Aesthetic resin for improving white blink effect and preparation method thereof

An aesthetic resin and white technology, applied in the field of resin and its preparation, can solve the problems of reduced visual depth, loss of three-dimensional flashing effect of pearlescent pigments, deterioration of super white effect, etc., achieve strong three-dimensional effect, soft and uniform flashing effect, and improve HAZE Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

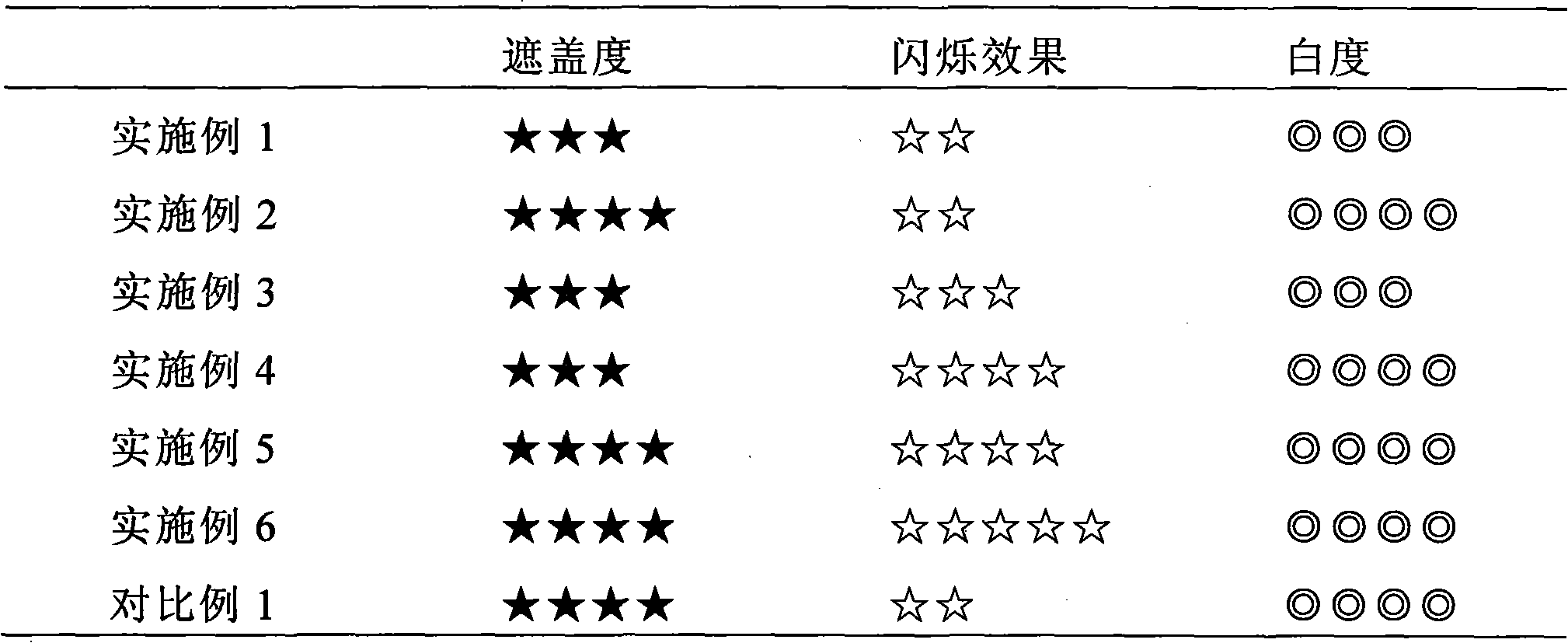

Examples

Embodiment 1

[0039] An aesthetic resin for improving white flashing effect, the method comprises the following steps:

[0040] (1) Prepare materials according to the following components and content (parts by weight):

[0041] Base resin 100;

[0042] White pigment 0.5;

[0043] Pearlescent pigment 0.2;

[0044] Lubricant 0.5;

[0045] Antioxidant 0.3;

[0046] Fluorescent whitening agent 0.05

[0047] (2) After the matrix resin, white pigment, pearlescent pigment, antioxidant, lubricant, and fluorescent whitening agent are fully mixed in a high-speed mixer, they are sent into a twin-screw extruder through a metering device, and Under conveying, shearing and kneading, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain an aesthetic resin with improved white shimmering effect.

[0048] Among them, the matrix resin is the transparent ABS / PMMA alloy of Shanghai Kumho Sunny Plastic Co., Ltd.;

Embodiment 2

[0055] An aesthetic resin for improving white flashing effect, the method comprises the following steps:

[0056] (1) Prepare materials according to the following components and content (parts by weight):

[0057] Base resin 100;

[0058] white pigment 1.0;

[0059] Pearlescent pigment 0.8;

[0060] Lubricant 0.5;

[0061] Antioxidant 0.3;

[0062] Fluorescent whitening agent 0.05

[0063](2) After the base resin, white pigment, pearlescent pigment, antioxidant, lubricant, and fluorescent whitening agent are fully mixed in a high-speed mixer, they are sent into a twin-screw extruder through a metering device, and Under conveying, shearing and kneading, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain an aesthetic resin with improved white shimmering effect.

[0064] Among them, the matrix resin is the transparent ABS / PMMA alloy of Shanghai Kumho Sunny Plastic Co., Ltd.;

Embodiment 3

[0071] An aesthetic resin for improving white flashing effect, the method comprises the following steps:

[0072] (1) Prepare materials according to the following components and content (parts by weight):

[0073] Base resin 100;

[0074] white pigment 1.0;

[0075] Pearlescent pigment 0.5;

[0076] Lubricant 0.5;

[0077] Antioxidant 0.3;

[0078] Fluorescent whitening agent 0.05

[0079] (2) After the base resin, white pigment, pearlescent pigment, antioxidant, lubricant, and fluorescent whitening agent are fully mixed in a high-speed mixer, they are sent into a twin-screw extruder through a metering device, and Under conveying, shearing and kneading, the materials are melted and compounded, and then extruded, drawn, cooled and pelletized to obtain an aesthetic resin with improved white shimmering effect.

[0080] Among them, the matrix resin is the transparent ABS / PMMA alloy of Shanghai Kumho Sunny Plastic Co., Ltd.;

[0081] The white pigment is rutile titanium diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com