A kind of method for preparing poly(aryl ether ketone) polymer

A technology of polyaryletherketone and polymer, which is applied in the field of synthesis of aryl etherketone polymer materials, and can solve problems such as shedding, different entrainment output, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

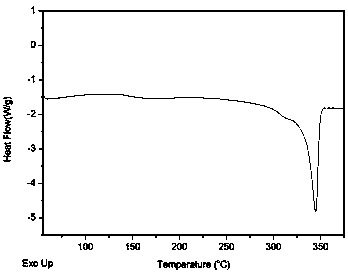

Embodiment 1

[0020] First put in 250 kg of diphenyl sulfone, then add 440.6 kg of 4,4'-difluorobenzophenone, 220 kg of hydroquinone, 300 kg of sodium carbonate, and then add 950 kg of diphenyl sulfone to start the membrane temperature machine to start slow heating. When most of the material in the polymerization tank is liquid (the temperature is generally around 140°C), start the stirring governor and adjust the speed at 10 Hz. Open the nitrogen valve of the polymerizer, feed high-purity nitrogen, adjust the nitrogen flow rate to 1.9m3 / h, turn on the induced draft fan, repeat 3 times, remove the oxygen in the polymerizer, and make the slight negative pressure of nitrogen in the system be -0.01 After Mpa, the heating reaction starts, the exhausted nitrogen is cooled by the reflux condenser, and the sublimable diphenyl sulfone entrained in the gas is recovered in liquid form to the heat-conducting oil heat-tracing buffer tank, and each batch is measured to adjust the batching ratio for recyc...

Embodiment 2

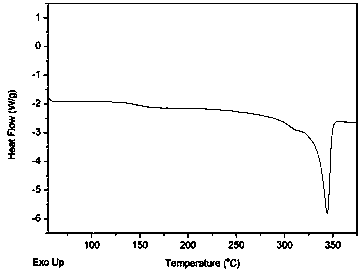

[0023] First put in 250 kg of diphenyl sulfone, then add 440.6 kg of 4,4'-difluorobenzophenone, 220 kg of hydroquinone, 300 kg of sodium carbonate, and then add 950 kg of diphenyl sulfone to start the membrane temperature machine to start slow heating. When most of the material in the polymerization tank is liquid (the temperature is generally around 140°C), start the stirring governor and adjust the speed at 10 Hz. Open the nitrogen valve of the polymerizer, feed high-purity nitrogen, adjust the nitrogen flow rate to 1.9m3 / h, turn on the induced draft fan, repeat 3 times, remove the oxygen in the polymerizer, and make the slight negative pressure of nitrogen in the system be -0.02 After Mpa, the heating reaction starts, the exhausted nitrogen is cooled by the reflux condenser, and the sublimable diphenyl sulfone entrained in the gas is recovered in liquid form to the heat-conducting oil heat-tracing buffer tank, and each batch is measured to adjust the batching ratio for recyc...

Embodiment 3

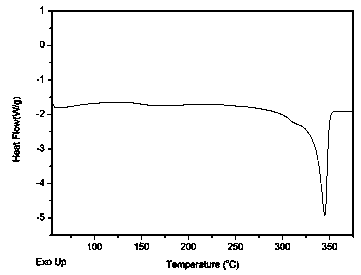

[0026]First put in 250 kg of diphenyl sulfone, then add 440.6 kg of 4,4'-difluorobenzophenone, 220 kg of hydroquinone, 300 kg of sodium carbonate, and then add 950 kg of diphenyl sulfone to start the membrane temperature machine to start slow heating. When most of the material in the polymerization tank is liquid (the temperature is generally around 140°C), start the stirring governor and adjust the speed at 10 Hz. Open the nitrogen valve of the polymerization kettle, feed high-purity nitrogen, adjust the nitrogen flow rate to 1.9m3 / h, turn on the induced draft fan, repeat 3 times, remove the oxygen in the polymerization kettle, and make the slight negative pressure of nitrogen in the system be -0.03 After Mpa, the heating reaction starts, the exhausted nitrogen is cooled by the reflux condenser, and the sublimable diphenyl sulfone entrained in the gas is recovered in liquid form to the heat-conducting oil heat-tracing buffer tank, and each batch is measured to adjust the batch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com