Hot pressing sintering method for cerium fluoride scintillation ceramic and cerium fluoride scintillation ceramic prepared thereby

A technology of hot pressing sintering and scintillation ceramics, which is applied in the field of cerium fluoride scintillation ceramics, which can solve the problems of ceramic infeasibility and achieve the effects of high density, small crystal grains and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

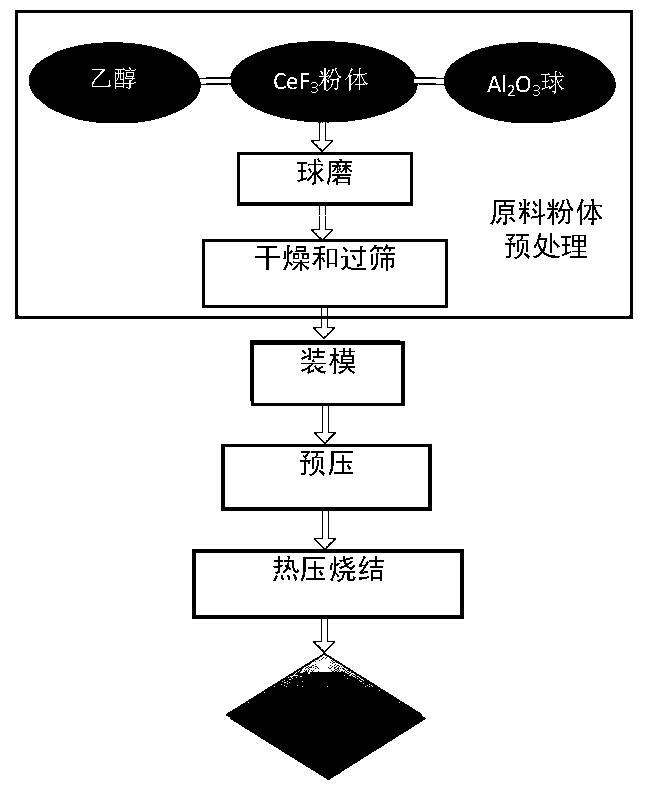

[0065] The preparation process is as follows:

[0066] (1) Put the high-purity raw material powder (Alfa company, purity 99.9%) directly into the alloy mold. Add graphite paper between the powder and the pressure head. The indenter, the inner wall of the mold cavity and the graphite paper are wiped clean with absolute ethanol.

[0067] (2) Pre-press the powder under a pressure of 20MPa, and remove the pressure after holding the pressure for 30s.

[0068] (3) Use mechanical pump and molecular pump to evacuate, and the vacuum degree reaches -3 Pa began to heat up. The heating rate is 5°C / min, and the holding temperature is 800°C. After 5 minutes of heat preservation, pressurization was started. The pressurization speed is 10MPa / min, pressurized to 300MPa in 30min, and the heat preservation and pressure holding are for 2h. At the end of the heat preservation, the manual decompression starts, and the decompression speed is consistent with the pressurization speed. The coolin...

Embodiment 2

[0080] (1) Weigh 40 g of high-purity raw material powder (Alfa company, purity 99.9%). Added to high purity Al 2 o 3 The ball mill tank, pre-added 120g high-purity Al in the ball mill tank 2 o 3 Grinding balls. Measure 19ml of absolute ethanol and add it to the ball mill jar. The ball milling process was carried out on a German star-shaped high-energy ball mill. The rotation speed is 120rmp / min, and the ball milling time is 5h.

[0081] (2) The slurry obtained by ball milling was poured into a drying dish, and dried in an oven for 1 hour, and the temperature was set at 80°C. After drying, pass through a 200-mesh sieve.

[0082] (3) The dried powder is put into a high pressure resistant mold. Same as step (1) in Example 1

[0083] (4) Same as step (2) in Example 1

[0084] (5) Same as step (3) in Example 1

[0085] Figure 10 It is a physical photograph of the ceramics of Example 2, with a thickness of 0.93mm.

[0086] Figure 11 is the transmittance curve of the ...

Embodiment 3

[0088] The holding temperature in the preparation process (3) is 950°C. All the other steps are the same as in Example 1.

[0089] Figure 12 is the transmittance curve of the ceramics of Example 3, and the reference curve is the transmittance of the ceramics of Example 1. The thickness of the ceramic sample of Example 3 is 0.85 mm, which is thicker than that of Example 1 ceramics of 0.75 mm. However, the transmittance is significantly improved compared with the ceramic in Example 1, which shows that increasing the hot pressing sintering temperature is beneficial to the increase of transmittance. The transmittance has reached 10% to 22% in the range of visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com