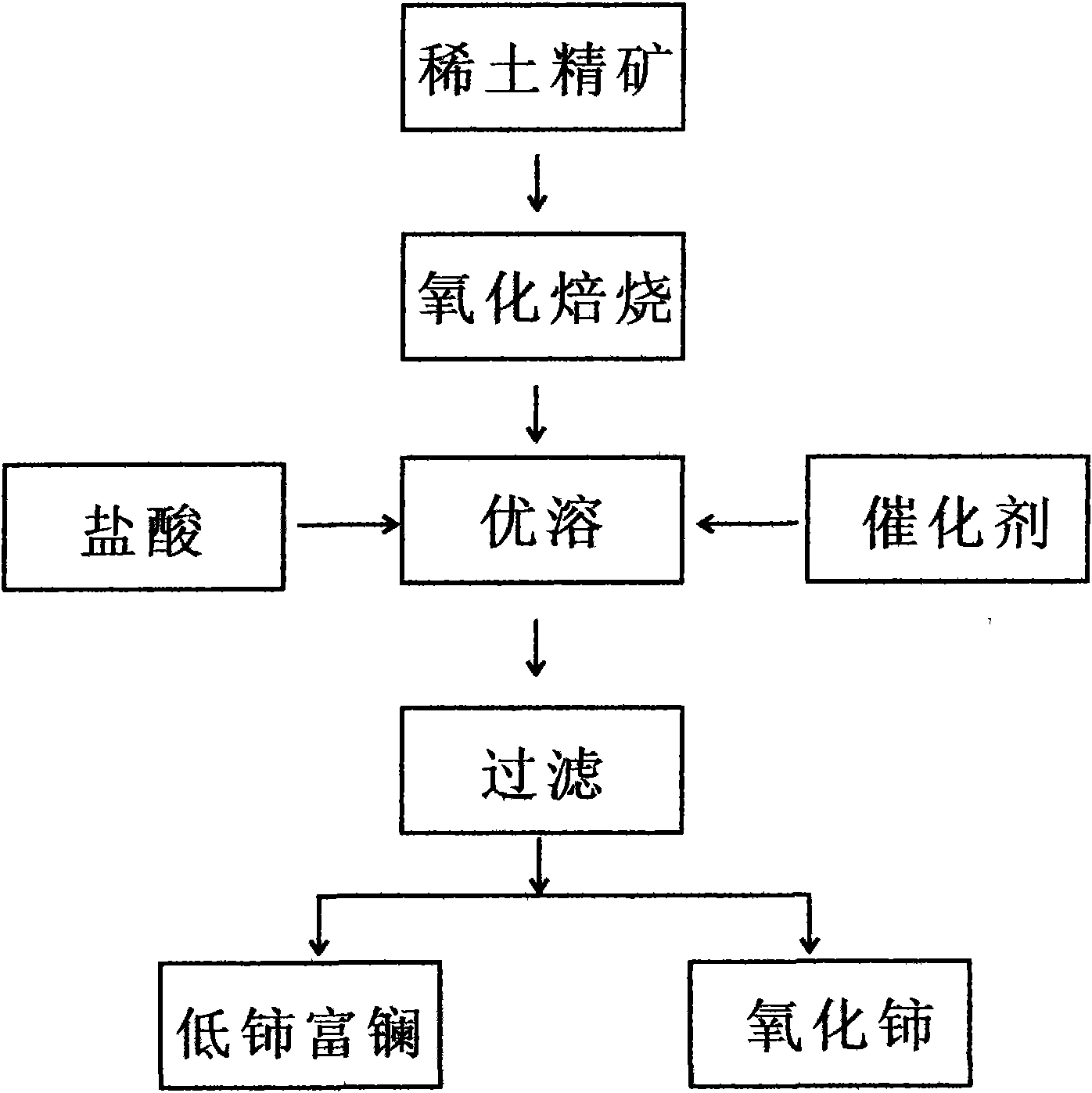

One-step production method for cerium poor rare earth fluoride and cerium fluoride

The invention relates to a non-ferrous metal rare-earth separating method, concretely, a one-step production method for cerium poor rare earth fluoride and cerium fluoride, wherein the one-step production method for cerium poor rare earth fluoride and cerium fluoride, comprising the following steps of: A. oxidizing and roasting rare-earth ore concentrate; B. selectively dissolving the rare-earth ore concentrate with dilute hydrochloric acid after oxidizing roasting, and adding a catalyst; C. filtrating and separating the SLAG and the solution after selective dissolution. The method of the invention can implement zero discharge of waste water, reduce the cost, increase product value, decrease process flow, and reduce labor strength.

Owner:LESHAN SHENGHE RARE EARTH CO LTD

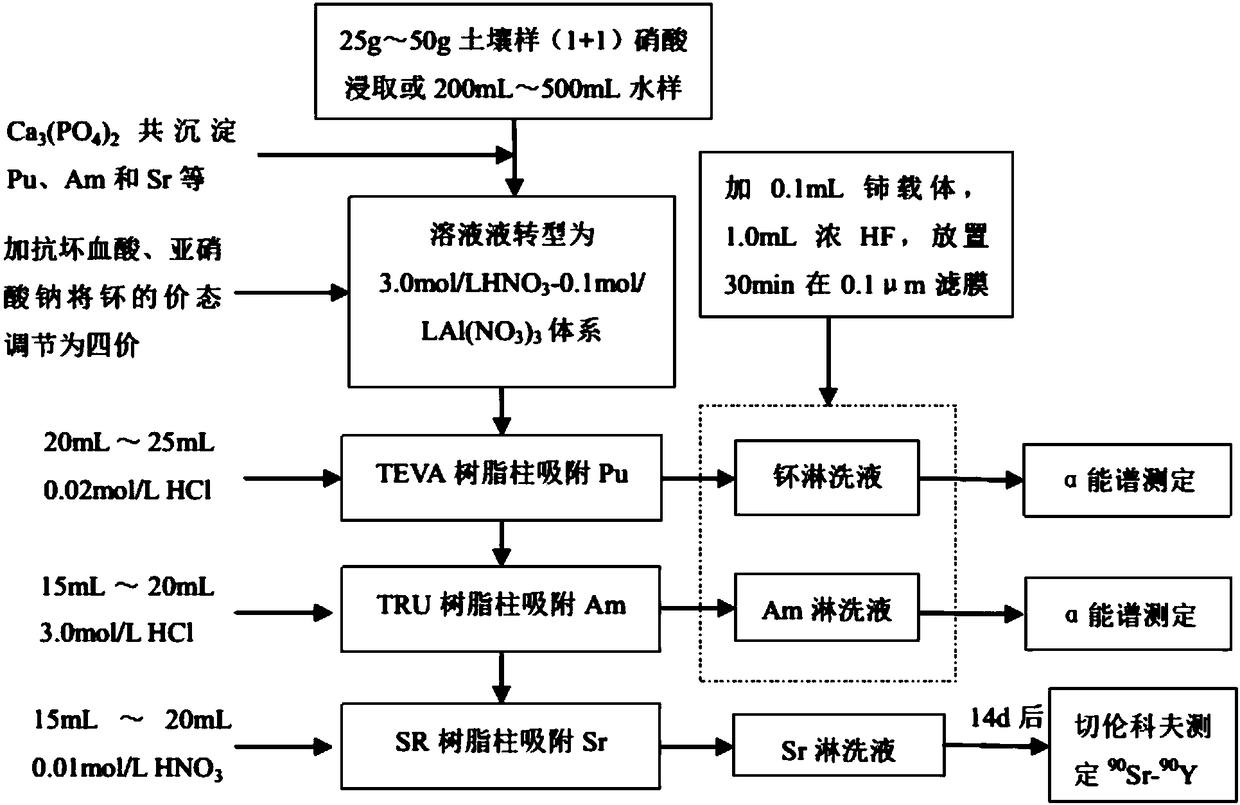

Method for separating and determining Pu, <241>Am and <90>Sr in low-radioactivity sample

InactiveCN108152112AShorten the analysis cycleLess staffX-ray spectral distribution measurementPreparing sample for investigationPu elementSodium nitrite

The invention relates to a method for separating and determining <238-240>Pu, <241>Am and <90>Sr in a low-radioactivity sample, which comprises the following steps: (1) sample pretreatment; (2) separation and enrichment of <238-240>Pu, <241>Am and <90>Sr: after ascorbic acid and sodium nitrite are added into a solution obtained in step (1) to regulate the valence state of plutonium into tetravalence, the solution passes through a TEVA, TRU and SR tandem extraction chromatography resin column, and the flow velocity is kept at 1mL / min to 1.2mL / min; at the moment, <238-240>Pu is adsorbed on the TEVA column, <241>Am is adsorbed on the TRU column, and <90>Sr is adsorbed on the SR column; 20mL to 25mL of hydrochloric acid solution which is 0.02mol / L is used for eluting <238-240>Pu on the TEVA column, 15mL to 20mL of hydrochloric acid solution which is 3.0mol / L is used for eluting <241>Am on the TRU column, and 15mL to 20mL of nitric acid solution which is 0.01mol / L is used for eluting <90>Sron the SR column; (3) determination of <238-240>Pu, <241>Am and <90>Sr: a cerium fluoride micro-deposition method is adopted to prepare an Alpha source, and the <238-240>Pu eluent and the <241>Am eluent are measured on the Alpha energy spectrum; the <90>Sr eluent is placed for 14 days, and after <90>Sr<-><90>Y is balanced, determination is carried out by the Cerenkov counting method. The analysismethod can be adopted to separate and enrich Pu, <241>Am and <90>Sr in a sample, and the period of analyzing Pu, <241>Am and <90>Sr is shortened.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

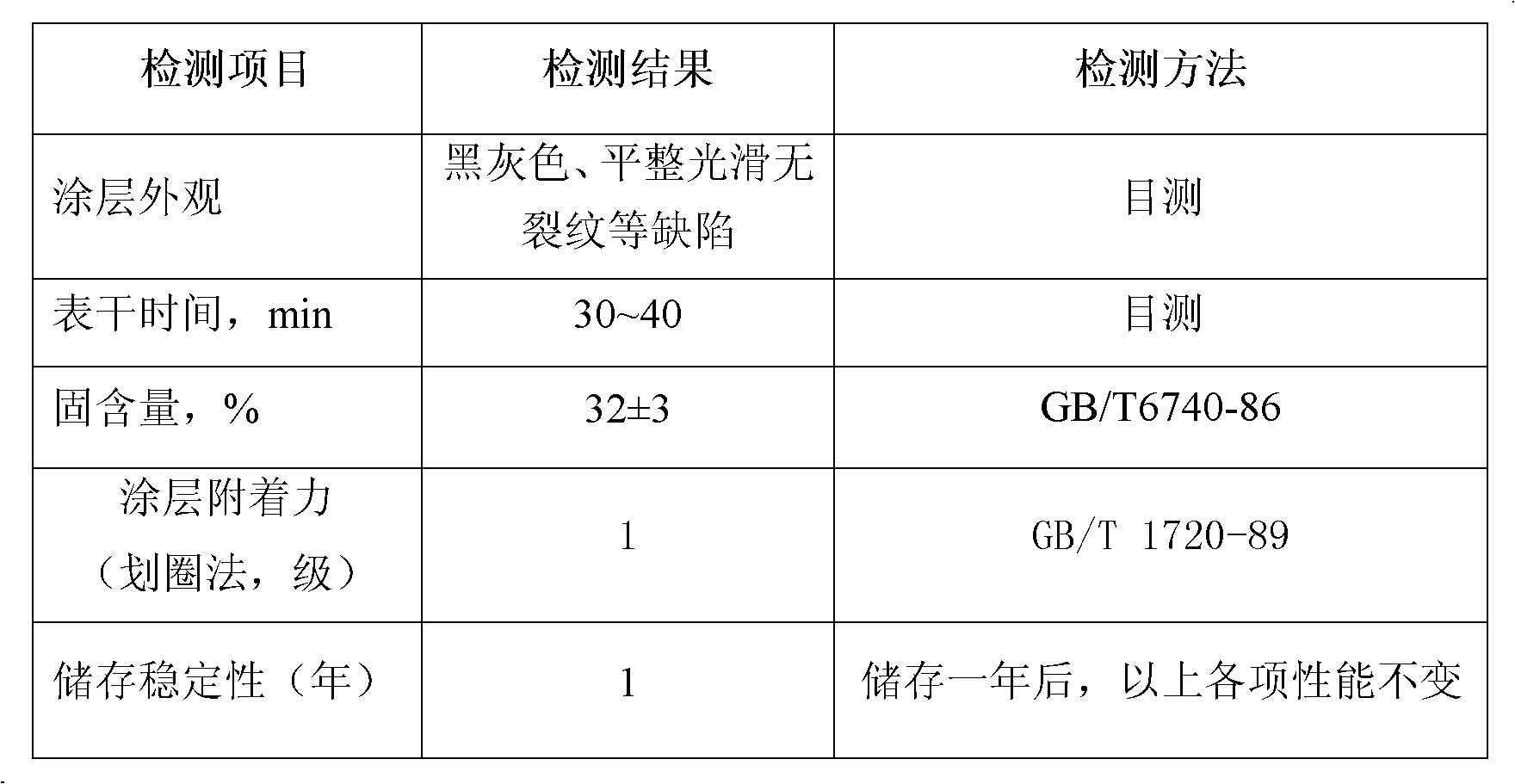

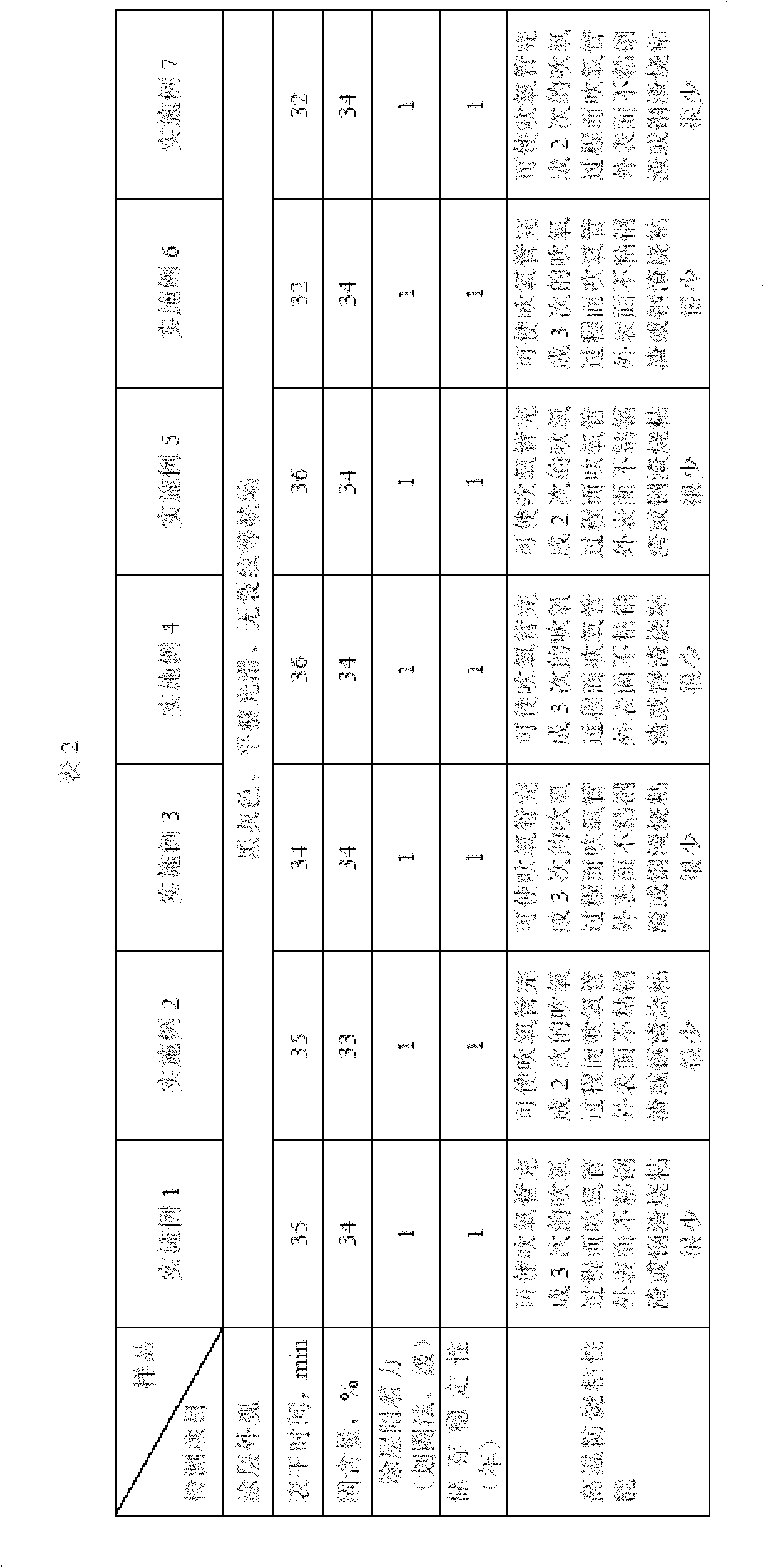

High-temperature burning sticking preventing coating

The invention relates to an ambient self-drying high-temperature burning sticking preventing coating which solves the problem of steel slag burning sticking prevention on the external surface of an oxygen blow pipe of a steel furnace. The high-temperature burning sticking preventing coating comprises the following components: 3.0-8.0% of silicon acrylic emulsion, 15.0-25.0% of graphite, 1.0-5.0% of molybdenum disulfide, 1.0-3.0% of rare earth cerium fluoride, 5.0-10.0% of metallic oxide, 1.0-3.0% of aerosol, 0.1-0.2% of potassium pyrophosphate and the balance of water, wherein the metallic oxide is a mixture of two or three compounds selected from antimony trioxide, copper oxide and aluminum oxide in any proportion. A coating layer prepared by using the high-temperature burning sticking preventing coating has good sticking force and excellent burning sticking preventing function and protection function on a metal base, the coating layer can be rapidly self-dried at room temperature. The oxygen blow pipe can complete 1 to 3 times of oxygen blowing process by painting the high-temperature burning sticking preventing coating on the external surface of the oxygen blow pipe once, and the external surface of the oxygen blow pipe is not stuck to steel slag or a little steel slag is burned and stuck.

Owner:贾文宝 +1

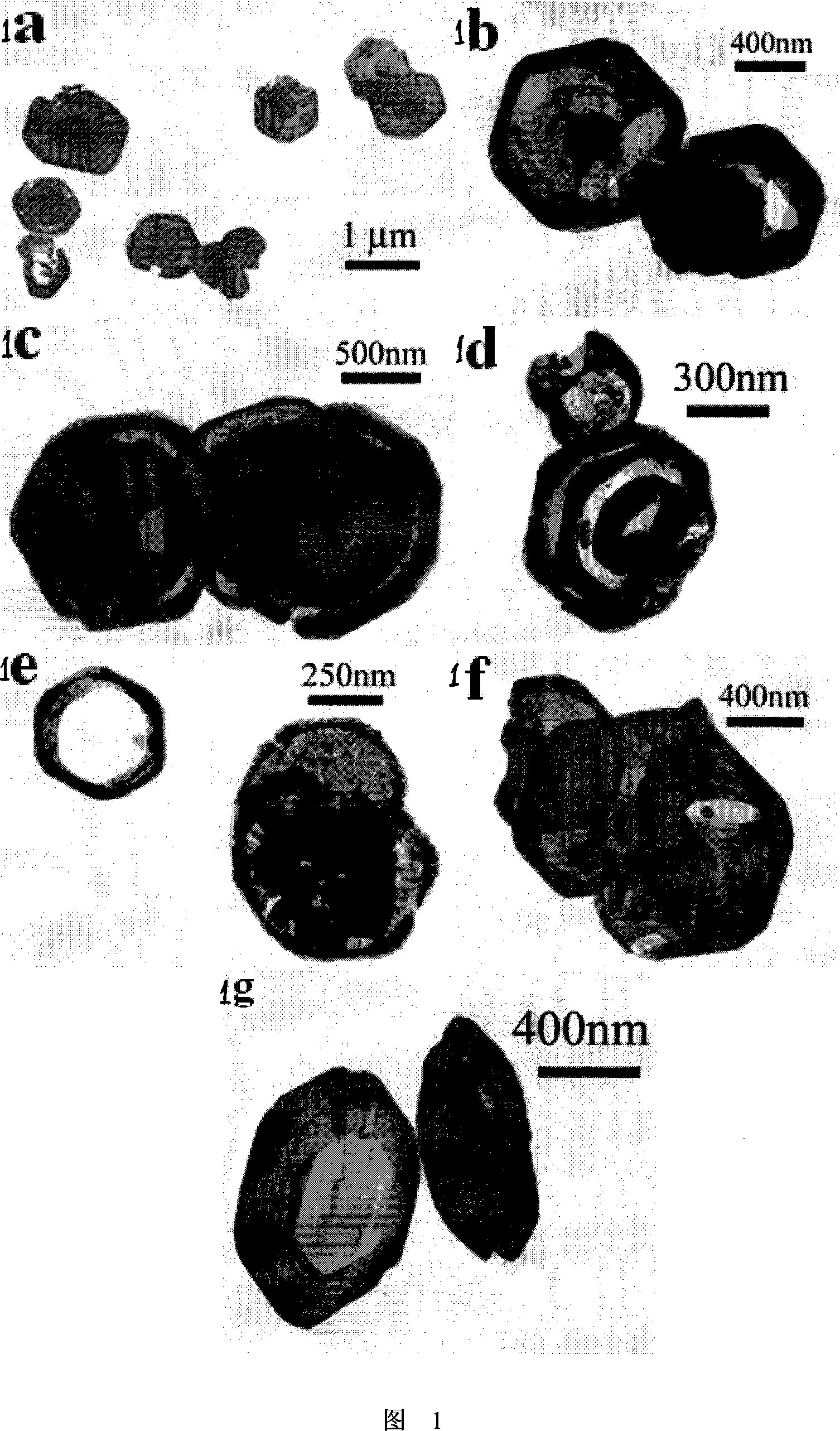

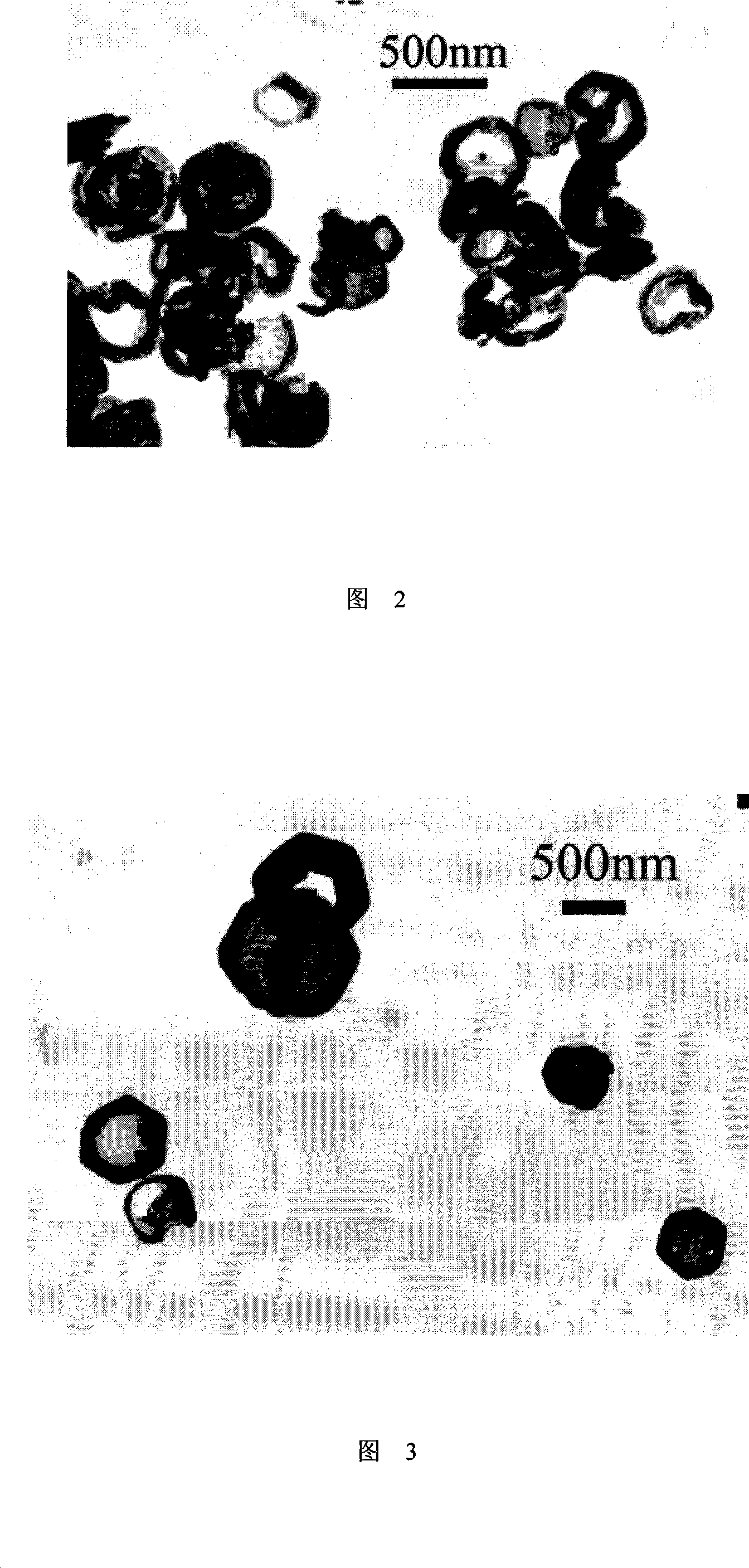

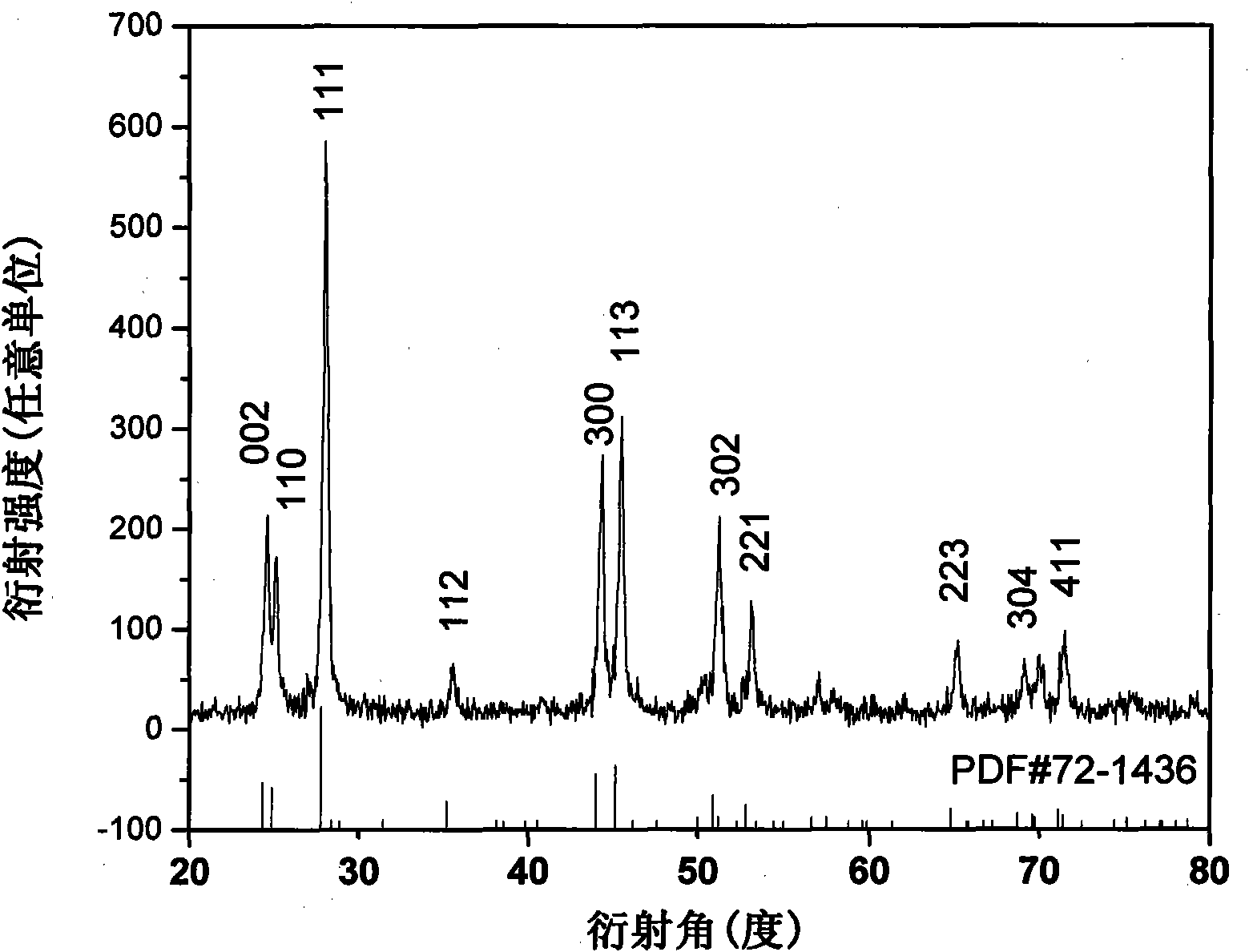

Method for producing cerium fluoride hollow nanostructured material

InactiveCN101172637AMeet the concentrationLow priceNanostructure manufactureFluoride preparationSucroseHigh pressure

A method for preparing hollow cerium fluoride nanometer structure material comprises the steps as follows: the oscillating reaction adopts potassium bromate, sodium bromate-organic acid or sugar-cerium-sulphuric acid, with the consistence of 0.06 plus or minus 0.04, 0.06 plus or minus 0.04, 0.02 plus or minus 0.02 and 0.6 plus or minus 0.4mol / L respectively; Naf is adopted as the fluorin source with consistence of 0.1 to 0.5mol / L; the preparative process of hydro-thermal reaction is performed under the temperature of 110 to 170 DEG C. The cerium source can be K7Ce6F31 powder, ammonium ceric nitrate or ceric ammonium sulfate; the organic acid or the sugar can use the organic matter such as propane diacid, oxalic acid, sucrose and glucose to replace the citric acid. The preparation of the hollow cerium fluoride nanometer structure material needs 12 to 100 hours in a high pressure kettle having polyfluortetraethylene as the lining. Furthermore, the invention prepares the hollow cerium fluoride nanometer structure materials with hexagonal or circular section respectively by controlling the temperature of the hydro-thermal reaction.

Owner:NANJING UNIV

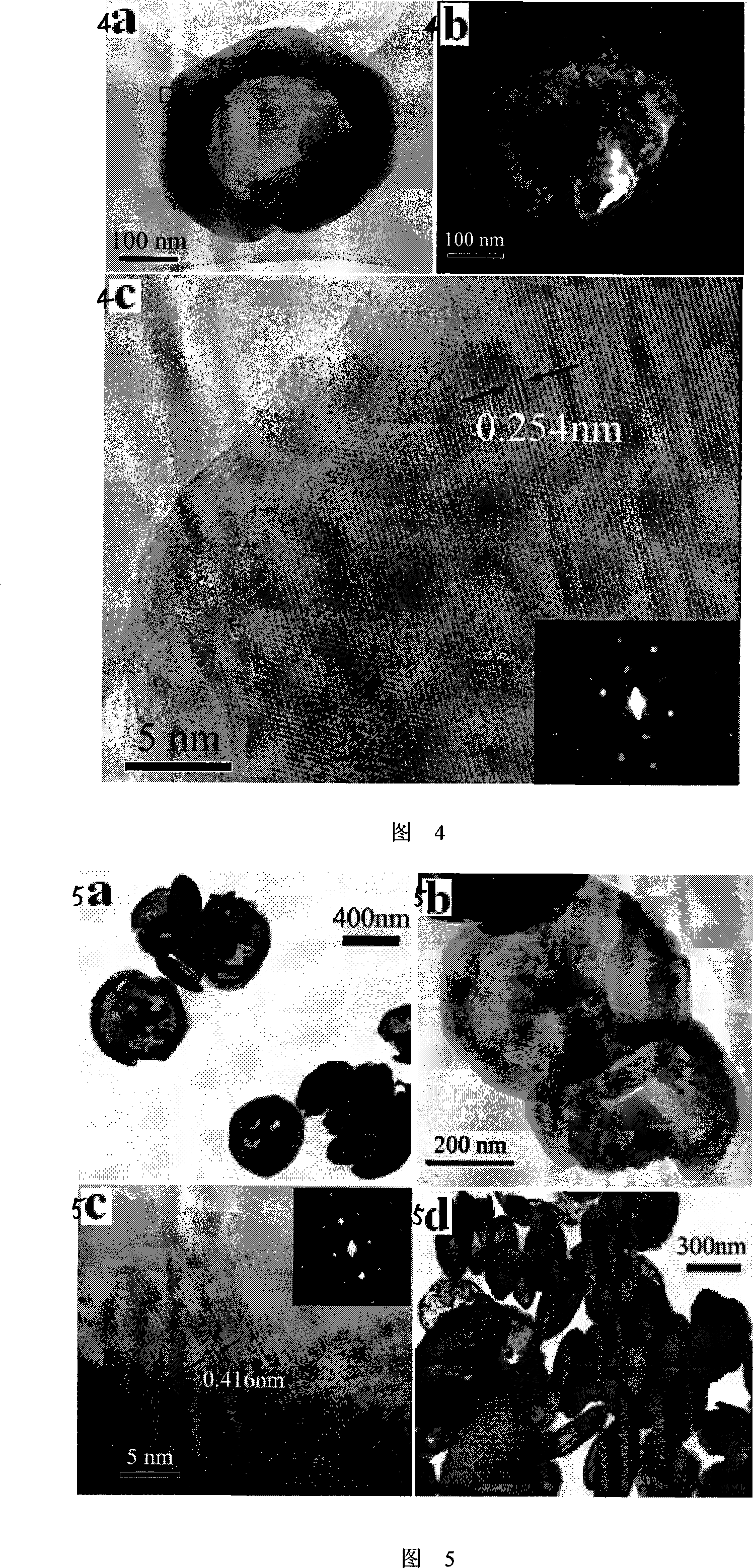

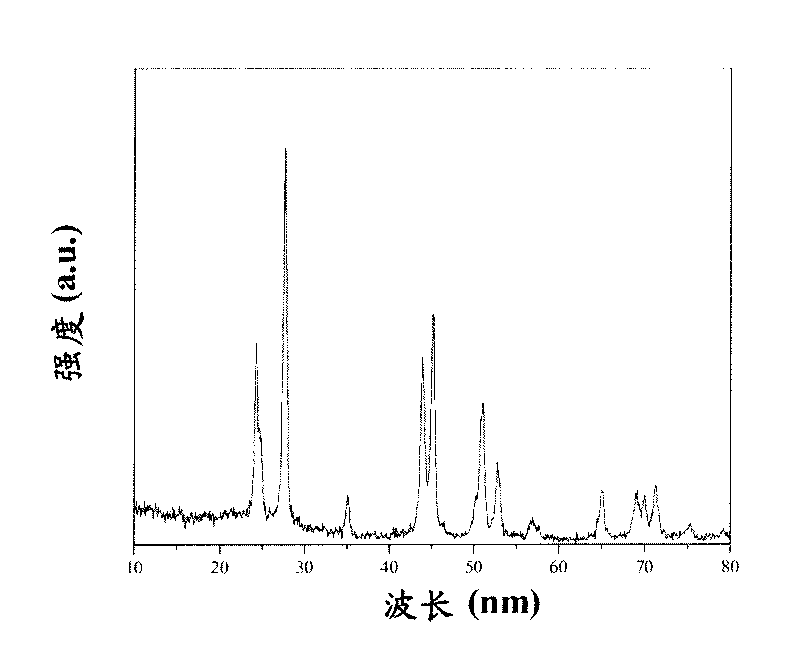

Dual mode luminous rare earth doped cerium fluoride nano crystal, preparation method and surface modification method thereof

InactiveCN101735816AMeet different application needsLuminescent compositionsDual modeUltraviolet lights

The invention provides a dual mode luminous rare earth doped cerium fluoride nano crystal, a preparation method thereof and a surface modification method thereof. The rare earth doped cerium fluoride nano crystal has a chemical composition formula, namely Ce0.74F3:0.2Yb / xTm / (0.06-x)Tb, wherein x=0.01-0.05. The crystal can realize dual mode luminescence of up-conversion excitation and down-conversion excitation under conditions such as ultraviolet light and a 980nm infrared laser. In addition, the method can prepare the rare earth doped cerium fluoride nano crystal having different structural shapes by controlling technological conditions. Moreover, the surface of the prepared doped cerium fluoride nano crystal can be modified by a surfactant so as to meet various requirements in the technical fields of anti-counterfeiting, biological marking and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

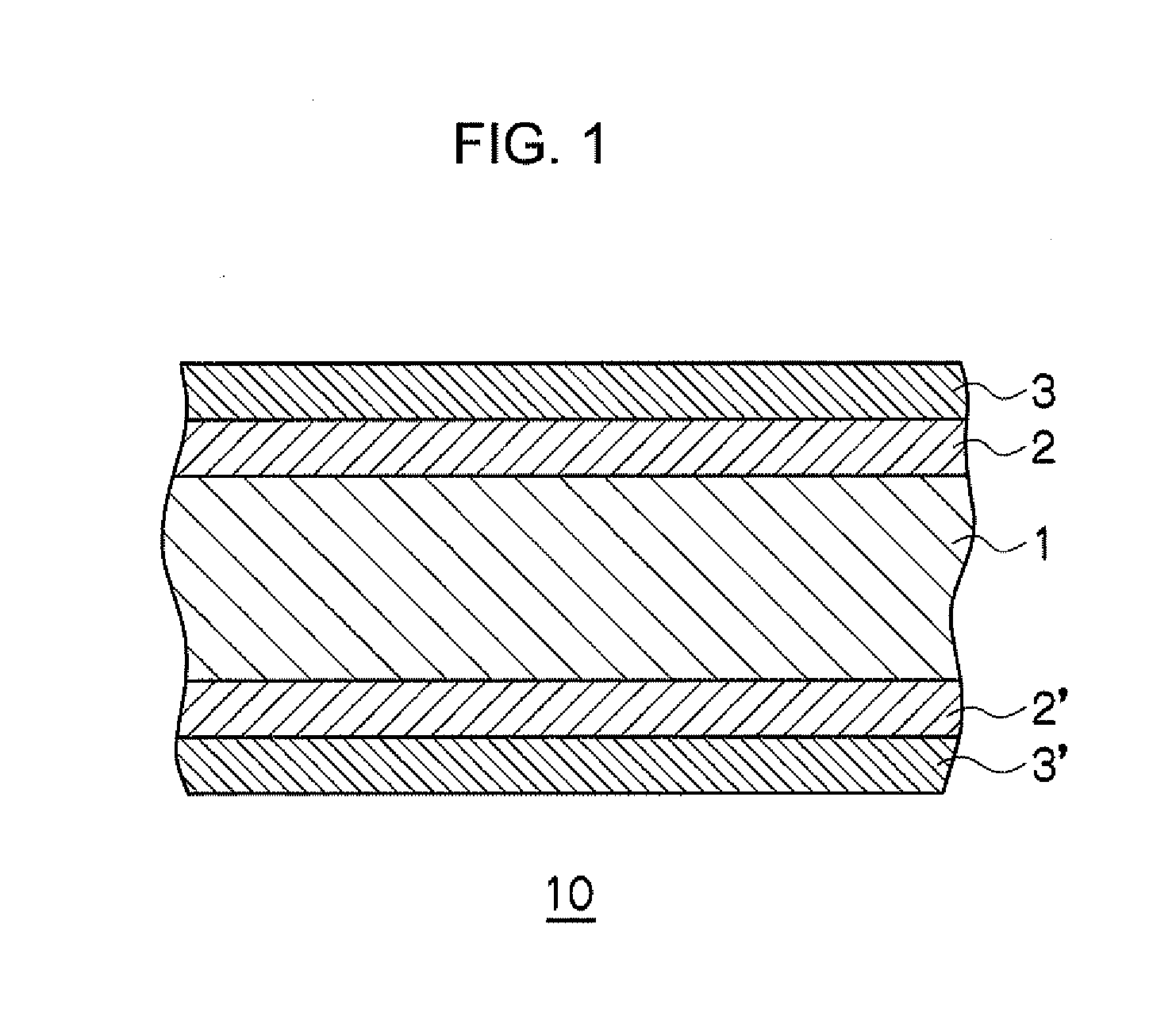

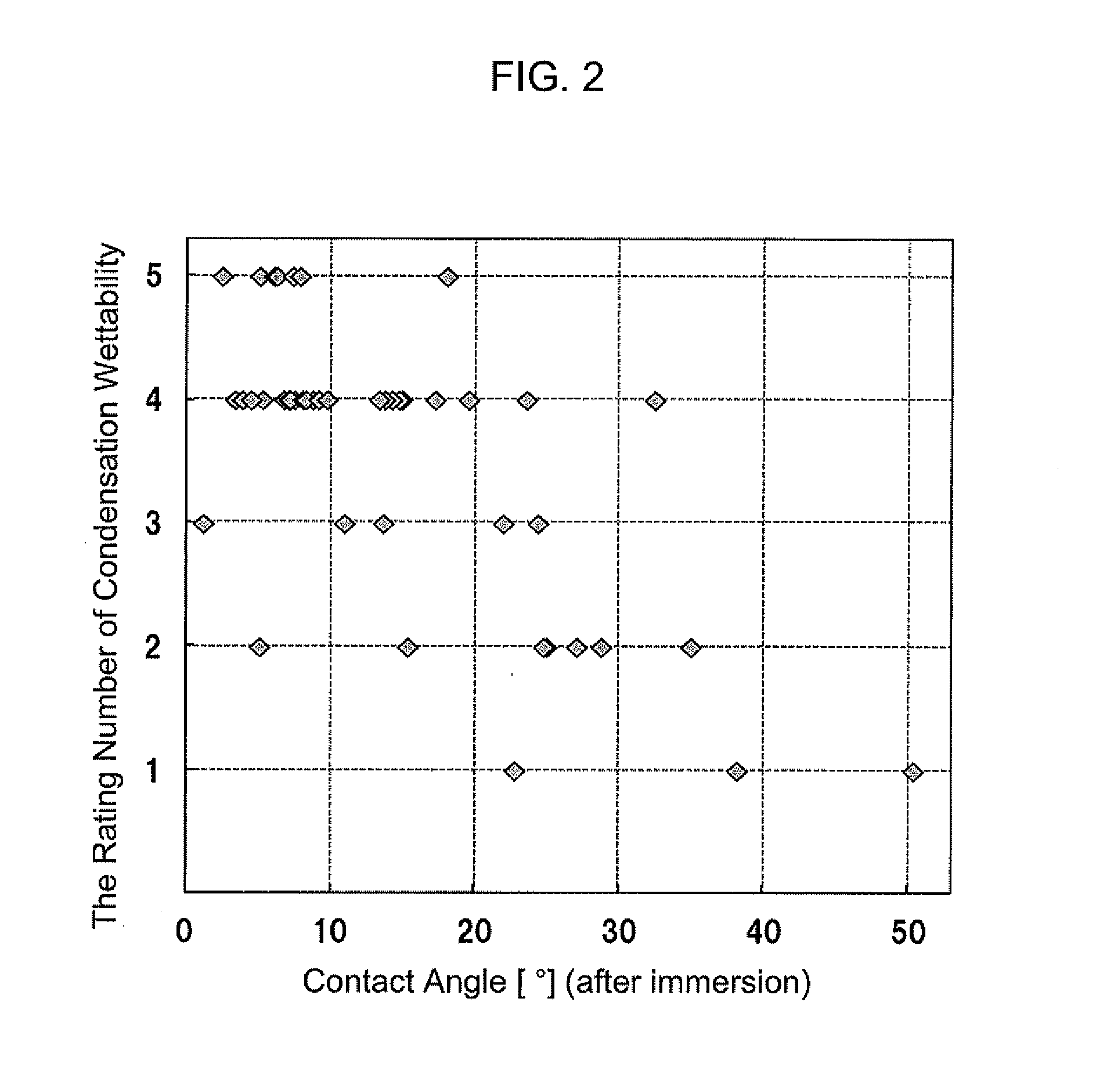

Hydrophilic film formed on a surface of a metal material, hydrophilization treatment agent and hydrophilization treatment method

InactiveUS20130196167A1Improve hydrophilicityGood mold resistanceAntifouling/underwater paintsPretreated surfacesHydrophilizationMetallic materials

A hydrophilic film is formed on the surface of a metal material, inhibits the growth of condensation water, and provides mold resistance, and a hydrophilization treatment agent is used for forming the hydrophilic film. The hydrophilization treatment agent has one or more compounds selected from poorly water-soluble cerium compounds; and a hydrophilic film prepared from the hydrophilization treatment agent. The poorly water-soluble cerium compounds are one or more compounds selected from cerium carbonate, cerium fluoride, cerium fluoride, and cerium oxide. By forming the hydrophilic film on the surface of a metal material, the growth of condensation water can be inhibited, and the mold resistance can be provided.

Owner:NIHON PARKERIZING

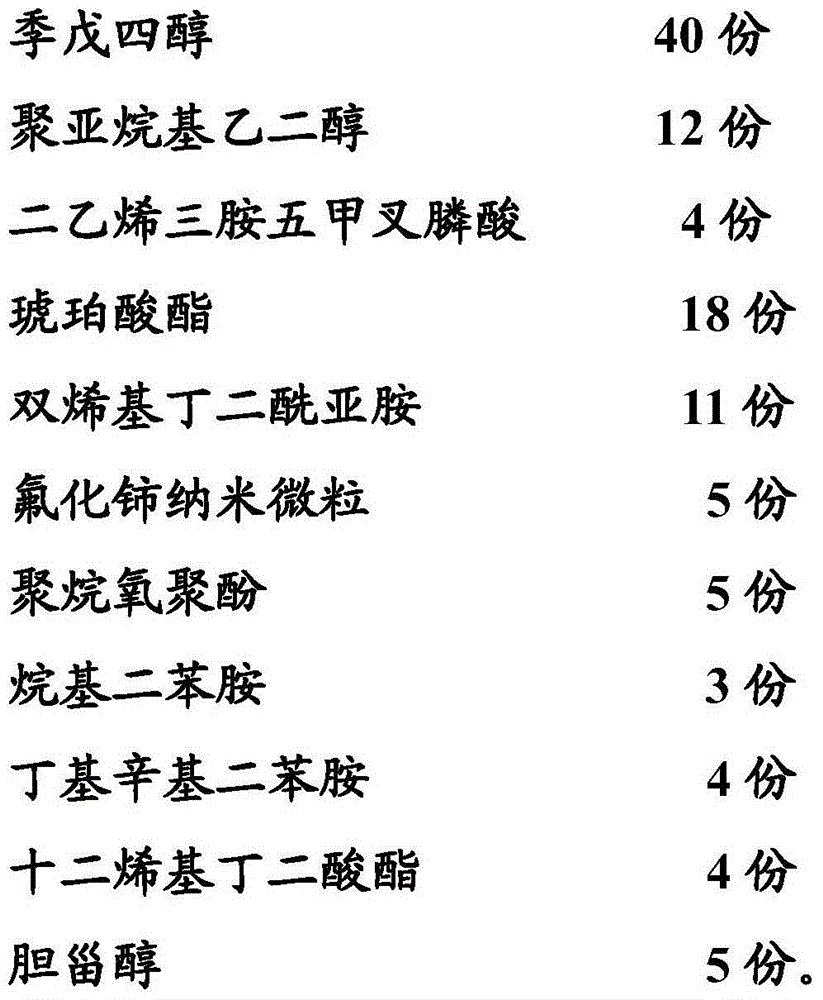

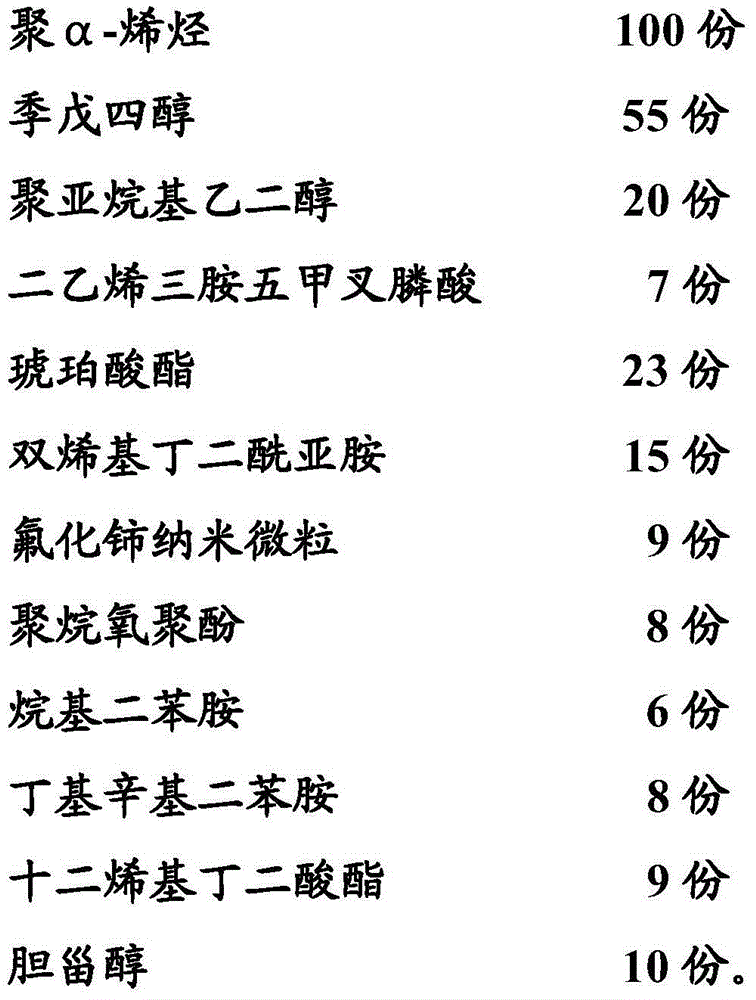

Preparation method of bearing lubrication oil

The invention provides a preparation method of bearing lubrication oil. The preparation method of the bearing lubrication oil comprises the following steps: step one, taking poly-alpha-olefin, tetramethylolmethane and polyalkylene glycol, and uniformly stirring and mixing to prepare base oil; step two, taking diethylenetriaminepenta acid, succinate, di-alkenyl succinimide, cerium fluoride nanoparticles, poly-alcoxyl polyphenol, alkyl diphenylamine, butyl-octyl diphenylamine and laurylene ester succinate, uniformly stirring and mixing to obtain a mixture A, and then adding the mixture A into the base oil and uniformly stirring to obtain a mixture B; step three, simultaneously stirring and adding cholesterol into the mixture B, then heating to 83 to 88 DEG C and preserving the heat for 2 to 5 hours; cooling the mixture to the room temperature and prepare the bearing lubrication oil. The bearing lubrication oil is excellent in performance; the abrasion resistance can be improved by over 30%; the flashing point reaches 240 DEG C; the viscosity index is 105 to 125; the acid value is 0.08 to 0.13mg of KOH / g.

Owner:NANTONG LAIBITE BEARING CO LTD

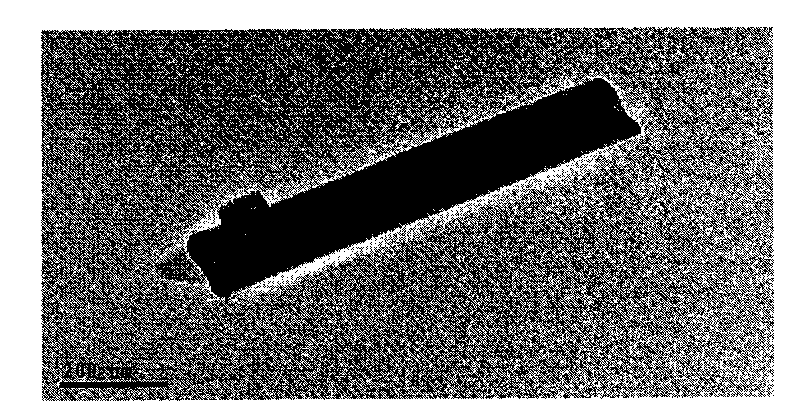

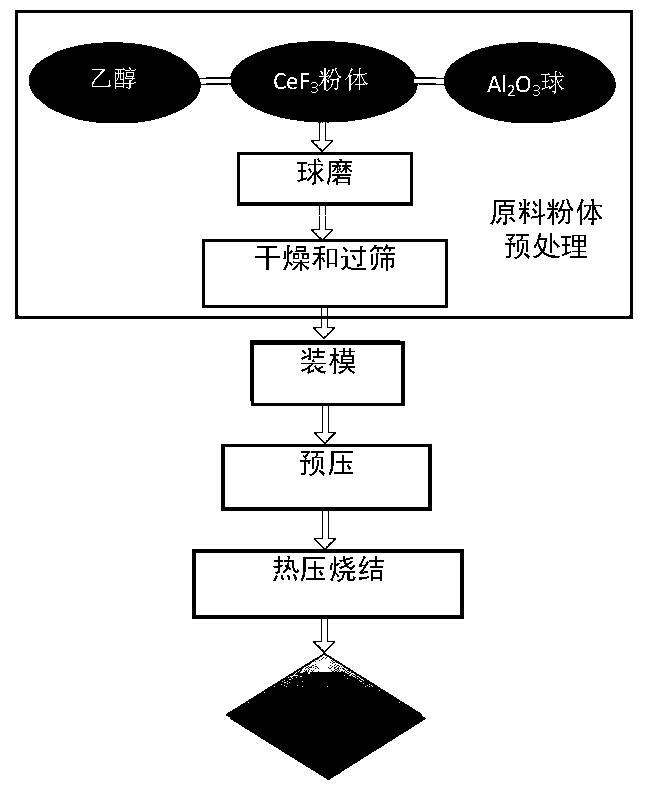

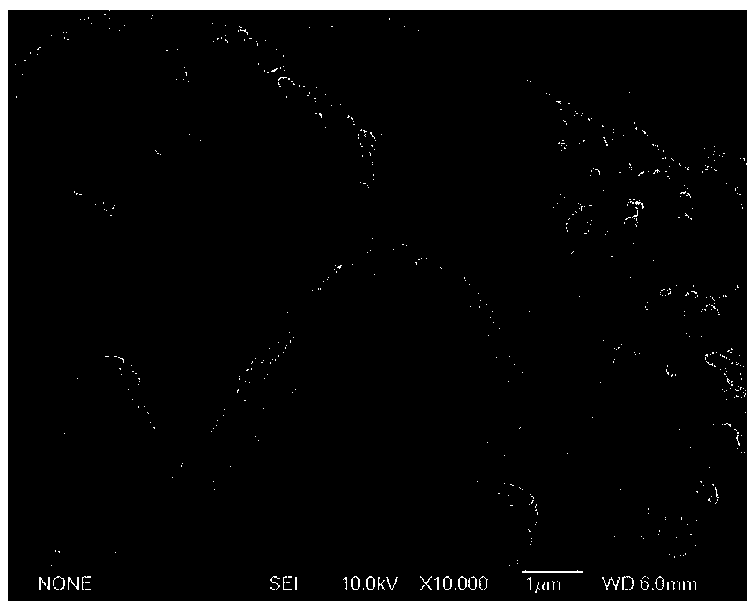

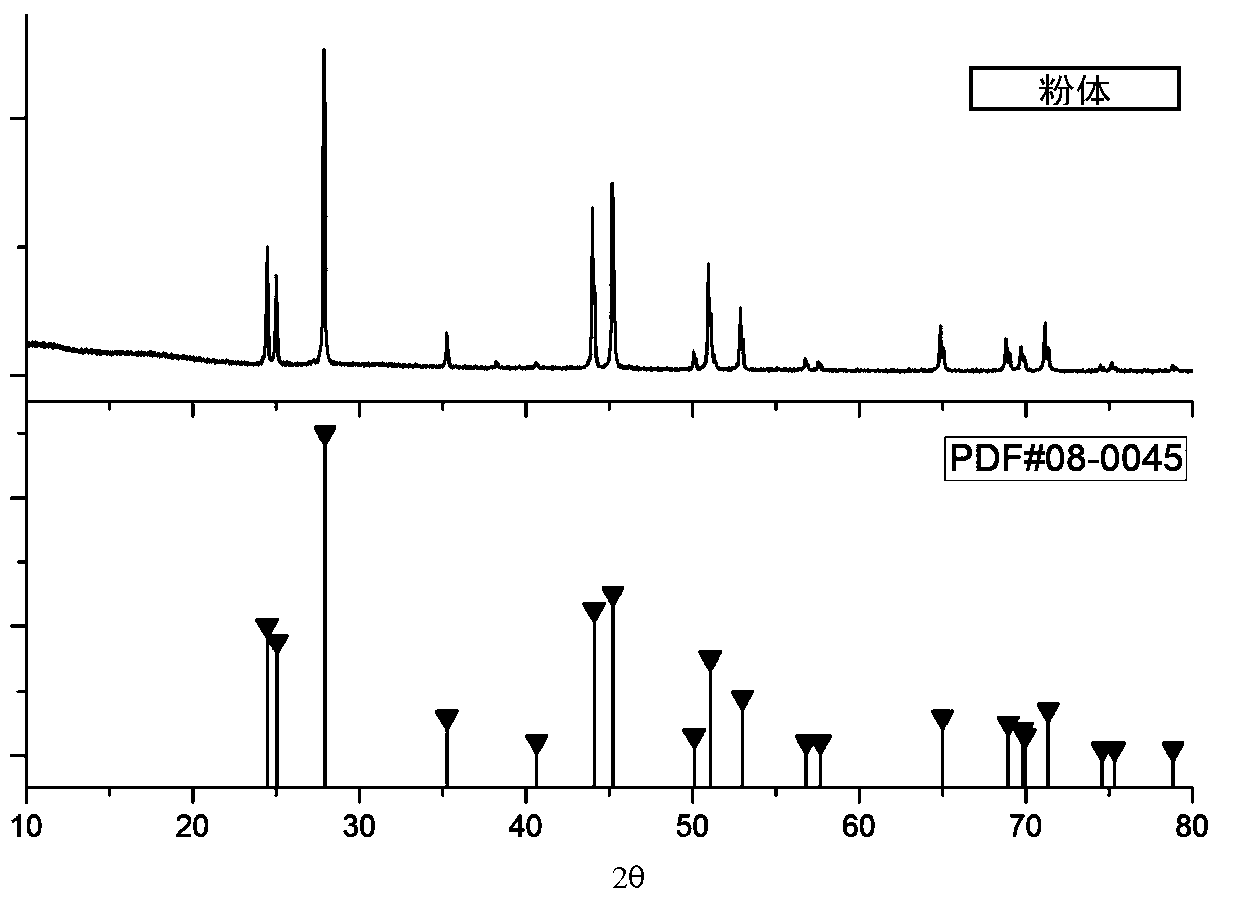

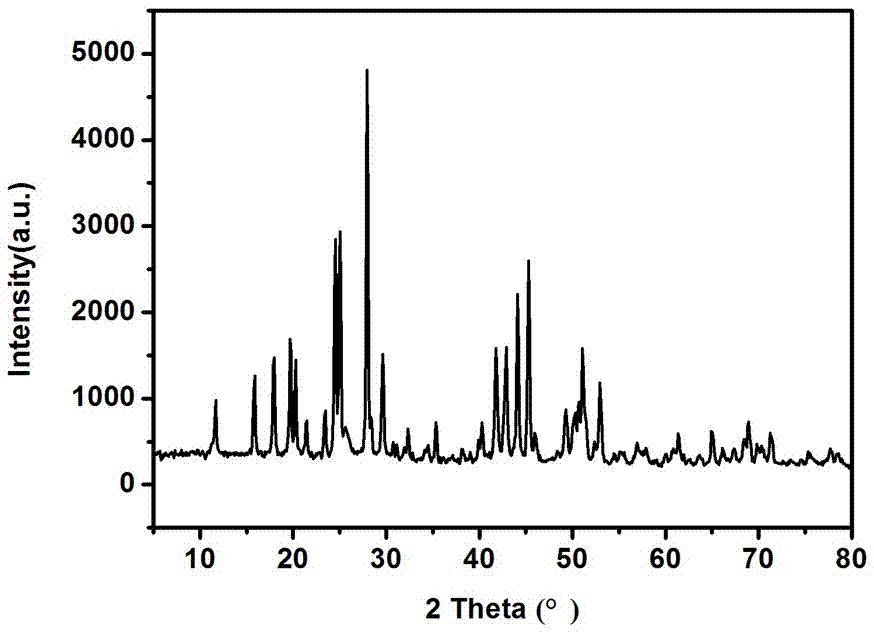

Hot pressing sintering method for cerium fluoride scintillation ceramic and cerium fluoride scintillation ceramic prepared thereby

InactiveCN103570355AImprove flicker performanceHigh visible light transmittanceVacuum pumpingVacuum pump

The invention relates to a hot pressing sintering method for a cerium fluoride scintillation ceramic and the cerium fluoride scintillation ceramic prepared thereby. The method includes: a pre-pressing process: under a specified pressure, conducting pre-pressing on high purity CeF3 powder with purity over 99% in a hot pressing mold; a heating process: removing the pre-pressing pressure, performing vacuum pumping to a vacuum degree of less than 5*10<-3>Pa, and then raising the temperature to 800-1000DEG C; and a hot pressing sintering process: keeping a temperature of 800-1000DEG C, carrying out pressurization to 100-300MPa, and maintaining the temperature and the pressure for 0.5-2.5h.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for microwave synthesis of cerium fluoride nano disk

InactiveCN101172638AGood size controlUniform sizeNanostructure manufactureFluoride preparationAcetic acidCerium nitrate

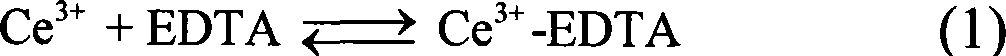

The invention discloses a preparative method for synthesizing cerium fluoride nanometer disc by microwave, the preparative method comprises the steps as follows: the complexing agent of EDTA Disodium is resolved into deionized water, and cerium nitrate is added to acquire solution under the mixing; the PH value of the solution is adjusted to 5.0 to 7.0, potassium fluoborate is added to make the reaction system under the mixing; the reaction system is heated in a microwave oven under backflow condition for 30 to 60 minute, and cooled naturally, separated by the centrifugation and washed fully with deionized water, collected and dried. The synthesizing method disclosed in the invention has the advantages of simple technique, low cost, quick process for saving energy, and high efficiency. The produced cerium fluoride nanometer disc has controllable and even size, with the average diameter of 150 to 600 nanometers and the thickness of 50 to 200 nanometers, therefore, the product is promising for wide application in the fields such as optics, photoelectronics, biologic marking and catalyzing, etc.

Owner:ZHEJIANG UNIV

Praseodymium-doped cerium fluoride/attapulgite up-conversion composite photocatalytic material and preparation method and application thereof

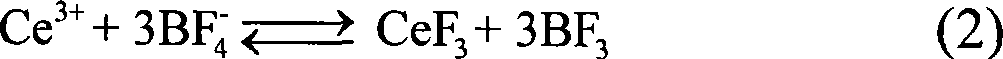

ActiveCN108479859AReduce compoundingBroaden the photoresponse rangeCatalyst activation/preparationTreatment with plural serial refining stagesMicrowaveDissolution

The invention belongs to the field of new chemical materials, and particularly relates to a praseodymium-doped cerium fluoride / attapulgite up-conversion composite photocatalytic material and a preparation method and application thereof. Pr(NO3)3.6H2O, Ce(NO3)3.6H2O, NH4F and attapulgite are added into deionized water for dissolution respectively, the system pH is adjusted to 4-5, and magnetic stirring is conducted to make the mixture evenly mixed; the mixture is transferred to a microwave hydrothermal reactor for reaction, the power is set to be 400 W, the reaction is carried out for 1-3 h, the temperature is set at 150-170 DEG C, a prepared sample is subjected to centrifugalization separation, then the sample is dried and ground, and thus the praseodymium-doped cerium fluoride / attapulgiteup-conversion composite photocatalytic material is prepared. The material can be applied to the field of photocatalytic desulfuration, and under sunlight for 3 h, the desulfulration rate can reach 95%.

Owner:CHANGZHOU UNIV

Preparation method of water-phase cerium fluoride microparticle and application thereof

InactiveCN106865594AImprove photocatalytic reactivityPromote growthWater/sewage treatment by irradiationWater treatment compoundsNitrateHexafluorotitanic acid

The invention relates to a preparation method of a water-phase cerium fluoride microparticle and application thereof, and belongs to the technical field of photocatalysis. The preparation method has the advantages that by using ceric ammonium nitrate or cerous nitrate as a cerium source, and using ammonium hexafluorotitanate or ammonium fluoride as a fluorine source, the water-phase cerium fluoride microparticle with good dispersivity is prepared by a simpler and mild preparation technology; the good phtocatalysis property is realized under the visible light condition, and the application field of cerium fluoride is widened.

Owner:KAIFENG UNIV

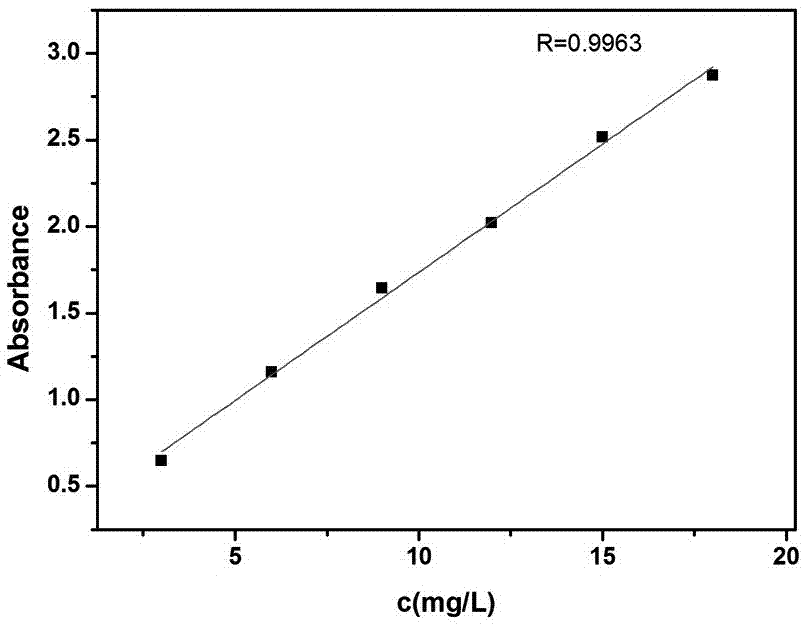

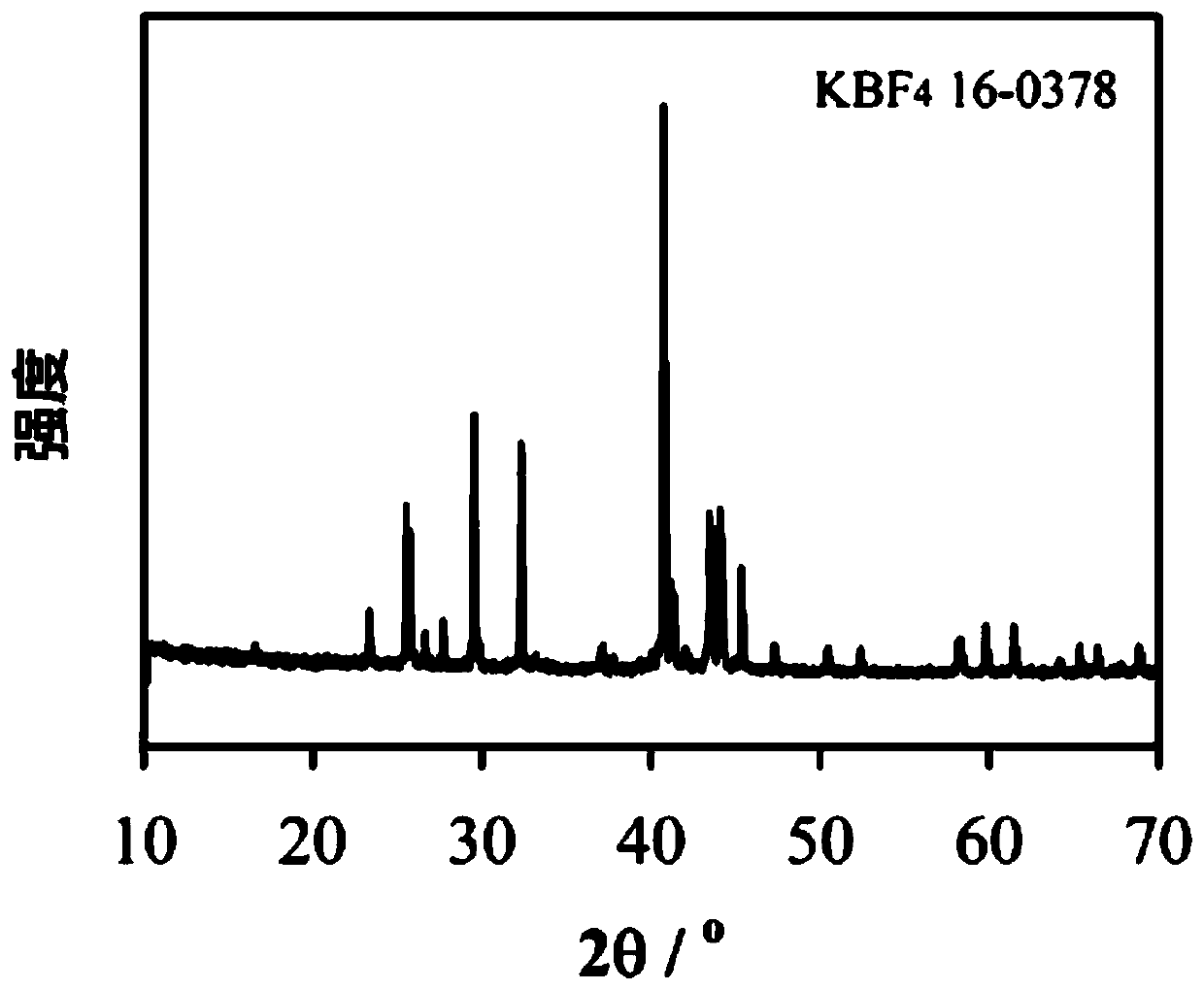

Method for recovering cerium and fluorine from bastnaesite leachate

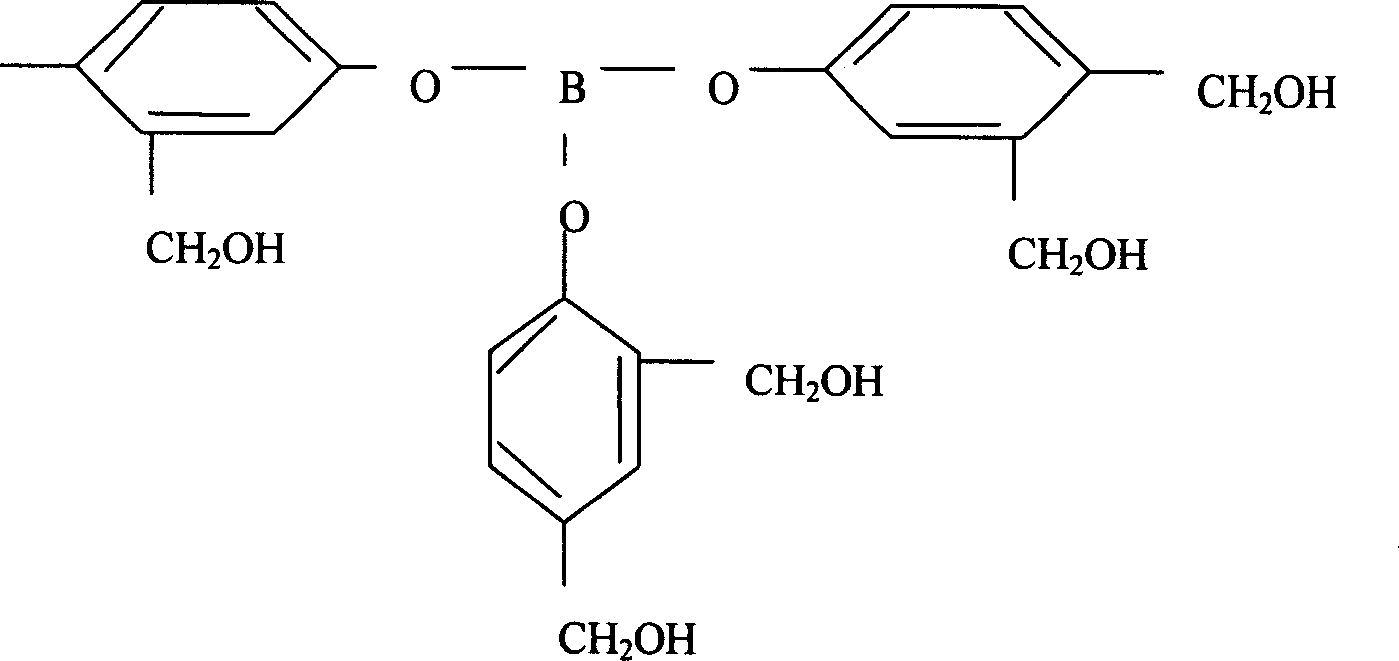

ActiveCN111484064AAvoid cloggingAvoid churnCerium oxides/hydroxidesTretrafluoboric acidPregnant leach solutionPhysical chemistry

The invention relates to a method for recovering cerium and fluorine from bastnaesite leachate, and the method comprises the following steps: taking sulfuric acid leachate of bastnaesite or bastnaesite and monazite mixed ore as a raw material solution, and adding 0.02-10g / L of boric acid into the raw material solution; extracting cerium in the raw material solution by using an extracting agent, and then carrying out reverse extraction, precipitation, separation and roasting to obtain CeO2; and then taking trialkyl phosphine oxide as an extracting agent to extract F in the extraction raffinate,and carrying out reverse extraction by using a KOH solution to obtain KBF4. According to the method disclosed by the invention, the cerium and the fluorine are separately recovered, and the F is prepared into the KBF4 in strip liquor, so that the problems that a mixing clarification tank is easily blocked in the operation process of a cerium fluoride precipitate in an extraction section, and an organic phase is lost due to the fact that the cerium fluoride precipitate carries the organic phase are avoided. According to the method, the Ce is recovered by using the extraction agents P507 and P204, so that the consumption of Cyanex923 is reduced, and the cost is reduced. Compared with a CeF3 product, the KBF4 product has more definite market requirements and higher additional value, and themethod better meets the market requirements and enterprise requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

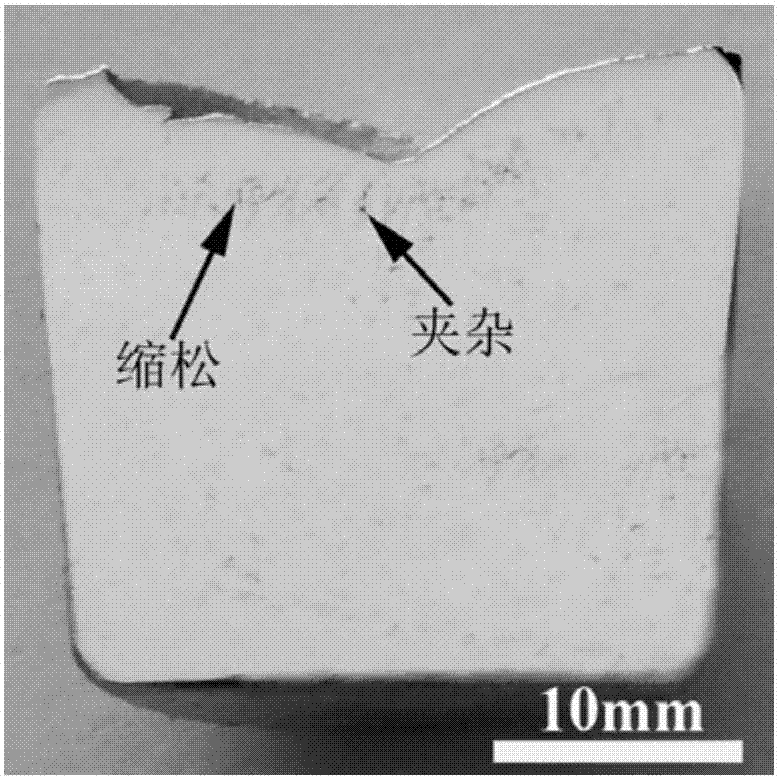

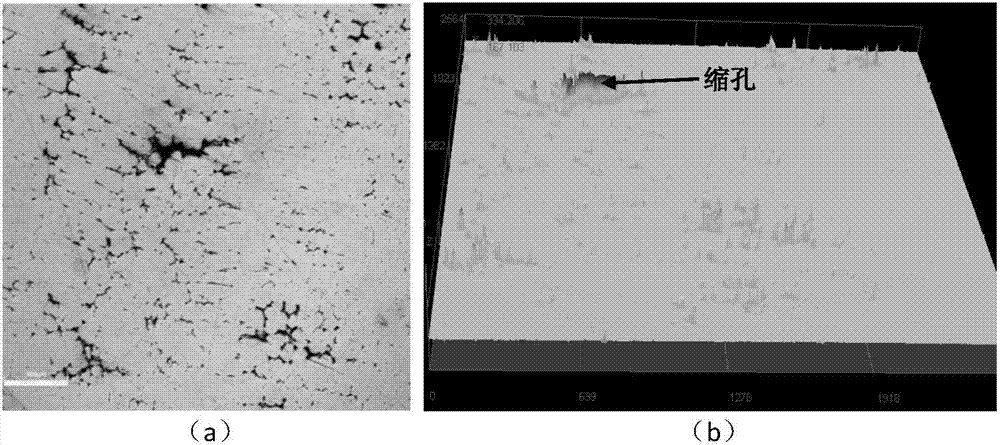

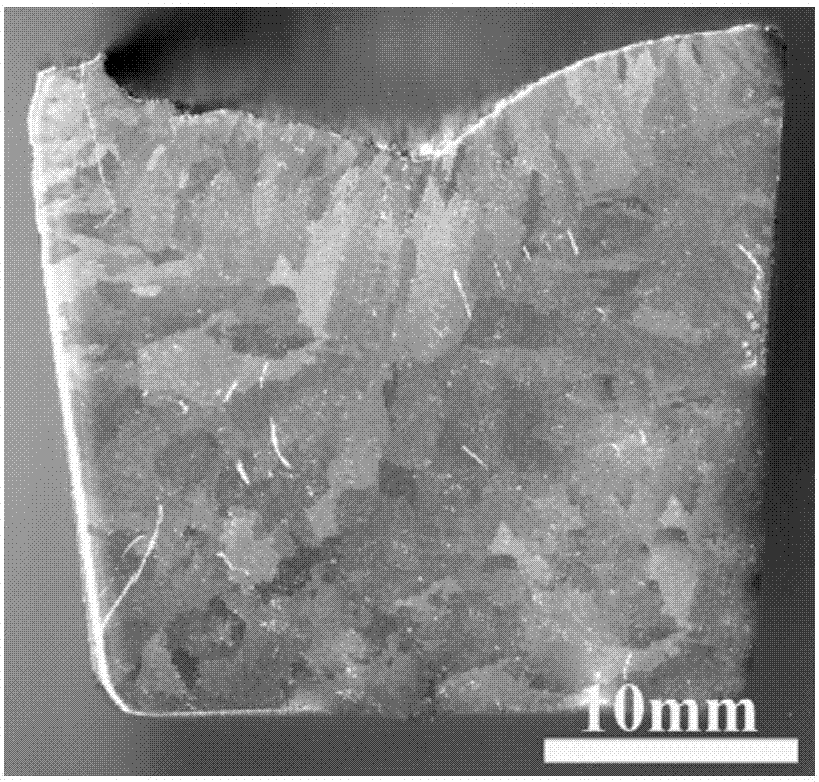

Aluminum alloy refining alterant and preparation method and application thereof

The invention discloses an aluminum alloy refining alterant and a preparation method and application thereof and belongs to the technical field of aluminum alloy smelting processing. The refining agent is composed of the components of, in percentage by mass, 30-60% of potassium chloride, 20-30% of sodium chloride, 10-25% of cerium fluoride and 10-25% of potassium fluoroaluminate. The invention furthermore provides the preparation method of the aluminum alloy refining alterant. The aluminum alloy refining alterant prepared through the method has the characteristics of being good in degassing and impurity removal effect, high in grain refining capacity, capable of improving microstructures of aluminum alloy ingot castings and the like and is good in industrial application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

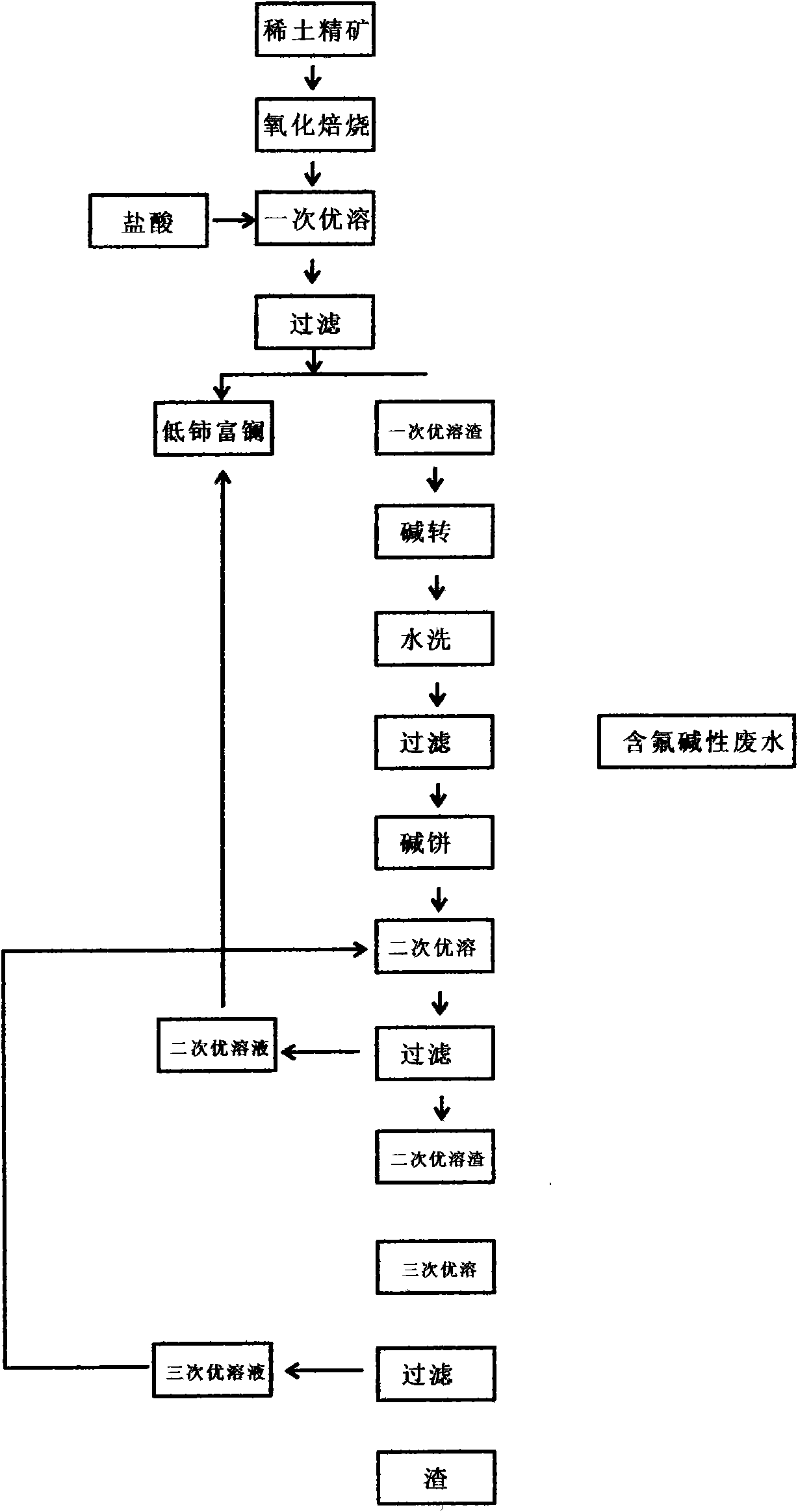

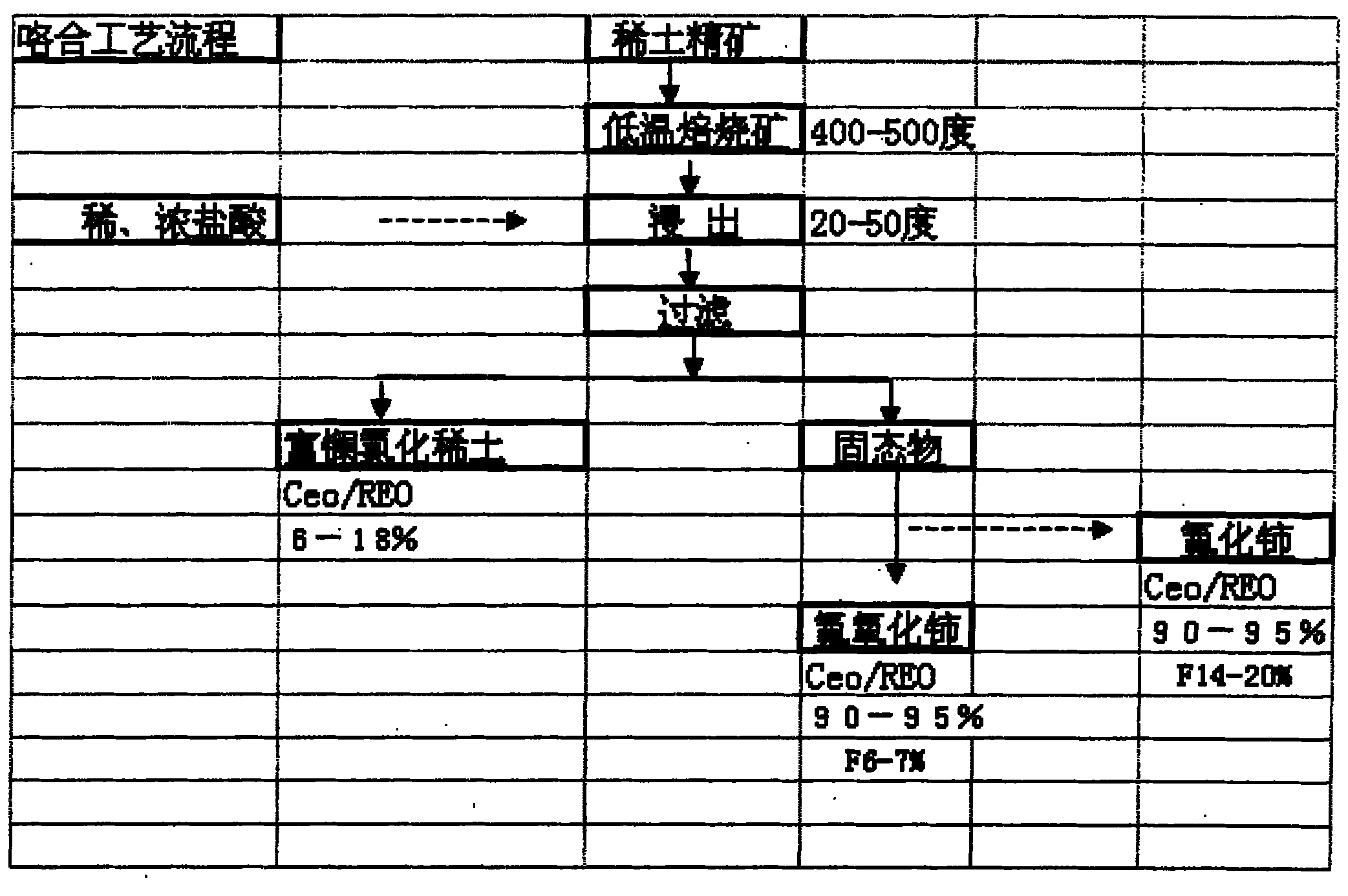

Bastnaesite (bastnasite) separation method

The invention relates to nonferrous metal rare earth separation, concretely relates to a method for separating lanthanum-enriched rare earth chloride, cerium fluoride and cerium oxyfluoride by bastnaesite and bastnasite hydrochloride. The method comprises the following steps: A, oxidizing and roasting bastnaesite and bastnasite at low temperature; B, dissolving out the oxidized and roasted concentrate at low temperature by hydrochloric acid; C, filtering and separating slag and liquid after dissolving out; D, separating cerium fluoride and fluoride ceria during the process of separating slag. The bastnaesite (bastnasite) separation method of the invention has the advantages that zero discharge of waste water is realized, the cost is reduced, product value is increased, the process flow is minimized and the labor intensity is reduced.

Owner:周毅

Mechanical anti-aging coating and preparation method thereof

InactiveCN106519839ANot easy to ageNot easy to fall offFireproof paintsPolyester coatingsEmulsionPentaerythritol

The invention relates to a mechanical anti-aging coating and a preparation method thereof. The preparation method comprises steps as follows: (1) weighing components in parts by weight as follows: 5-10 parts of rare-earth cerium fluoride, 7-11 parts of pentaerythritol, 4-8 parts of sodium hexametaphosphate, 3-6 parts of alkyd resin, 1-3 parts of diatomite, 9-14 parts of an acrylic emulsion, 6-10 parts of a shell powder and 4-9 parts of talc; (2) adding rare-earth cerium fluoride and pentaerythritol to a reaction kettle, adding the acrylic emulsion after stirring, heating the mixture to 80 DEG C, and stirring the mixture for a reaction; (3) adding sodium hexametaphosphate, and stirring the mixture at the rotating speed of 1,200 rpm for 60 min; (4) adding alkyd resin and diatomite, heating the mixture to 70 DEG C, stirring the mixture at the constant temperature, and cooling the mixture to the room temperature; (5) adding the shell powder, and stirring the mixture to be uniform to obtain a mixed solution; (6) adding the mixed solution to a stirrer and adding the talc. The coating has the benefits as follows: the coating is high-temperature-resistant, cannot age easily and cannot age and fall off easily even under the high-temperature exposure condition.

Owner:程志鹏

Preparation method of automobile engine crankshaft through powder metallurgy

InactiveCN105478781AImprove performance indicatorsHigh glossTurbinesOther manufacturing equipments/toolsPerformance indexStearic acid

The invention discloses a preparation method of an automobile engine crankshaft through powder metallurgy. The preparation method comprises the following process step of preparation of the following raw materials in parts by weight: 70-72 parts of iron powder, 1.3-1.8 parts of molybdenum powder, 1.3-1.8 parts of zinc oxide, 4.5-5.5 parts of stearic acid, 1.4-1.8 parts of tantalum carbide, 1.4-1.6 parts of silicon nitride, 1.2-1.5 parts of nickel powder, 2.2-3.4 parts of tungsten powder, 1.5-1.9 parts of cerium fluoride, 0.3-0.5 part of graphite powder, 1.3-1.6 parts of an inhibition phase and 1.5-1.8 parts of a lubricant, wherein the inhibition phase is prepared from the following raw materials in percentage by mass: 4-7% of NbC, 20-22% of VC, 13-15% of TaC, 8-10% of graphene and the balance being carbon powder. The preparation method disclosed by the invention has the advantages that a special proportioning of the raw materials is adopted, so that the performance index of produced products is high, the lustrousness is good, the stability is high, the phenomena of cracks and the like are not liable to occur, and the service life is long.

Owner:WUHU HONGKUN AUTO PARTS

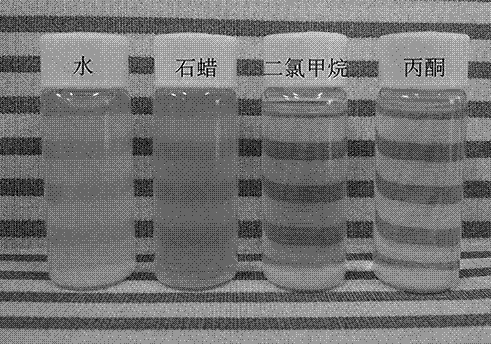

Aluminum powder coloring coating with long-acting lubrication and corrosion prevention functions and preparation method thereof

PendingCN111117324ASolve friction and wear problemsSolve corrosiveAnti-corrosive paintsEpoxy resin coatingsSalt spray testFirming agent

The invention discloses an aluminum coloring coating with long-acting lubrication and corrosion prevention functions. The aluminum coloring coating is composed of a binder, a solid lubricant, an additive and a dispersion medium. The solid lubricant is polytetrafluoroethylene, the binder is bisphenol A epoxy resin, the curing agent is diaminodiphenol, the additive is flake aluminum silver powder, cerium fluoride and oxidized polyethlene wax powder, and the dispersion medium is a mixed solvent of ethanol, acetone and ethylene glycol monoethyl ether. The coating has the advantages of high adhesive force, good flexibility and strong impact resistance, and has the lubricating and anti-corrosion functions, especially, the neutral salt spray test can reach more than 1000 hours, the aluminum coloring coating can used for surface protection of titanium alloy, stainless steel, nickel-based alloy fasteners and threaded connection, can solve the problems of frictional wear and potential corrosionof the fasteners and body structure connecting pieces, and improves the pre-tightening force level under the condition of meeting interference assembly; and the aluminum coloring coating can also be applied to structural fasteners of other high-end aviation weapons, and has a wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fabric Conditioning Fabric Care Articles Comprising a Particulate Lubricant Agent

InactiveUS20110028380A1Inorganic/elemental detergent compounding agentsCationic surface-active compoundsParticulatesPlatelet

A fabric conditioning articles containing a particulate lubricant agent comprising a platelet which is optionally hexagonal in shape, said platelet optionally having a planar aspect ratio of particle size to thickness of from about 50 to about 300. Non-limiting examples of suitable particulate lubricant agents can include materials such as a boron nitride, a tungsten disulfide, a molybdenum disulfide, a polytetrafluorethylene (PTFE), a talc, a calcium fluoride, a cerium fluoride and a tungsten disulfide, and a mixture thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Method for directly preparing cerium fluoride by extraction and separation

ActiveCN102465203AEliminate the preparation processGranularity controllableFluoride preparationRare earth metal compoundsRare earthReducing agent

The invention relates to a method for directly preparing cerium fluoride by extraction and separation, which comprises the following steps: 1) taking a sulphuric acid rare earth solution containing quadravalence cerium and fluorine or a nitric acid rare earth solution as a raw material, using a P507 organic solvent extractant for extraction and separation to obtain organic phase loading quadravalence cerium and fluorine; 2) using a stripping liquid prepared by inorganic acid and a reducing agent for stripping the loaded organic phase obtained in the step 1), reducing the Ce<4+> ion in the loaded organic phase by a reducing substance in the stripping liquid to Ce<3+> ion, combining with fluorine in the loaded organic phase to form cerium fluoride deposition and then enters in water phase, filtering to obtain the cerium fluoride powder. The method for directly preparing cerium fluoride by extraction and separation has the advantages that quadravalence cerium and fluorine in the organic phase are stripped by a cerium fluoride deposition mode to water phase during the rare earth extraction separation process, according to the invention, the separation, purification and material preparation are combined, so that cerium fluoride deposition preparation process can be omitted, the technology flow can be shortened, the powder material with controllable granularity and uniform particle size distribution can be obtained. The preparation cost is low, fluorine in ore can be effectively recovered and used, and the original auxiliary material consumption and production cost can be reduced.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for preparing terbium-doped cerium fluoride porous nanospheres based on herring sperm DNA template

The invention relates to a method for preparing terbium-doped cerium fluoride porous nanospheres based on a herring sperm deoxyribonucleic acid (DNA) template, and belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparing mixed solution, namely dissolving Tb4O7 in nitric acid, evaporating to obtain a Tb(NO3)3 crystal, adding deionized water and Ce(NO3)3.6H2O to obtain mixed solution of Ce(NO3)3 and Tb(NO3)3 (the terbium nitrate accounts for 5 mole percent), and dripping herring sperm DNA aqueous solution into the mixed solution of Ce(NO3)3 and Tb(NO3)3 to form mixed solution of Ce(NO3)3, Tb(NO3)3 and herring sperm DNA; (2) preparing CeF3:5 percent Tb<3+> precipitates, namely dripping NH4F aqueous solution into the mixed solution to obtain the CeF3:5 percent Tb<3+> precipitates; and (3) preparing CeF3:5 percent Tb<3+> porous nanospheres, namely transferring the CeF3:5 percent Tb<3+> precipitates to a hydrothermal reaction kettle, reacting at the temperature of 160 DEG C for 12 hours, performing centrifugal separation on precipitates, washing by using absolute ethanol, and performing vacuum drying at the temperature of 60 DEG C for 24 hours to obtain the CeF3:5 percent Tb<3+> porous nanospheres with good crystal forms and the diameter of 30 to 60nm. The method is simple, practicable, economic and environmental-friendly, and has a wide application prospect.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com