Solvent-based colored paint with high flickering degree effect and preparation method of solvent-based colored paint

A scintillation and solvent-based technology, applied in coatings and other directions, can solve the problems of complex formula design, narrow range of raw materials, long production cycle, etc., to achieve the effect of improving the scintillation effect, widening the selection range, and saving coating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

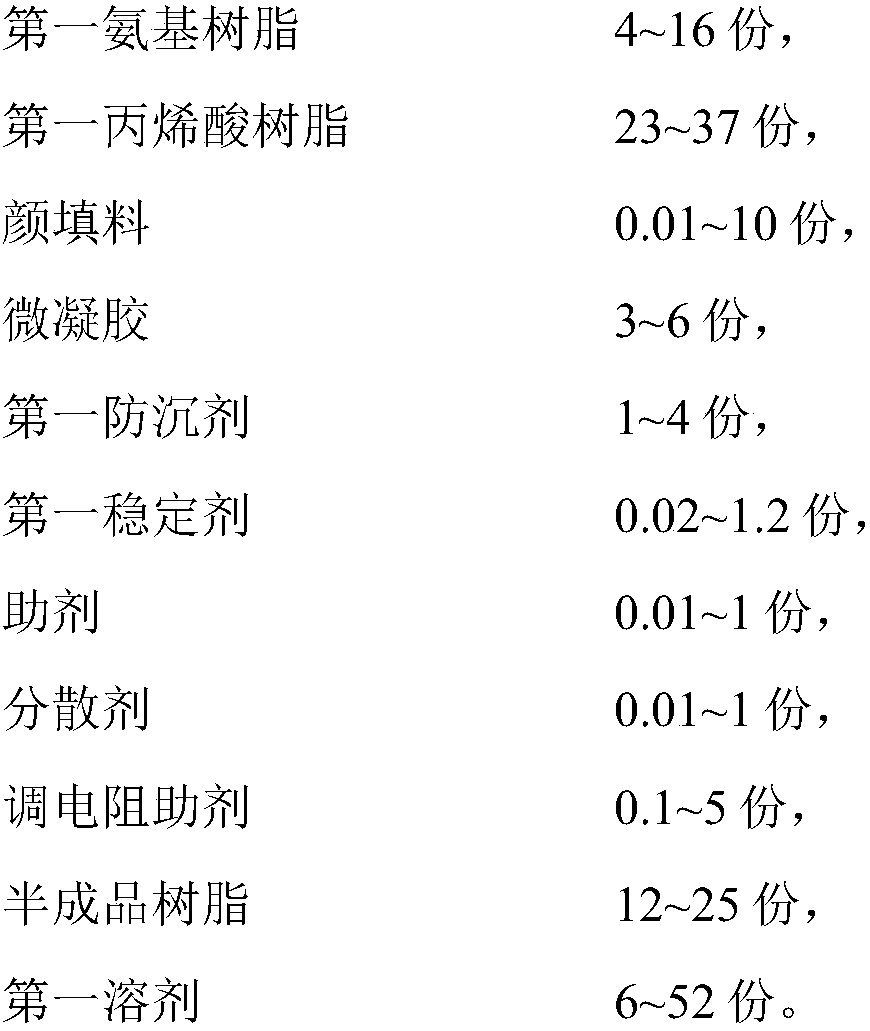

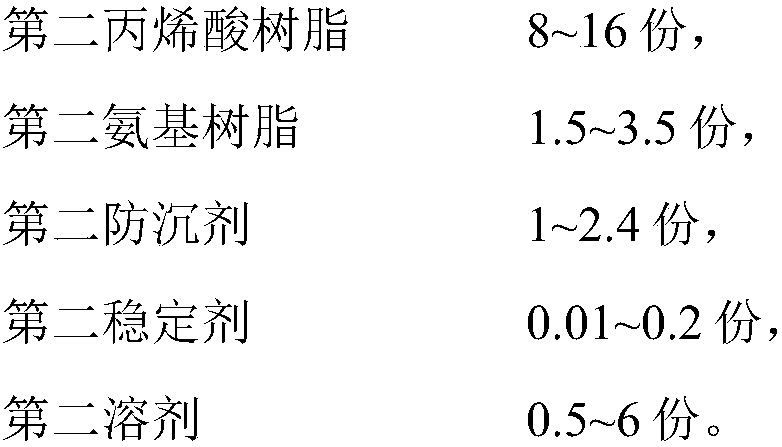

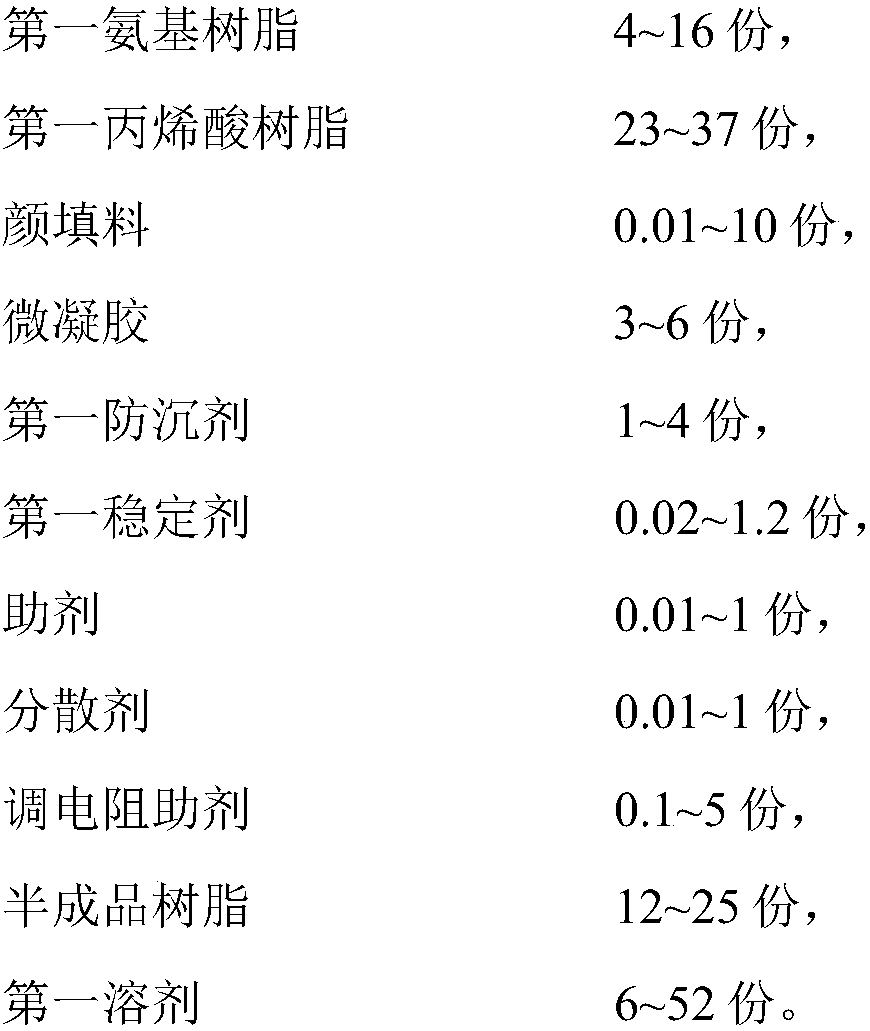

[0052] The formula of the solvent-based paint of blue flashing effect is shown in Table 1:

[0053] Table 1

[0054]

[0055]

[0056] The preparation method of the solvent-based paint with blue flickering effect comprises the following steps:

[0057] Step 1: Clean the equipment and pipes with xylene before feeding, and conduct a shrinkage test on the cleaned solvent, and operate after confirming that it is qualified;

[0058] In container A, put serial numbers 1, 2, and 3 in Table 1 in sequence, stir at low speed (<300rpm) for 15 minutes (mins), and confirm that the dispersion is uniform and there are no large particles.

[0059] Step 2: Confirm that the fineness of No. 4 in Table 1 is <= 5μm, under stirring, use the feeding funnel to add to container A at a speed of 20kg / min, stir at a speed of 300rpm for 15mins, and then use the feeding at a speed of 20kg / min while stirring Add No. 5 in Table 1 into the funnel and stir for 15 mins.

[0060] Step 3: In container B,...

Embodiment 2

[0085] The formula of the solvent-based paint with blue flashing effect is shown in Table 6:

[0086] Table 6

[0087]

[0088]

[0089] The preparation method of the solvent-based paint with blue flickering effect comprises the following steps:

[0090] Step 1: Clean the equipment and pipes with xylene before feeding, and conduct a shrinkage test on the cleaned solvent, and operate after confirming that it is qualified;

[0091] Put serial numbers 1, 2, and 3 into container A in turn, stir at low speed (<300rpm) for 15mins, and confirm that the dispersion is uniform and there are no large particles.

[0092] Step 2: Confirm that the fineness of No. 4 is <= 5μm, under stirring, use the feeding funnel to add to container A at a speed of 20kg / min, stir at a speed of 300rpm for 15mins, and then use the feeding funnel to add it to it at a speed of 20kg / min while stirring Add No. 5 and stir for 15mins.

[0093] Step 3: Add serial numbers 7, 8, 9, and 10 in sequence to cont...

Embodiment 3

[0119] The formula of the solvent-based paint with blue flashing effect is shown in Table 11:

[0120] Table 11

[0121]

[0122] The preparation method of the solvent-based paint with blue flickering effect comprises the following steps:

[0123] Step 1: Clean the equipment and pipes with xylene before feeding, and conduct a shrinkage test on the cleaned solvent, and operate after confirming that it is qualified;

[0124] Put serial numbers 1, 2, and 3 into container A in turn, stir at low speed (<300rpm) for 15mins, and confirm that the dispersion is uniform and there are no large particles.

[0125] Step 2: Confirm that the fineness of No. 4 is <= 5μm, under stirring, use the feeding funnel to add to container A at a speed of 20kg / min, stir at a speed of 300rpm for 15mins, and then use the feeding funnel to add it to it at a speed of 20kg / min while stirring Add No. 5 and stir for 15mins.

[0126] Step 3: Add serial numbers 7, 8, 9, and 10 in sequence to container B, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com