Rare earth silicate double salt scintillating material and preparation method thereof

A technology of scintillation materials and rare earth nitrates, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of unfavorable crystal growth, low luminous efficiency, and more energy consumption, and achieve good physical and chemical stability and scintillation performance, The effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

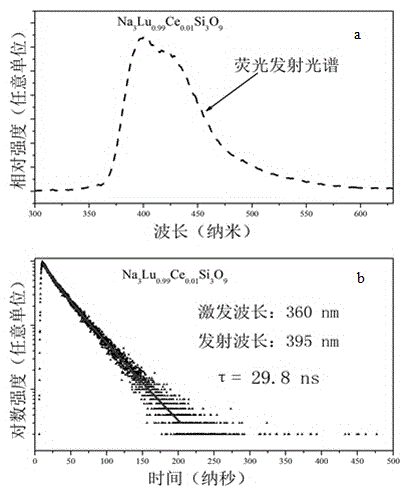

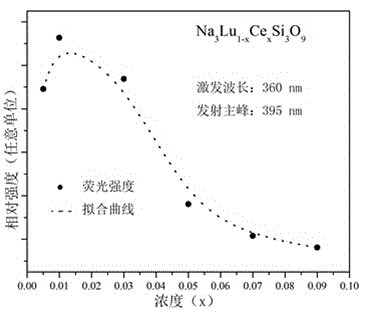

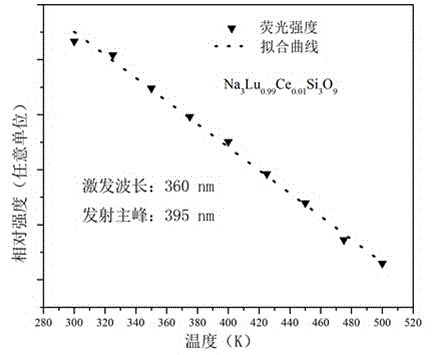

[0027] Weigh silicon dioxide (SiO 2 ) 0.9013 g, anhydrous sodium carbonate (Na 2 CO 3 ) 0.7949 g, lutetium oxide (Lu 2 o 3 ) 0.9848 g, cerium oxide (CeO 2 ) 0.0043 g, ground and mixed evenly in a mortar, transferred to an alumina crucible, put the crucible into a large alumina crucible, then put the large crucible into a heating furnace, and calcined at 1100 °C for 8 Hours, naturally cooled to room temperature, and ground to obtain powder scintillation material.

Embodiment 2

[0029] Weigh silicon dioxide (SiO 2 ) 0.9013 g, anhydrous sodium carbonate (Na 2 CO 3 ) 0.7949 g, lutetium oxide (Lu 2 o 3 ) 0.9848 g, cerium oxide (CeO 2 ) 0.0086 g, ground and mixed evenly in a mortar, transferred to an alumina crucible, put the crucible into a large alumina crucible, then put the large crucible into a heating furnace, and calcined at 1100 °C for 8 Hours, naturally cooled to room temperature, and ground to obtain powder scintillation material.

Embodiment 3

[0031] Weigh silicon dioxide (SiO 2 ) 0.9013 g, anhydrous sodium carbonate (Na 2 CO 3 ) 0.7949 g, lutetium oxide (Lu 2 o 3 ) 0.9848 g, cerium oxide (CeO 2 ) 0.0258 g, ground and mixed evenly in a mortar, transferred to an alumina crucible, put the crucible into a large alumina crucible, then put the large crucible into a heating furnace, and calcined at 1100 °C for 8 Hours, naturally cooled to room temperature, and ground to obtain powder scintillation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com