Glass containing rare earth ion doped lutetium iodide micro-crystals and preparation method of glass film

A technology of glass thin film and rare earth ion, which is applied in the field of preparation of glass and glass thin film, can solve problems such as device development limitations, and achieve the effects of overcoming incomplete uniformity, high doping concentration, and good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

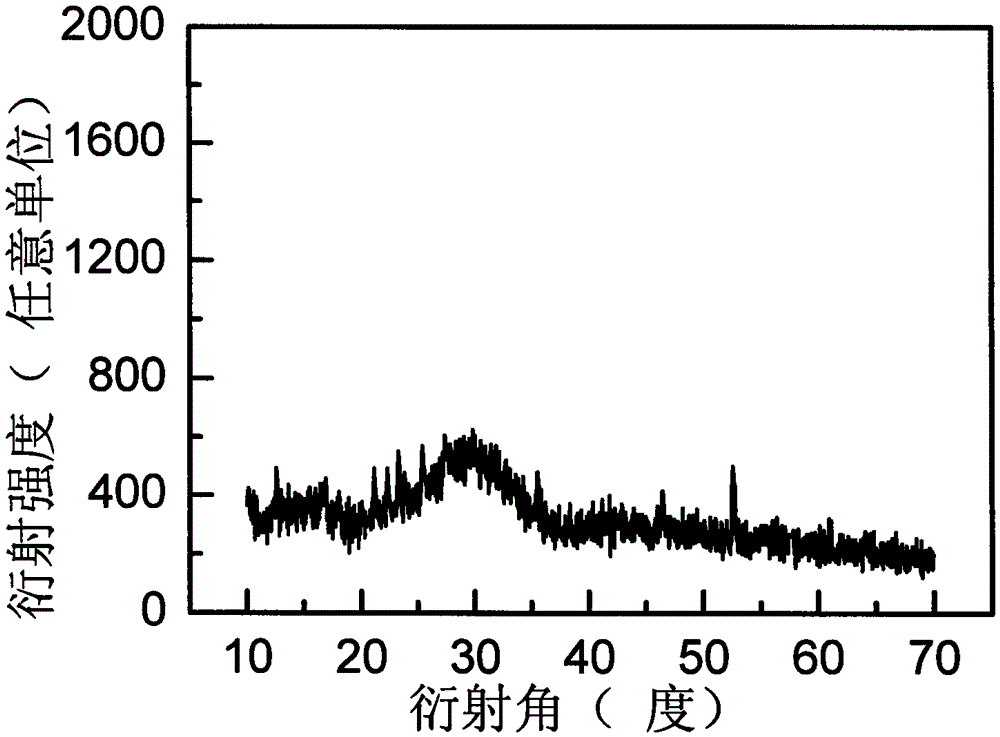

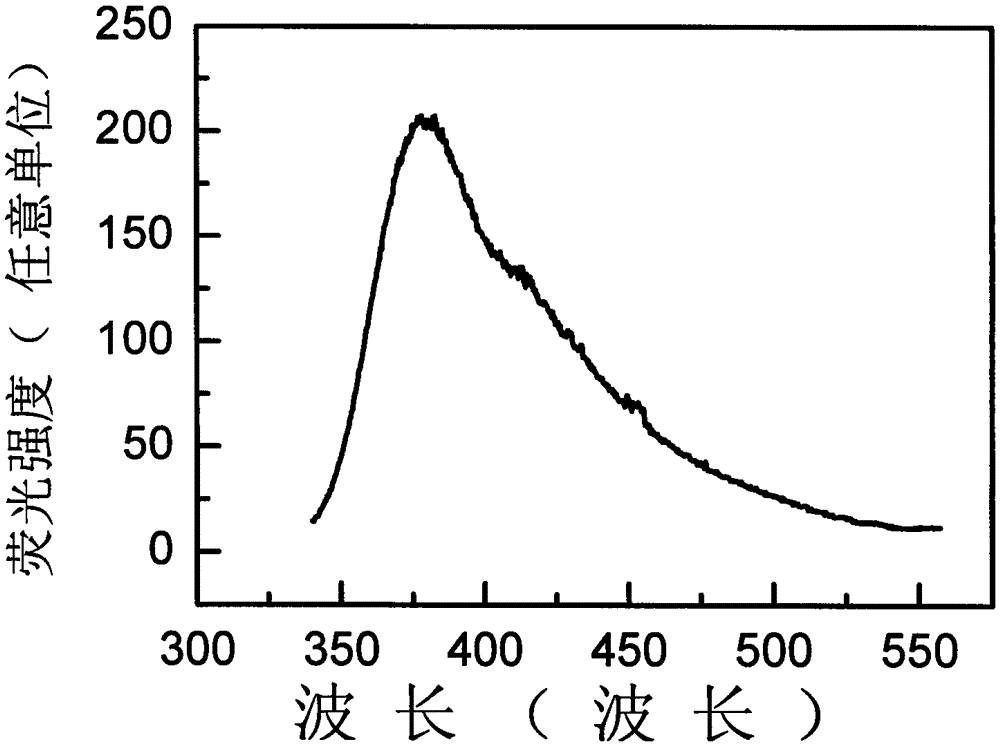

Embodiment 1

[0040] The preparation method of rare earth ion-doped lutetium iodide crystallite glass and glass film, comprising the following steps:

[0041] (1), will prepare the raw material composition by mole percent: ethyl orthosilicate: 73mol%, niobium ethoxide: 16mol%, lutetium iodide: 10mol%, cerium iodide: 1mol%, take by weighing the total amount of 20 grams The analytically pure raw materials for each preparation are ready for use;

[0042] (2), according to following mol ratio: both ethyl orthosilicate and niobium ethoxide sum: dehydrated alcohol: distilled water=1: 2.5: 1.6, weigh corresponding dehydrated alcohol and distilled water respectively, stand-by;

[0043] (3), take one-third of the dehydrated alcohol that is weighed in the step (2), dissolve the whole niobium ethoxide weighed in the step (1) into it, add acetylacetone quickly, the volume of niobium ethoxide and acetylacetone The ratio is 1: 1, and strong magnetic stirring is carried out, gradually dripping in the dis...

Embodiment 2

[0054] (1), basically the same as Example 1, the difference is that in step (1), the raw materials are prepared by the following mole percentages: ethyl orthosilicate: 74mol%, niobium ethoxide: 10mol%, lutetium iodide: 13mol%, Cerium iodide: 3 mol%, weigh the total amount of 20 grams of each analytically pure preparation raw material and set it aside; in step (8), the pulling speed of the glass substrate in the gel solution is controlled at 0.4 mm / s, and the pulling is repeated 2 times, the interval between each pulling is 15 minutes, and the coated film is dried at room temperature for 4 hours to obtain a glass film; in step (10), the temperature is first heated to 100° C. and kept for 1.5 hours to remove residual water. and ethanol, and then heated to 360°C for 30 minutes to remove residual organic matter. The heating rate for glass is 12°C per hour, the cooling rate is 20°C per hour, and the heating rate for glass film is 1 hour per hour. 40 ° C, the cooling rate is 50 ° C ...

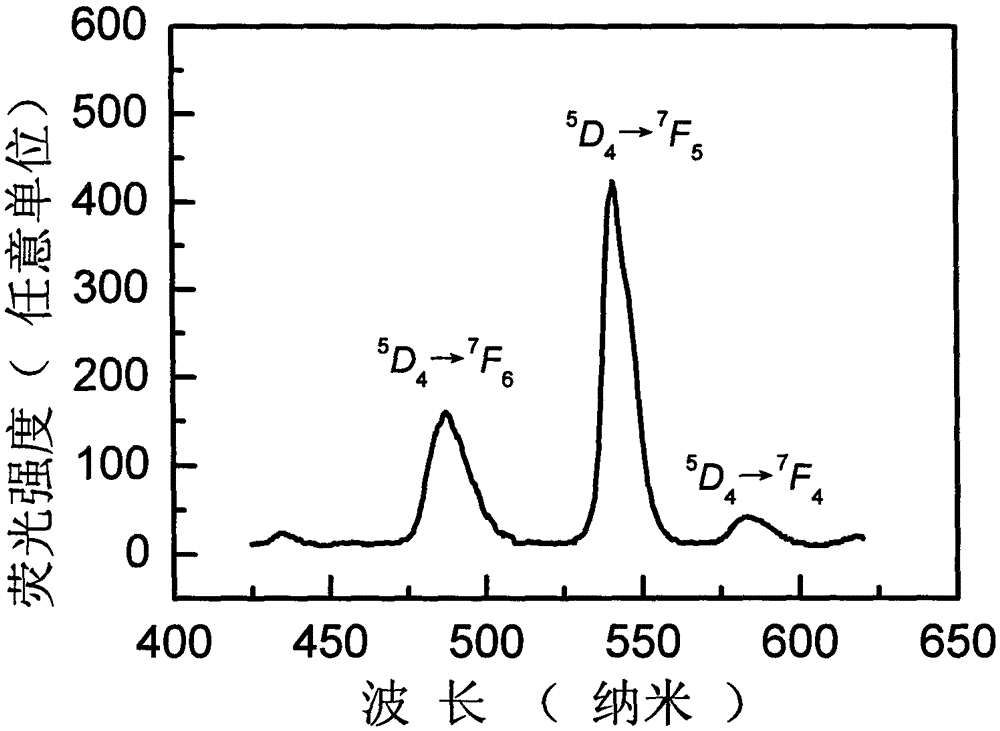

Embodiment 3

[0057] (1), it is basically the same as Example 1, the difference is that in step (1), the raw materials are prepared according to the following mole percentages: ethyl orthosilicate: 75mol%, niobium ethoxide: 5mol%, lutetium iodide: 15mol%, Europium iodide: 5 mol%, weigh each preparation raw material with a total amount of 20 grams of analytical grade and set it aside for use; in step (8), the pulling speed of the glass substrate in the gel solution is controlled at 1 mm / s, and the extraction is repeated. Pulling 5 times, the interval between each pulling is 15 minutes, and the coated film is dried at room temperature for 4 hours to obtain a glass film; in step (10), the temperature is first heated to 100° C. and kept for 2 hours to remove residual water and ethanol, and then heated to 360°C for 40 minutes to remove residual organic matter, the heating rate for glass was 15°C per hour, the cooling rate was 20°C per hour, and the heating rate for glass film was 10°C per hour. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com