A method for improving the high temperature water vapor oxidation resistance of heat-resistant steel

A heat-resistant steel, water vapor technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as the inability to generate protective films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

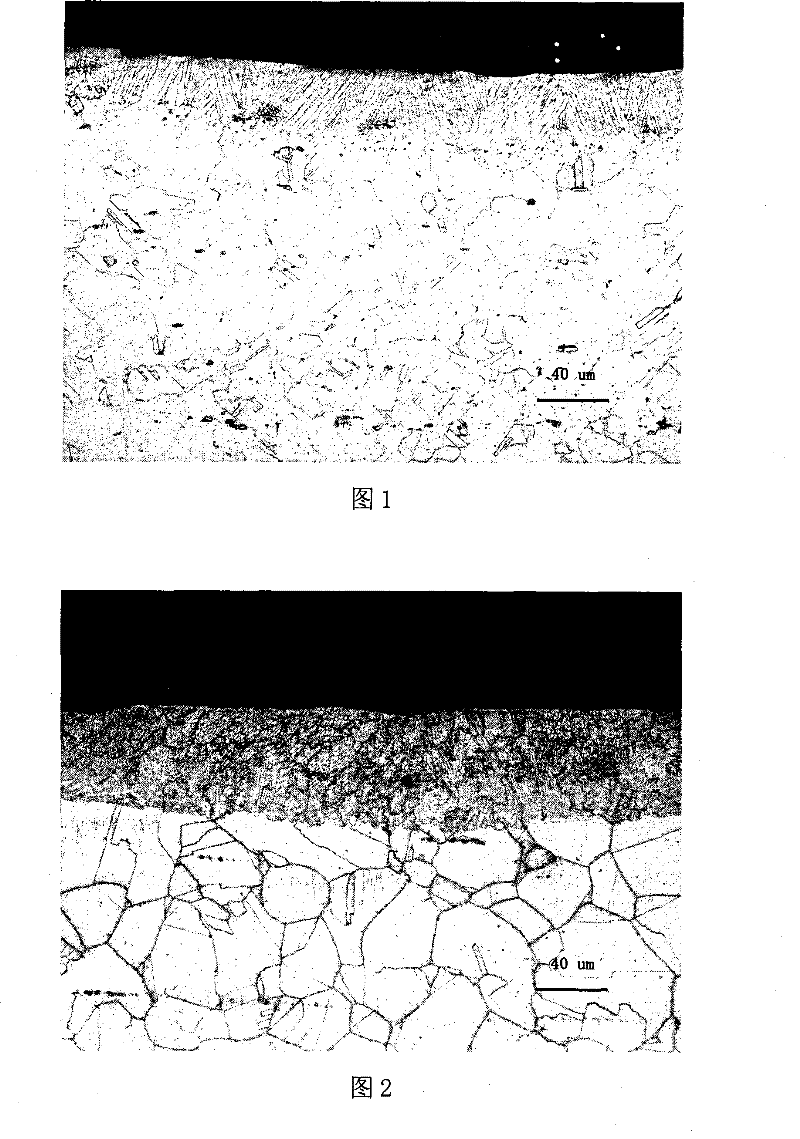

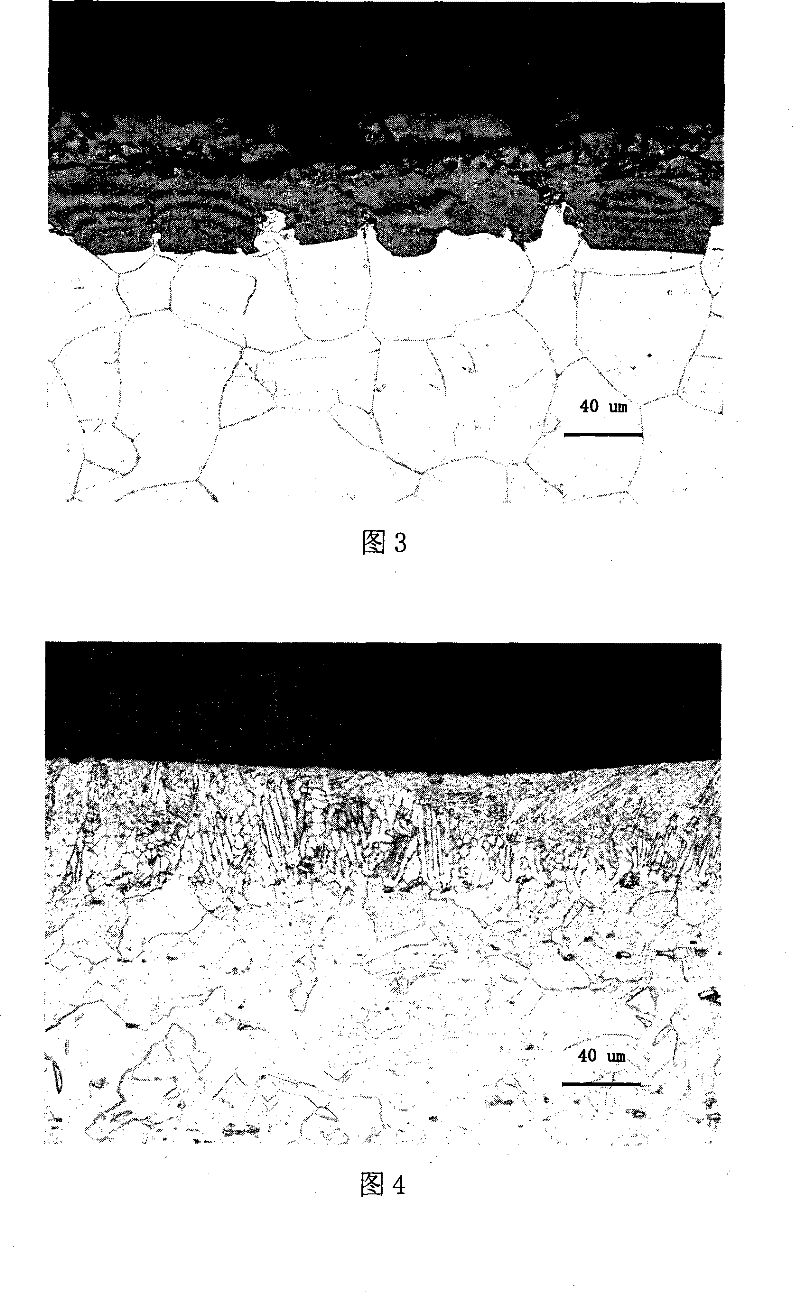

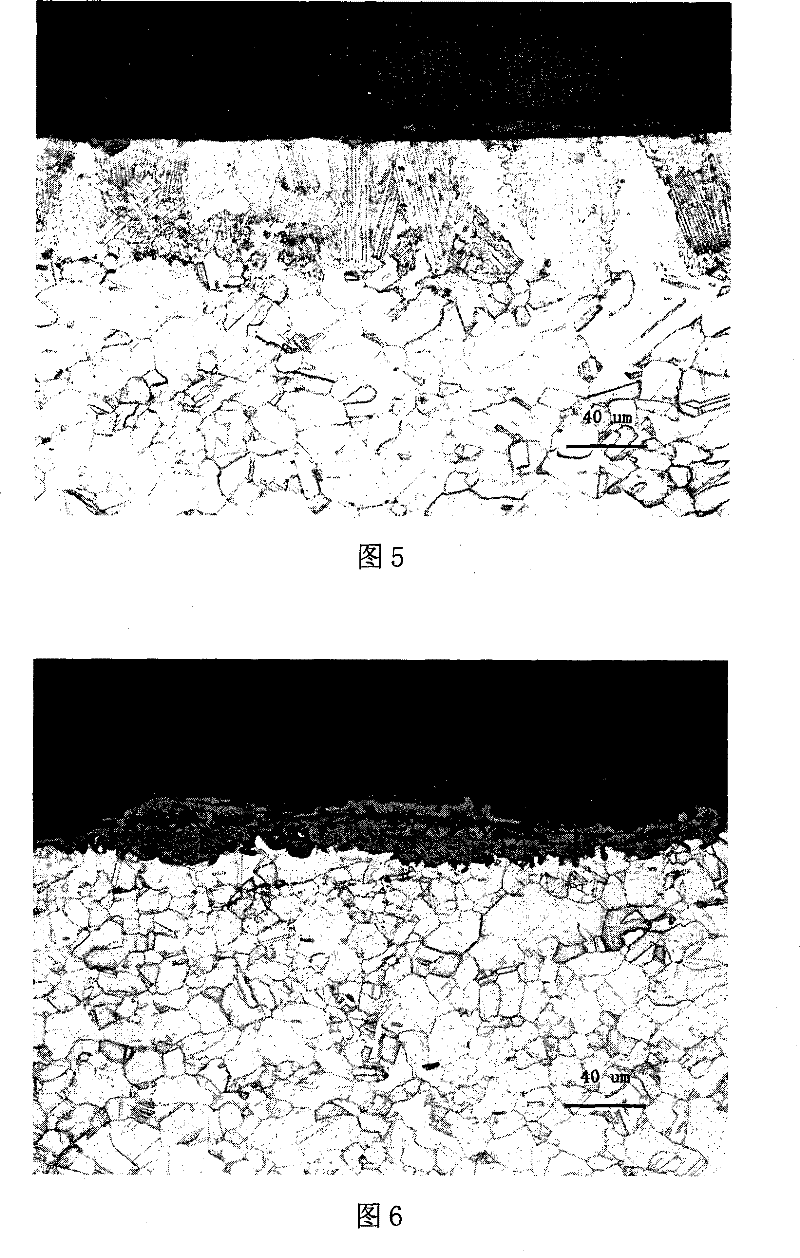

[0025] In the present invention, the surface of the heat-resistant steel to be treated is subjected to laser surface remelting treatment, so that the surface layer of the heat-resistant steel is 10 3 ~10 7 ℃ / s above the rate of heating and melting, and then 10 3 The cooling rate above ℃ / s solidifies, and a fine-grained region with a grain size below 25 μm is formed on the surface of the heat-resistant steel. The resistance to high temperature water vapor oxidation is improved through defects such as high-density grain boundaries, subgrain boundaries, dislocations, and vacancies of the treatment layer.

[0026] In order to further improve the steam oxidation resistance of the laser remelted layer on the heat-resistant steel surface, a coating containing Cr, Al or Si elements is formed on the heat-resistant steel surface by pretreatment before the laser surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com