Halogenated perovskite quantum dot composite material for neutron detection and preparation method thereof

A composite material and calcium halide technology, applied in the field of radiation detection, can solve the problems of large-volume preparation and harsh use conditions, low light yield and energy resolution, complex preparation process, etc., and achieve excellent scintillation performance, low cost, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

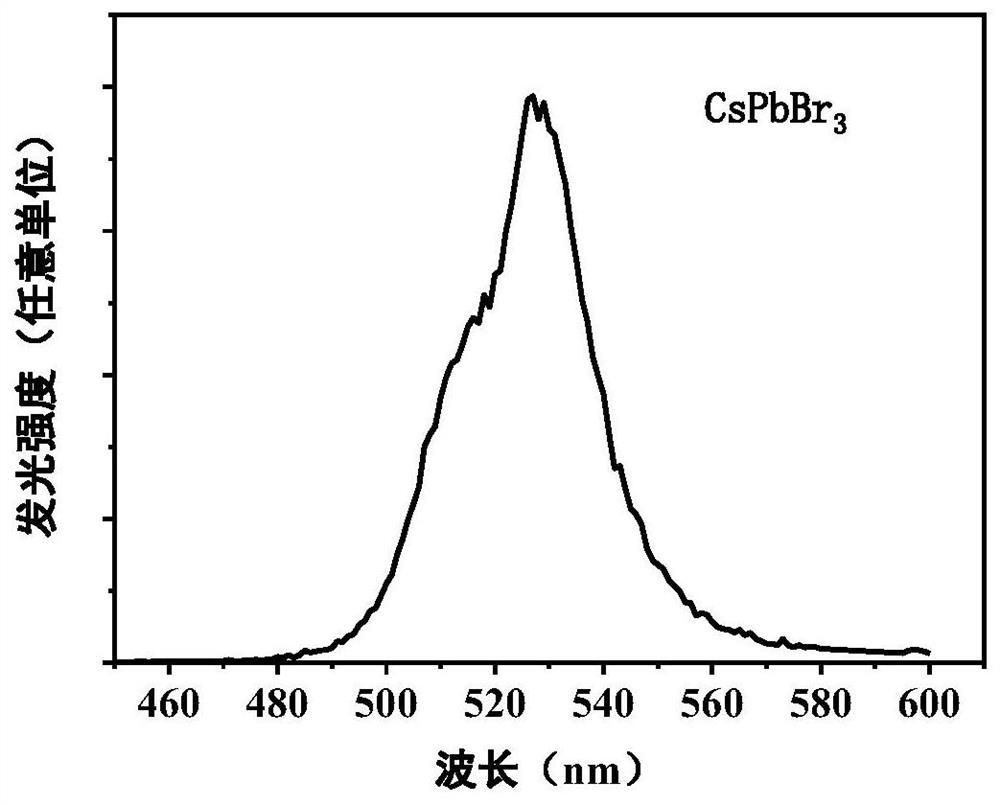

[0051] Example 1 Rich 10 B-CsPbBr 3 Halide Perovskite Composite Inorganic Glass Material Bulk

[0052] The first step: the stoichiometric ratio (molar ratio) design of the composite material, its specific component is B 2 o 3 : SiO 2 : ZnO: SrO: CsO: PbO: NaBr (mol%) = 52: 21: 6: 5: 7: 3: 6, with SiO 2 、H 10 BO 3 , ZnO, SrCO 3 、CsCO 3 , PbO: NaBr is used as the raw material, weighed and ground evenly according to the components, then melted at a high temperature of 1050 ° C for 20 minutes, and quenched in a mold to prepare a glass block precursor.

[0053] Step 2: The prepared glass is subjected to secondary heat treatment in a box-type muffle furnace. The holding temperature is 450°C, the holding time is 8h, and the heating rate is 5°C / min. Then the glass sample is cooled to room temperature and taken out to obtain the required CsPbBr 3 Halide perovskite composite inorganic glass material bulk.

[0054] The CsPbBr that embodiment 1 prepares 3 The block sample of h...

Embodiment 2

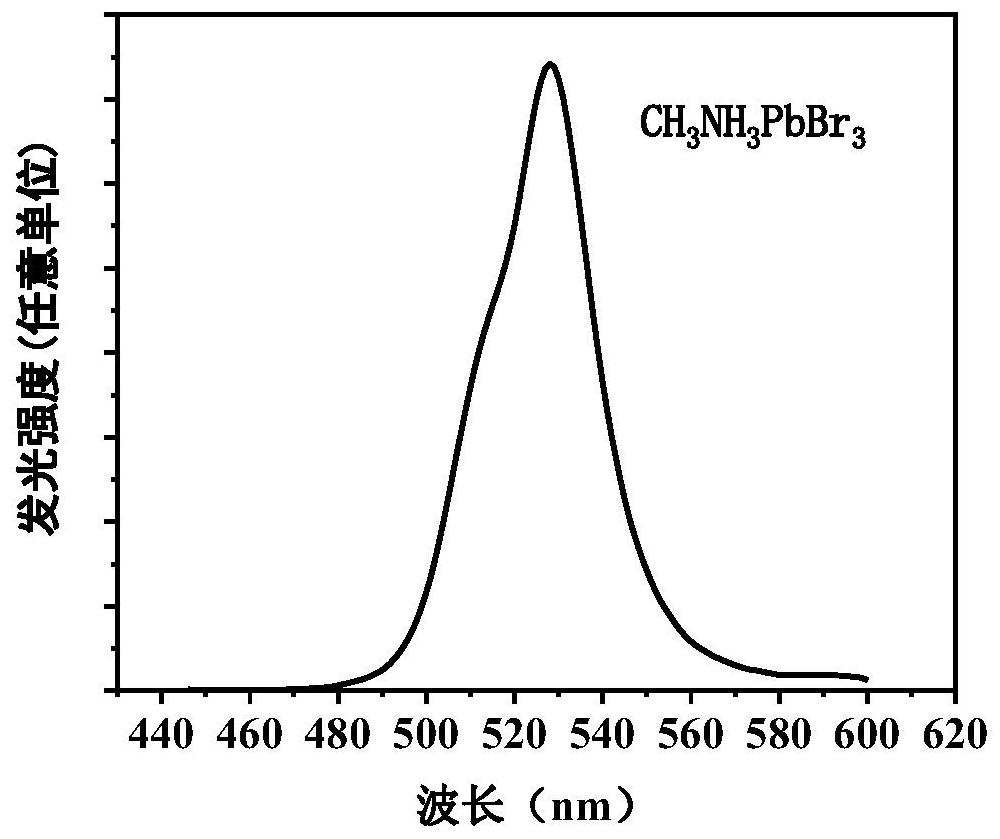

[0056] Example 2 Rich 6 CH of Li 3 NH 3 PbBr 3 Halide perovskite composite organic polymer material bulk

[0057] Step 1: CH 3 NH 3 PbBr 3 Synthesis of Perovskite Quantum Dot Precursor Solution, CH 3 NH 2 Stir with 0.5mol / L HBr solution at a molar ratio of 1:1 at 0°C until the solution is clear, then place the solution in an oil bath and heat it to 70°C, and let it stand for 12 hours, then filter to obtain a light yellow color Precipitate. After the precipitate was repeatedly washed with absolute ethanol, it was recrystallized with anhydrous ether, and the obtained white crystal was vacuum-dried at a temperature of 50 degrees Celsius for 12 hours to obtain the desired CH 3 NH 3 Br. Then 11.2 g of CH 3 NH 3 Br with 29.4g of PbBr 2 The molar ratio is 5:4, mixed and dissolved in N,N-dimethylformamide ethanol solvent with a volume of 200ml, stirred and heated to 70°C, the stirring time is 120min, and the prepared target CH 3 NH3 PbBr 3 Perovskite quantum dot precur...

Embodiment 3

[0061] Example 3 Rich 10 B-CsPbI 3 Halide perovskite composite inorganic glass material optical fiber

[0062] The first step: the stoichiometric ratio (molar ratio) design of the composite material, its specific component is B 2 o 3 : SiO 2 : ZnO: SrO: CsO: PbO: NaI (mol%) = 52: 21: 6: 5: 7: 3: 6, with SiO 2 、H 10 BO 3 , ZnO, SrCO 3 、CsCO 3 , PbO:NaI was used as the raw material, weighed and ground evenly according to the components, and then melted at a high temperature of 1050°C for 20 minutes, quenched in a mold to prepare a glass block precursor, and then annealed in a muffle furnace for 5 hours, and the temperature was set at 350°C.

[0063] The second step: the prepared glass is turned and processed, combined with the quartz glass sleeve and placed in the drawing tower. The temperature of the drawing tower is 900°C, the drawing speed is 40m / °C, the inner diameter of the optical fiber sleeve is 3cm, the outer diameter is 30cm, and the core layer- The cladding ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com