High-precision CO2 flooding foam crude oil metering device and metering method under high gas-liquid ratio

A metering device and gas-liquid ratio technology, which is applied in the direction of measurement, earthwork drilling, mining fluid, etc., can solve the problems of large error, low measurement accuracy, inaccurate measurement, etc., achieve reasonable structure, high measurement accuracy, and improve the measurement level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

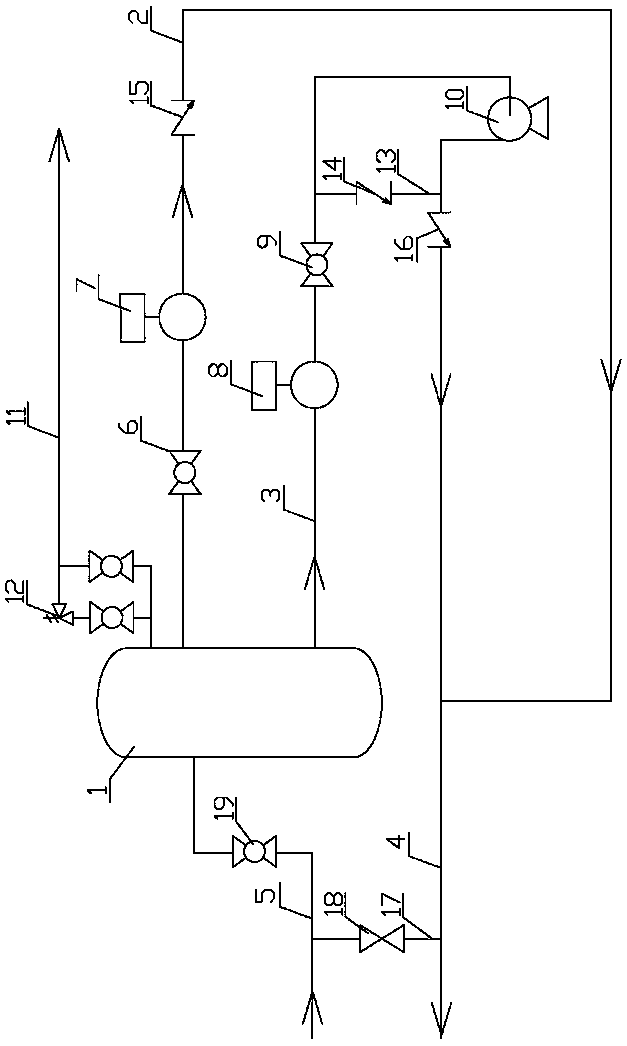

[0023] Embodiment 1, as attached figure 1 As shown, the high precision CO 2 The high gas-liquid ratio foam crude oil metering device includes a vertical metering separator 1, a gas phase metering pipeline 2, a liquid phase metering pipeline 3, an oil outlet pipeline 4 and a PLC, and the liquid inlet of the vertical metering separator 1 is connected with a liquid inlet Pipeline 5, the gas outlet of vertical metering separator 1 is connected with one end of gas phase metering pipeline 2, the liquid outlet of vertical metering separator 1 is connected with one end of liquid phase metering pipeline 3, and the other end of gas phase metering pipeline 2 The other end of the liquid phase metering pipeline 3 is respectively connected with the oil outlet pipeline 4, and the gas phase electric valve 6 and the gas phase flowmeter 7 are connected in series on the gas phase metering pipeline 2, and the mass flowmeter is connected in series on the liquid phase metering pipeline 3 Flow mete...

Embodiment 2

[0032] Embodiment 2, as the optimization of above-mentioned embodiment, as attached figure 1 As shown, the top of the vertical metering separator 1 is communicated with a vent line 11, and a vent safety valve 12 is connected in series on the vent line 11. Setting the venting pipeline and venting safety valve can prevent safety accidents such as explosion of the tank caused by too high pressure in the vertical metering separator 1. When the pressure in the vertical metering separator 1 is too high, the venting safety valve will jump to discharge excess gas in the tank , reduce the pressure inside the tank and ensure the safe operation of production.

Embodiment 3

[0033] Embodiment 3, as the optimization of above-mentioned embodiment, as attached figure 1 As shown, there is a bypass line 13 connected between the liquid phase metering line 3 after the liquid phase electric valve and the liquid phase metering line 3 after the pipeline centrifugal pump 10, and a bypass line check valve 14 is connected in series on the bypass line . When the pipeline centrifugal pump 10 breaks down, the liquid in the vertical metering separator 1 can be directly discharged from the bypass line 13 to ensure the safe operation of production; the bypass line check valve 14 can prevent the liquid from flowing back and ensure the measurement accuracy precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com