Lanthanum, dysprosium and cerium co-doped lutetium-yttrium orthosilicate scintillating material and crystal growth method

A technology of yttrium lutetium silicate and scintillation material, which is applied in the directions of crystal growth, polycrystalline material growth, single crystal growth, etc., can solve the problems of unqualified optical quality, reduced scintillation performance, weak light transmittance, etc., and achieves the promotion of charge migration. and energy level transition, ensuring uniformity and stability, and improving the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

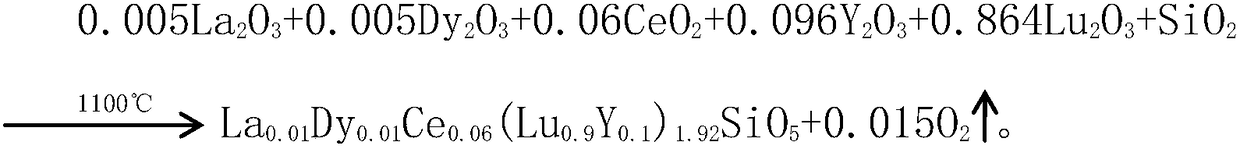

[0021] S1: 0.005 La 2 O 3 , 0.005 copies of Dy 2 O 3 , 0.06 part of CeO 2 , 0.096 copies of Y 2 O 3 , 0.864 copies of Lu 2 O 3 , 1 part SiO 2 After mixing uniformly, the temperature was raised to 1100°C at a rate of 10°C / min, and calcined for 30h. The chemical formula of solid-phase synthesis was La 0.01 Dy 0.01 Ce 0.06 (Lu 0.9 Y 0.1 ) 1.92 SiO 5 the polycrystalline block;

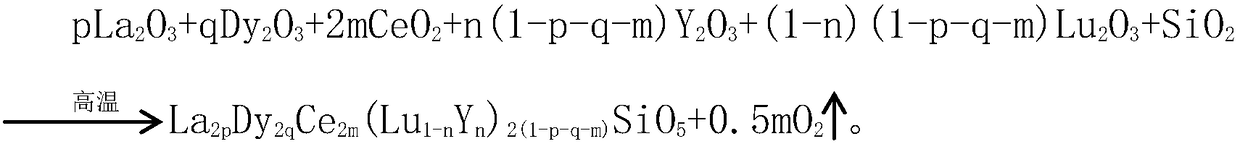

[0022] Its solid-phase synthesis reaction equation:

[0023]

[0024] S2: at room temperature, press the polycrystalline material block obtained from S1 at a pressure of 300 MPa, and then fill it with nitrogen at a flow rate of 5 L / min to 0.15 MPa, and heat the polycrystalline to a molten state under the nitrogen atmosphere to obtain an initial crystal growth melt;

[0025] S3: Rotate the LYSO seed crystal in the direction at a rotation speed of 6rpm, and pull it upward at a pulling speed of 0.8mm / h. When the crystal diameter grows to 90mm, the rotation speed and pulling speed gradually...

Embodiment 2

[0027] With embodiment 1, the difference is as follows:

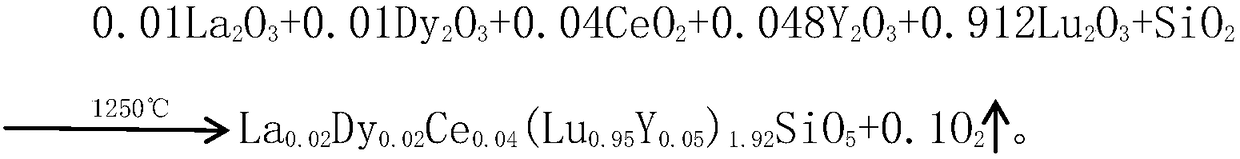

[0028] S1: 0.01 part of La per mole 2 O 3 , 0.01 copies of Dy 2 O 3 , 0.04 part of CeO 2 , 0.048 copies of Y 2 O 3 , 0.912 Lu 2 O 3 , 1 part SiO 2 After mixing uniformly, the temperature was raised to 1250°C at a rate of 10°C / min, and calcined for 65h. The chemical formula of solid-phase synthesis was La 0.02 Dy 0.02 Ce 0.04 (Lu 0.95 Y 0.05 ) 1.92 SiO 5 the polycrystalline block;

[0029] Its solid-phase synthesis reaction equation:

[0030]

[0031] S2: The pressing pressure is 460MPa, the protective gas is helium and the gas flow is 18L / min;

[0032] S3: The seed crystal is La 0.02 Dy 0.02 Ce 0.04 (Lu 0.95 Y 0.05 ) 1.92 SiO 5 Single crystal, and in the direction, the rotation speed is 18rpm, the pulling speed is 3mm / h, and the crystal diameter is grown to 100mm.

Embodiment 3

[0034] With embodiment 1, the difference is as follows:

[0035] S1: 0.02 La 2 O 3 , 0.02 copies of Dy 2 O 3 , 0.02 part of CeO 2 , 0.0095 copies of Y 2 O 3 , 0.9405 copies of Lu 2 O 3 , 1 part SiO 2After mixing uniformly, the temperature was raised to 1400 °C at a rate of 10 °C / min, and calcined for 100 h. The chemical formula of solid-phase synthesis was La 0.04 Dy 0.04 Ce 0.02 (Lu 0.99 Y 0.01 ) 1.9 SiO 5 the polycrystalline block;

[0036] Its solid-phase synthesis reaction equation:

[0037]

[0038] S2: The pressing pressure is 630MPa, the protective gas is argon and the gas flow is 30L / min;

[0039] S3: The seed crystal is La 0.04 Dy 0.04 Ce 0.02 (Lu 0.99 Y 0.01 ) 1.9 SiO 5 Single crystal, and in the direction, the rotation speed is 30rpm, the pulling speed is 5mm / h, and the crystal diameter is grown to 110mm.

[0040] Following table is the effect analysis of embodiment 1-3:

[0041]

[0042] It can be seen from the above table that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com