Preparation method of glass film containing rare earth ion doped Ba2GdCl7 micro-crystal

A technology of rare earth ions and glass thin films, which is applied in the field of preparation of glass-ceramic thin films, can solve problems such as device development limitations, achieve the effects of overcoming incomplete uniformity, preventing decomposition and volatilization, and promoting formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Containing rare earth ions doped with Ba 2 GdCl 7 The preparation method of the glass thin film of crystallite, comprises the steps:

[0039] (1), prepare the raw materials by mole percentage: tetraethoxygermanium: 59mol%, gallium ethoxide: 16mol%, barium chloride: 16mol%, gadolinium chloride: 8mol%, cerium chloride: 1mol%, weigh the total Quantity is the analytically pure each preparation raw material of 30 grams;

[0040] (2), the hydrolysis of tetraethoxygermanium: the tetraethoxygermanium weighed in the step (1) is dissolved in dehydrated alcohol, and the mol ratio of dehydrated alcohol and tetraethoxygermanium is 2: 1, fast Add acetylacetone, the volume ratio of acetylacetone to tetraethoxygermanium is 0.8:1, and carry out strong magnetic stirring, gradually drop distilled water, the molar ratio of distilled water to tetraethoxygermanium is 0.8:1, and carry out hydrolysis at room temperature React for 1 hour to make solution A;

[0041] (3), hydrolysis of galli...

Embodiment 2

[0050] It is basically the same as Example 1, except that the raw materials are prepared in the following molar percentages in the step (1): tetraethoxygermanium: 53mol%, gallium ethylate: 8mol%, barium chloride: 24mol%, gadolinium chloride: 12mol%, europium chloride: 3mol%, each preparation raw material is weighed respectively; In the step (7), the pulling speed of the glass substrate in the gel solution is controlled at 1 mm / s, and the pulling is repeated 5 times, each time The pulling interval time is 15 minutes; in step (8), heat up to 100°C at a rate of 50°C per hour, and then heat up the furnace to 340°C at a rate of 50°C per hour; in step (9), gradually heat up the furnace to 750°C, and react at this temperature for 2 hours.

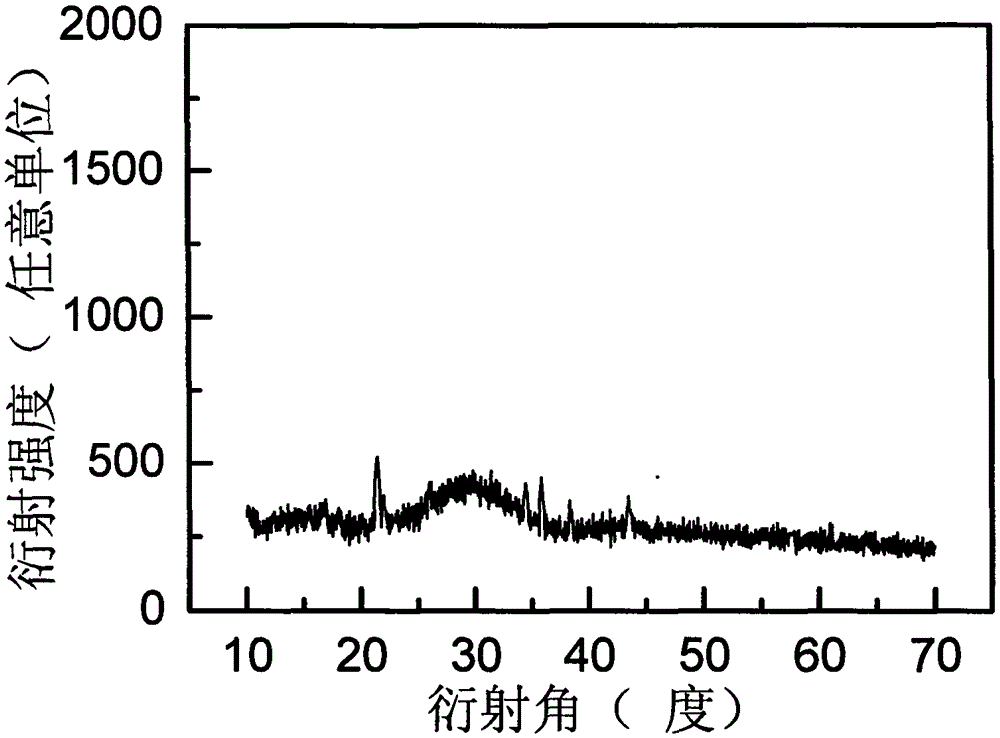

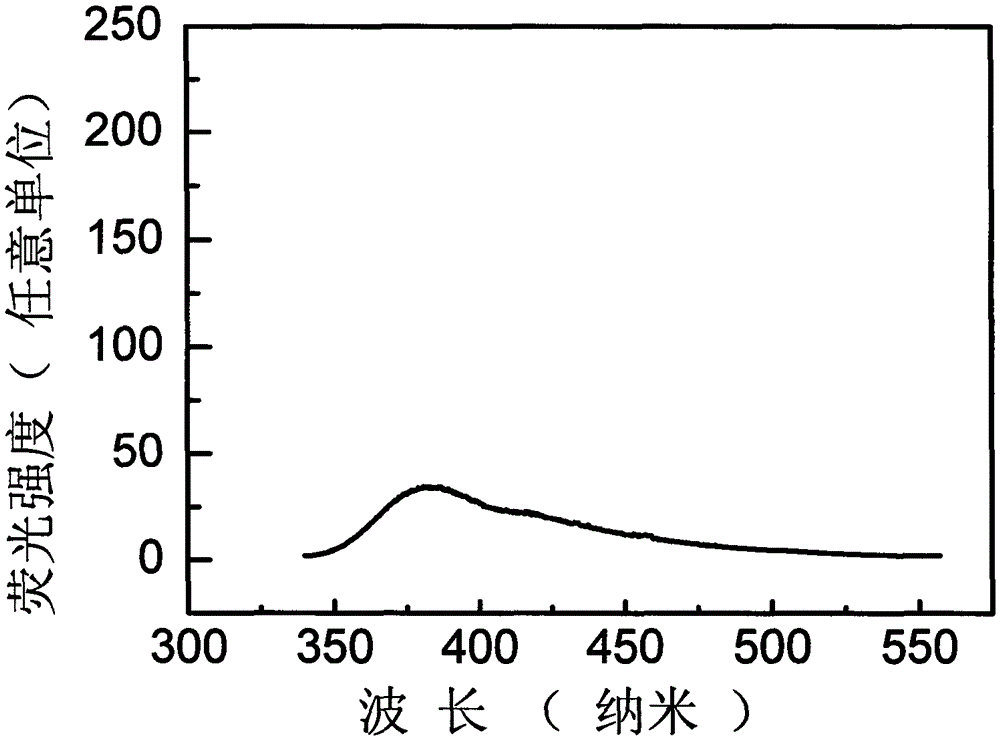

[0051] For prepared Eu-containing 3+ Ion-doped Ba 2 GdCl 7 The microcrystalline glass film was tested for performance, and the XRD pattern of the glass film after hydrogen chloride treatment was the same as figure 1 Basically the same, but the...

Embodiment 3

[0053] It is basically the same as Example 1, except that the raw materials are prepared in the following molar percentages in the step (1): tetraethoxygermanium: 56mol%, gallium ethylate: 12mol%, barium chloride: 20mol%, gadolinium chloride: 10mol%, terbium chloride: 2mol%, each preparation raw material is weighed respectively; In the step (7), the pulling speed of the glass substrate in the gel solution is controlled at 0.6 mm / s, and the pulling is repeated 3 times, each time Pull interval time is 15 minutes; In step (8), heat up to 100 DEG C with the rate of 40 DEG C per hour, then heat up furnace to 340 DEG C with the speed of 40 DEG C per hour; In step (10), gradually heat up furnace to 730°C and react at this temperature for 3 hours.

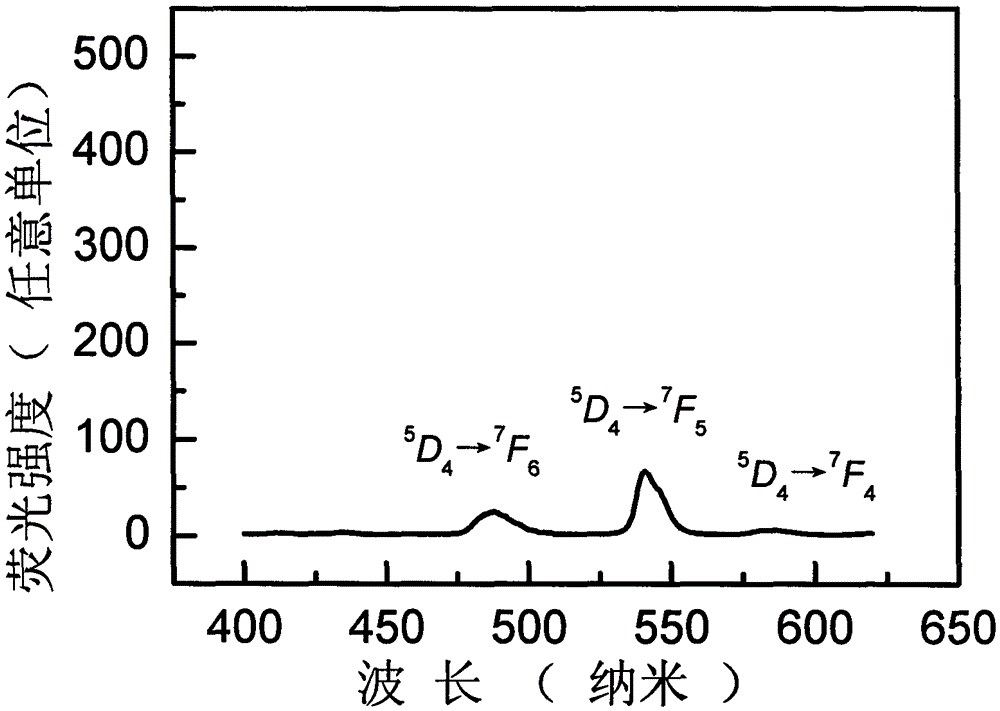

[0054] For prepared Tb-containing 3+ Ion-doped Ba 2 GdCl 7 The microcrystalline glass film was tested for performance, and the XRD pattern of the glass film after hydrogen chloride treatment was the same as figure 1 Basically the same,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com