Patents

Literature

92results about How to "Improve flicker performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

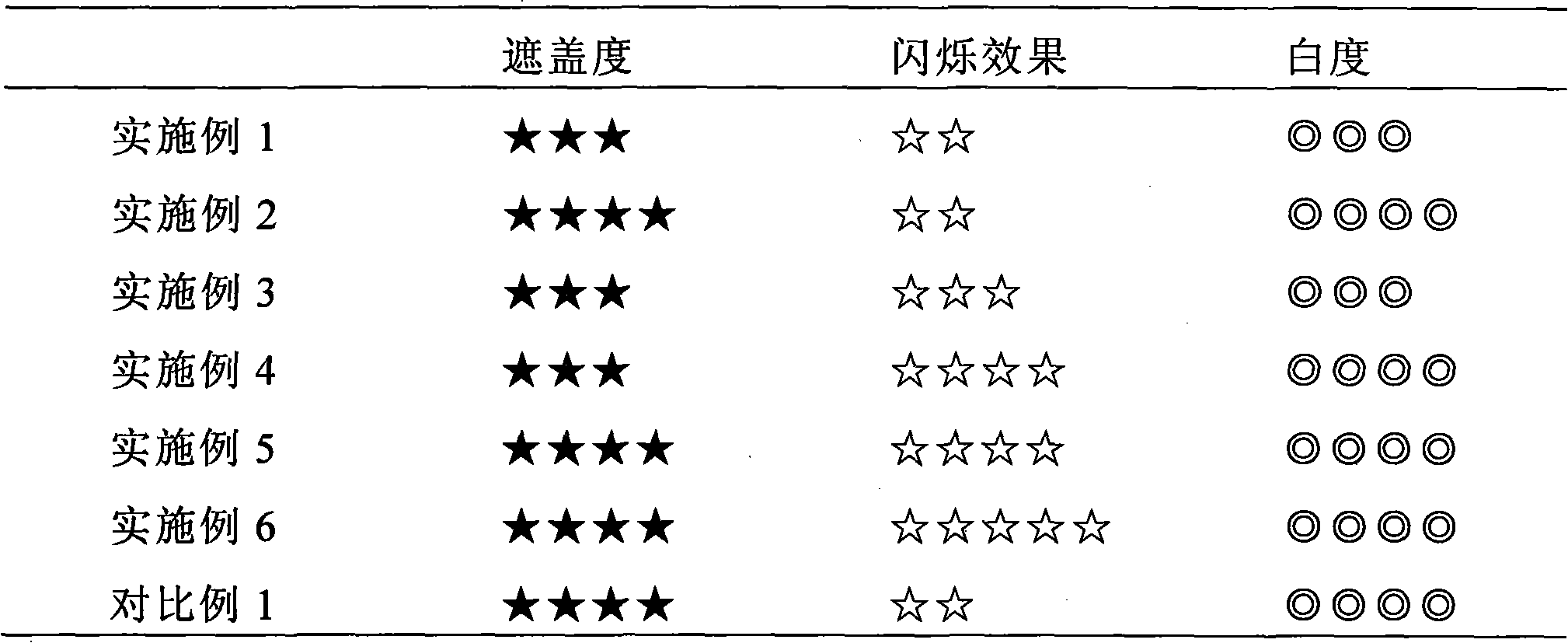

Aesthetic resin for improving white blink effect and preparation method thereof

The invention relates to an aesthetic resin for improving white blink effect and a preparation method thereof. The aesthetic resin comprises 100 weight portions of resin matrix, 0.1-5.0 weight portions of white pigment, 0.1-2.0 weight portions of pearlescent pigment, 0-0.5 weight portions of cross-linked polymer, 0.1-3.0 weight portions of lubricant, 0.1-1.0 weight portions of anti-oxidant, and 0.001-0.15 weight portions of fluorescent brightener. The preparation method comprises the following steps: stirring and mixing the raw materials in a high speed mixer, then putting the mixed raw materials in a double screw extruder, under the conveying, shearing and mixing of the screws, melting and compounding the materials, then carrying out extrusion, pulling, cooling, and dicing on the materials to obtain the product. Compared with the prior art, the disadvantages of poor blink effect of present white aesthetic resin under the conditions of high whiteness and high-cover ratio are overcome, thus the apparent effect of the white aesthetic resin is greatly enhanced, the feasibility of a white blink free-spraying scheme is increased, and the market potential in the fields of automobile, household appliance, consumer electronics and the like is raised.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Aesthetical resin capable of eliminating injection-molding weld lines and preparation method thereof

The invention relates to an aesthetical resin capable of eliminating injection-molding weld lines and a preparation method thereof. The aesthetical resin comprises the following components in part by weight: 100 parts of thermoplastic resin, 0 to 5 parts of powdered aluminium, 0 to 5 parts of diamantes, 0.1 to 1 parts of antioxidant, 0.1 to 1 parts of dispersing agent and 0.1 to 5 parts of pigment; after the materials are prepared according to the components and the parts by weight, the materials are put into a medium-speed mixer, the rotating speed and the time are controlled, mixed material is obtained, and finally, a double-screw extruder is used to extrude and granulate the mixed material, so that the product is obtained. Compared with the prior art, the invention has the advantages of high surface glossiness, good mirror effect, bright color, good flowability, simple and continuous flow, high production efficiency and stable product quality, meets SGS and ROHS heavy metal safety standards and can be recycled.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

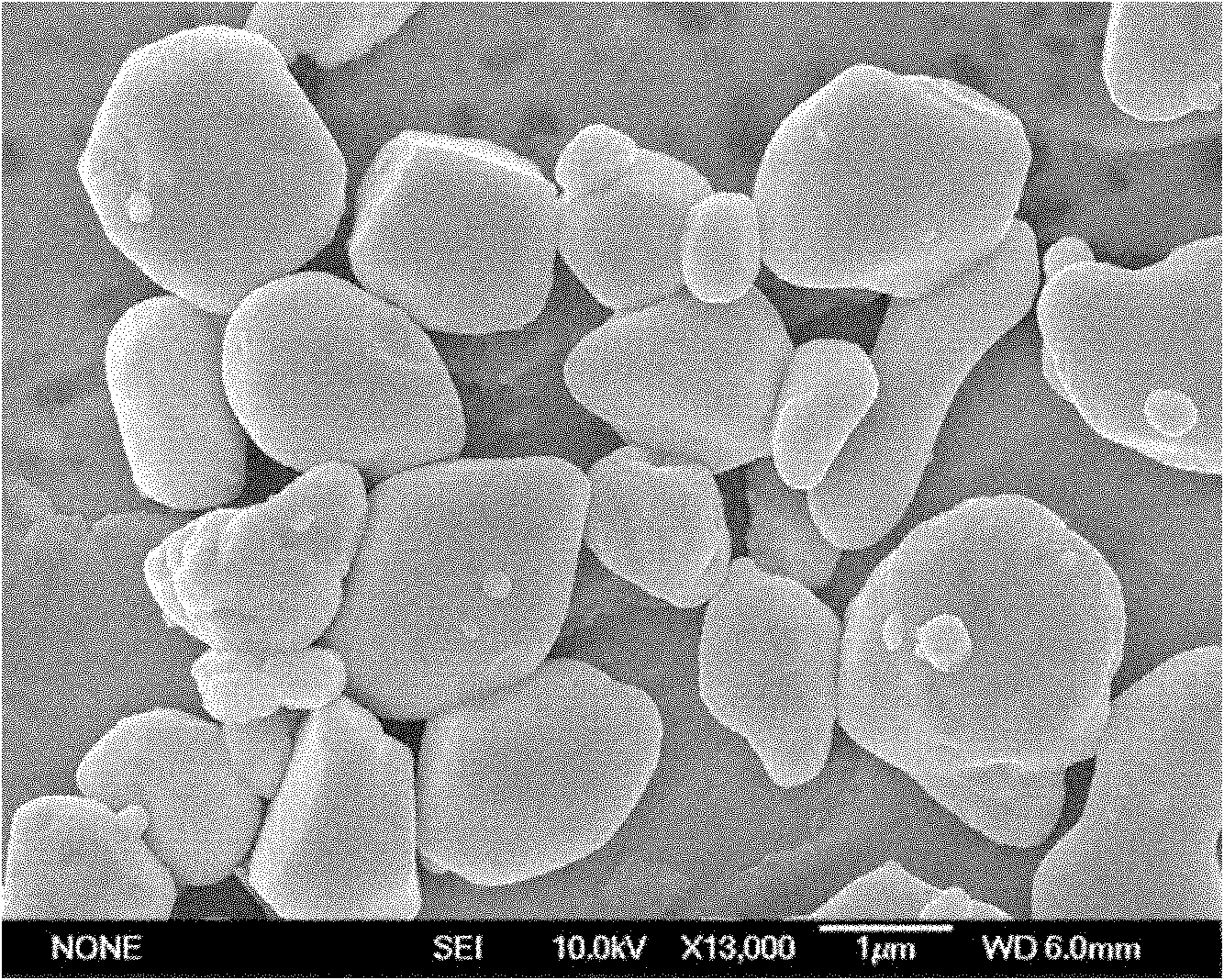

Method for manufacturing novel ball aluminum pigment

ActiveCN101629027AGood dispersionImprove flicker performancePigment physical treatmentPigment treatment with non-polymer organic compoundsGlass ballFilter press

The invention relates to a method for manufacturing a novel ball aluminum pigment, which adopts a formula comprising the following raw materials: atomized ball aluminum powder, organic matters, aerosol and a ball milling medium. The method comprises the following steps: (1) mixing the atomized ball aluminum powder, the organic matters and the aerosol in a certain proportion and then putting the mixed raw materials in a vertical ball mill for milling by using glass balls with a diameter of 0.5-1 mm as the milling medium; (2) carrying out sieving and filter pressing to manufacture raw materials into an aluminum paste filter cake; and (3) adding the aluminum paste filter cake to a proper organic matter to knead so as to manufacture a finished ball aluminum pigment product.

Owner:长沙族兴新材料股份有限公司

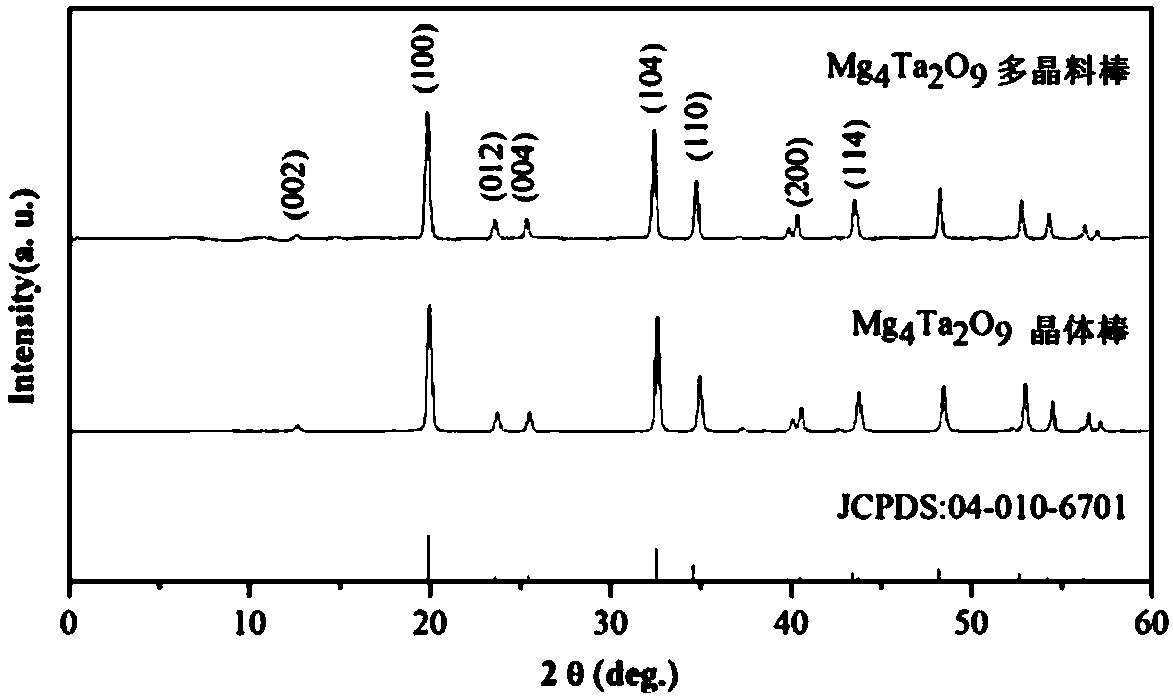

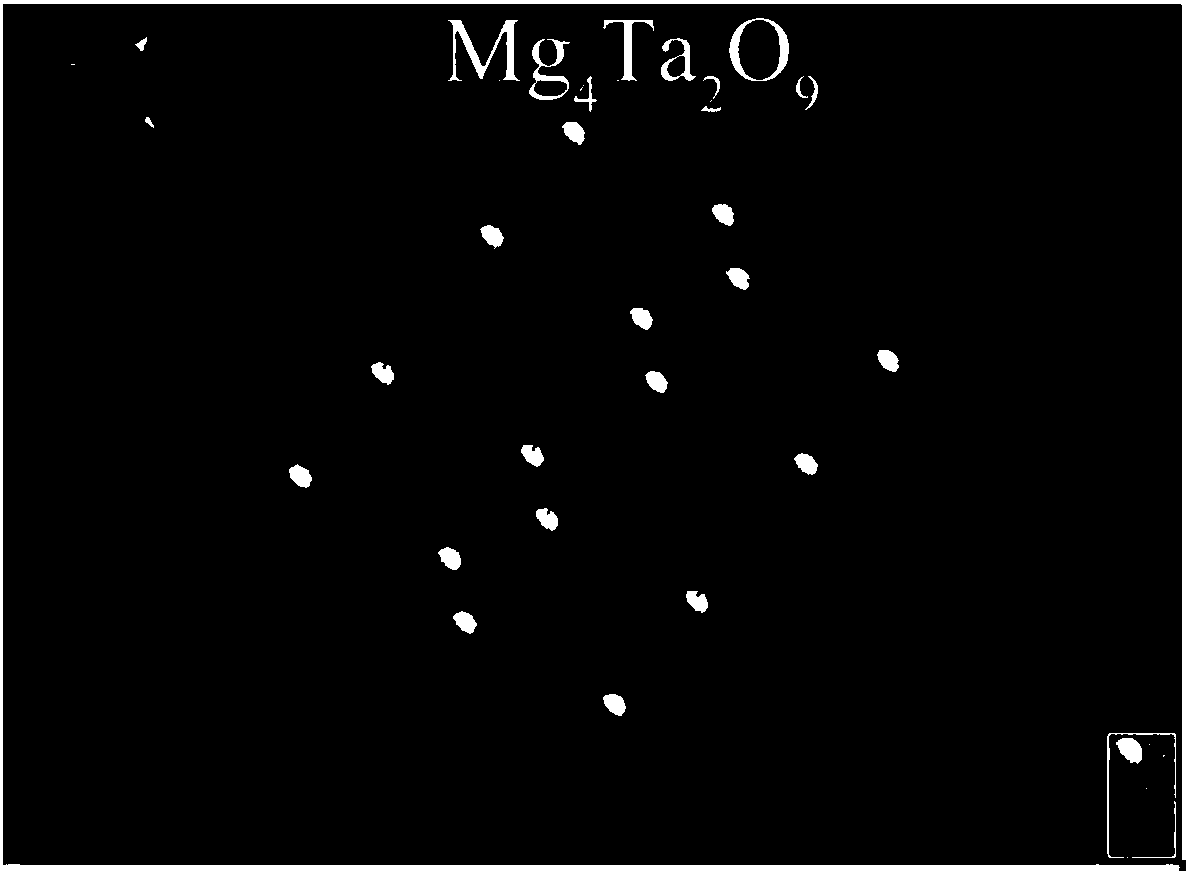

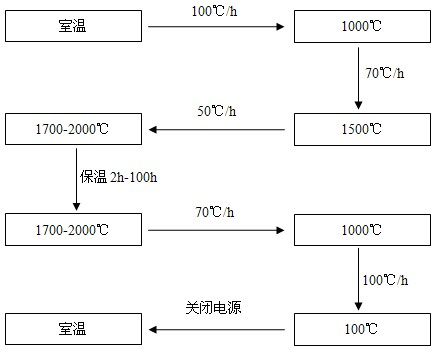

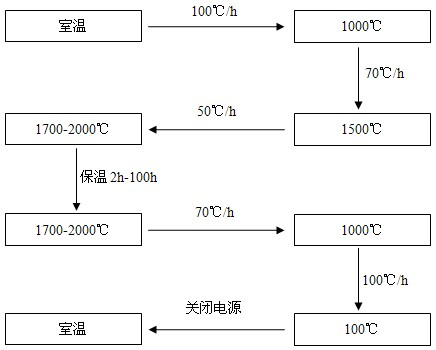

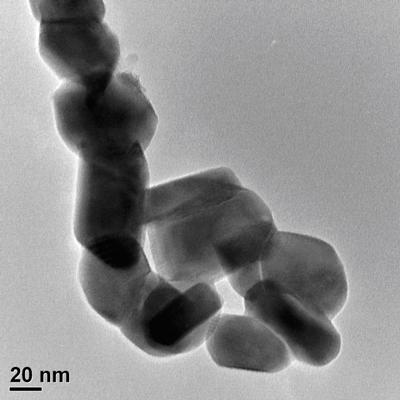

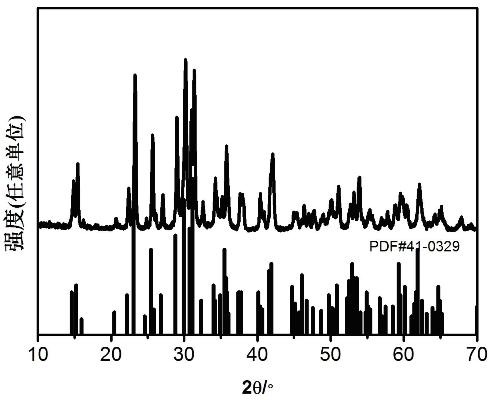

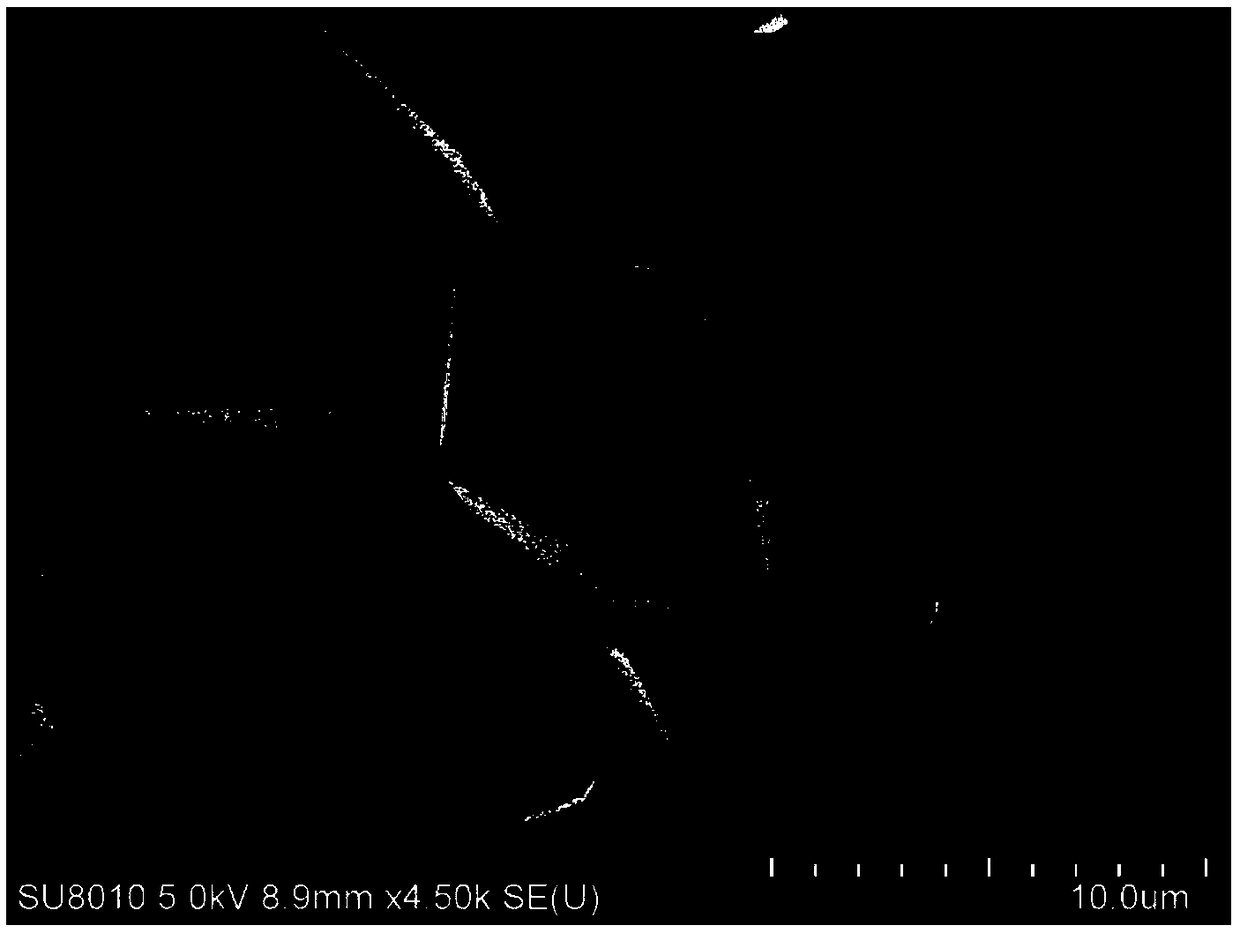

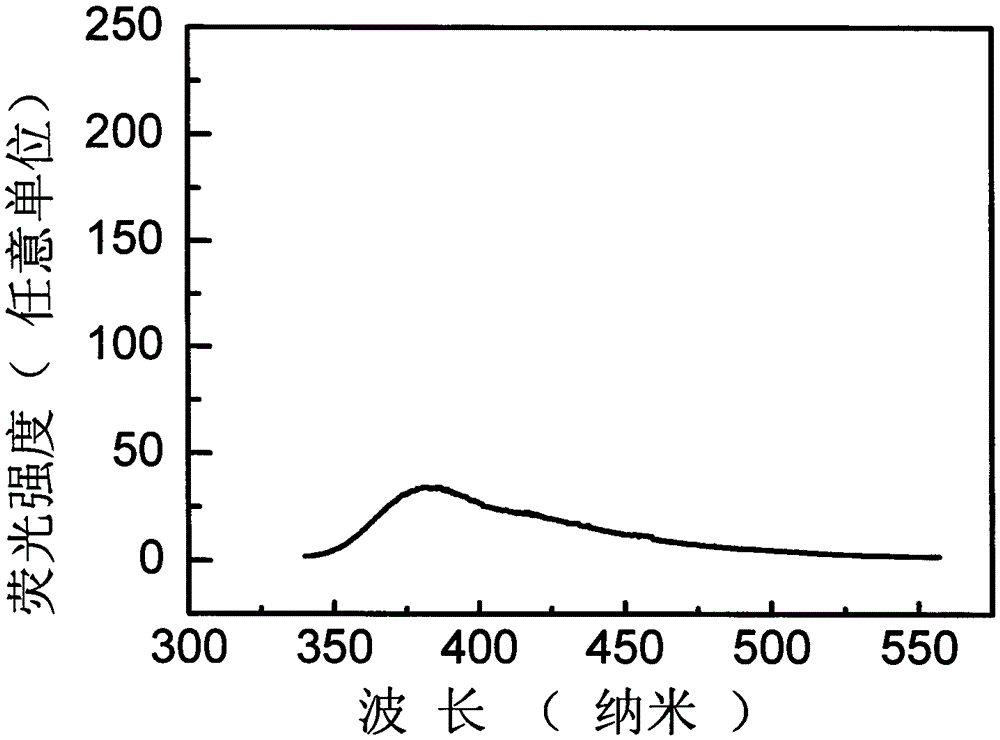

Intrinsic luminescent scintillation crystal magnesium tantalum oxide, and preparation method and use thereof

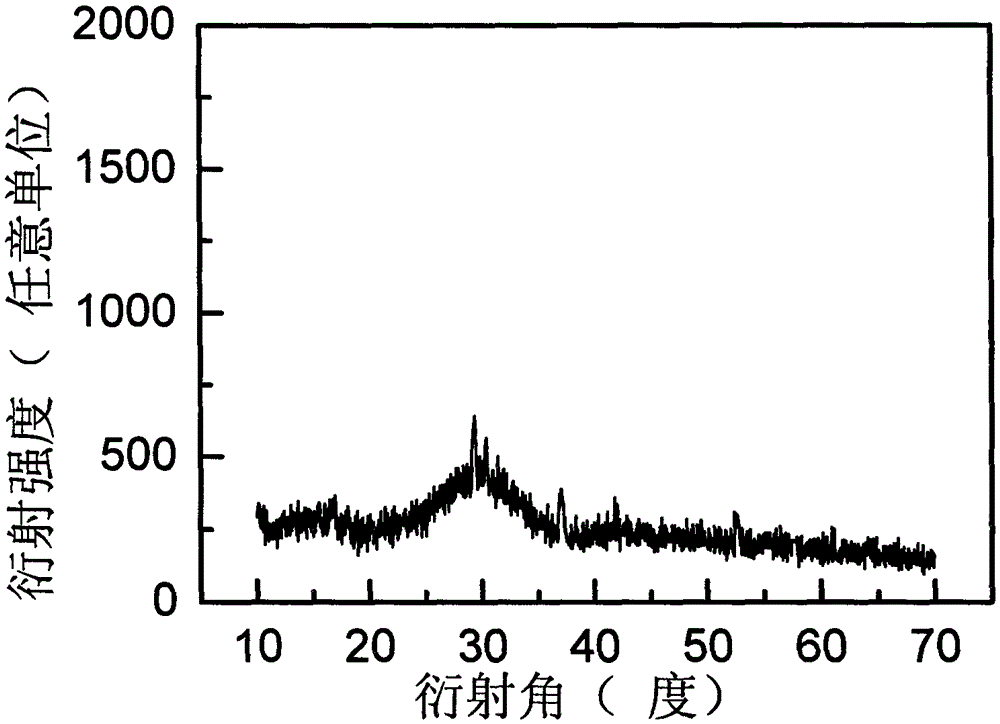

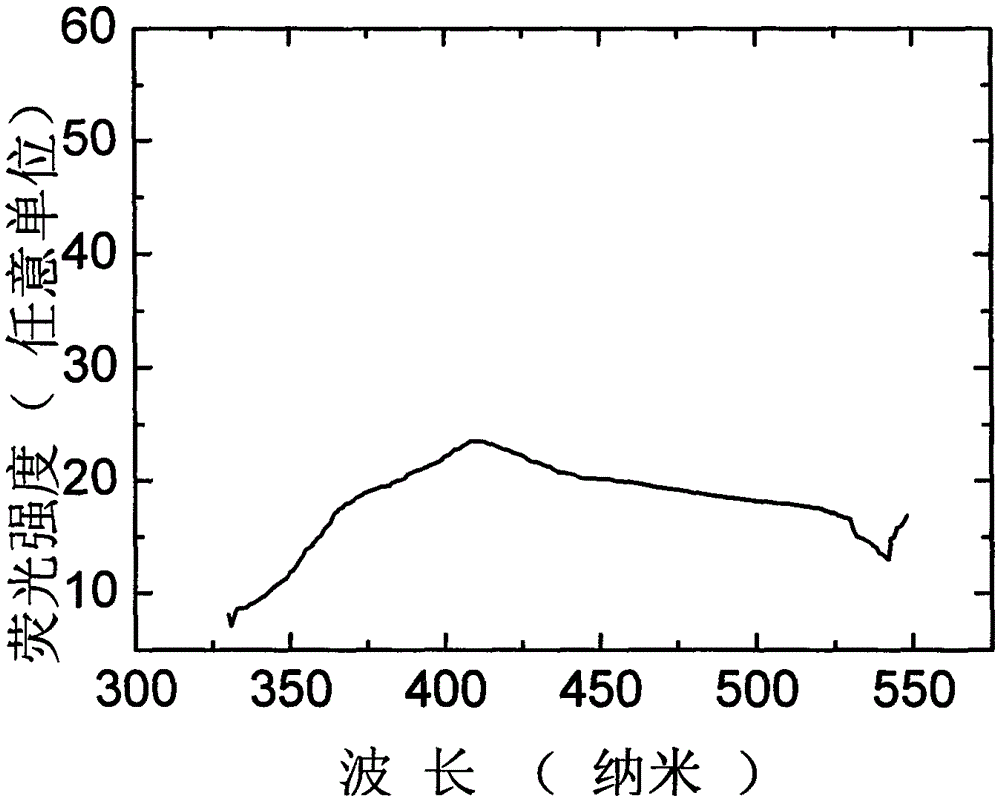

ActiveCN108221055AStable structureImprove flicker performancePolycrystalline material growthBy zone-melting liquidsHexagonal crystal systemScintillation crystals

The invention provides a scintillation crystal magnesium tantalum oxide. The chemical formula of the crystal is Mg4Ta2O9, the crystal belongs to a hexagonal crystal system and has an ilmenite structure, the scintillation light yield is 16000 photons / M eV, the decay time is 5 [mu]s, and the energy resolution is 6.2%. The invention also provides a use of the Mg4Ta2O9 as a scintillation crystal material, and a preparation method of the Mg4Ta2O9. The preparation method comprises the following steps: MgO and Ta2O5 which are used as initial powders are uniformly mixed according to a molar ratio of 4.04:1, and are processed to form a raw material rod, the raw material rod is pre-sintered to obtain a pure-phase, dense and uniform polycrystalline rod, and the colorless and transparent rod-shaped crystal having a size of phi 4 mm * L 62 mm grows by adopting an optical floating zone technology. The method has the advantages of stable melting zone, simplicity in operation, effectiveness in inhibition of the volatilization of MgO, and maintenance of uniform composition and stable crystal quality.

Owner:SHANGHAI INST OF TECH

Bismuth silicate-germanate mixed crystal and preparation method thereof

InactiveCN102011187AImprove flicker performanceReduce manufacturing costPolycrystalline material growthFrom frozen solutionsCruciblePhysical chemistry

The invention discloses a bismuth silicate-germanate mixed crystal and a preparation method thereof, belonging to the single crystal field. The molecular formula of the bismuth silicate-germanate mixed crystal is Bi4Si3-xGexO12. The preparation method comprises the following steps: using high-purity Bi2O3, SiO2 and GeO2 as raw materials to fully grind, presinter and obtain a polycrystalline material; and placing seed crystal at the bottom of a crucible in advance, placing the synthesized polycrystalline material in the crucible, and transferring the crucible to a crystal growing furnace while controlling the temperature to 1050-1150 DEG C, the temperature gradient of the solid-liquid interface to 20-50 DEG C / cm and the growth velocity to 0.2-0.5mm / h. The raw material components of the bismuth silicate-germanate mixed crystal provided by the invention are adjustable and are distributed evenly; the mixed crystal has the scintillation property of bismuth silicate and the scintillation property of bismuth germanate, the mixed crystal has large size; the preparation method adopts stable temperature field and simple processing equipment; and multicrystal can grow at the same time, the growth efficiency of the mixed crystal is high, the production cost is low and the mixed crystal is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Method for preparing lutetium gadolinium oxide transparent ceramic scintillator

The invention discloses a method for preparing a transparent Gd2(1-x-y)Lu2xEu2yO3 ceramic scintillator. Gd2(1-x-y)Lu2xEu2yO3 ceramic powder is prepared by a combustion method which uses glycine as a combustion agent, the dry powder compression is adopted, then the pressureless sintering is performed in vacuum or reducing atmosphere, the sintering temperature is between 1,600 and 1,900 DEG C, and the transparent Gd2(1-x-y)Lu2xEu2yO3 ceramic scintillator can be obtained. The ceramic scintillator emits red light under the excitation of ultraviolet light or X rays, and can be used for scintillating materials of imaging and detection of medical and industrial X rays.

Owner:CHINA JILIANG UNIV

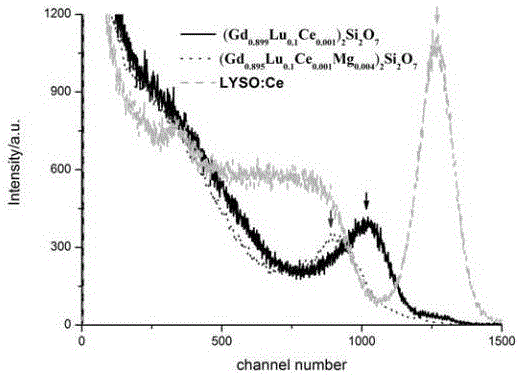

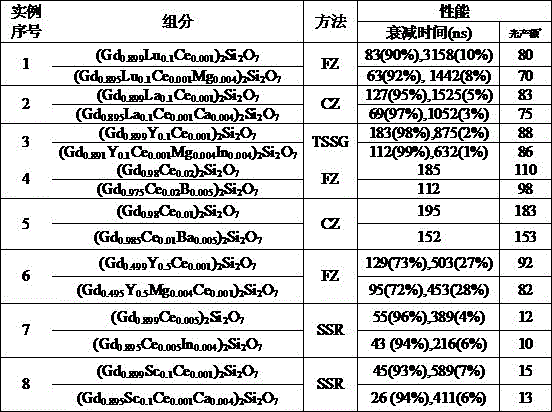

Cerium-doped gadolinium disilicate luminescent material and preparation method thereof

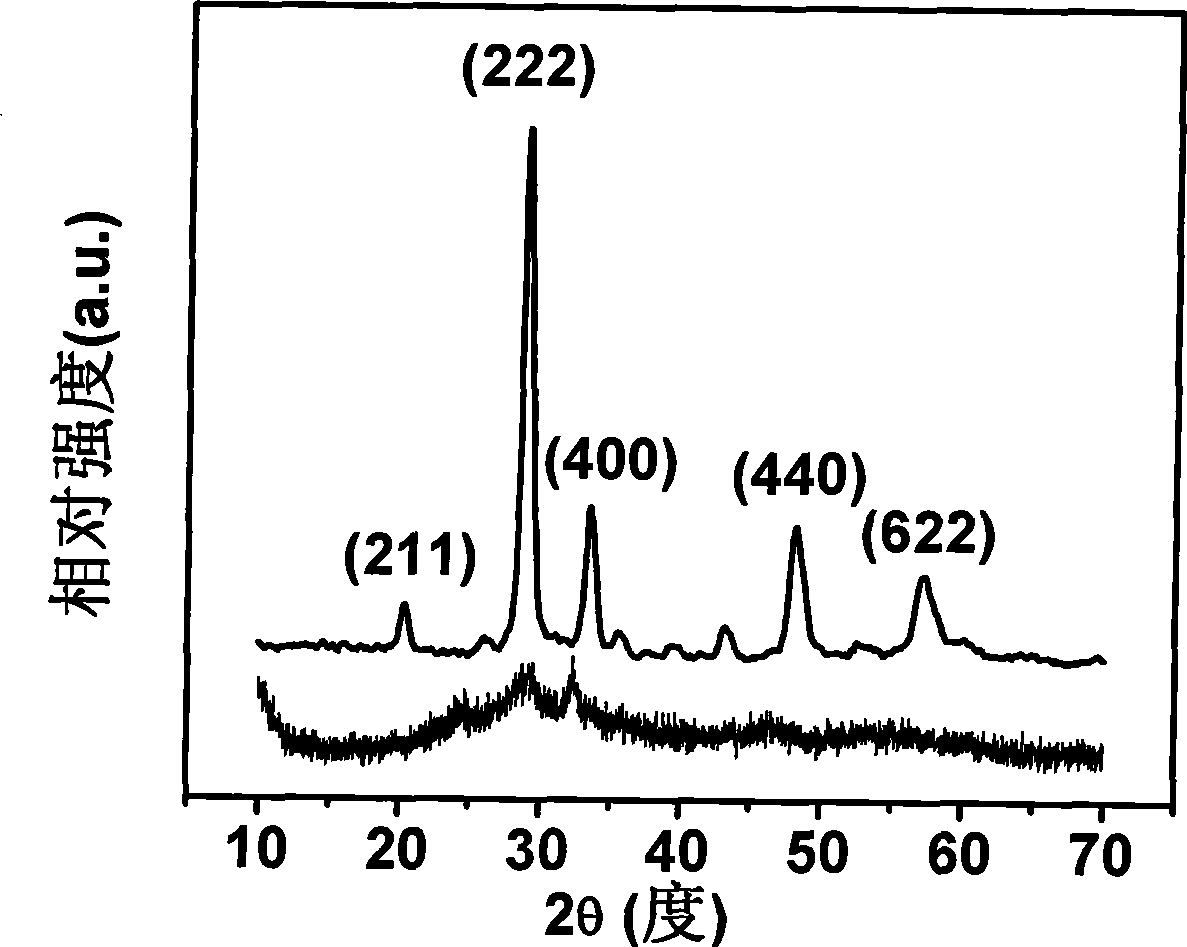

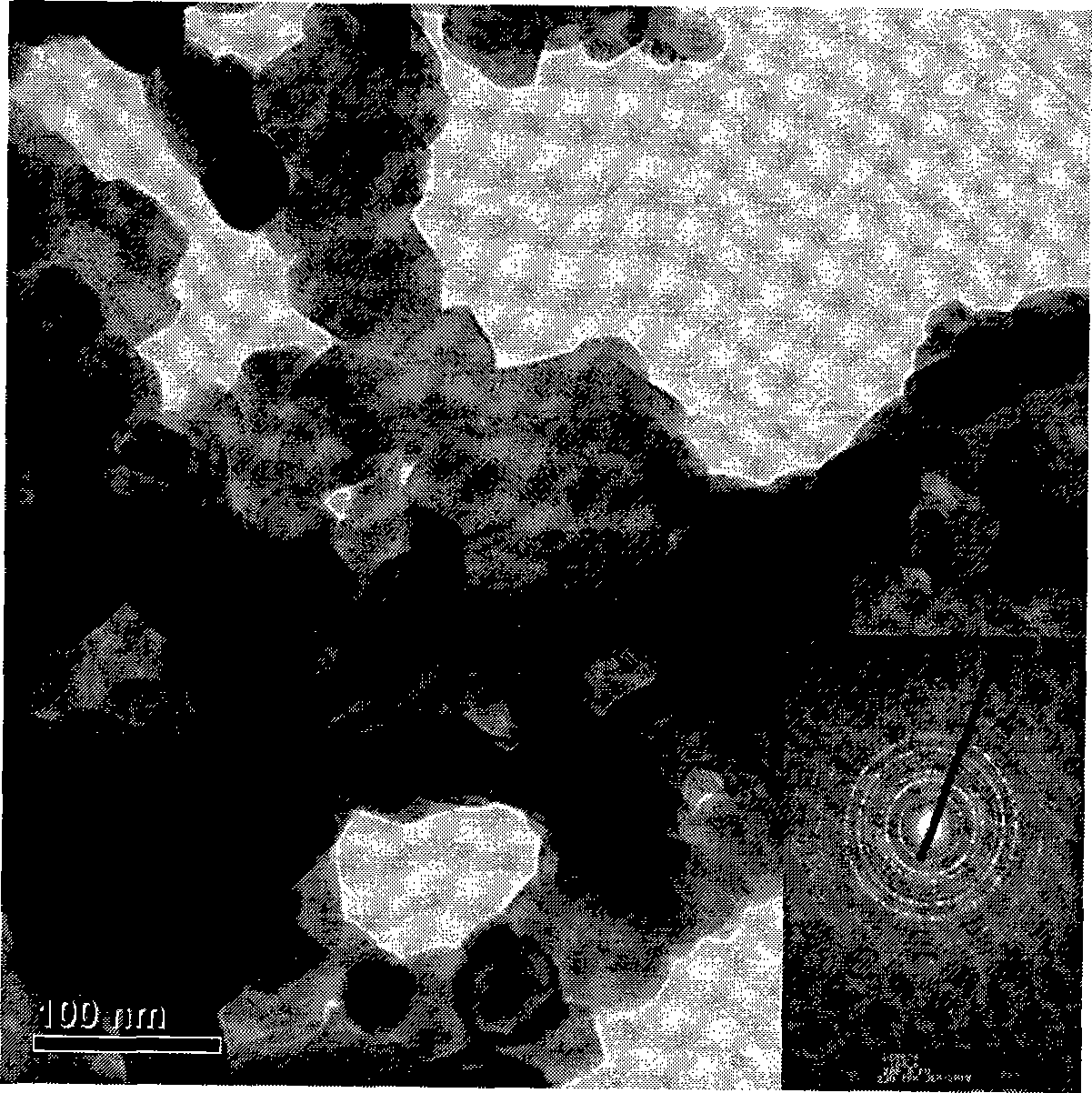

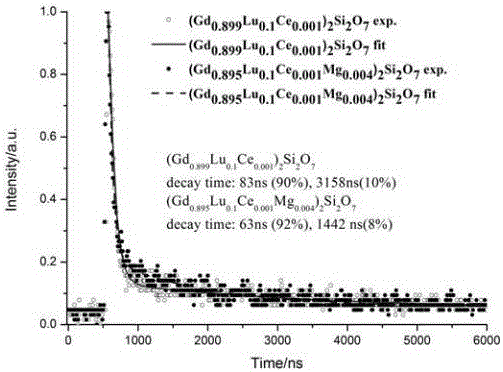

InactiveCN105969354AImprove flicker performanceShort decay timePolycrystalline material growthBy zone-melting liquidsFluorescenceSilicic acid

The invention discloses a cerium-doped gadolinium disilicate luminescent material and a preparation method thereof. The chemical formula of the material is (Gd[1-x-y-z]KxCeyMz)2Si2O7, wherein K is one or combination of more of La, Lu, Y and Sc; M is one or combination of more of Mg<2+>, Ca<2+>, Ba<2+>, B<3+> and In<3+>; and 0<=x<=0.995, 0.00001<=y<=0.05, and 0<=z<=0.05. The main group ions Mg<2+>, Ca<2+>, Ba<2+>, B<3+> and In<3+> are additionally added into the luminescent material cerium-doped gadolinium disilicate to prepare the cerium-doped gadolinium disilicate scintillator monocrystals and fluorescent powder. Compared with the gadolinium disilicate luminescent material without doped main group ions, the phosphor-decay time of the main-group-ion-doped cerium-doped gadolinium disilicate scintillator monocrystals and fluorescent powder is obviously shortened, and the scintillation properties of the cerium-doped gadolinium disilicate scintillator monocrystals and fluorescent powder are optimized.

Owner:SHANGHAI UNIV

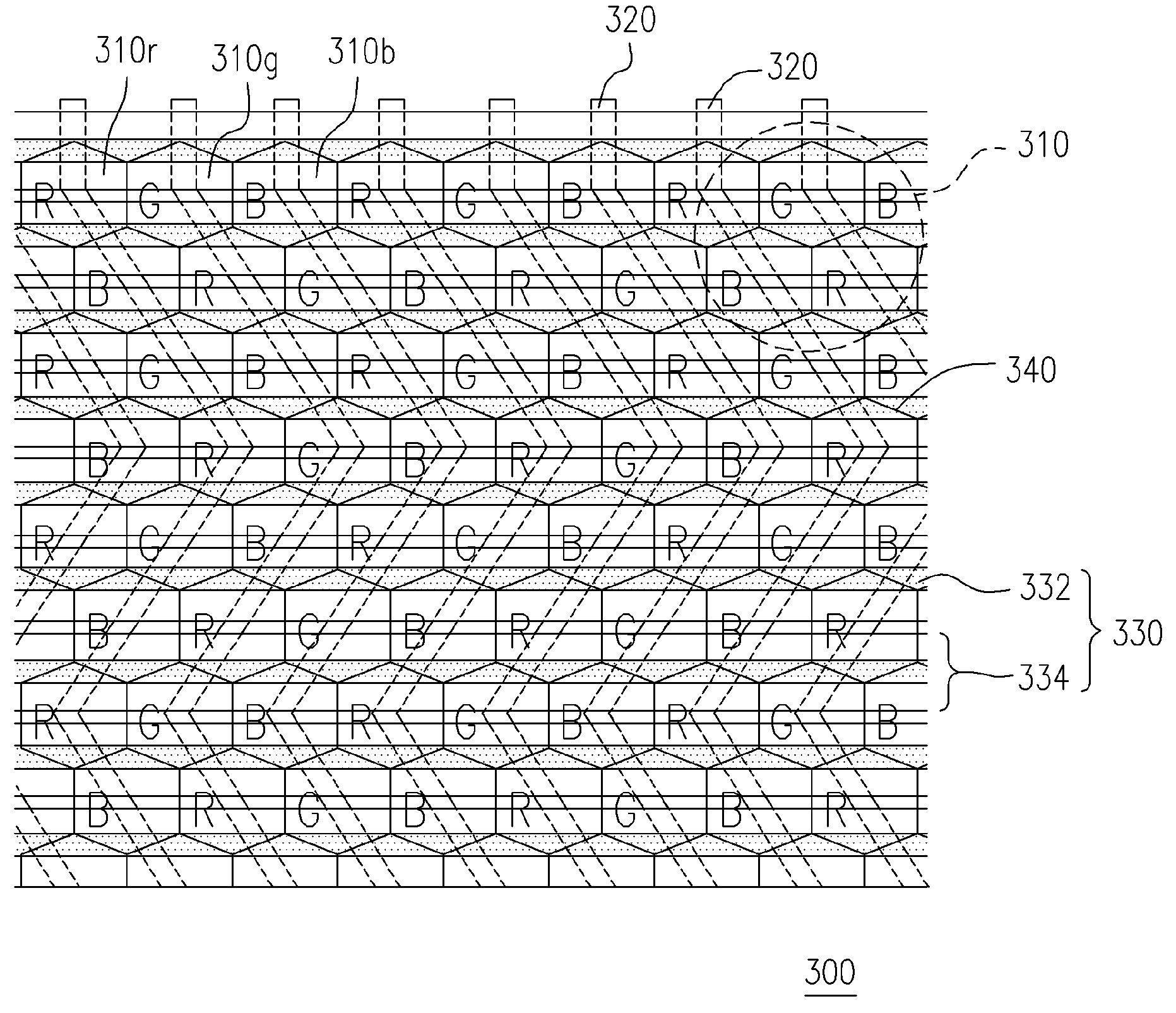

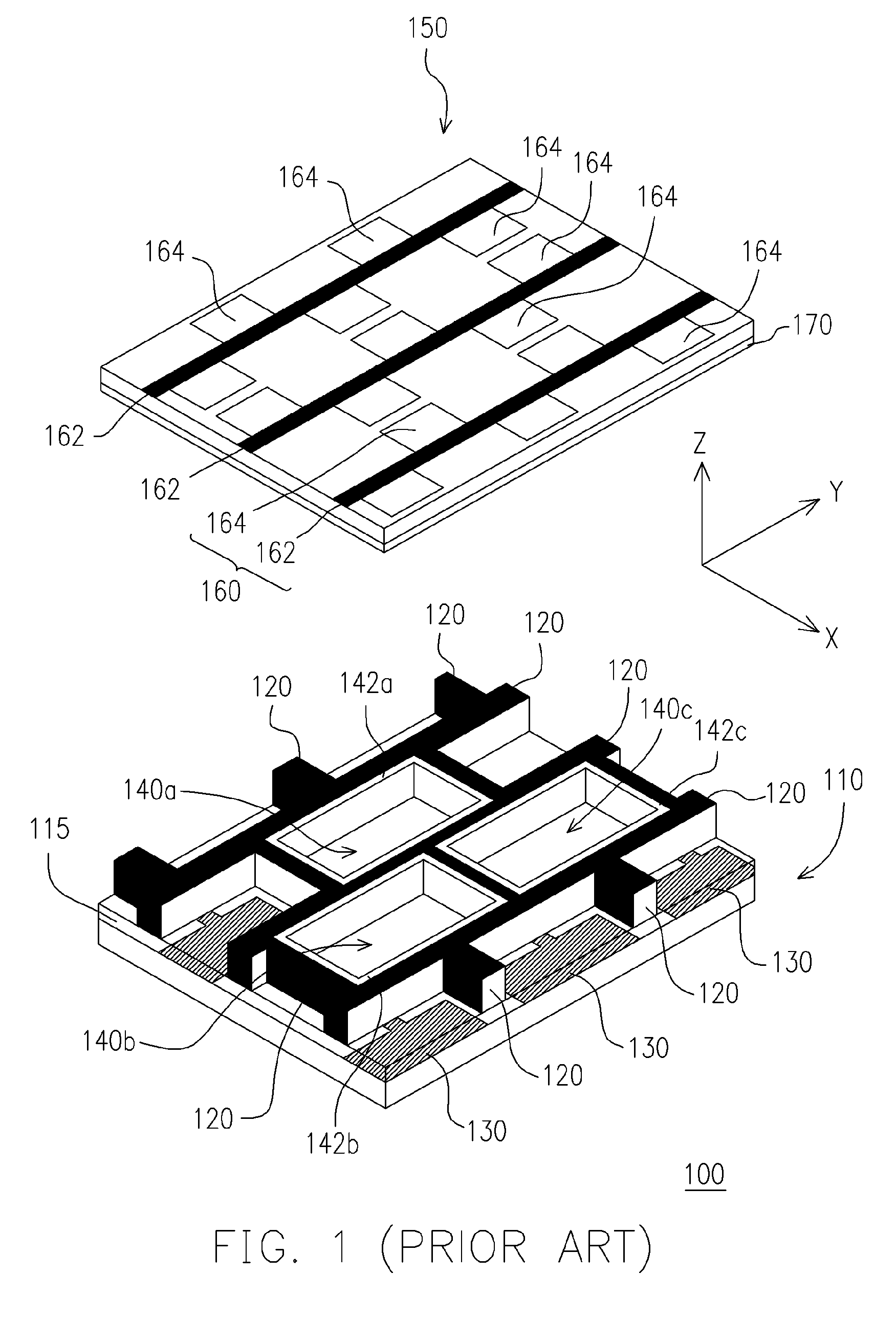

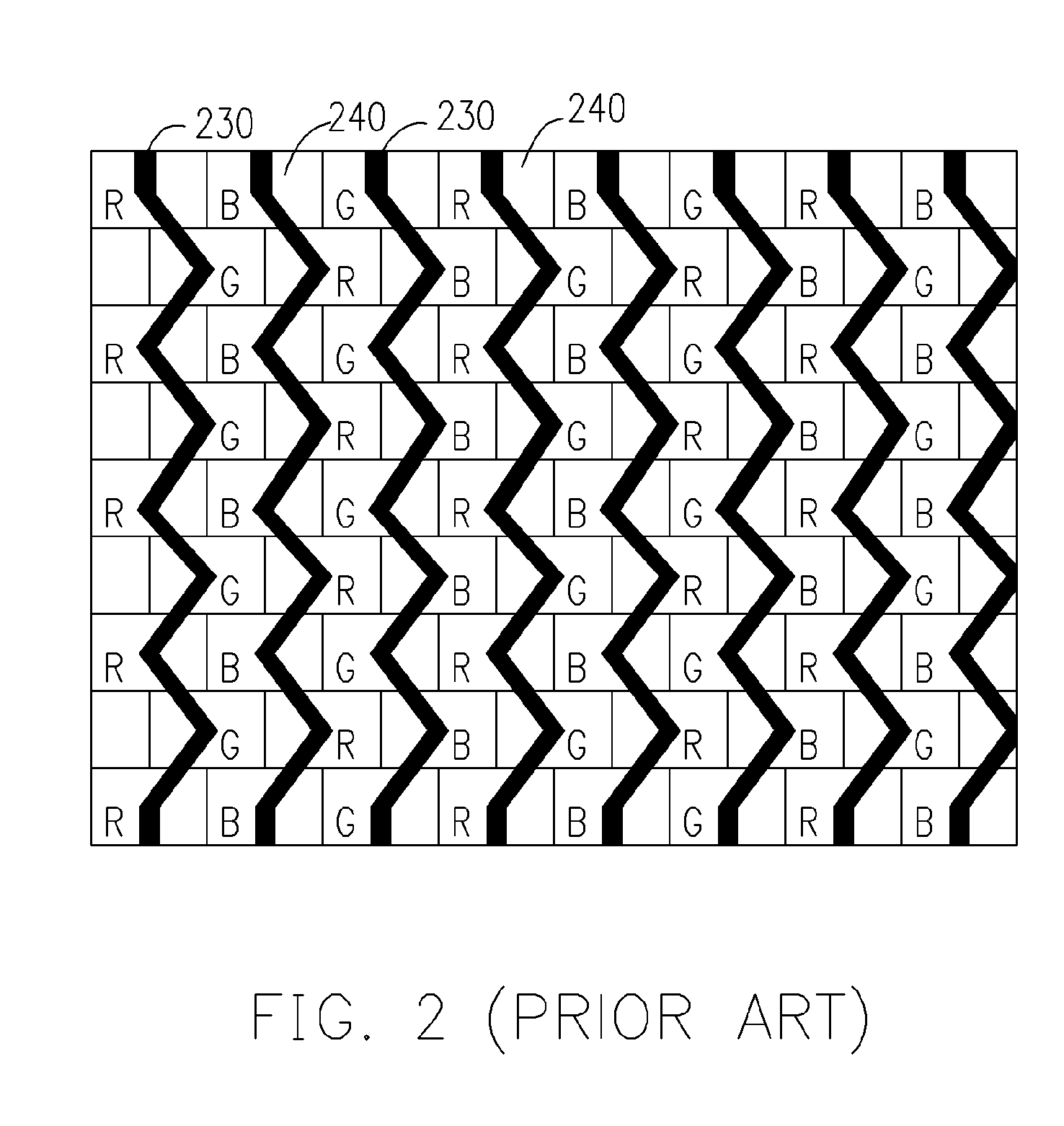

Alternating current plasma display panel

InactiveUS6972527B2Reduce data volumeImprove flicker performanceStatic indicating devicesGas discharge lampsData-drivenAlternating current

An alternating current plasma display panel is provided. The alternating current plasma display panel includes a plurality of first sub-pixels, a plurality of second sub-pixels, a plurality of third sub-pixels, a plurality of common data electrodes and a plurality of row electrodes. The first sub-pixels, the second sub-pixels and the third sub-pixels are disposed in a delta configuration. The common data electrodes are disposed below the sub-pixels, and the row electrodes are disposed above the sub-pixels. The amount of the first sub-pixels, the second sub-pixels and the third sub-pixels passed through by each of the common data electrodes are the same. The alternating current plasma display panel can reduce the number of data driving chips and effectively improve the quality of image.

Owner:AU OPTRONICS CORP

Method for preparing scintillating crystal of orthosilicate with bivalent cerium ions doped

InactiveCN1563517AReduce quenchingImprove flicker performancePolycrystalline material growthBy pulling from meltQuenchingIon

The key of a preparation method for metasilicate scintillation crystals doped with 3-valence Ce ions is that its growing formula is doped with 3-valence Ce compounds which can be any one of the followings : Ce(OH)3, Ce2 ( C2 O4)3, Ce (CH3 Co6)3 and Ce2 (CO3)3. The raw material is sintered and grown in the neutral atmosphere and the crystals can reduce the quenching to Ce3+ illumination and increase its scintillation performance for about 5%-10%.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

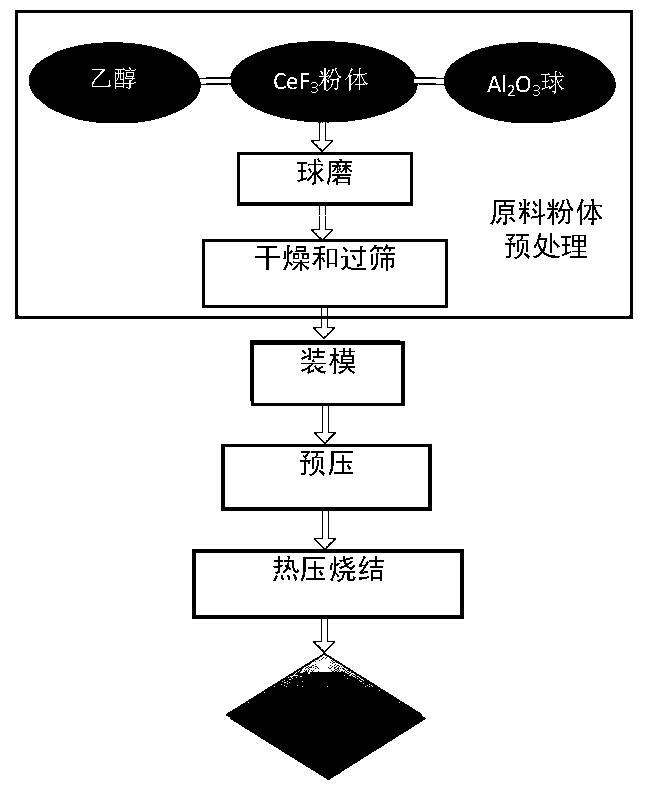

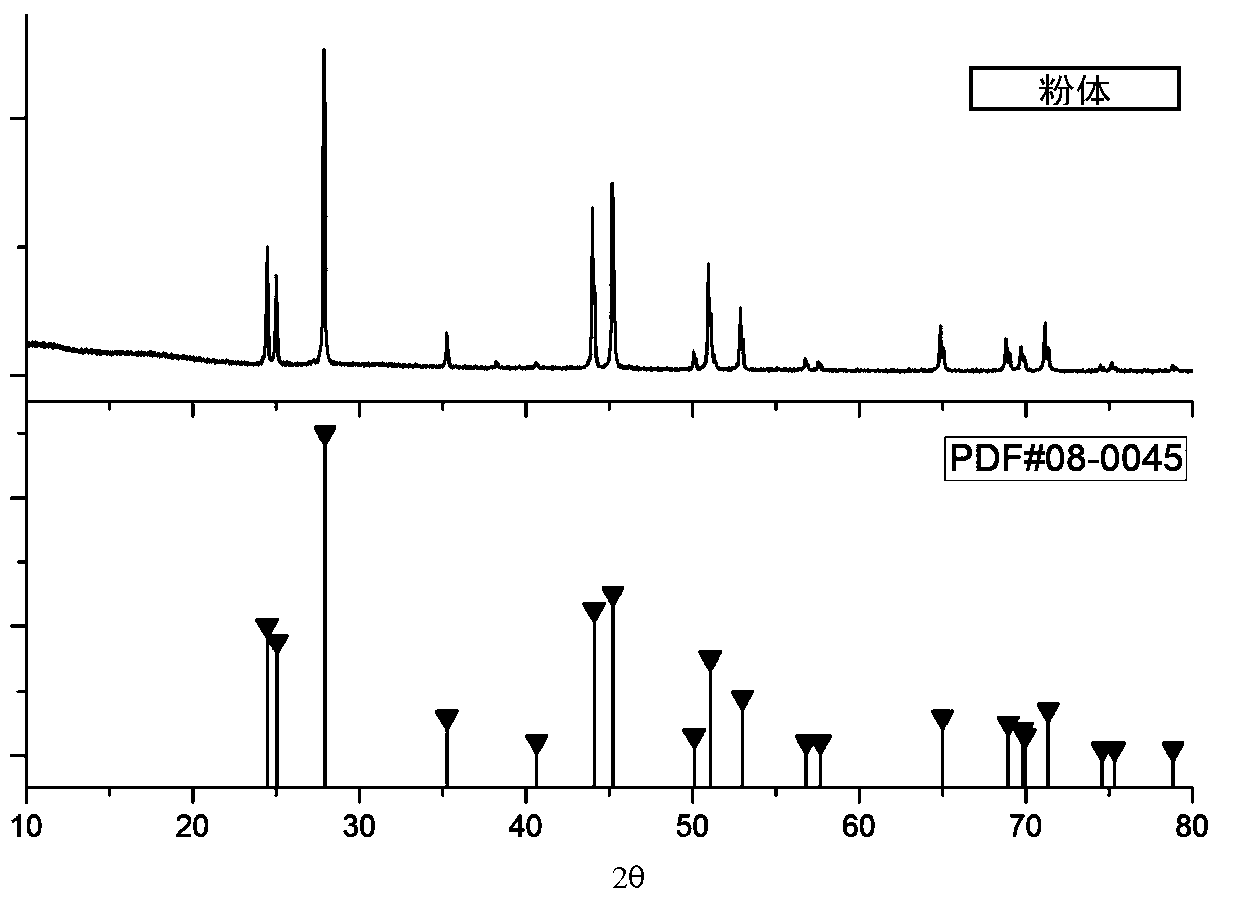

Hot pressing sintering method for cerium fluoride scintillation ceramic and cerium fluoride scintillation ceramic prepared thereby

InactiveCN103570355AImprove flicker performanceHigh visible light transmittanceVacuum pumpingVacuum pump

The invention relates to a hot pressing sintering method for a cerium fluoride scintillation ceramic and the cerium fluoride scintillation ceramic prepared thereby. The method includes: a pre-pressing process: under a specified pressure, conducting pre-pressing on high purity CeF3 powder with purity over 99% in a hot pressing mold; a heating process: removing the pre-pressing pressure, performing vacuum pumping to a vacuum degree of less than 5*10<-3>Pa, and then raising the temperature to 800-1000DEG C; and a hot pressing sintering process: keeping a temperature of 800-1000DEG C, carrying out pressurization to 100-300MPa, and maintaining the temperature and the pressure for 0.5-2.5h.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

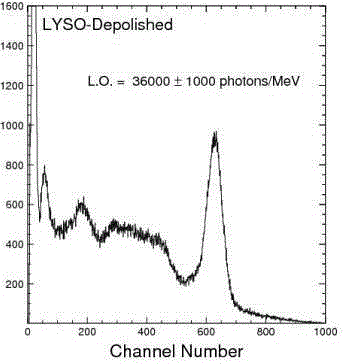

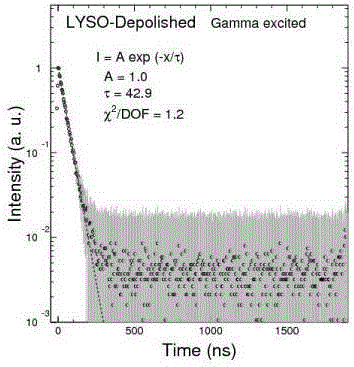

Method for improving scintillation property of cerium-doped LYSO crystals grown through Bridgman-Stockbarger method

ActiveCN105220234AEliminate oxygen vacanciesImprove uniformityPolycrystalline material growthAfter-treatment detailsCrucibleTransmittance

The invention discloses a method for improving the scintillation property of cerium-doped LYSO crystals grown through a Bridgman-Stockbarger method. The crystals are subjected to high-temperature thermal treatment under a neutral or oxidizing atmosphere condition, so that the crystals are transformed into colorless and transparent from a sandy color or other colors, and meanwhile the scintillation property the crystals is obviously improved. It is shown through testing results that the transmittance of the crystals at 420 nm is 83.5%, the optimal light output is 36,000+ / -1,000 photons / MeV, and the fall time is 42.9 ns. The comprehensive performance of the crystals reaches the advanced level at home and abroad.

Owner:成都东骏激光股份有限公司

Preparation method of lead tungstate powder with high scintillation property

InactiveCN101973583AHigh luminous intensityImprove flicker performanceLuminescent compositionsTungsten compoundsChemical reactionTungstate

The invention discloses a preparation method of a lead tungstate powder with high scintillation property, comprising the following specific steps of: a) dropwise adding a water soluble lead salt solution into a water soluble tungstate solution with a pH value being not less than 7 at the uniform velocity so that the coprecipitation chemical reaction is conducted at 30-80 DEG C; b) filtering, washing and drying the obtained lead tungstate precipitation; and c) carrying out thermal treatment on the obtained lead tungstate crystal grains. By the invention, the luminescence peak of the lead tungstate powder body is within the blue light wave band of 450-500nm and belongs to fast luminescence component; the luminescence strength is high and is remarkably improved by about 15 times in comparison with the luminescence strength of the power obtained by grinding lead tungstate crystal grains which grow by a descending method, can reach the luminescence level of the power obtained by grinding of bismuth germanate crystal grains which grow by a descending method and has excellent scintillation property; in addition, the invention has the advantages of simple operation, short reaction time, low requirements on experimental equipment, high controllability and the like, and is suitable for large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Metal sliver-coated glass-based effect pigment and preparation method thereof

ActiveCN102391687AIncrease brightnessImprove flicker performanceInorganic pigment treatmentPrinting inkGlass sheet

The invention relates to a glass sheet-based metal sliver-coated effect pigment and a preparation method of the pigment. The pigment is obvious in silvery white reflected light brightness and blinking effect, can be taken as an effect pigment to be used in any pigment fields, and is widely used for cosmetics, decorative materials, printing ink, coating and the like.

Owner:FUJIAN KUNCAI MATERIAL TECH

Method for converting visually yellow cerium doped lutetium yttrium oxyorthosilicate crystals into colorless cerium doped lutetium yttrium oxyorthosilicate crystals in neutral atmosphere

ActiveCN102492979AImprove transmittanceImprove flicker performancePolycrystalline material growthFrom solid stateLutetiumPhysical chemistry

The invention discloses a method for converting visually yellow cerium doped lutetium yttrium oxyorthosilicate crystals into colorless cerium doped lutetium yttrium oxyorthosilicate crystals in neutral atmosphere. The visually yellow cerium doped lutetium yttrium oxyorthosilicate crystals are heated in neutral atmosphere for a certain period of time to ensure that oxygen is diffused from the cerium doped lutetium yttrium oxyorthosilicate crystals, so Ce<4+> is changed into Ce<3+>, and the crystals become colorless. According to the method, the crystals are treated at high temperature in neutral atmosphere, so residual oxygen is removed from the crystals, and the visually yellow cerium doped lutetium yttrium oxyorthosilicate crystals are converted into colorless yellow cerium doped lutetium yttrium oxyorthosilicate crystals; therefore, transmissivity of the 420-nm part of the crystals is improved. The scintillation property of the crystals can be improved obviously. By the method, primary crystals are subjected to reduction heat treatment, so the properties of the crystals can be improved, and the properties of the crystal products which are not appropriately oxidized can be recovered. The properties of the crystals are greatly improved, and the utilization rate of the crystals is further improved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

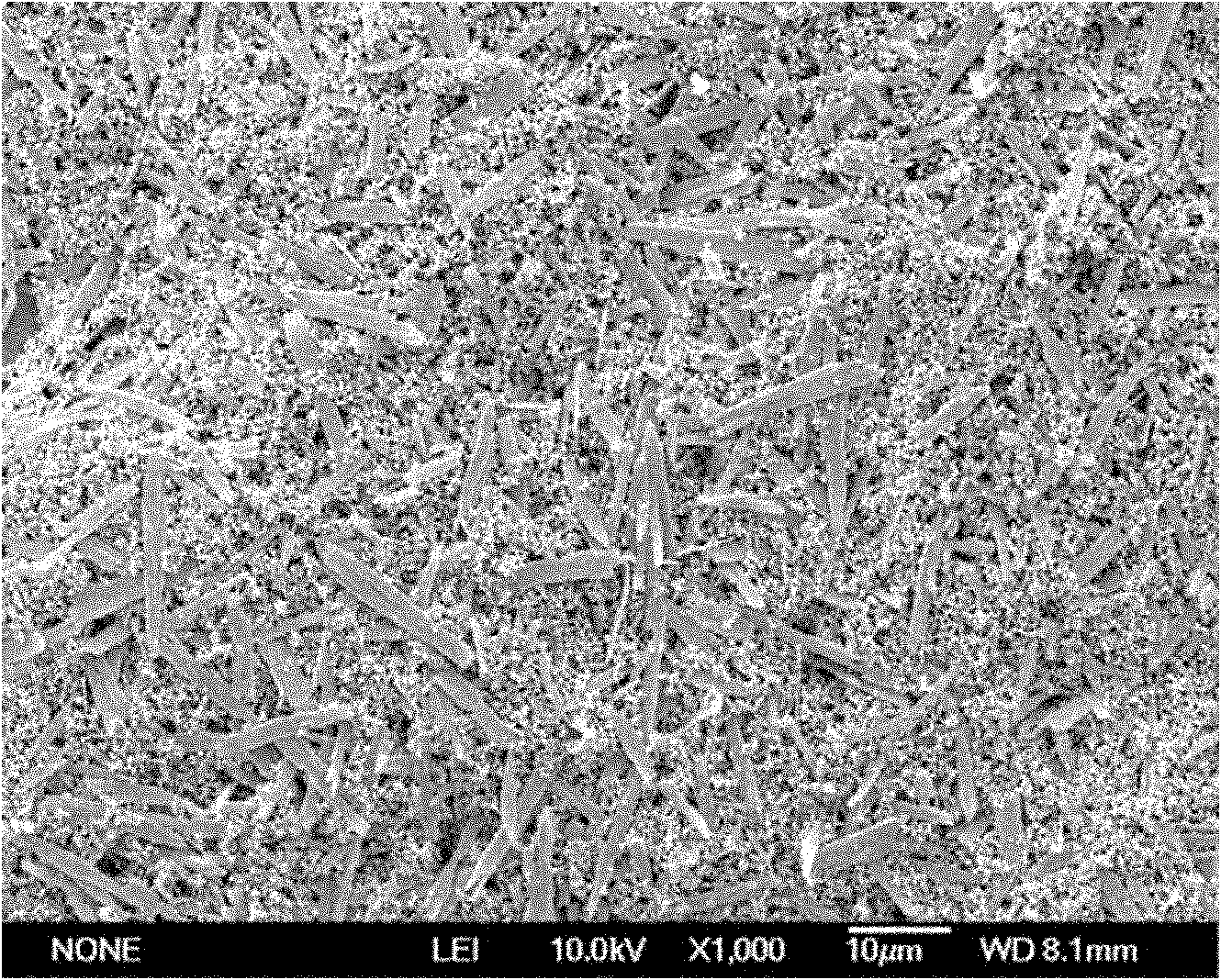

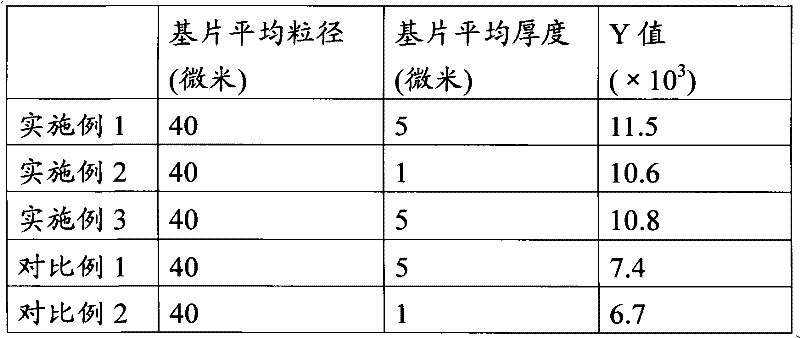

Pressureless sintering preparation method of Ce:Lu2SiO5 polycrystal flicker optical ceramics

InactiveCN102557598AFully densified preparationImprove flicker performanceMicron scaleCrystallography

The invention relates to a method for preparing Ce:Lu2SiO5 polycrystal flicker optical ceramics by adopting a pressureless sintering process, which belongs to the technical field of a preparation process of rare earth doped polycrystal flicker optical ceramics. The method adopts a sol-gel method to compose signal-phase sub-micron level Ce:Lu2SiO5 ceramic powder at low temperature, dry pressing and isostatic pressing are carried out on the powder, then pressureless sintering is carried out on the powder at 1600-1800 DEG C under flowing H2 atmosphere condition to obtain the Ce:Lu2SiO5 polycrystal flicker optical ceramics. relative density of the obtained materials achieves more than 98.5% of the theoretical density, has good lighting acts under stimulation of the X-ray, and a main emission peak is located at 440nm.

Owner:SHANGHAI UNIV

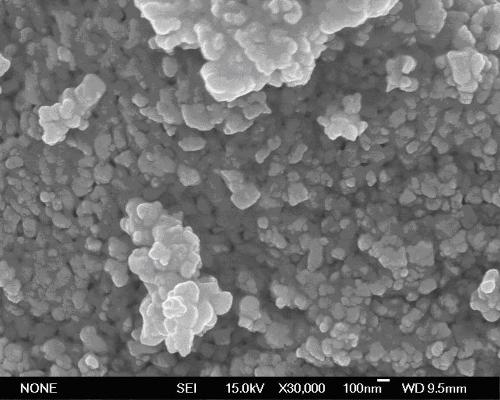

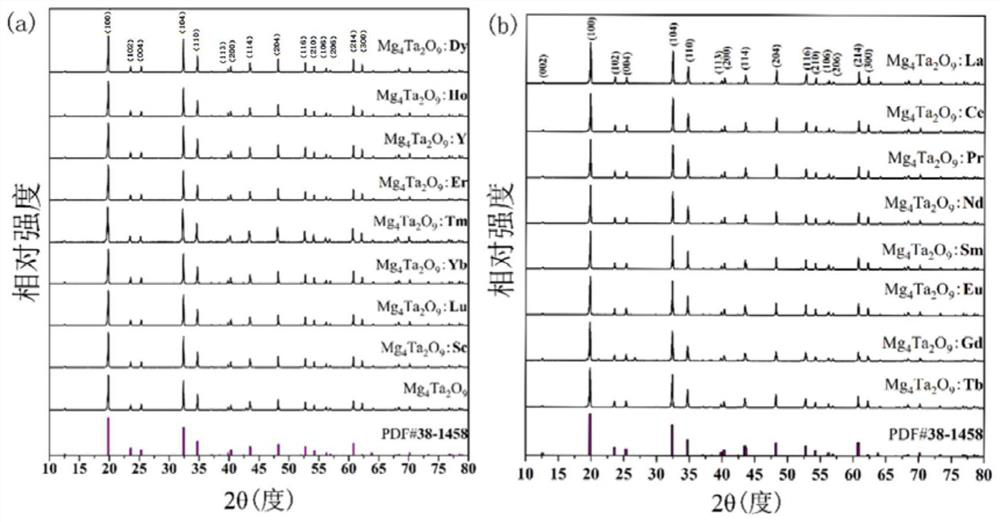

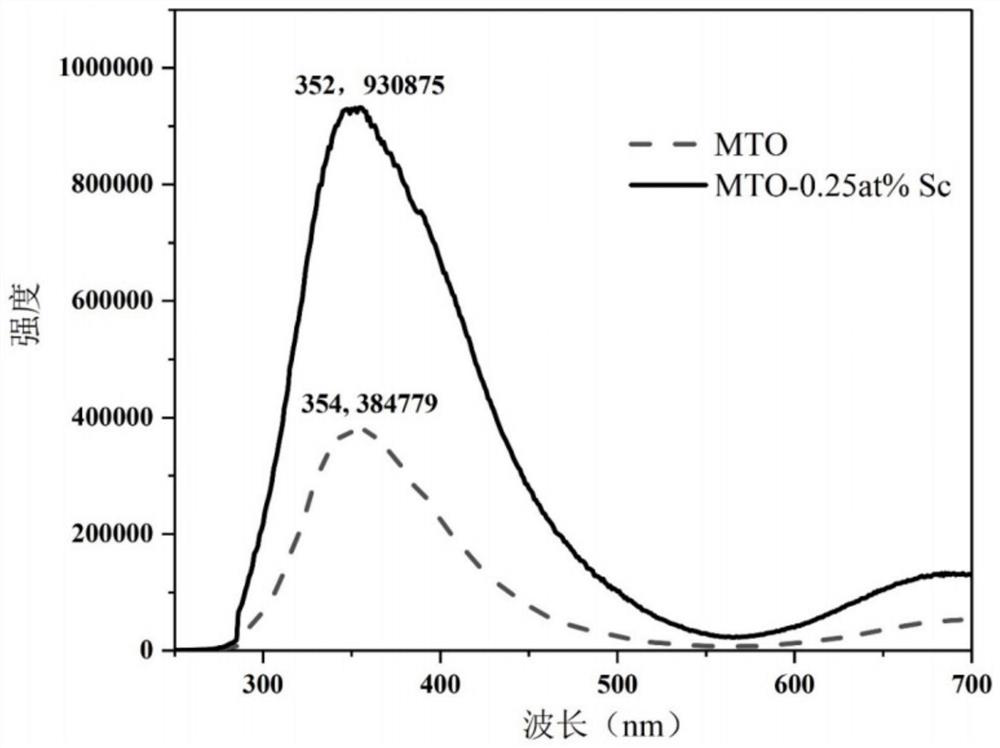

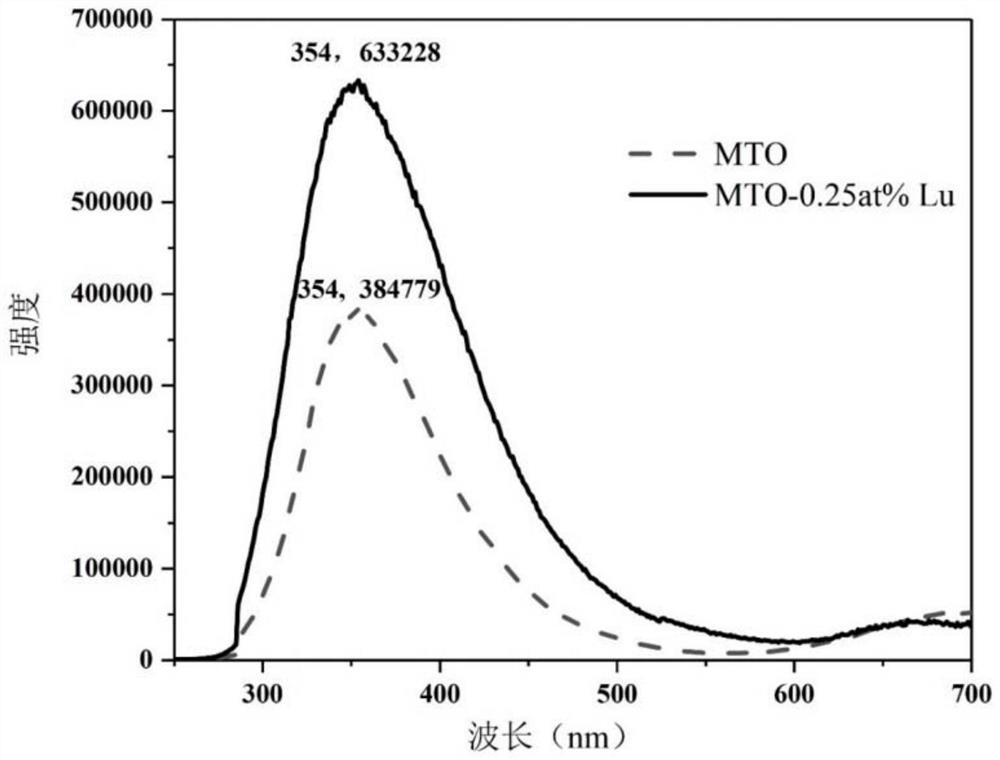

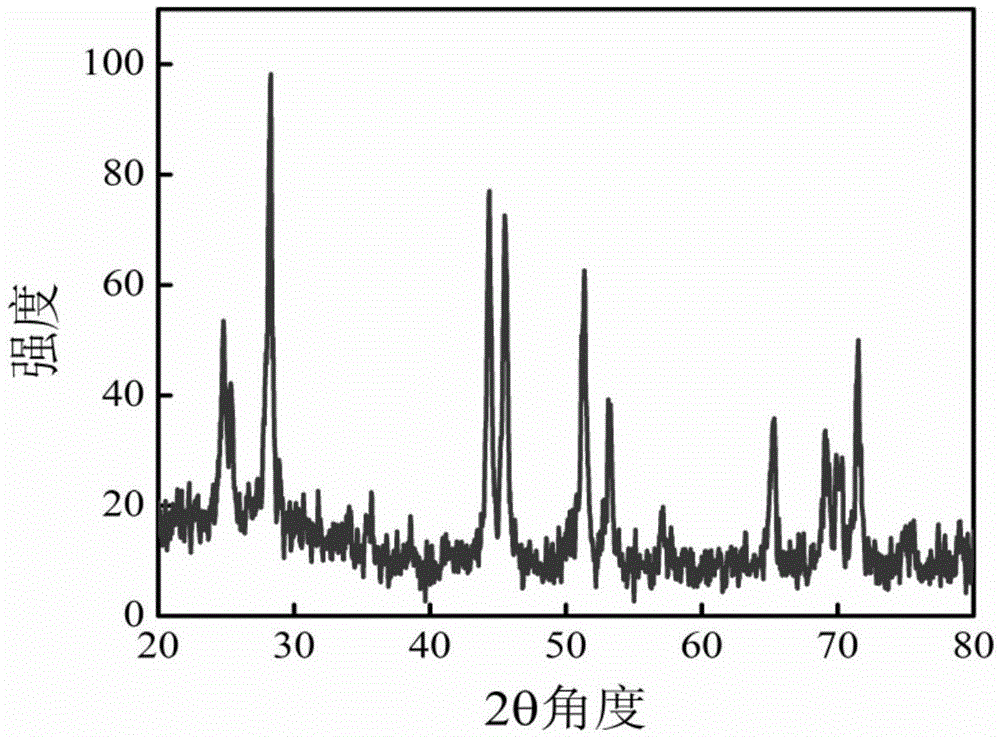

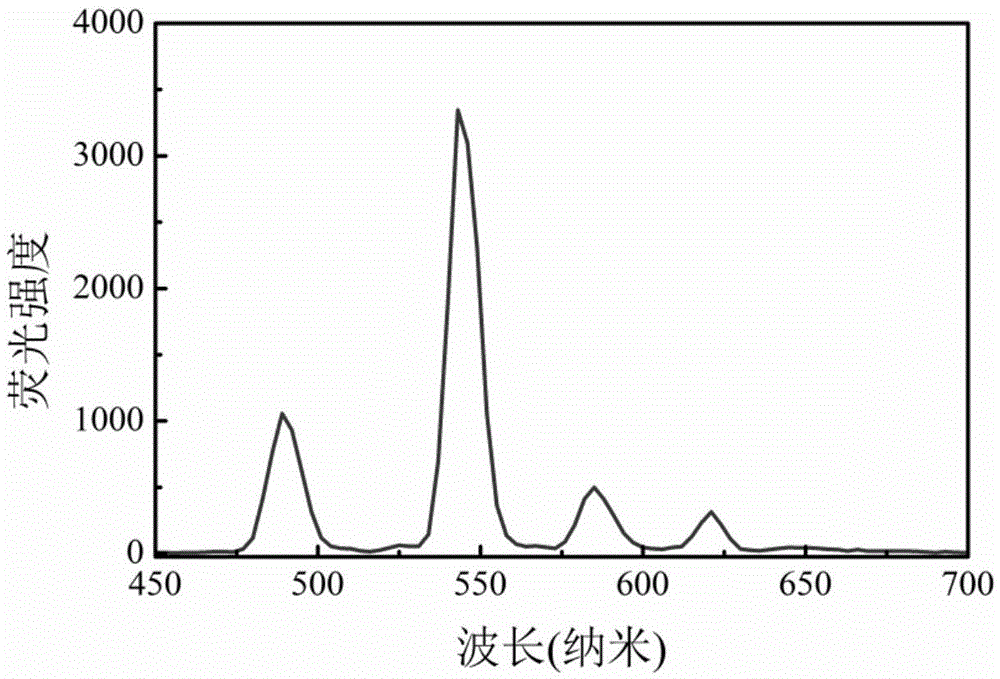

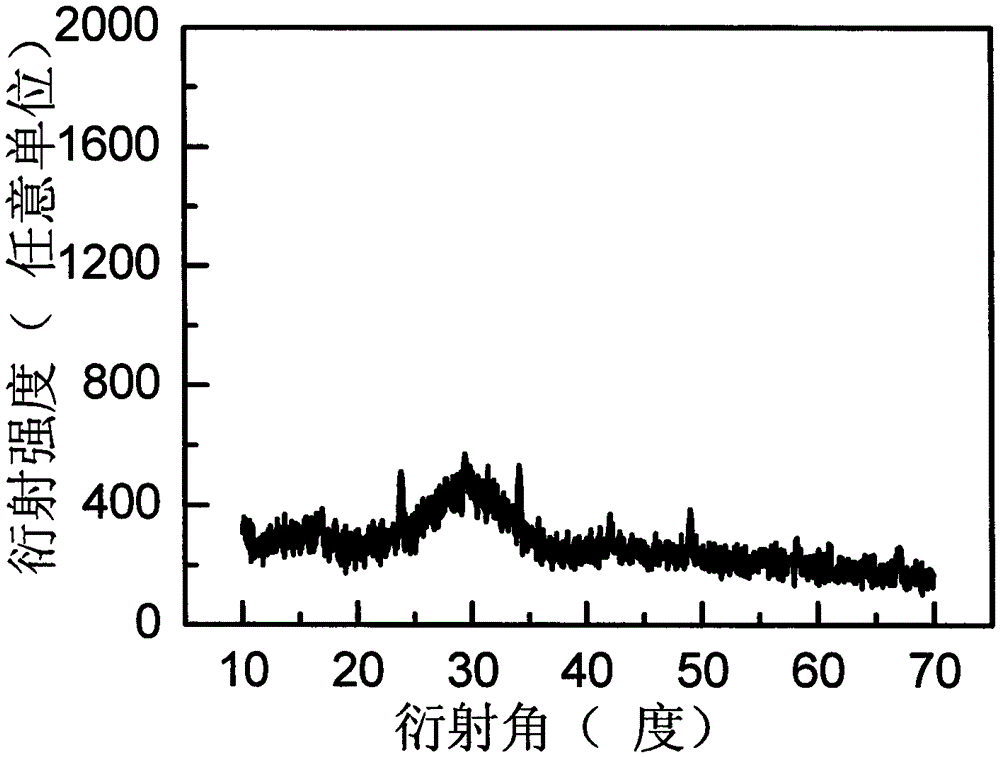

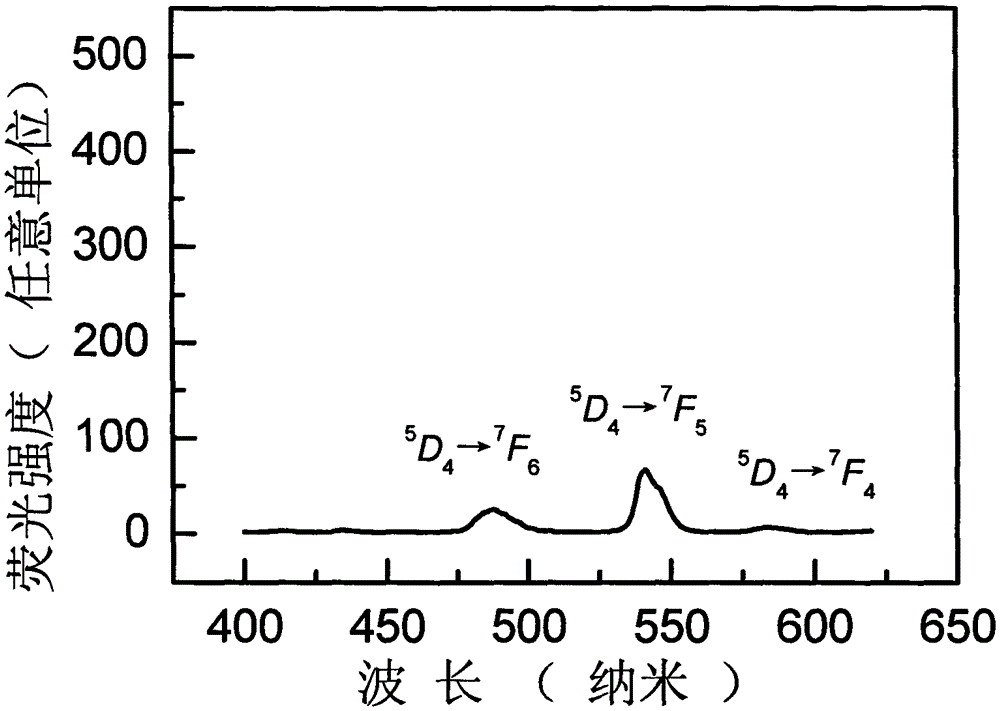

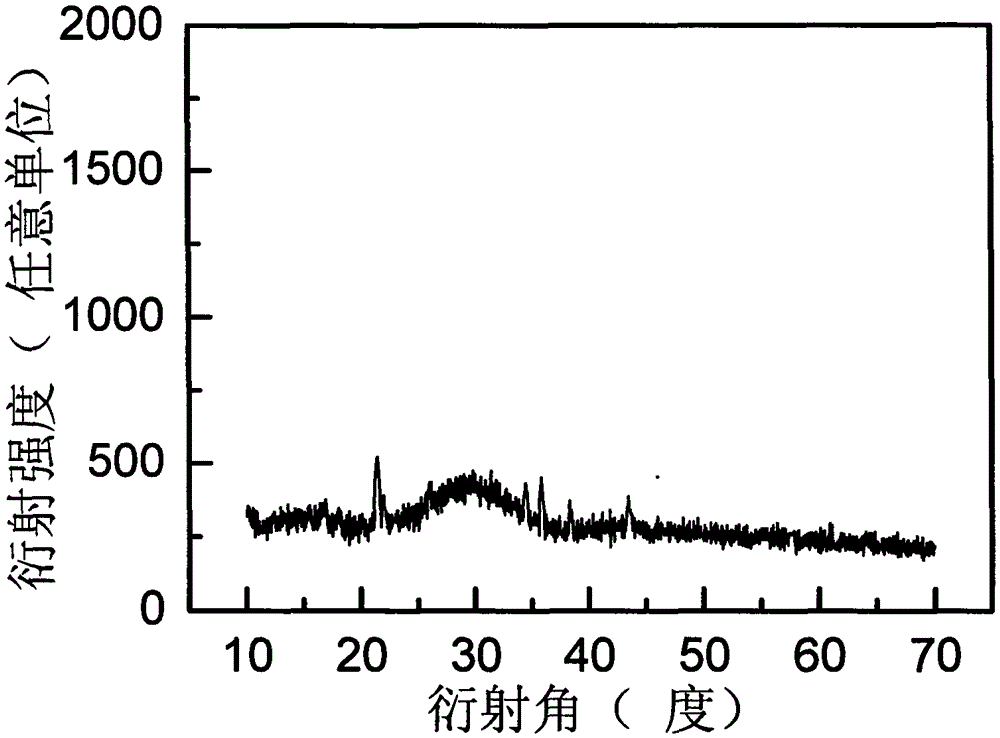

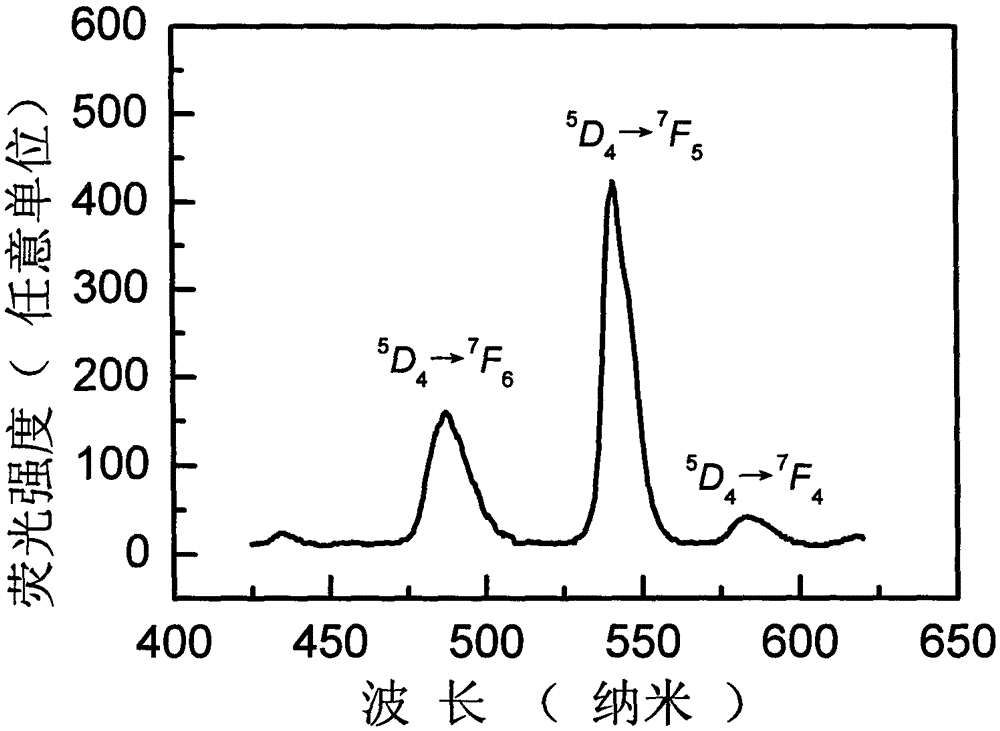

Rare earth doped magnesium tantalate series scintillation luminescent material and preparation method and application thereof

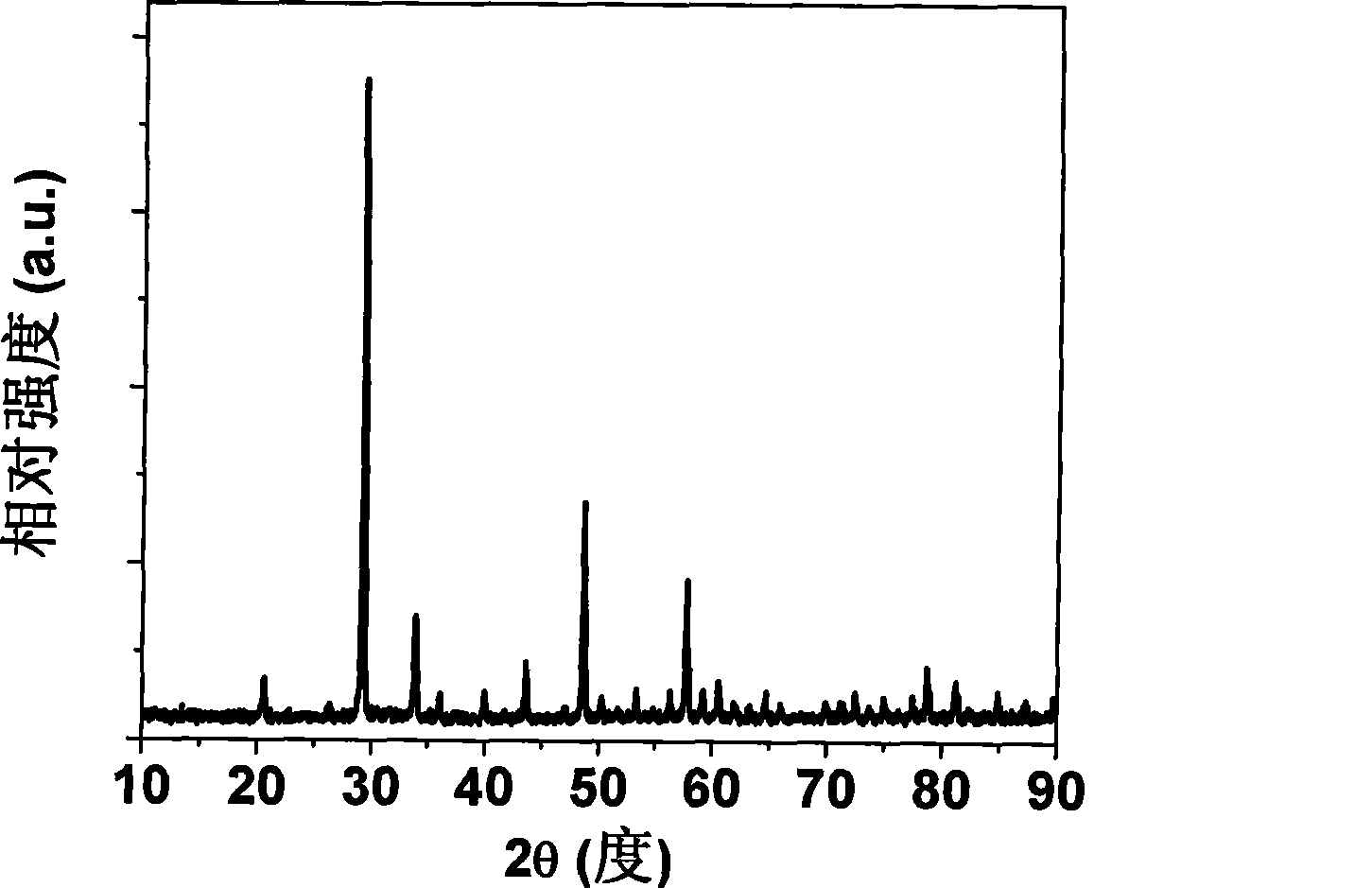

ActiveCN113462388ASimple preparation processImprove light outputLuminescent compositionsMaterial analysis using radiation diffractionChemical compositionLuminescent material

The invention discloses a rare earth doped magnesium tantalate series scintillation luminescent material and a preparation method and application thereof. The chemical composition expression of the rare earth doped magnesium tantalate series scintillation luminescent material disclosed by the invention is Mg4Ta2O9:RE. The scintillation luminescent material is synthesized by adopting a high-temperature solid-phase method and stably exists in the air, and the process is safe, simple and easy to control. According to the scintillation luminescent material disclosed by the invention, under the excitation of X rays, the light yield of an obtained Mg4Ta2O9:RE sample doped with different rare earth is 13848 to 43917 ph / MeV. The light yield of a sample Mg4Ta2O9:0.25at% Gd is the highest, is 81% of that of CsI (Tl), and is 2.4 times of that of Mg4Ta2O9 (MTO for short) and CdWO4.

Owner:SHANGHAI INST OF TECH

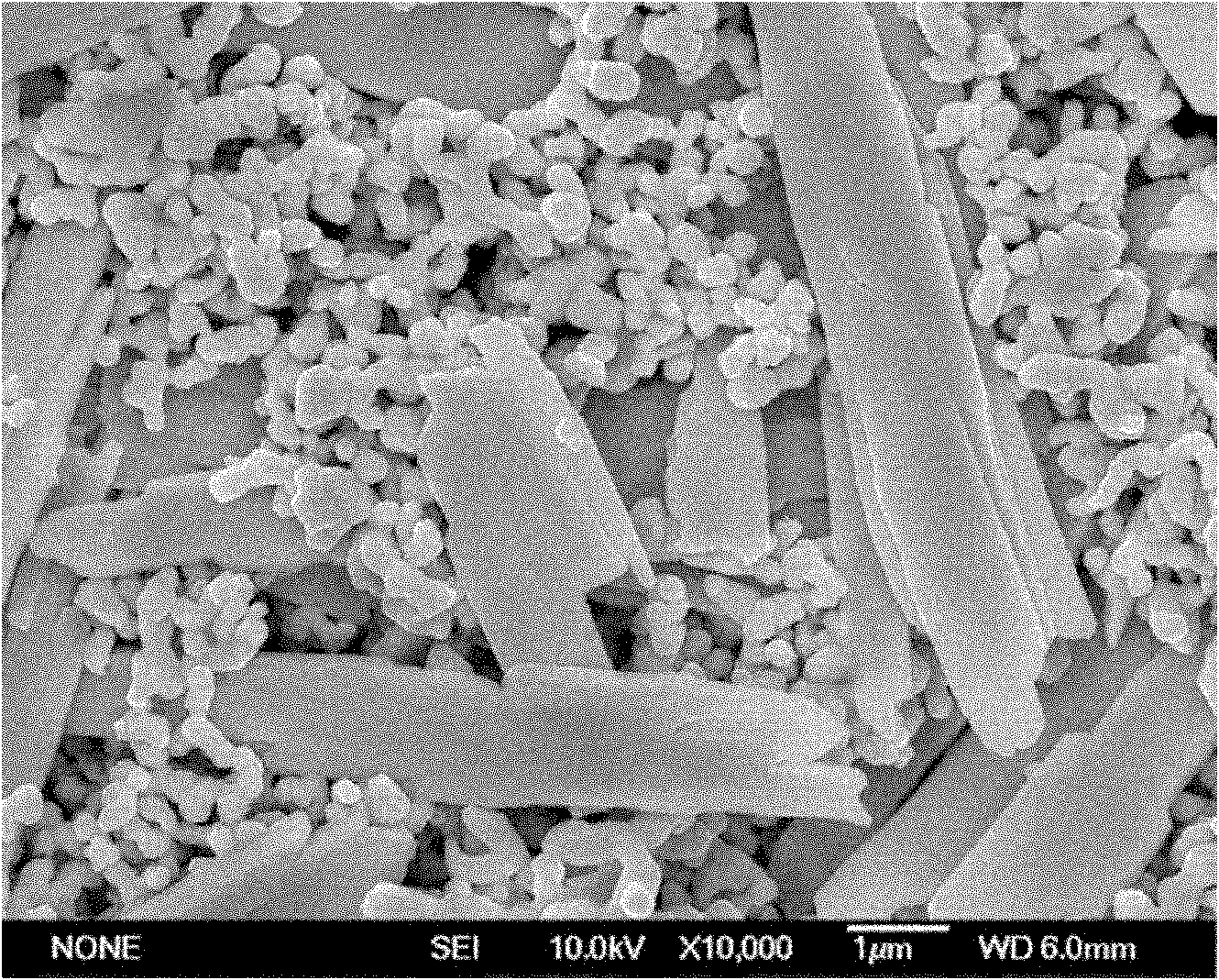

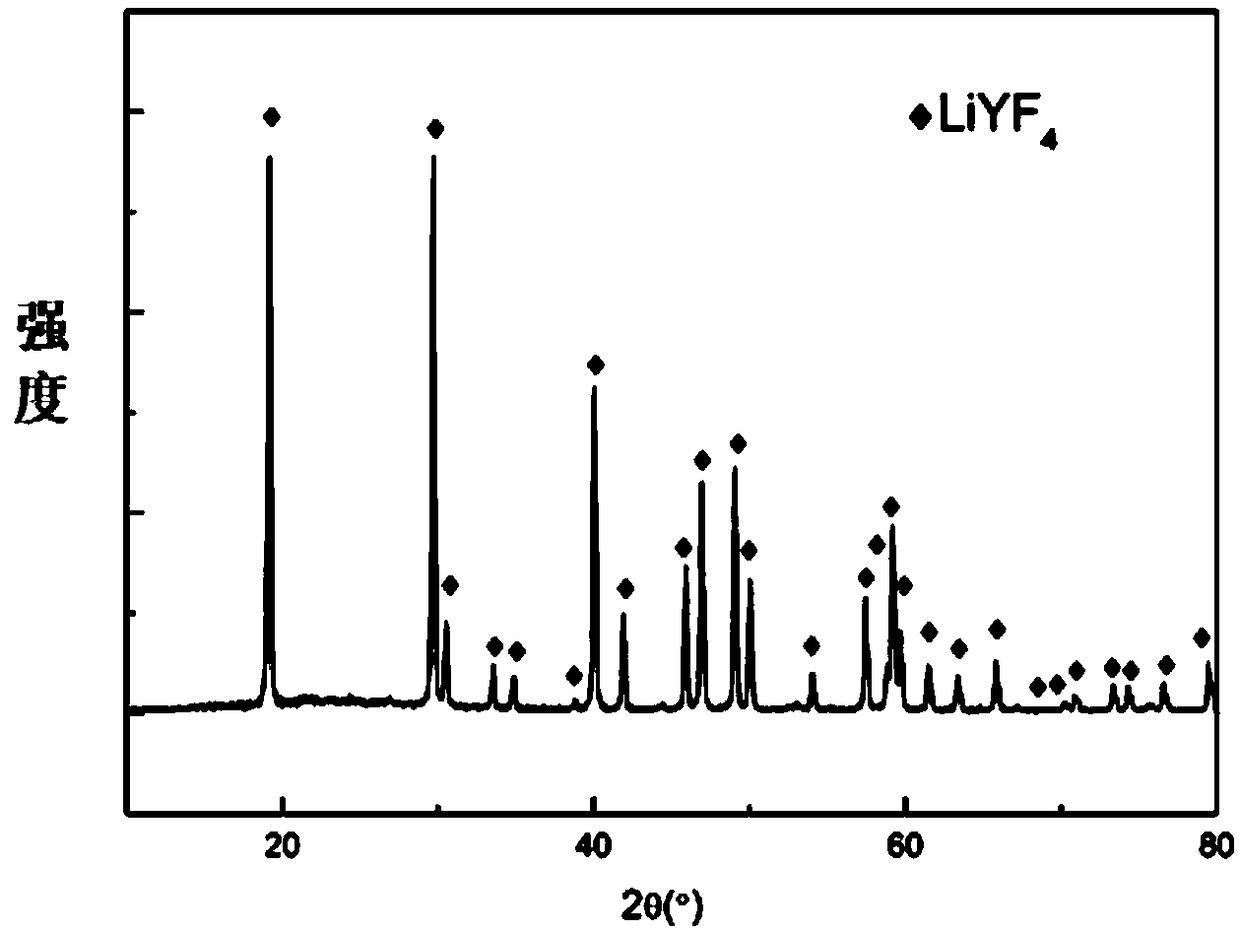

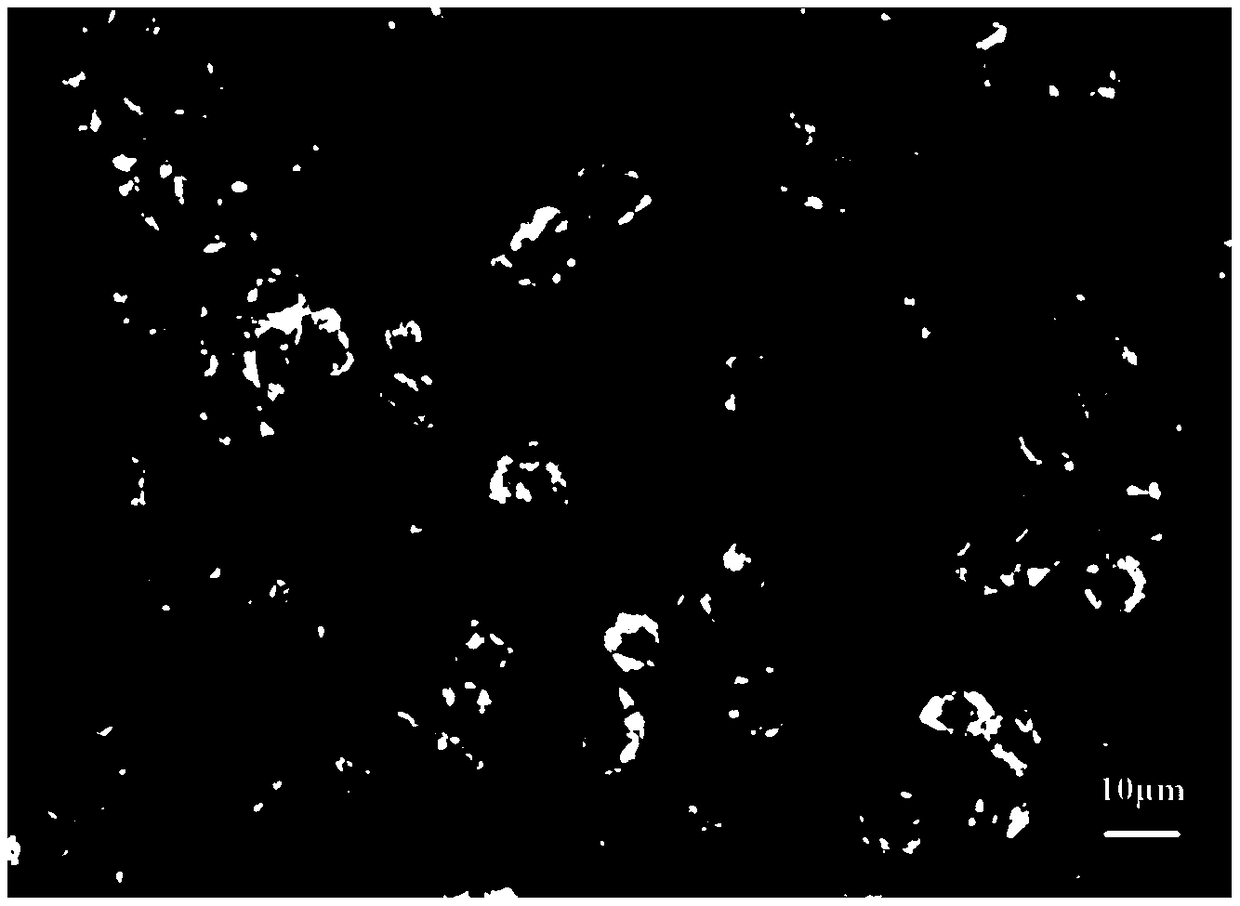

Yttrium lithium fluoride-doped scintillating microcrystal and preparation method and application thereof

InactiveCN108893116AUniform sizeHigh transparencyLuminescent compositionsRare-earth elementMicrometer

The application discloses yttrium lithium fluoride-doped scintillating microcrystal and a preparation method thereof. The yttrium lithium fluoride-doped scintillating microcrystal has a chemical formula shown as formula I: LiM10.02M2xY0.98-xF4, wherein M1 and M2 are selected from rare-earth elements, and 0.01<x<0.06. The yttrium lithium fluoride-doped scintillating microcrystal is 8-15 mu m in size that is of micrometer level, has good transparency and good size uniformity, has good scintillating property, has the potential of large-scale production, and has the potential application value inthe field of high-energy ray detection.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

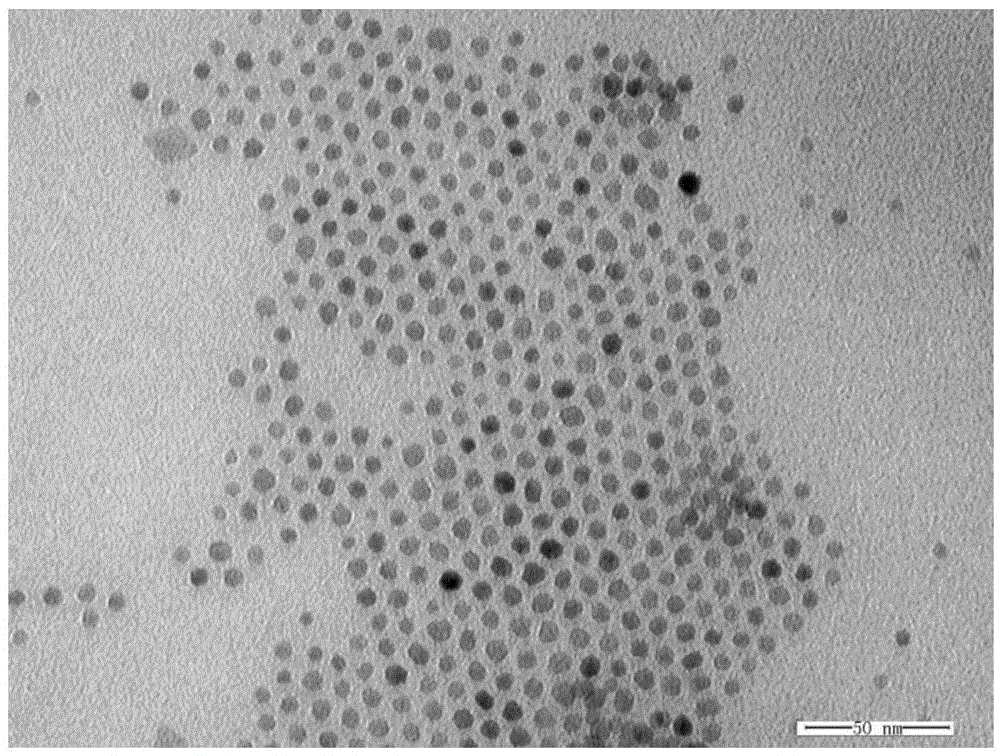

Oil soluble nanometer scintillation crystal and preparation method thereof

InactiveCN105623665AHigh fluorescence intensityGood fluorescence stabilityPolycrystalline material growthFrom normal temperature solutionsScintillation crystalsLanthanide

The invention relates to an oil soluble nanometer scintillation crystal and a preparation method thereof.LaCl3 and RECl3 lanthanide compounds are heated under the inert gas shielding and dissolved into an oleic acid and octadecene mixed solution, a NH4F methanol solution is added dropwisely at uniform speed on the stirring condition, a reaction is performed for 10-120 min at the temperature of 260-320 DEG C after methyl alcohol is removed, the oil soluble nanometer scintillation crystal with the average grain size being 4-10 nanometers is obtained, RE is the lanthanide Tb or lanthanides Tb and Ce, the oil soluble nanometer scintillation crystal of different fluorescence emission strengths is obtained by changing the varieties and / or ratio of the LaCl3 and the RECle lanthanide compounds, and the obtained oil soluble nanometer scintillation crystal has the advantages of being high in fluorescence intensity and good in fluorescence stability under X-ray irradiation excitation, and can be widely applied to the fields of biological medicine, material science and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

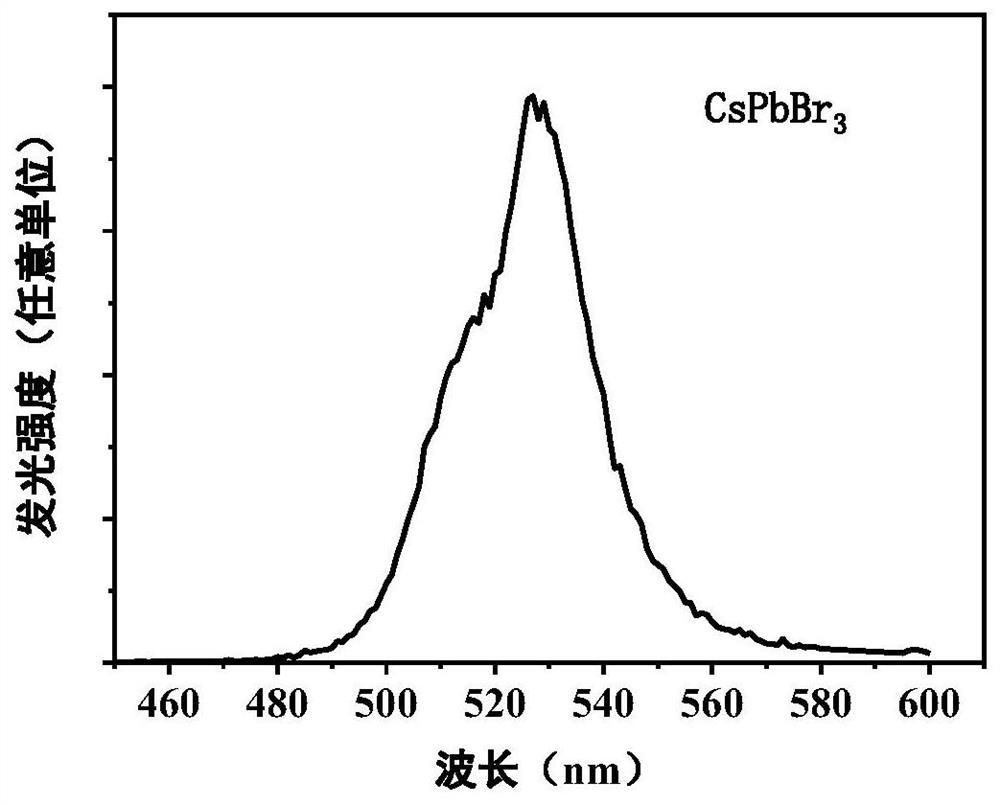

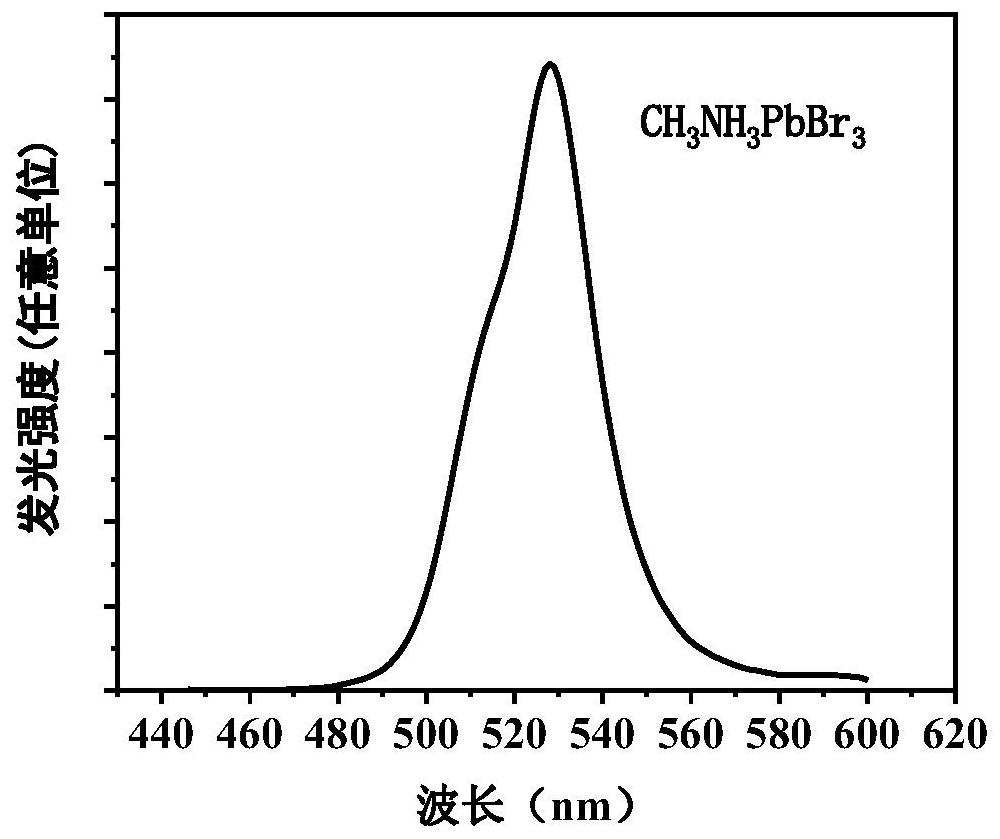

Halogenated perovskite quantum dot composite material for neutron detection and preparation method thereof

PendingCN112684492ALarge interception sectionImprove flicker performanceMeasurement with scintillation detectorsLuminescent compositionsGlass matrixQuantum dot

The invention belongs to the technical field of radiation detection, and discloses a halogenated perovskite quantum dot composite material for neutron detection and a preparation method thereof. The composite material is prepared from an organic polymer or inorganic glass matrix composite perovskite halide quantum dot material with high neutron interception capability. The matrix with high neutron interception capability can intercept incident neutrons and convert the neutrons into secondary charged particles so as to excite the doped halogenated perovskite quantum dots to flicker and emit light. Compared with a traditional neutron detection material, the composite material has the advantages of being low in cost, capable of preparing large-size samples, excellent in scintillation performance and the like, and the prepared composite material can be applied to the fields of neutron safety detection, oil well exploration, neutron treatment, high-energy physical experiments and the like.

Owner:SOUTH CHINA UNIV OF TECH

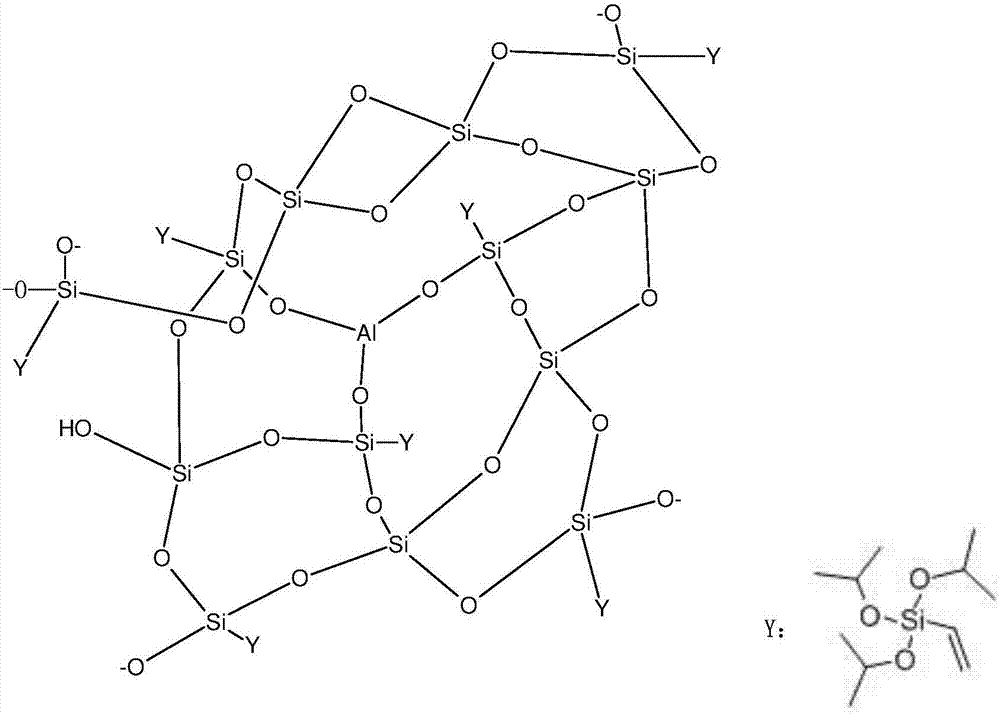

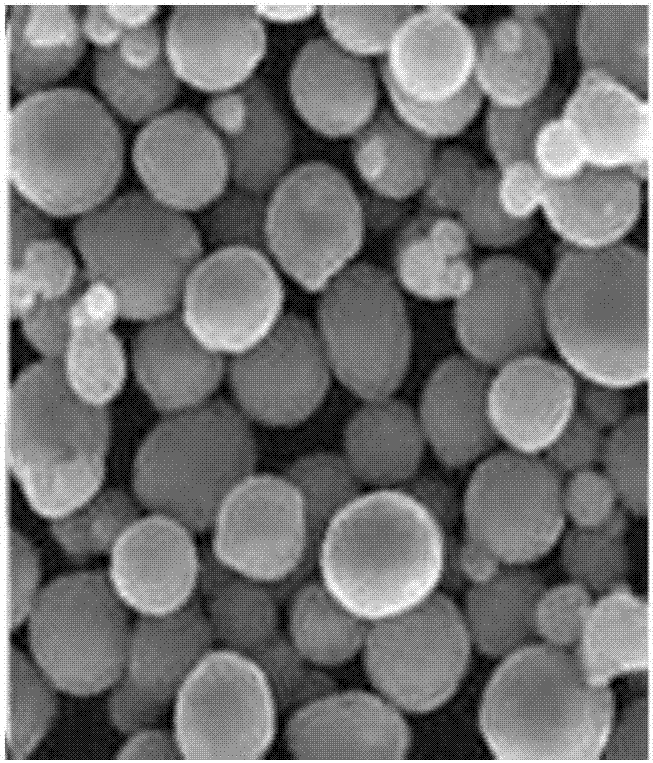

Silicon film coated aluminum pigment as well as preparation method and application thereof

InactiveCN107502002AWon't breakUniform colorPowdery paintsPigment treatment with organosilicon compoundsWeather resistanceNetwork structure

The invention discloses silicon film coated aluminum pigment as well as a preparation method and application thereof. The silicon film coated aluminum pigment is aluminum pigment coated with a Si-O-Si film having N layers of network structures, every two adjacent network structures are connected with each other by means of a coupling agent, and N is more than or equal to 3. The silicon film coated aluminum pigment can be used only when being dry mixed with a powder coating, so that the coating rate is increased; a binding process is not needed, so that the problems of caking scrap and poor bonding effects which are caused by difficult control of the process can be avoided, the aluminum pigment is not damaged, and the metallic luster effect is guaranteed; furthermore, after the aluminum pigment is sprayed, the twinkle effect of a paint film is improved; in addition, the paint film is high in surface hydrophobicity, so that the acid and alkali resistance and weather resistance of the paint film are greatly improved. The coupling agent comprises long chains of polycarbon and functional groups; in a reaction process, the long-chain carbon has a steric hindrance effect and the hydrolyzed functional groups contain charges of the same properties, so that the particles of the aluminum pigment do not agglomerate by means of adsorption, and the phenomenon of caking scrap is avoided.

Owner:长沙族兴新材料股份有限公司

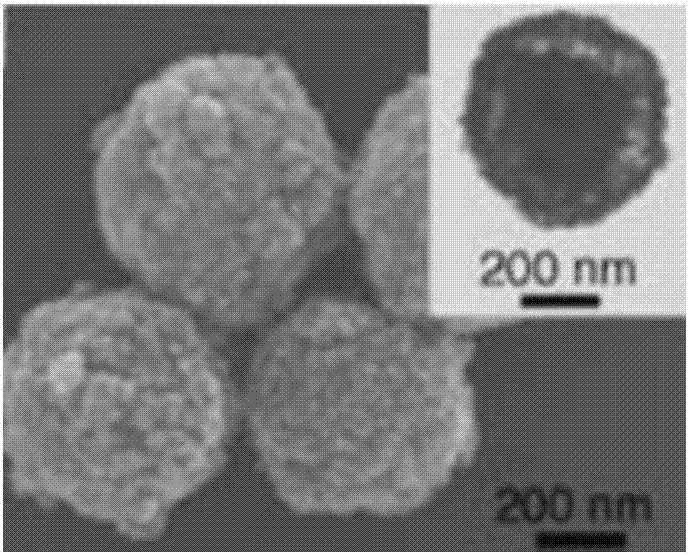

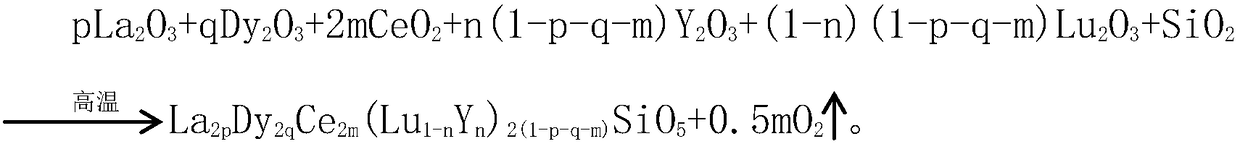

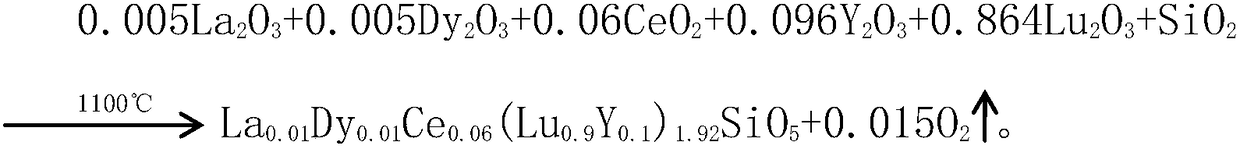

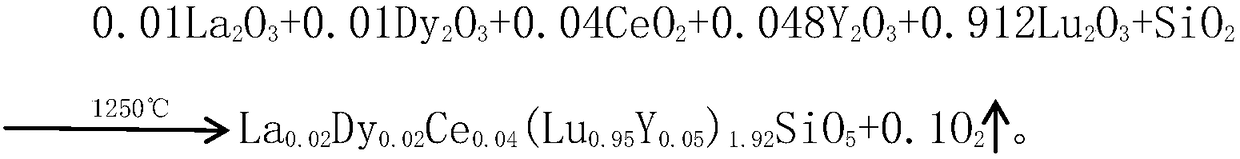

Lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and crystal growth method

ActiveCN108560053AIncrease vacanciesAvoid excessive oxidationPolycrystalline material growthFrom solid stateLutetiumCerium

The invention discloses a lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and a crystal growth method of the lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material. The chemical formula of the scintillating crystal is La2pDy2qCe2m(Lu(1-n)Yn)2(1-p-q-m)SiO5, wherein p is more than 0 and less than or equal to 0.02, q is more than 0 and less than or equal to 0.02, m is more than 0 and less than or equal to 0.03, n is more than or equal to 0.01 and less than or equal to 0.1, p, q and m meet the condition that pplus q plus m is more than 0 and less than or equal to 0.05; the growth method is as follows: S1: synthesizing a poly-crystal material block at the solid phase at the high temperature; S2: compressing and fusing the poly-crystal at the atmosphere of the protective gas; and S3: growing at equal diameter, and using a PID algorithm to automatically cool and anneal. The Dy and the La are doped in LYSO, the vacancy for growing the crystal is increased, the excessive oxidation of the crystal is avoided, the scintillating performance of the crystal is guaranteed, the luminescence spectrum of the crystal is expanded, and the case substitution rates of the ions Lu and Y are increased by means of cold isostaitc pressing, the automatic temperature-controlled growth is implemented through the PID algorithm, and the consistency of the crystals growing in batches is guaranteed.

Owner:安徽晶宸科技有限公司

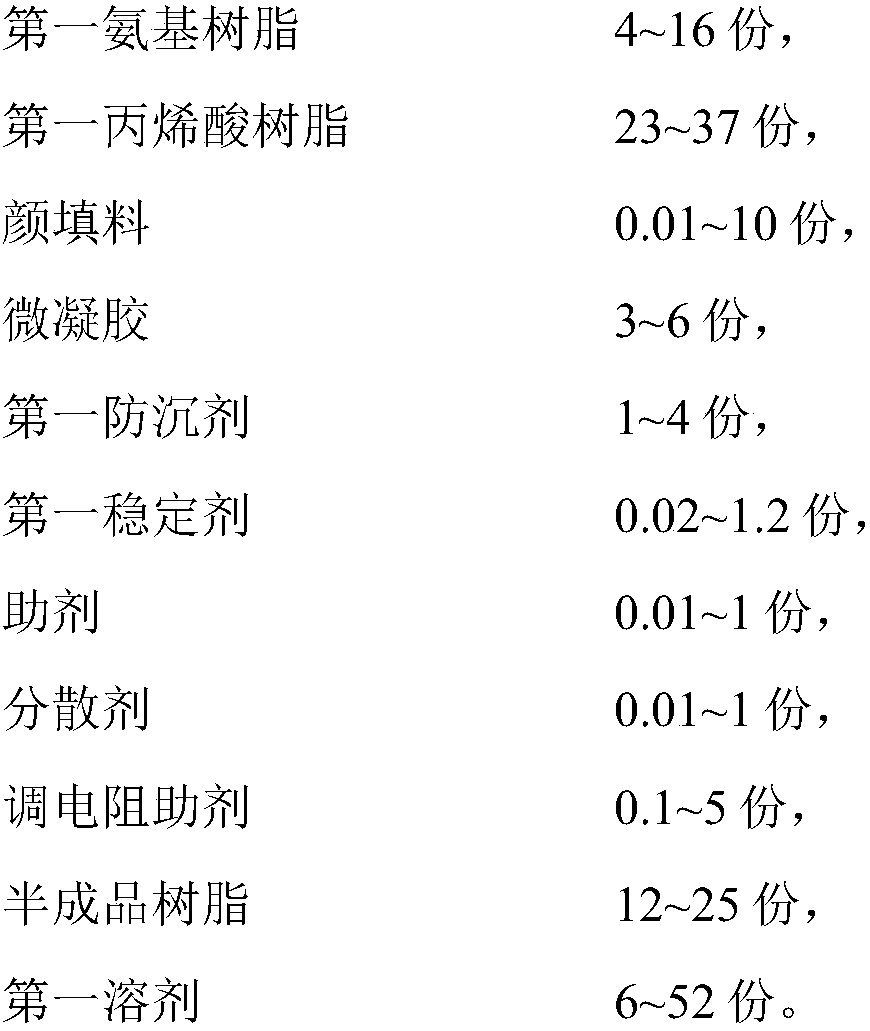

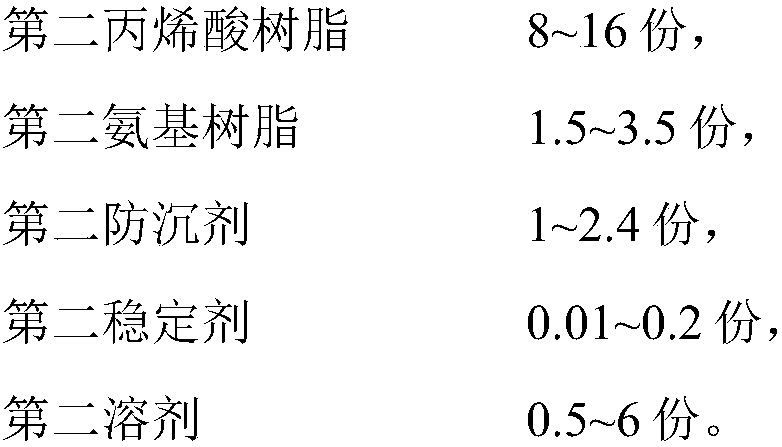

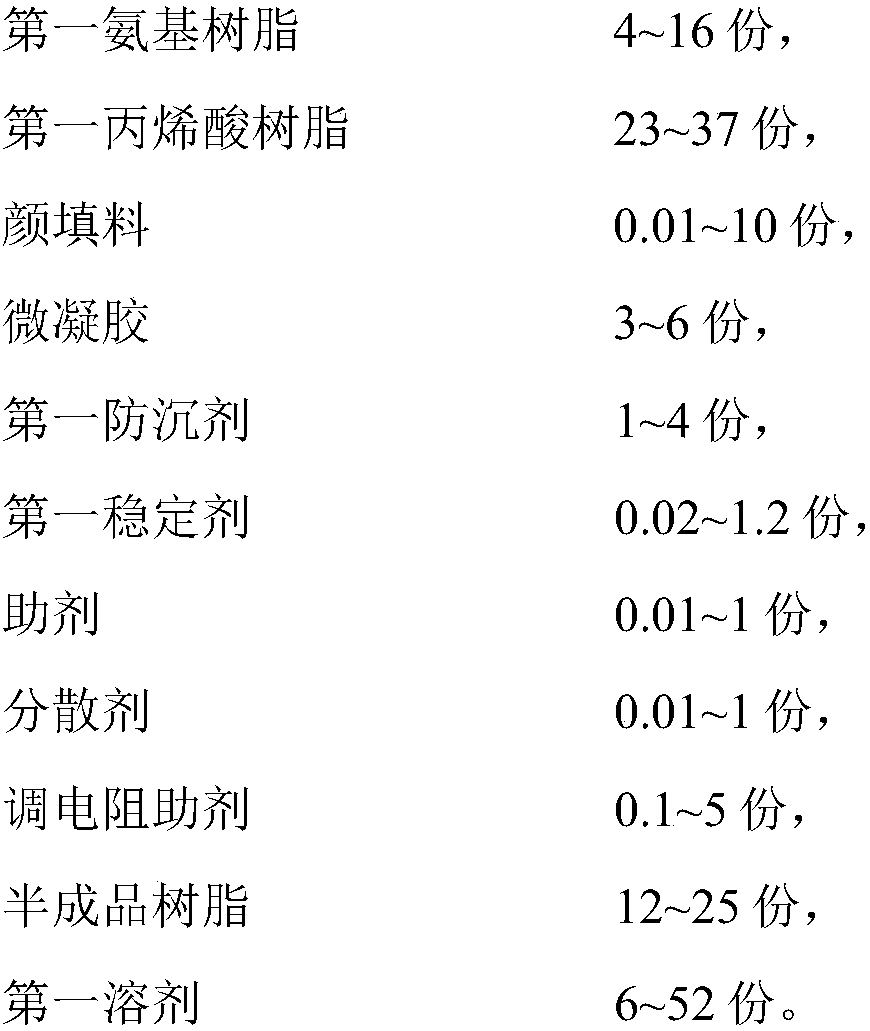

Solvent-based colored paint with high flickering degree effect and preparation method of solvent-based colored paint

ActiveCN107603370ASolve production requirementsAddress construction requirementsCoatingsWater basedElectrical resistance and conductance

The invention discloses solvent-based colored paint with a high flickering degree effect. The solvent-based colored paint is prepared from the following components in parts by weight: 4 to 16 parts offirst amino resin, 23 to 37 parts of first acrylic resin, 0.01 to 10 parts of pigment filler, 3 to 6 parts of microgel, 1 to 4 parts of a first anti-settling agent, 0.02 to 1.2 parts of a first stabilizer, 0.01 to 1 part of an auxiliary, 0.01 to 1 part of a dispersant, 0.1 to 5 parts of a resistance regulation auxiliary, 12 to 25 parts of semi-finished resin and 6 to 52 parts of a first solvent.According to the solvent-based colored paint with the high flickering degree effect, glass powder serving as the pigment filler is added into coating, and can be suitable for both solvent-based coating and water-based coating, so that a paint film with high flickering effect is finally obtained. The coating prepared with the preparation method is high in performance, high in storage stability, high in product quality stability and low in cost, and is suitable for low, middle and high-grade vehicle models in the market.

Owner:LANGFANG NIPPON PAINT

Glass film containing rare earth ion-doped Cs2LiYCl6 microcrystalline and preparation method of glass film

The invention discloses a chemical constitution of a glass film containing rare earth ion-doped Cs2LiYCl6 microcrystalline and a sol-gel preparation method of the glass film. The glass film is characterized by comprising the following components by mol percent: 71mol%-75mol% of germanium dioxide, 5mol%-10mol% of aluminum sesquioxide, 5mol%-10mol% of phosphorus pentoxide, 8mol%-12mol% of Cs2LiYCl6 and 1mol%-3mol% of rare-earth chloride, wherein rare-earth chloride is one of cerium chloride, europium chloride or terbium chloride. The sol-gel preparation method has the advantages that sol-gel is a low-temperature wet chemical method glass preparation technique, and glass is prepared by virtue of hydrolysis and chemical polymerization reaction of precursor raw materials, and a film material can be prepared under certain liquid viscosity; by virtue of low temperature synthesis conditions, the decomposition and the volatilization of the chloride raw material can be effectively prevented.

Owner:NINGBO UNIV

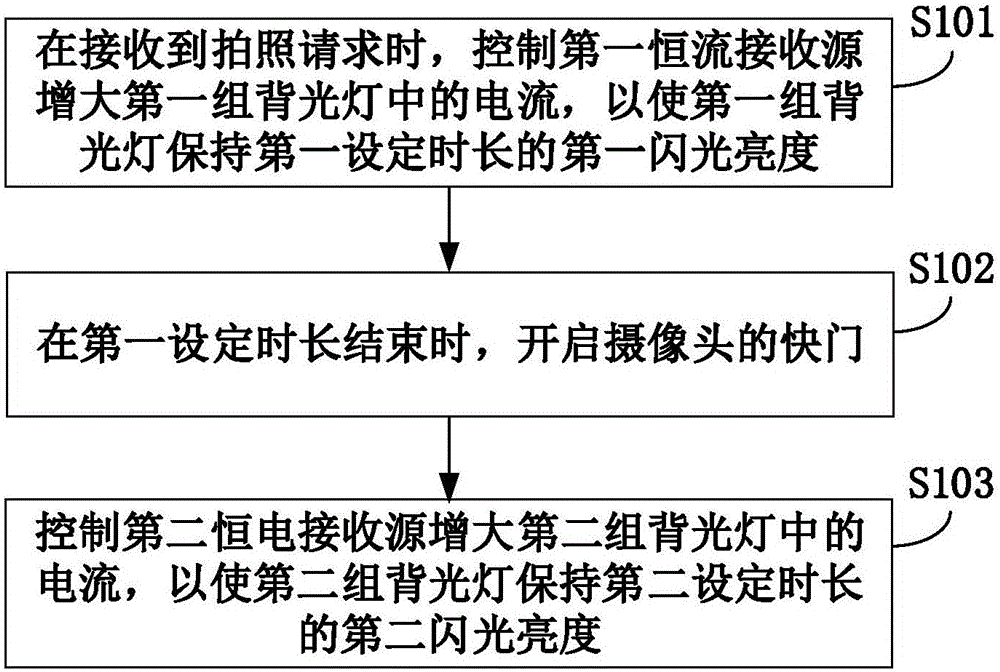

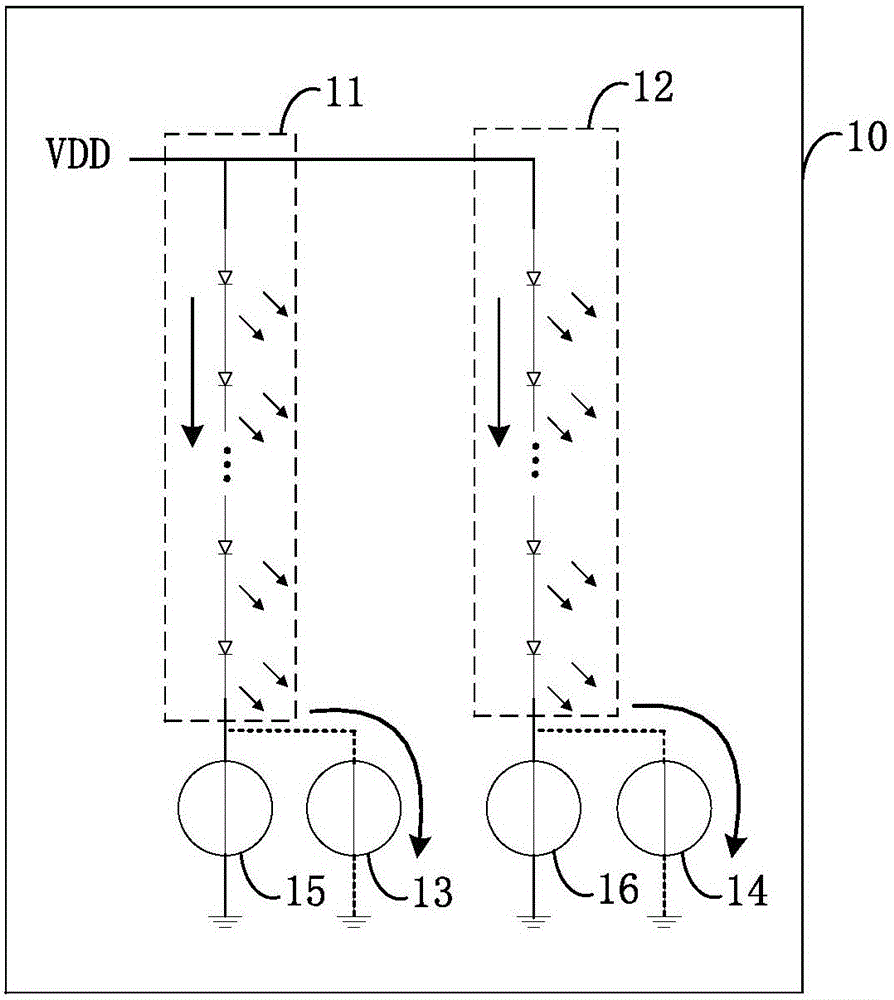

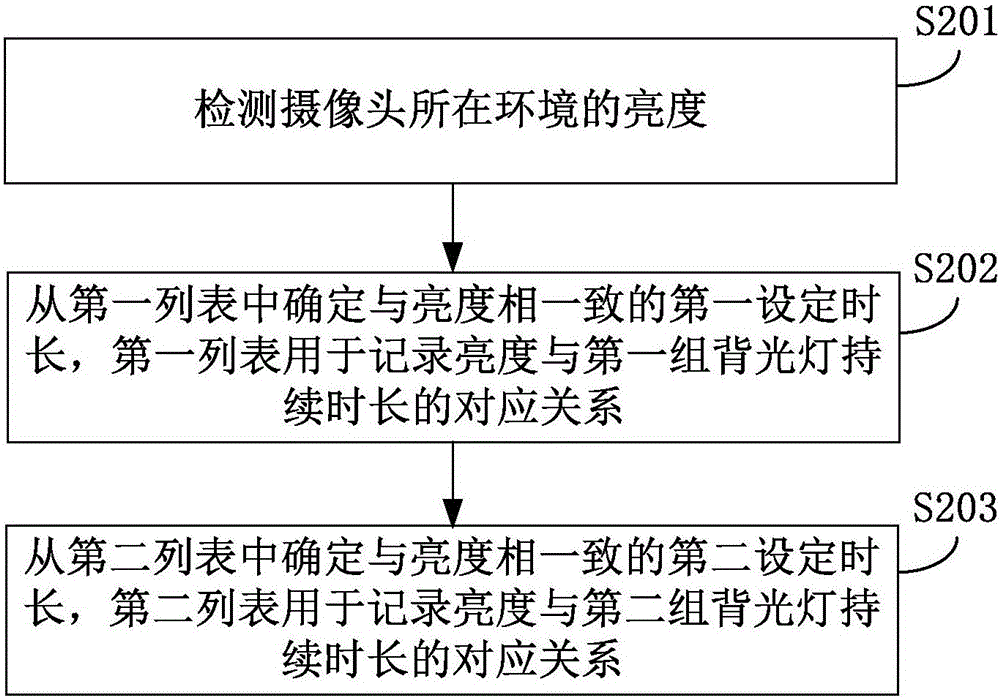

Light supplement method and device, and electronic device

InactiveCN106170042AImproves the ability to blink instantlyImprove photo experienceTelevision system detailsColor television detailsTime-sharingDepth of field

The invention relates to a light supplement method and device, and an electronic device. The method comprises the steps of: when a shooting request is received, controlling a first constant current receiving source to increase the current in a first group of backlight lamps so as to enable the first group of backlight lamps to maintain a first flash brightness for a first set time length; when the first time length ends, starting a shutter of a camera; and controlling a second constant current receiving source to increase the current in a second group of backlight lamps so as to enable the second group of backlight lamps to maintain a second flash brightness for a second set time length. According to the technical scheme, the first group of backlight lamps and the second group of backlight lamps are respectively driven in a time sharing mode, the instant flashing capability of the LED backlight lamps is improved, the camera is enabled to have a large field depth effect under a dark environment, and the shooting experience of the user is effectively is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

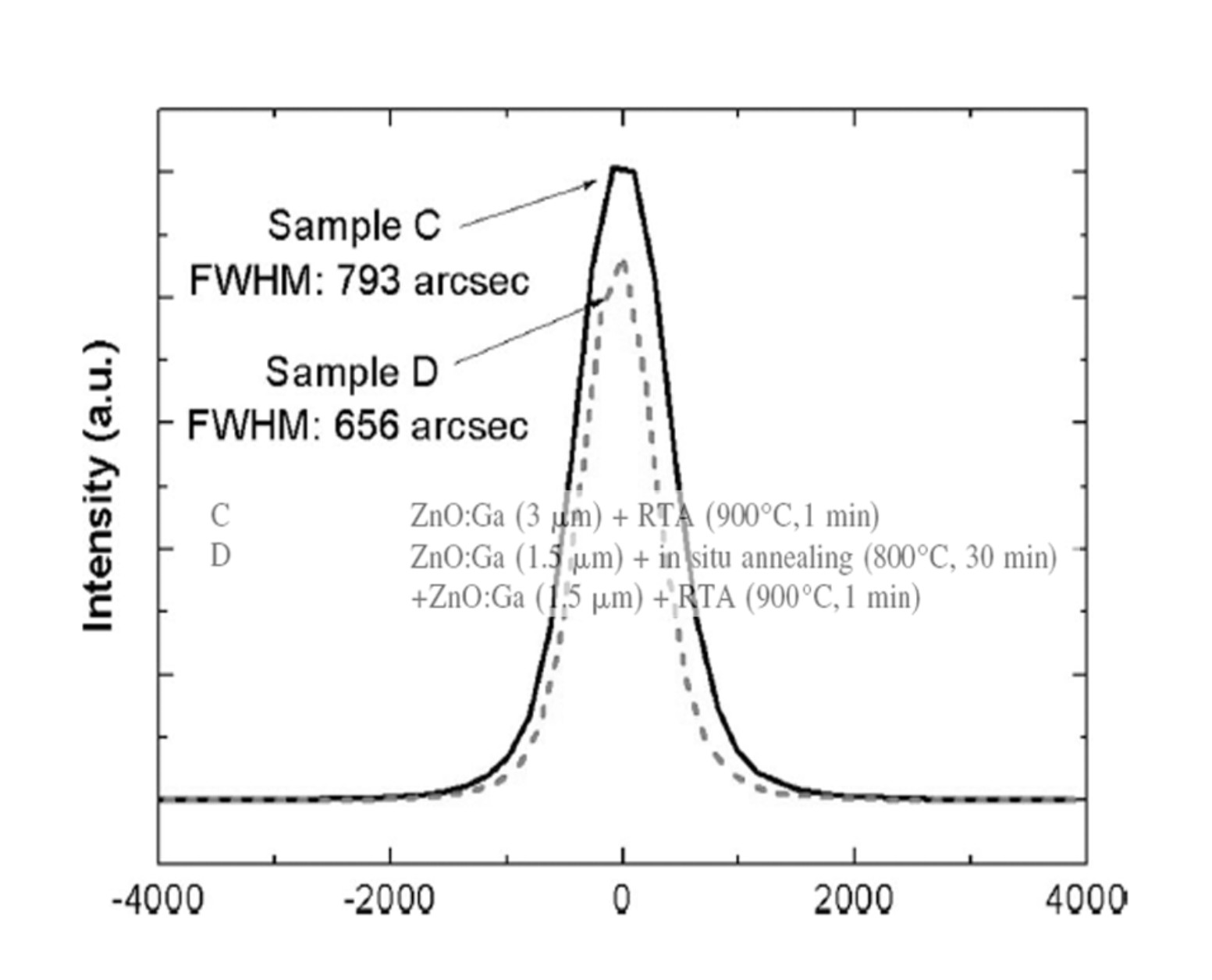

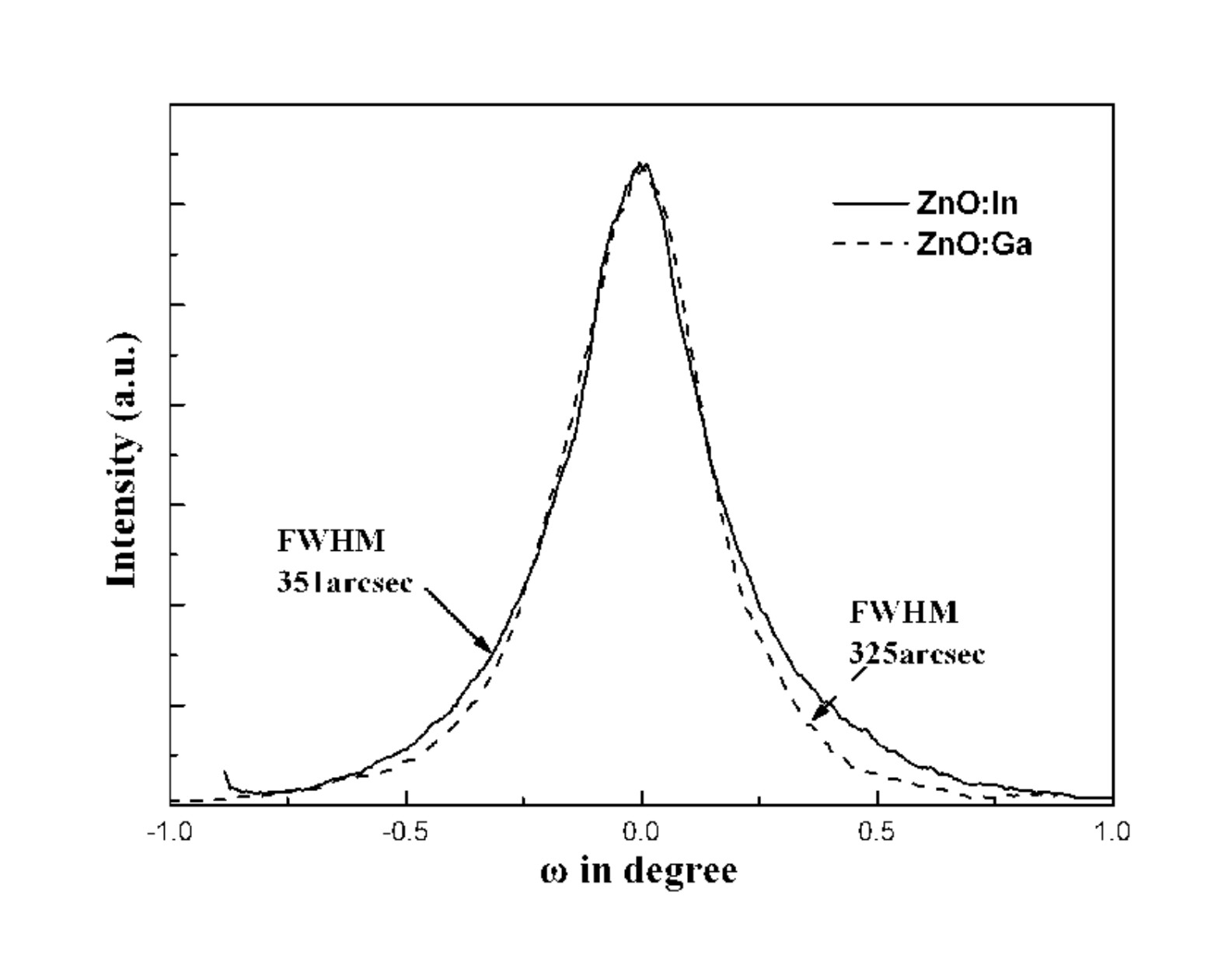

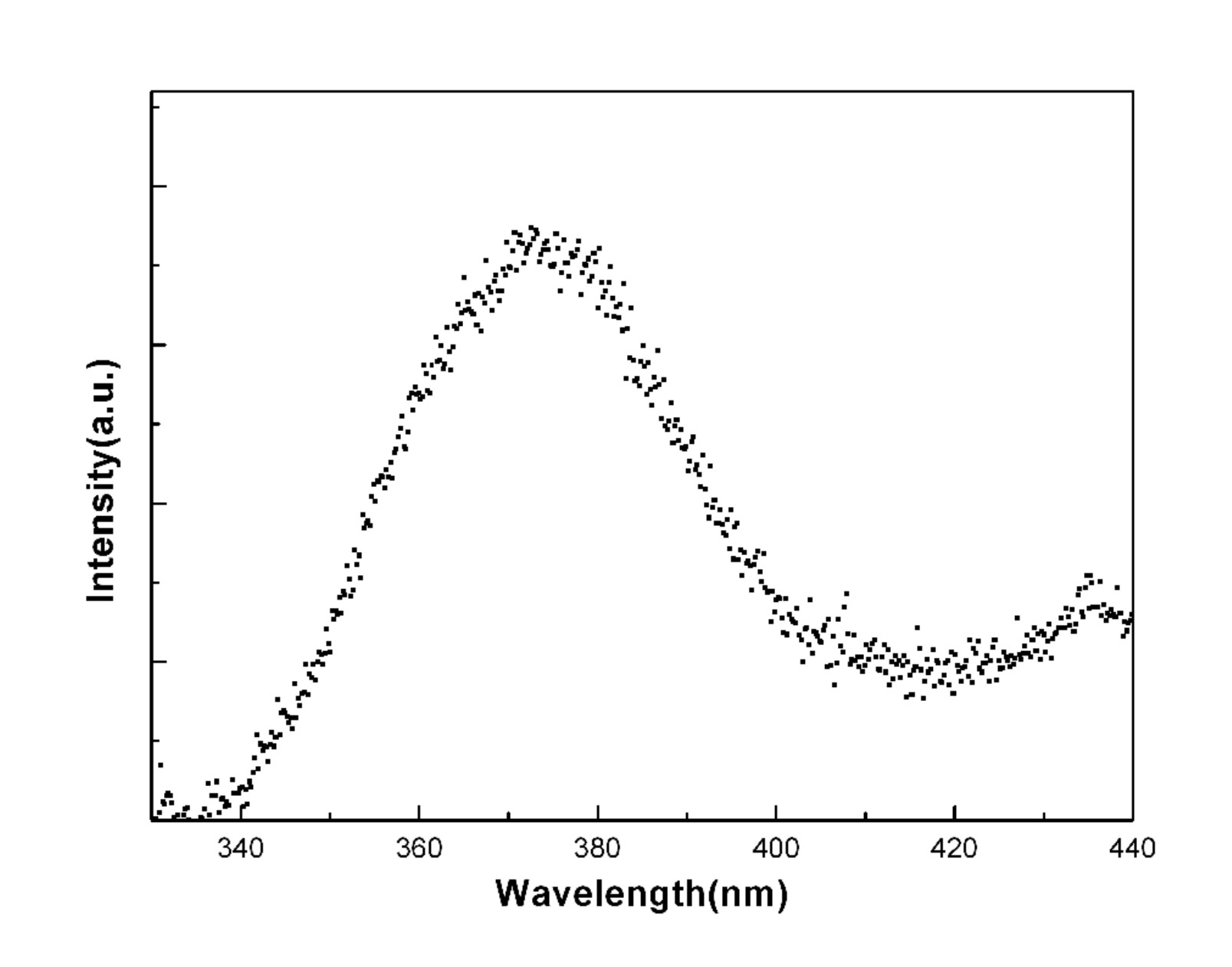

Preparation method of ZnO-based scintillating thick film

InactiveCN102627965AEasy to manufactureReduce the cost of growthLuminescent compositionsX-rayLuminescence

The invention discloses a preparation method of a ZnO-based scintillating thick film. The preparation method includes the three steps of: first, preparing ZnO-based ceramic target material; then, adopting a sapphire (side R) on which a ZnO monocrystal thick film grows as a substrate, and depositing a ZnO-based thick film on the substrate through a magnetically confined inductance coupling physical sputtering method; and finally, carrying out high-temperature rapid annealing treatment and low-temperature annealing treatment in a hydrogen-containing atmosphere. The thick film deposition employs an in situ annealing-regrowth two-step method. The ZnO-based scintillating thick film prepared by the method of the invention has good crystallization quality, and can realize ultrafast attenuation and luminescence under X-ray radiation, as well as has high light yield. Compared with ZnO scintillating power, ceramics and crystal materials, the ZnO-based scintillating thick film prepared by the method of the invention has the characteristics of convenient preparation, low growth cost, small volume and high utilization rate, controllable size of surface area, and easy integration, etc.

Owner:EAST CHINA NORMAL UNIV

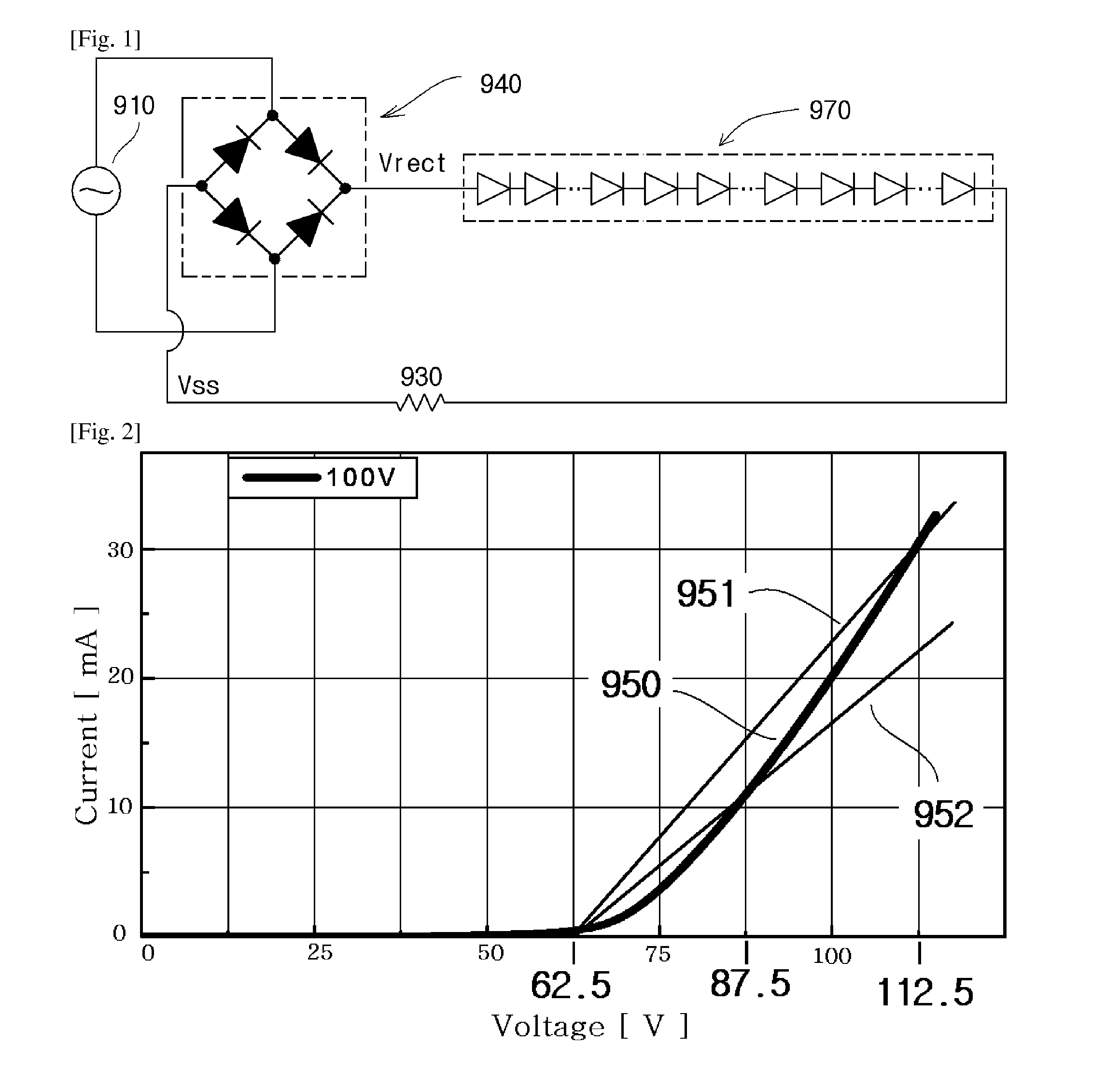

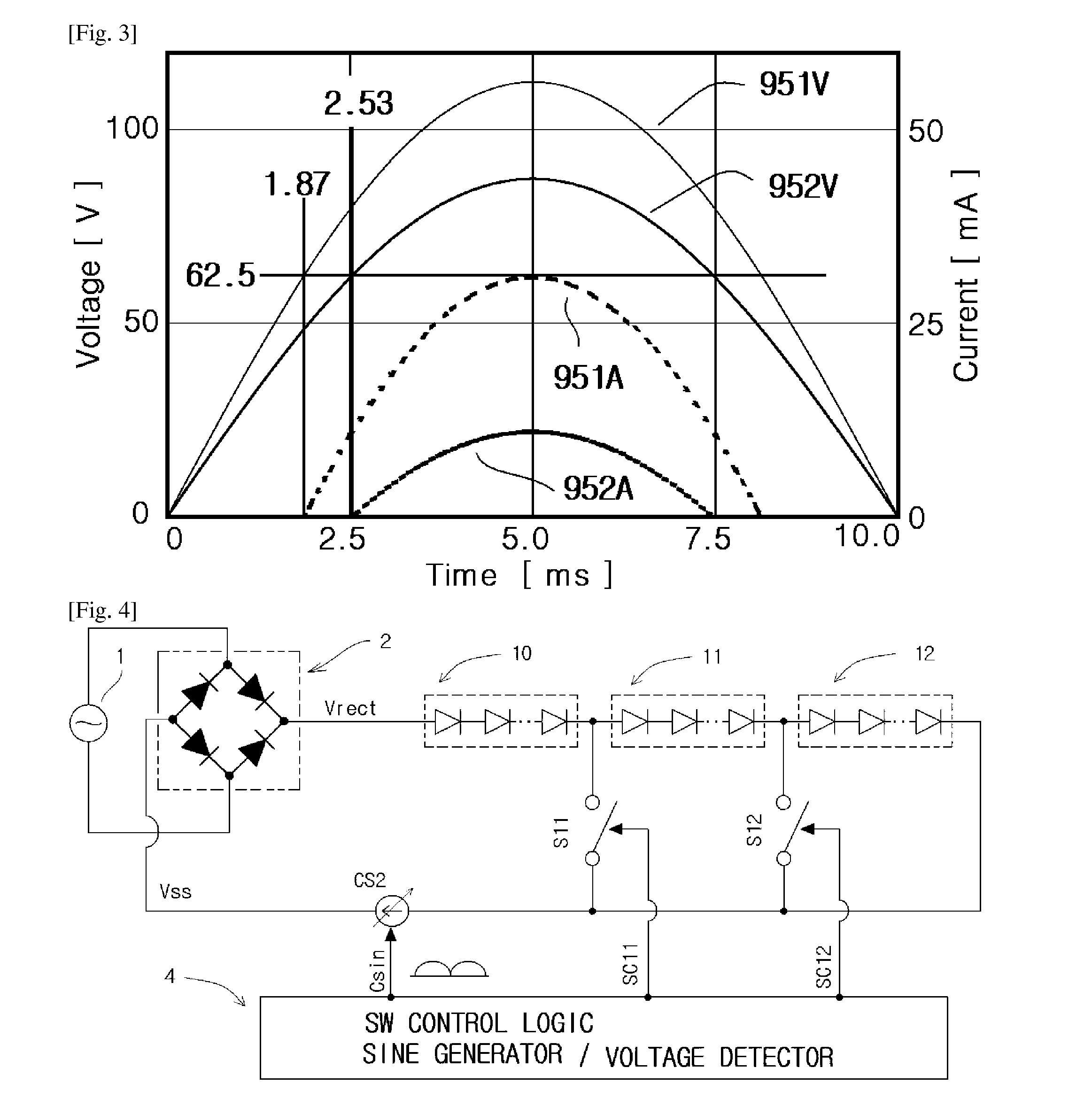

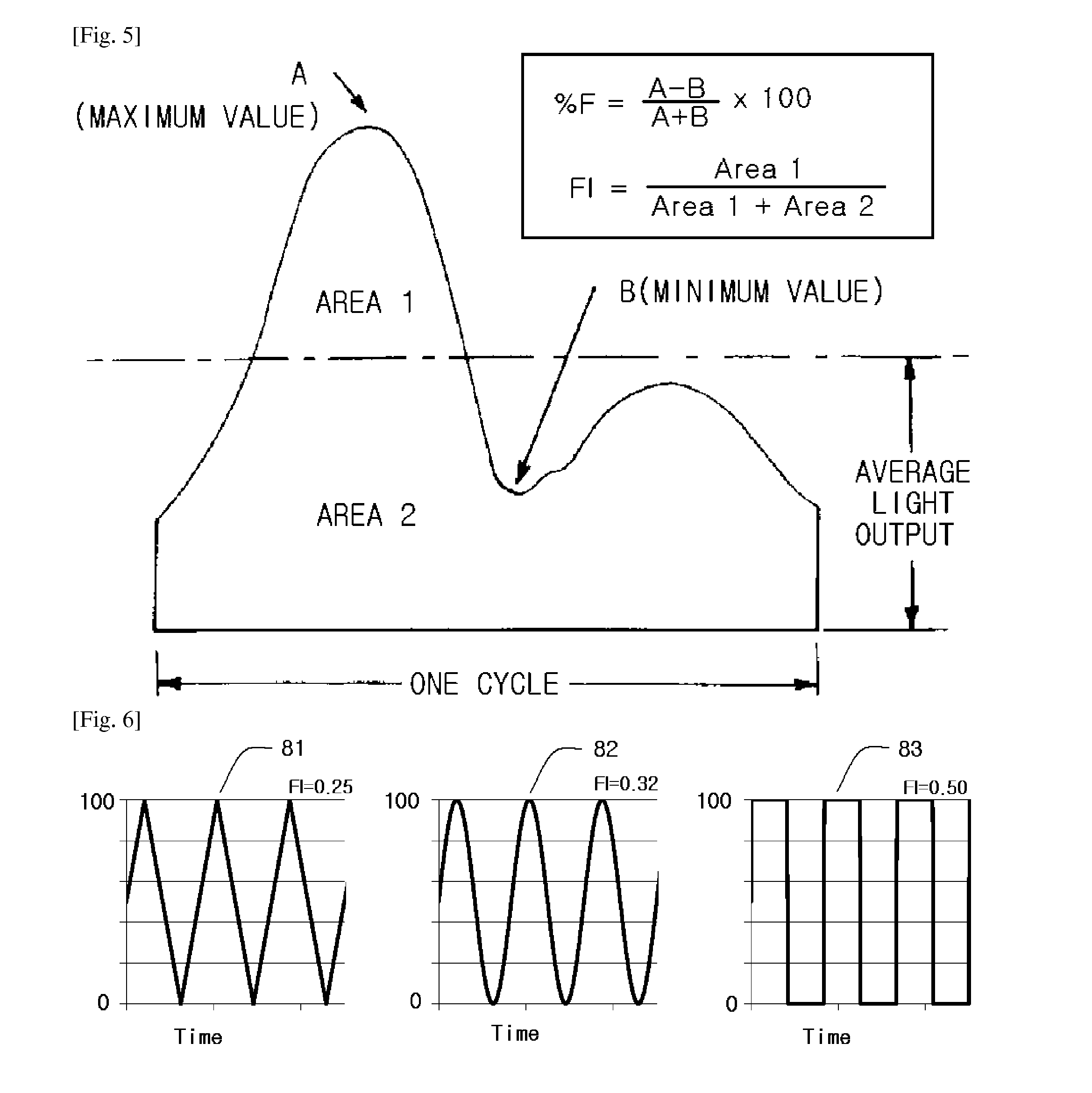

LED lighting apparatus having improved flicker performance

ActiveUS20150022104A1Improve flicker performanceReduce the differenceElectrical apparatusElectroluminescent light sourcesEngineeringBallast

Provided is a lighting apparatus using LEDs (light-emitting diodes having improved flicker performance. In general, in a direct-drive LED lighting apparatuses of the related art which use no switching-mode power supply (SMPS), percent flicker (hereinafter referred to as “% F”) is 100%. In contrast, the % F of the LED lighting apparatus having improved flicker performance according to the present invention is 40% or less that is equivalent to the % F of fluorescent lamps using a magnetic ballast.

Owner:LEE DON WON

Preparation method of glass film containing rare earth ion doped Ba2GdCl7 micro-crystal

The invention discloses a sol-gel preparation method of glass and glass film containing rare earth ion doped Ba2GdCl7 micro-crystal. The sol-gel preparation method is characterized by adopting the following preparation raw materials: 53-59mol% of tetraethoxygermanium, 8-16mol% of gallium ethoxide, 16-24mol% of barium chloride, 8-12mol% of gadolinium chloride and 1-3mol% of rare earth chloride, wherein rare earth chloride is cerium chloride, europium chloride or terbium chloride. The sol-gel preparation method has the advantages that a sol-gel method is a technology for preparing glass by low-temperature aqueous chemical synthesis and is characterized by obtaining glass and the glass film through precursor raw material hydrolysis and polymerization chemical reaction processes, so that the film material can be prepared under the condition of certain liquid viscosity; the low-temperature synthesis condition can conduce to effectively preventing decomposition and volatilization of the chloride raw material.

Owner:NINGBO UNIV

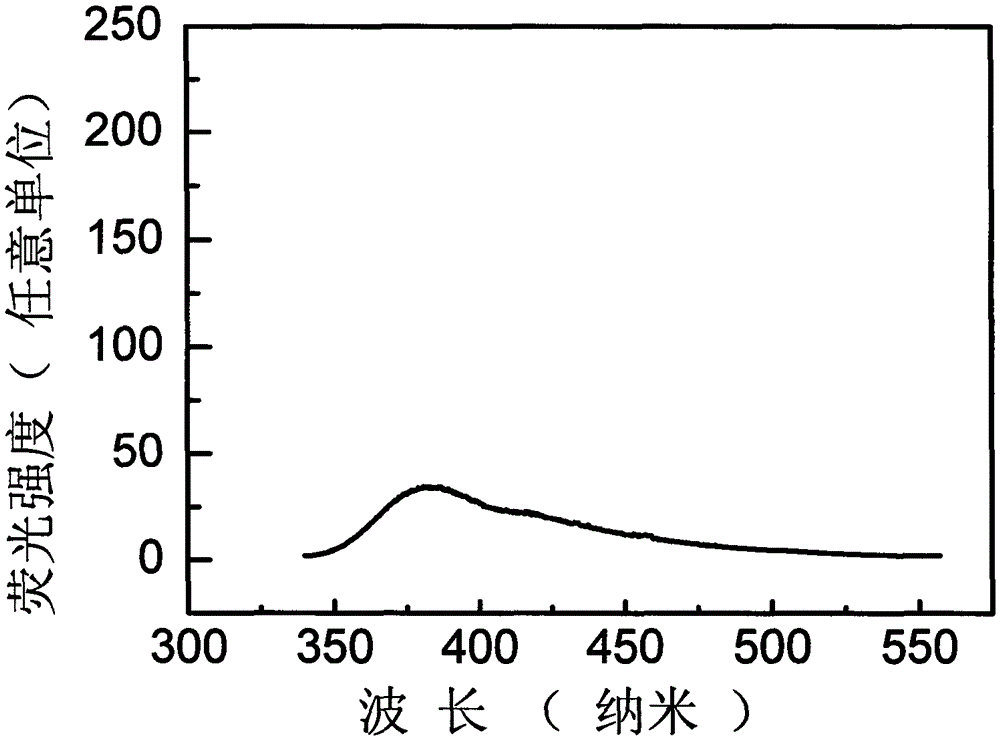

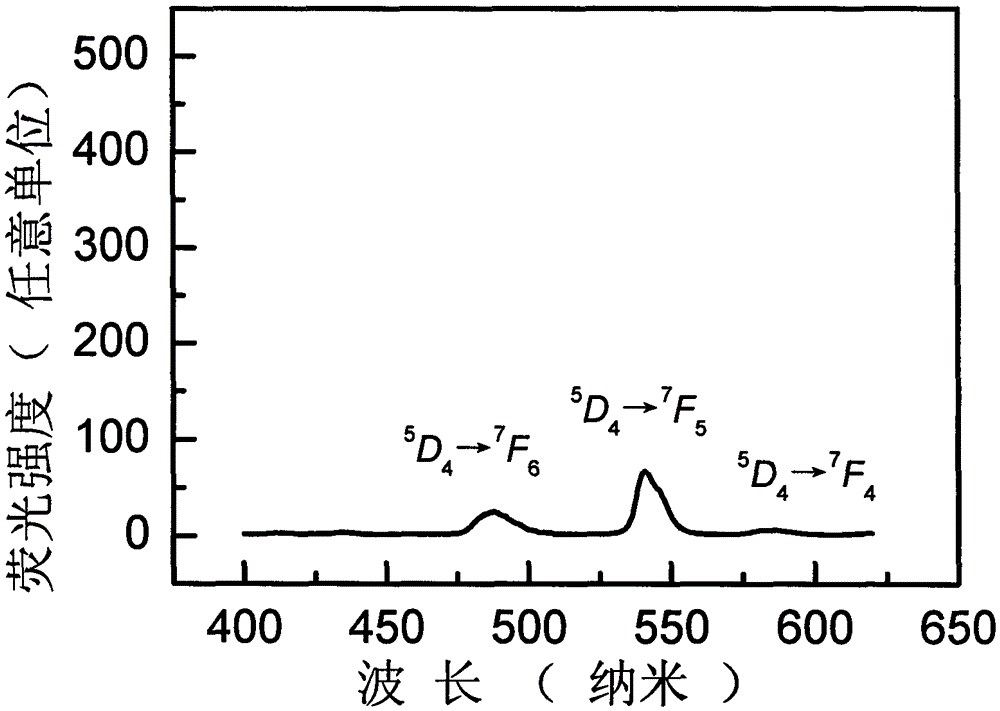

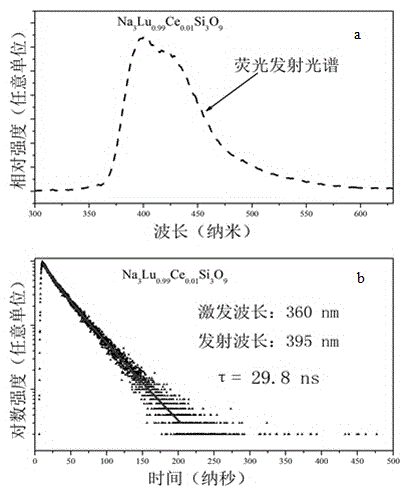

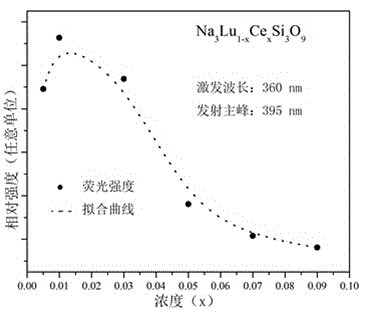

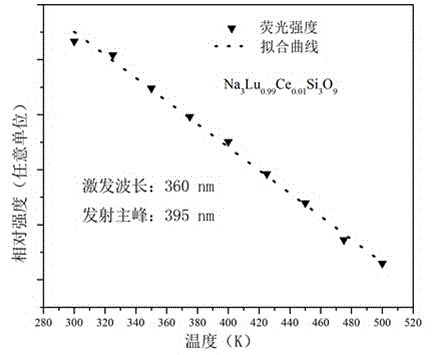

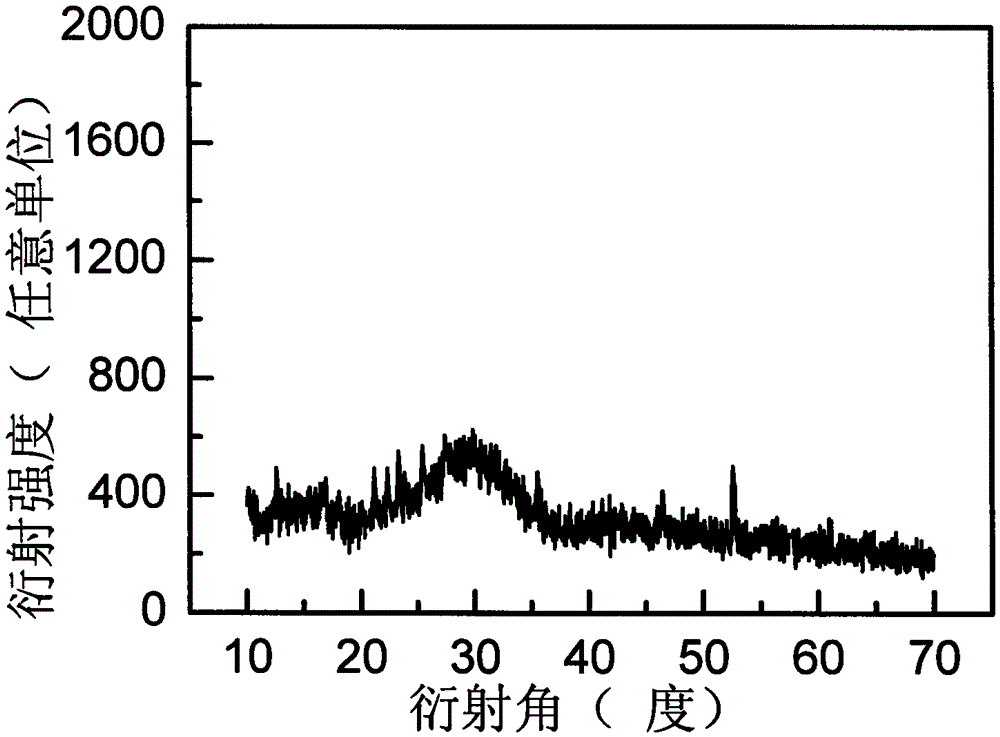

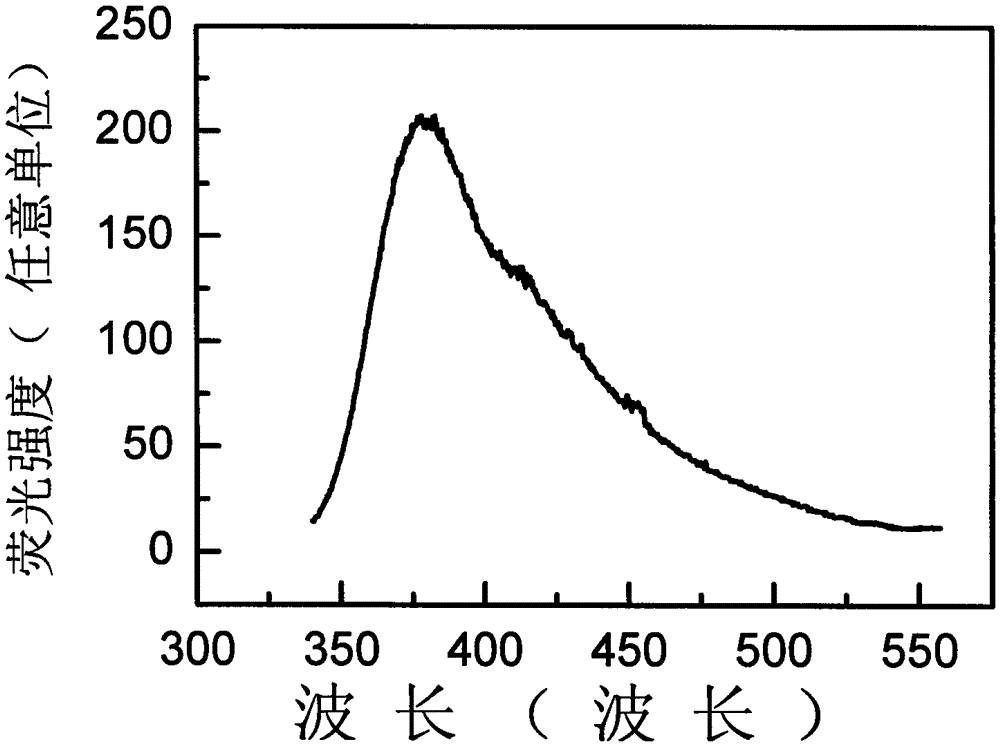

Rare earth silicate double salt scintillating material and preparation method thereof

InactiveCN104861976AEasy to grow and prepareImprove stabilityLuminescent compositionsFluorescenceSilicic acid

The invention belongs to the technical field of scintillating materials, and particularly discloses a rare earth silicate double salt scintillating material and a preparation method thereof. The chemical constitution formula of the rare earth silicate double salt scintillating material is M<3>RE<1-x>Ce<x>Si<3>O<9>, wherein x is a molar ratio of RE replaced by Ce, and x is greater than 0 and less than or equal to 0.3; M is selected from one or more of Li, Na, K, Rb and Cs; RE is selected from one or more of La, Gd, Y and Lu. The scintillating material can emit strong fluorescence when being excited by X-ray; the luminescence wavelength is 320-580 nm; the fluorescence lifetime when the scintillating material is excited by ultraviolet is about 30 ns; the rare earth silicate double salt scintillating material can stably exist in the air, is excellent in physical and chemical stability and scintillation property, and has the practical application value.

Owner:SUN YAT SEN UNIV

Glass containing rare earth ion doped lutetium iodide micro-crystals and preparation method of glass film

The invention discloses glass containing rare earth ion doped lutetium iodide micro-crystals and a preparation method of a glass film. The glass is characterized by being prepared from the following raw materials by mole percent: 73-75mol% of ethyl orthosilicate, 5-16mol% of niobium ethoxide, 10-15mol% of lutetium iodide and 1-5mol% of rare earth iodide, wherein rare earth iodide is one of cerium iodide, europium iodide and terbium iodide. The glass has the advantages as follows: a sol-gel method is a low-temperature wet-chemical method glass preparation technology, and the glass is obtained through hydrolysis and polymerization chemical reaction of precursor raw materials, so that the glass can be prepared into a film material at a certain liquid viscosity and iodide raw materials are prevented from being decomposed and volatilized through low-temperature synthesis conditions; the glass prepared through the sol-gel method can generate a certain micropores in the material due to volatilization and decomposition of the solvent, and the micropores provide the good environment for generation of nano iodide micro-crystals, so that defects that crystallization particles are nonuniform and glass devitrification occurs due to incomplete uniformity of glass smelting chemical constituents and crystallization processing temperature can be overcome to a certain extent.

Owner:NINGBO UNIV

Glass film containing divalent europium ion doped strontium bromide microcrystals and preparation method thereof

The invention discloses a glass film containing divalent europium ion doped strontium bromide microcrystals. The film is characterized by comprising 72-74 mol% of aluminum oxide, 10-15 mol % of phosphorus pentoxide, 10-15 mol% of strontium bromide and 1-3 mol% of europium bromide. The invention has the following advantages: a sol-gel method is a low temperature wet chemical glass preparation technology; glass is obtained by hydrolysis and polymeric chemical reaction process of precursor materials, so the glass can be made into a film material under certain liquid viscosity; low-temperature synthesis conditions effectively prevent decomposition and volatilization of bromide raw materials; and the glass prepared by the sol-gel method, due to volatilization and decomposition of the solvent, can generate certain micropores in the material, and the micropores provide a good environment for generating the nano bromide microcrystals, so as to overcome non-uniformity of crystallization particles and glass devitrification due to the chemical composition of glass melting and incompletely uniform crystallization treatment temperature.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com